Wanneer onze productielijnen worden verscheept agrarische drones 1 overseas, buyers often ask one critical question: “How do I know your warehouse is real?” This doubt stems from horror stories of fake stock listings, delayed shipments, and inventory mismatches that cost farmers entire growing seasons.

To verify overseas warehouses, request physical address proof, conduct video calls with warehouse staff, demand real-time inventory reports, use third-party inspection services, and check integration with logistics tracking systems. These steps confirm actual stock availability and shipping capabilities before you commit funds.

Let me walk you through the exact verification methods we recommend to our distributors worldwide. These tactics help you separate genuine overseas facilities from paper promises.

How can I confirm my drone supplier actually has a local warehouse in the US or Europe?

Our export team frequently fields this question from American and European buyers. The concern is valid. Many suppliers claim local warehouses but actually dropship from China, causing 4-6 week delays.

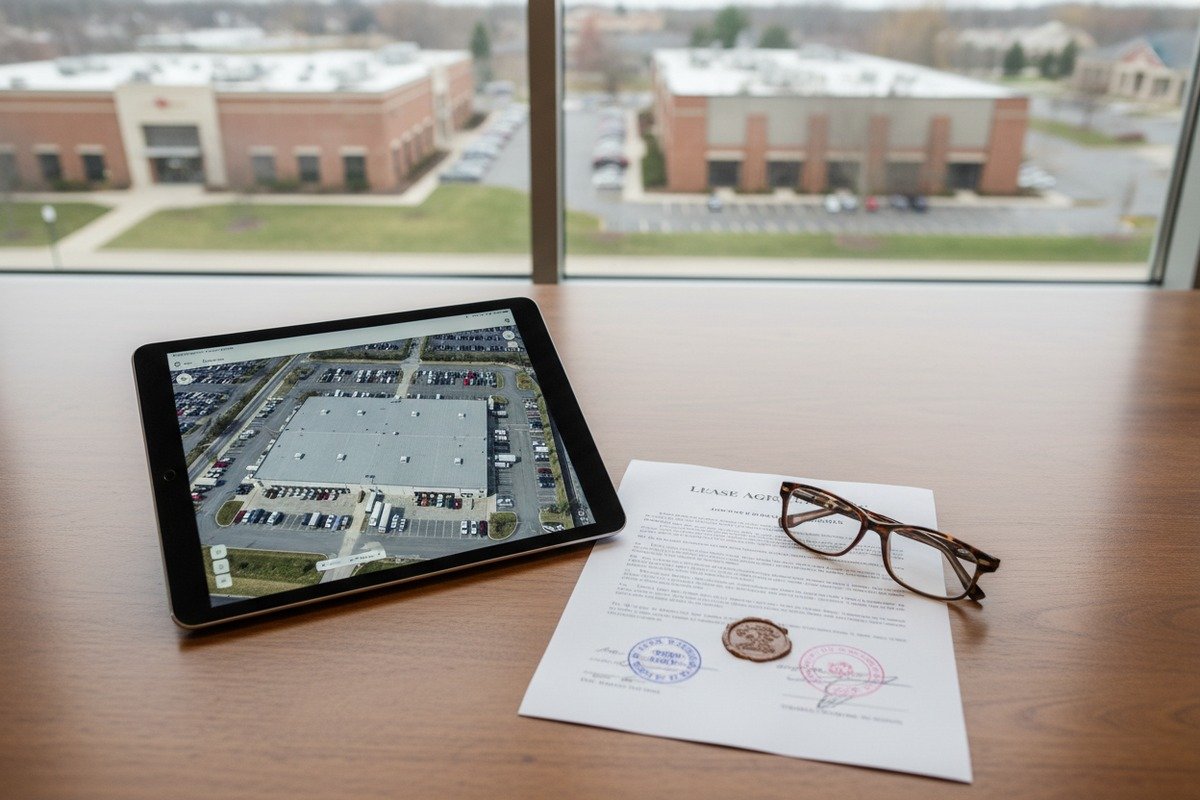

Confirm a supplier's local warehouse by requesting the physical address, verifying it through Google Maps or satellite imagery, scheduling live video tours, checking business registration records in that country, and asking for utility bills or lease agreements showing the warehouse location.

Start With Basic Address Verification

The first step is simple. Ask for the complete warehouse address. Then verify it independently. Use Google Maps Street View 2 to see the building. Check if it looks like a commercial warehouse facility. Look for loading docks, large doors, and commercial signage.

Cross-reference the address with public business records. In the US, check state business registration databases. In Europe, check national company registries. The warehouse operator should appear as a registered business at that location.

Schedule a Live Video Tour

A legitimate supplier will agree to a video call showing the warehouse interior. During the call, ask to see:

- Drone inventory on shelves with visible model numbers

- Shipping labels and packaging areas

- Staff members working in the facility

- Date-stamped newspapers or screens showing current date

If a supplier refuses or makes excuses, consider it a red flag. Our team conducts these tours weekly for serious buyers.

Request Documentation Proof

| Documenttype | What It Proves | Red Flag If Missing |

|---|---|---|

| Lease Agreement | Legal occupancy of space | Supplier may not control the warehouse |

| Utility Bills | Active operations at location | Warehouse may be dormant or fake |

| Zakelijke licentie | Legal authority to operate | Potential compliance issues |

| Insurance Certificate | Professional coverage for stored goods | Your inventory may lack protection |

| Recent Shipping Labels | Active fulfillment from that address | Stock may not actually ship from there |

Use Third-Party Verification Services

When stakes are high, hire inspection companies like SGS, Bureau Veritas, or Intertek. Third-Party Verification Services 3 They send inspectors to physically visit the warehouse. They verify inventory counts, storage conditions, and operational capabilities. This costs money but provides independent confirmation.

Some buyers also use freight forwarders with local presence. Ask your logistics partner to visit the warehouse before you place a large order.

What specific documentation should I request to verify a supplier's overseas storage and shipping capabilities?

In our experience exporting to the US and Europe, documentation tells the full story. Paper trails reveal whether a supplier can actually deliver or just makes promises.

Request ISO 9001 quality certificates, warehouse operator licenses, customs bond documentation, carrier agreements, inventory management system access, shipping performance reports, and product-specific certifications like CE and FCC marks. These documents verify both storage infrastructure and fulfillment capabilities.

Quality Management Documentation

Start with the supplier's Quality Management System certification. ISO 9001:2015 4 is the global standard. Request the actual certificate and verify it on the certification body's website. Check that the scope covers drone manufacturing and distribution.

Also request:

- Recent internal audit reports

- Quality control procedures for drone testing

- Calibration records for testing equipment

- Defect tracking logs

Logistics and Shipping Documentation

| Document | Doel | Hoe te controleren |

|---|---|---|

| Carrier Contracts | Proves relationships with shipping companies | Ask for redacted contracts showing carrier names |

| Customs Broker Agreement | Shows import/export capability | Verify broker license with customs authorities |

| Bonded Warehouse Certificate | Confirms compliant storage for imports | Check with local customs office |

| Shipping Performance Reports | Shows on-time delivery rates | Request 6-12 months of data |

| Tracking System Integration | Enables real-time shipment visibility | Ask for demo access to their system |

Product Certification Requirements

Agricultural drones need specific certifications for different markets. For US sales, FCC certification 5 covers radio frequency compliance. CE marking is mandatory for European Union sales. Request copies of these certificates and verify them with issuing bodies.

For agricultural spraying drones, additional certifications may include:

- IP ratings for dust and water resistance

- Battery safety certifications (UN38.3 for lithiumbatterijen 6)

- Propeller safety testing documentation

- Payload capacity test reports

Inventory Transparency Documents

A trustworthy supplier provides real-time inventory visibility. Request access to their Warehouse Management System 7 or regular inventory reports. These should show:

- Current stock levels by model and variant

- Incoming shipment schedules

- Average days in inventory

- Safety stock thresholds

Our warehouse systems integrate with major e-commerce platforms. Buyers can see live stock counts before ordering.

Will using a supplier with local warehouses help me avoid customs delays and high door-to-door delivery costs?

When we calibrate our flight controllers and test our spraying systems, we think about the full journey to the customer. Local warehouses transform that journey dramatically.

Yes, suppliers with local warehouses eliminate import customs delays since goods are pre-cleared. They reduce delivery times from 4-6 weeks to 2-7 days, lower shipping costs by 40-60% through bulk import economics, and avoid per-shipment customs fees. This makes urgent repairs and seasonal restocking far more practical.

How Customs Delays Happen

International shipments face multiple checkpoints. Each creates potential delays:

- Export customs clearance in origin country

- Airline or shipping line transit

- Import customs clearance in destination country

- Customs inspection if flagged

- Duty and tax payment processing

- Final mile delivery

Agricultural drones face extra scrutiny. Lithium batteries trigger hazmat reviews. High-value electronics may require detailed declarations. Sensors and cameras can raise security concerns.

With local warehouse stock, items 1-5 are already complete. The supplier handled import clearance when stocking the warehouse. Your order ships domestically.

Cost Comparison Analysis

| Cost Factor | Direct China Shipping | Local Warehouse Shipping |

|---|---|---|

| Shipping Cost per Drone | $150-400 | $30-80 |

| Customs Brokerage Fee | $75-150 per shipment | $0 (pre-paid) |

| Import Duties | 0-25% of value | Included in price |

| Delivery Time | 4-6 weeks | 2-7 days |

| Expedited Shipping Premium | +$200-500 | +$20-50 |

| Risk of Customs Hold | Middelhoog | Geen |

Seasonal Timing Benefits

Agricultural operations run on strict seasonal schedules. Planting windows, spraying seasons, and harvest timing cannot wait for shipping delays. A supplier with local warehouse stock can fulfill urgent orders within days.

Our US warehouse maintains buffer stock before peak agricultural seasons. When a farmer's drone fails mid-season, replacement parts ship immediately rather than waiting weeks.

Hidden Cost Considerations

Local warehouses do add some costs. Suppliers must pay for warehouse space, inventory financing, and local staff. These costs typically appear in slightly higher unit prices. However, total cost of ownership usually favors local warehouse sourcing when you factor in:

- Reduced shipping costs per unit

- No emergency expedite fees

- Lower inventory holding costs for buyers

- Reduced downtime costs from faster delivery

Door-to-Door Delivery Simplification

True door-to-door delivery from local warehouses means exactly that. The supplier handles everything from warehouse shelf to customer doorstep. No customs paperwork for you. No freight forwarder negotiations. No surprise duty bills.

For buyers importing multiple units, local warehouses eliminate the need for your own customs broker relationships and import licenses.

How do I ensure the overseas warehouse stocks the specific agricultural drone parts I need for urgent repairs?

Our engineers know that a grounded drone during spraying season costs farmers real money. Parts availability determines whether downtime lasts days or weeks.

Ensure parts availability by requesting SKU-level inventory reports, confirming safety stock policies for critical components like batteries, propellers, motors, and sensors. Verify the warehouse uses inventory management software with low-stock alerts, and establish pre-positioned inventory agreements for your most-used parts.

Identify Your Critical Parts List

Start by listing components most likely to need replacement. For agricultural spraying drones, this typically includes:

- Propellers (high wear from debris)

- Spray nozzles (clogging and chemical wear)

- Batteries (cycle degradation)

- Motors (dust and moisture exposure)

- Pumps (chemical corrosion)

- Sensors (calibration drift, physical damage)

- Landing gear (impact damage)

Request confirmation that these specific SKUs are stocked locally. Generic assurances are not enough.

Verify Inventory Management Systems

Modern warehouses use Warehouse Management Systems that track every item. Ask the supplier to demonstrate:

- Real-time stock visibility by SKU

- Automatic reorder triggers when stock falls below thresholds

- Historical data on stock-out incidents

- Lead time for replenishment from China

Safety Stock and Reorder Policies

| Component Category | Aanbevolen veiligheidsvoorraad | Typical Lead Time if Out |

|---|---|---|

| Schroeven | 20+ sets per drone model | 3-5 weeks from China |

| Batterijen | 10+ per model | 4-6 weeks (hazmat shipping) |

| Motoren | 5+ per model | 3-4 weeks |

| Sproeikoppen | 50+ assorted | 2-3 weeks |

| Electronic Boards | 3-5 per model | 4-6 weeks |

| Sensoren | 5+ per type | 3-4 weeks |

Ask specifically about safety stock levels. A good supplier maintains buffer inventory to handle demand spikes during agricultural seasons.

Pre-Positioning Agreements

For large-volume buyers, negotiate pre-positioned inventory. This means the supplier stocks specific parts quantities dedicated to your account. You pay a deposit or commitment fee. In return, you guarantee parts availability when you need them.

Our team offers this arrangement to distributors serving agricultural customers. We monitor their usage patterns and adjust pre-positioned stock accordingly.

Emergency Fulfillment Protocols

Even with good planning, emergencies happen. Ask about expedited shipping options from the local warehouse. Same-day or next-day delivery should be available for critical repairs during peak season.

Also ask about emergency protocols when local stock runs out:

- Can they air-freight from China with priority handling?

- Do they have relationships with other regional warehouses for cross-shipping?

- What is the fastest possible delivery in a true emergency?

Quality Control for Stored Parts

Parts sitting in warehouses can degrade. Batteries lose capacity over time. Rubber components age. Electronic boards can develop issues in humid storage. Verify the warehouse maintains:

- Climate-controlled storage for batteries

- Humidity control for electronics

- First-in-first-out inventory rotation

- Regular quality checks on stored inventory

- Proper handling protocols for sensitive components

Conclusie

Verifying overseas warehouses protects your investment and ensures reliable delivery. Request documentation, conduct video tours, use third-party inspections, and confirm specific parts inventory. These steps separate trustworthy suppliers from empty promises and keep your agricultural operations running smoothly.

Voetnoten

1. Biedt een uitgebreid overzicht van landbouwdrones en hun toepassingen. ↩︎

2. Explains the functionality and scope of Google Street View for visual verification. ↩︎

3. Official website for a leading provider of third-party inspection and certification services. ↩︎

4. Dedicated resource explaining the ISO 9001:2015 quality management system standard. ↩︎

5. Official US government information on FCC certification and licensing requirements. ↩︎

6. Official US DOT information on regulations for transporting hazardous lithium batteries. ↩︎

7. Provides a comprehensive definition and overview of Warehouse Management Systems. ↩︎

8. Official European Union information on CE marking requirements and compliance. ↩︎