Every week, our quality control team receives calls from buyers who discovered their drones failed within the first 50 flight hours ISO 16750-3 standards 1. The root cause? Inadequate burn-in testing 2 before shipment.

To verify factory burn-in testing, request detailed test documentation including flight logs, environmental stress records, and component performance data. Confirm tests simulated real agricultural conditions like dust, humidity, and temperature extremes. Review third-party certifications and ask for video evidence of your specific units undergoing testing protocols.

Let me walk you through exactly what to look for and how to protect your investment when purchasing agrarische drones 3.

What specific documentation should I request to confirm my drones passed a rigorous burn-in test?

When our engineering team finishes a production batch, we generate comprehensive documentation packages for every unit payload stress cycles 4. Without proper records, you have no way to verify what actually happened during testing.

Request a complete burn-in test certificate with serial numbers, flight logs showing motor temperatures and vibration data, battery cell internal resistance reports, environmental chamber records, and liquid system pressure test results. These documents should match your specific units, not generic samples.

Essential Documents You Must Demand

The documentation package tells you everything about what your drone experienced before shipping. Here is what a complete package should include:

| Documenttype | Wat het bewijst | Red Flag If Missing |

|---|---|---|

| Burn-in Test Certificate | Unit completed full test cycle | No verification possible |

| Flight Performance Report | Hover stability, RTH function tested | Unknown flight behavior |

| Battery Health Report | Cell IR values within spec | Early battery failure risk |

| Environmental Test Log | Temperature/humidity exposure data | Unknown durability |

| Liquid System Test Report | Spray pattern and pump pressure verified | Inconsistent application |

Understanding Flight Performance Reports

A proper flight performance report covers multiple test scenarios. Look for hover stability data showing drift measurements under various wind conditions. The Return-to-Home functionality must show successful completion rates. Flight endurance numbers should reflect full payload conditions, not empty hover times.

Our test pilots run each agricultural drone through a minimum of five complete flight cycles before approval. Each cycle includes takeoff, GPS lock verification, payload simulation, spray system activation, and precision landing. The report should show timestamps for each event.

Battery Documentation Deep Dive

Battery health documentation deserves special attention. The internal resistance of individual cells 5 reveals manufacturing quality. Cells with mismatched IR values will degrade faster and create safety risks.

Ask your supplier about their battery warranty structure. A warranty based on charge cycles rather than calendar months protects you better. For example, 500 charge cycles gives you concrete usage limits instead of a vague 12-month period.

| Battery Metric | Aanvaardbaar bereik | Concerning Range |

|---|---|---|

| Cell IR Variance | < 5% between cells | > 10% variance |

| Initial Capacity | > 95% rated capacity | < 90% capacity |

| Temperature Rise | < 10°C during discharge | > 15°C rise |

Verifying Serial Number Matching

Every document must reference specific serial numbers. Cross-check these numbers against the physical units you receive. Generic test reports that lack serial numbers offer zero verification value.

How can I verify that the factory's testing process actually simulates the high-stress conditions of my local farm operations?

Our production facility in Xi'an uses environmental chambers specifically calibrated for agricultural applications. But not every manufacturer invests in proper simulation equipment, and you need to know how to check.

Verify high-stress simulation by requesting environmental chamber specifications showing temperature ranges from -10°C to 50°C, humidity testing up to 95%, and vibration protocols matching ISO 16750-3 standards. Ask about dust ingress testing and payload stress cycles that replicate real field conditions.

Environmental Chamber Specifications

The testing environment must match or exceed the conditions your drones will face. If you operate in the American Midwest with hot summers and cold springs, the chamber should cover that full range.

| Environmental Factor | Standard Test Range | Enhanced Agricultural Range |

|---|---|---|

| Temperatuur | 0°C to 40°C | -10°C to 50°C |

| Humidity | 30% to 70% RH | 20% to 95% RH |

| Trilling | Basic ISO levels | Full ISO 16750-3 |

| Dust Exposure | Minimaal | IP54 or higher rated |

| UV Exposure | Often skipped | Essential for ag use |

Dust and Moisture Testing

Agricultural operations generate enormous amounts of dust. Pesticide spraying creates moisture exposure. Your drones must survive both simultaneously.

Ask specifically about IP-classificaties 6 and how they were verified. An IP54 rating means dust won't interfere with operation and water splashes from any direction are safe. Higher ratings like IP65 or IP67 provide better protection but cost more to achieve.

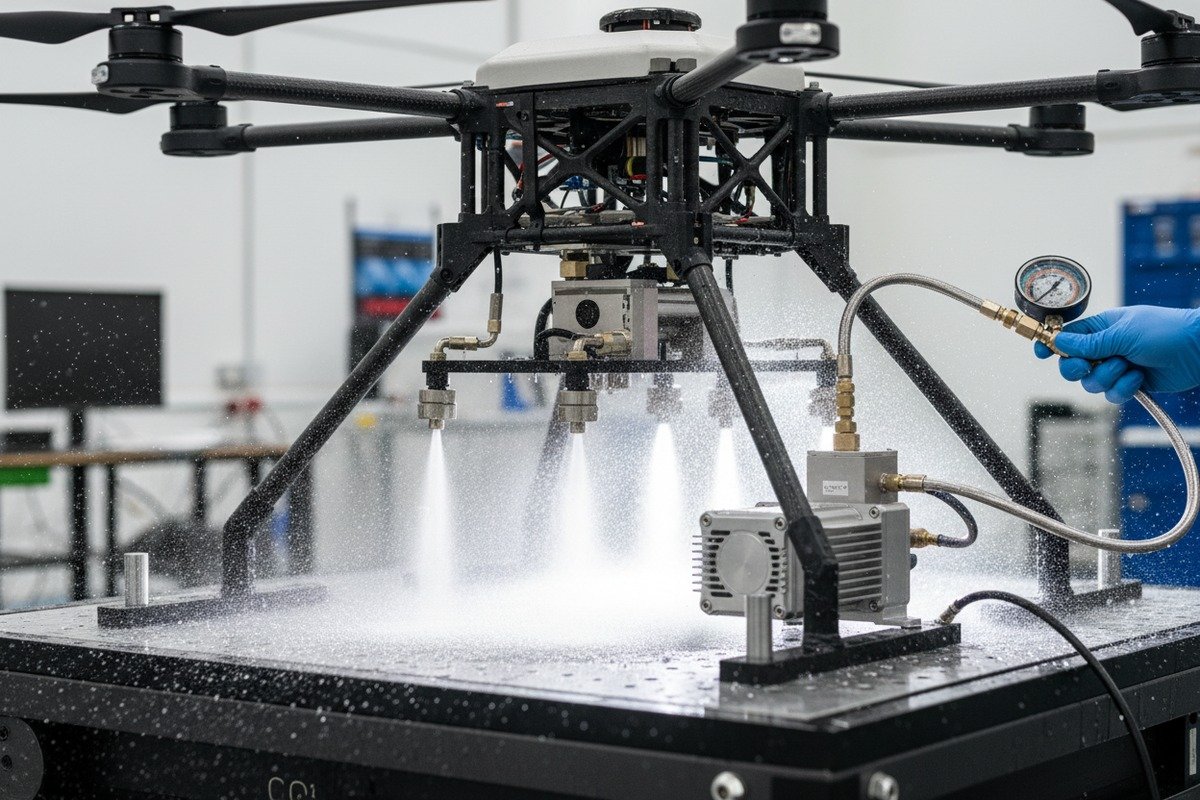

When we test liquid system components, we run pressure tests at 1.5 times the normal operating pressure. This reveals weak seals and connection points before they fail in the field.

Payload Stress Simulation

Empty drone testing tells you nothing about real performance. Agricultural drones carry heavy pesticide tanks, and weight changes constantly during operation as liquid depletes.

Proper burn-in includes flights with full payload, half payload, and near-empty conditions. The flight controller must maintain stability across this entire range. Ask for documentation showing test weights used during each flight cycle.

Comparing Lab Testing to Field Conditions

Some industry experts argue that lab testing cannot fully replicate field complexity. They have a point. Variables like wind gusts, uneven terrain, and swarm coordination are difficult to simulate.

However, comprehensive lab testing catches 80% or more of potential failures. The remaining issues typically emerge during the first 50 hours of field operation, which is why strong warranty terms matter.

A hybrid approach works best. Accept thorough factory burn-in as your baseline protection, then implement your own controlled field testing protocol before full deployment.

What key performance indicators should I look for in a professional burn-in report before I approve my shipment?

Our quality assurance team reviews dozens of data points before approving any shipment. Buyers who understand these KPIs can make informed decisions and catch problems early.

Key performance indicators in burn-in reports include motor temperature rise under load, vibration signatures at each RPM range, battery voltage sag percentages, GPS lock acquisition times, IMU drift measurements, and spray system flow rate consistency. Values outside manufacturer specifications indicate potential failures.

Motor Performance Metrics

Motors are the heart of any multirotor drone. Temperature data during sustained operation reveals bearing quality and winding integrity.

A healthy motor should not exceed 60°C above ambient temperature during normal operation. Temperature spikes or asymmetric readings between motors indicate problems. Similarly, current draw should remain balanced across all motors within 5%.

Vibration analysis requires specialized equipment. Look for reports showing vibration levels at idle, mid-throttle, and full throttle. Abnormal vibration patterns often indicate propeller imbalance, motor bearing wear, or frame resonance issues.

Battery Performance Under Load

Static battery tests mean little. What matters is how the battery performs when the drone demands full power.

Voltage sag percentage 7 measures how much the battery voltage drops under load. A healthy agricultural drone battery should show less than 15% sag at maximum continuous discharge. Higher sag indicates high internal resistance or cell degradation.

Temperature monitoring during discharge reveals thermal management effectiveness. Cells that heat unevenly will age unevenly, leading to premature pack failure.

Flight Controller and Sensor Calibration

The flight controller integrates data from GPS, IMU, compass, and barometer sensors 8. Each must be calibrated and verified.

GPS lock acquisition time should be under 60 seconds in open sky conditions. Longer times suggest antenna issues or receiver problems. Position accuracy should be within 1-2 meters for precision agricultural applications.

IMU drift measurements show sensor stability over time. Excessive drift causes flight instability and reduces RTH accuracy. Compass calibration must be performed at the factory and verified before shipping.

Spray System Specific KPIs

Agricultural spraying drones have unique requirements beyond basic flight performance.

| Spray System KPI | Target Value | Failure Threshold |

|---|---|---|

| Flow Rate Consistency | ±5% variation | >10% variation |

| Pump Pressure Stability | ±0.2 bar | >0.5 bar swing |

| Nozzle Pattern Uniformity | >90% coverage | <80% coverage |

| Tank Seal Integrity | Zero leakage at 2x pressure | Any leakage |

Flow meter calibration accuracy directly affects application rates. If your flow meter reads 10% high, you waste 10% of every chemical load. This adds up quickly across a growing season.

Interpreting Anomalies in Reports

Not every out-of-spec reading indicates a failure. Context matters. A motor that runs slightly hot might have been tested in a warm chamber. A GPS lock time of 90 seconds in an indoor test environment is normal.

Ask your supplier to explain any anomalous readings. Legitimate manufacturers will provide detailed explanations. Evasive answers suggest data fabrication or inadequate testing.

Can I ask my supplier for digital flight logs or video proof to ensure the burn-in testing was completed for my specific units?

During a recent shipment to a distributor in Texas, we provided complete video documentation of every test flight. This level of transparency should be standard practice.

Yes, you can and should request digital flight logs and video evidence for your specific units. Flight logs provide timestamped data on motor performance, battery usage, and sensor readings. Video proof shows physical testing execution. Both should reference serial numbers matching your ordered units.

Types of Digital Evidence to Request

Digital evidence comes in several forms. Each serves a different verification purpose.

Flight controller logs contain the most detailed information. These binary files record every sensor reading, control input, and system state at high frequency. They require specialized software to decode but provide irrefutable evidence of flight testing.

Telemetry exports offer a more accessible format. These typically include GPS tracks, altitude profiles, battery voltage curves, and motor RPM data. Most drone flight apps can export this data to CSV or PDF formats.

Video documentation shows the physical reality of testing. Request footage showing your unit's serial number, the test environment, and the actual flight operations. Time-stamped video with visible serial numbers is difficult to fake.

Verifying Log Authenticity

Log files can be manipulated by sophisticated actors. Several verification methods help ensure authenticity.

Check timestamps against logical sequences. A flight log showing 100 hours of testing completed in one day is obviously fabricated. Look for reasonable test durations spread across multiple days.

Cross-reference data between sources. Motor temperatures in the flight log should match the burn-in report. GPS coordinates should match the factory location. Inconsistencies indicate data problems.

Hash verification provides cryptographic proof that files have not been modified. Some advanced flight controllers generate hash codes for log files. Ask if this feature is available.

Video Documentation Best Practices

Not all video evidence is equally useful. Here is what makes video documentation credible:

| Video Element | Good Practice | Rode vlag |

|---|---|---|

| Serial Number | Clearly visible in frame | Hidden or obscured |

| Timestamp | Embedded in video file | Editable text overlay |

| Continuous Shot | Uncut footage | Multiple cuts |

| Milieu | Recognizable test facility | Generic background |

| Test Actions | Complete sequences shown | Only selected moments |

Setting Expectations with Suppliers

Request video documentation before placing your order. Include it as a contract requirement. Suppliers who refuse video documentation may have something to hide.

Define your expectations clearly. Specify that you want video showing serial number close-ups, environmental chamber entry, flight testing, and liquid system operation. Provide a checklist the supplier can follow.

Be reasonable about costs. Video documentation requires labor time and storage resources. Some suppliers charge modest fees for enhanced documentation packages. This is often worthwhile for high-value orders.

Using Third-Party Verification Services

If you cannot visit the factory yourself, consider third-party inspection services. Companies like SGS, Bureau Veritas, and regional inspection agencies can witness testing and provide independent verification.

Third-party inspectors should be present during actual testing, not just reviewing completed documentation. Their reports carry more weight because they have no financial interest in approval.

For large orders, the cost of third-party inspection is negligible compared to the risk of receiving untested or defective units.

Conclusie

Verifying factory burn-in testing protects your investment and your reputation. Request comprehensive documentation, confirm environmental simulation, analyze KPIs carefully, and demand digital evidence for your specific units.

Voetnoten

1. Details the ISO 16750-3 standard for environmental conditions and mechanical load testing of road vehicle electronics. ↩︎

2. Explains the purpose and methodology of burn-in testing for detecting early failures in electronics. ↩︎

3. Provides an overview of agricultural drones, their uses, and benefits in farming operations. ↩︎

4. Outlines the importance and methodology of testing drones with varying payloads to ensure stability and performance. ↩︎

5. Explains battery internal resistance, its causes, and importance for performance and state of health. ↩︎

6. Comprehensive and authoritative explanation of IP (Ingress Protection) ratings. ↩︎

7. Wikipedia provides a clear definition of voltage sag, including its magnitude (percentage) and duration. ↩︎

8. Describes the functions of GPS, IMU, compass, and barometer sensors in drone flight control and navigation. ↩︎