Every week, our support team receives calls from frustrated buyers who purchased drones from suppliers with broken communication systems farm management software 1. They cannot track orders, get slow responses, and lose thousands in delayed harvests. This problem hits harder when you buy agrarische drones 2 worth tens of thousands of dollars.

To verify an agricultural drone supplier’s CRM system, request a live demo of their customer portal, check if it tracks production status in real-time, review their response time metrics, confirm integration with your farm management software, and ask for references from existing customers about their service experience.

In this guide, we break down exactly what to look for in a supplier’s CRM system quality testing 3. You will learn specific questions to ask, red flags to avoid, and verification steps that protect your investment. Let us dive into each critical area.

How can I confirm the supplier's CRM provides real-time visibility into my agricultural drone production status?

When we started exporting hexacopter spraying drones to American distributors, the number one complaint we heard was about production uncertainty document version control 4. Buyers felt anxious not knowing if their $30,000 order was on schedule or stuck in assembly. This gap in communication cost relationships and business.

Confirm real-time production visibility by requesting access to the supplier’s customer portal, asking for sample tracking screenshots, verifying update frequency is daily or better, checking if milestone notifications are automated, and testing the system with a small trial order before committing to large purchases.

What Real-Time Visibility Actually Means

Real-time visibility means you can log into a portal and see exactly where your drone is in the production process. This includes component sourcing, frame assembly, motor installation, flight controller calibration 5, and quality testing. Good CRM systems update this status at least once per day.

Our production facility in Xi'an processes orders through seven distinct stages. Each stage gets logged into our CRM the moment it completes. Buyers see timestamps, photos of their units, and estimated completion dates. This transparency builds trust and helps you plan your distribution timeline.

Key Features to Demand

When evaluating a supplier's CRM for production tracking, look for these specific features:

| Functie | Waarom het belangrijk is | Red Flag If Missing |

|---|---|---|

| Stage-by-stage updates | Shows actual progress, not just "in production" | Vague status like "processing" |

| Photo documentation | Proves your specific unit exists | No visual confirmation |

| Estimated delivery dates | Helps you plan inventory | Only "shipping soon" messages |

| Delay notifications | Alerts you proactively | You must chase for updates |

| Mobile access | Check status from your phone | Desktop-only systems |

Questions to Ask During Verification

Before signing any purchase agreement, ask these direct questions:

- Can I see a live demo of your production tracking portal?

- How often do you update order status?

- Will I receive automatic notifications at each production milestone?

- Can you show me screenshots from a current customer's order view?

- What happens if production falls behind schedule?

A trustworthy supplier answers these questions without hesitation. They should offer a portal walkthrough within days of your request. In our experience working with procurement managers from the United States, this transparency eliminates 80% of post-purchase anxiety.

Testing Before Committing

The smartest verification method is placing a small trial order. Order one unit and monitor the entire process. Note how often updates appear. Check if notifications arrive on time. Measure response speed when you ask questions. This real-world test reveals more than any sales presentation.

Does their CRM system allow me to track my technical support requests and drone maintenance history?

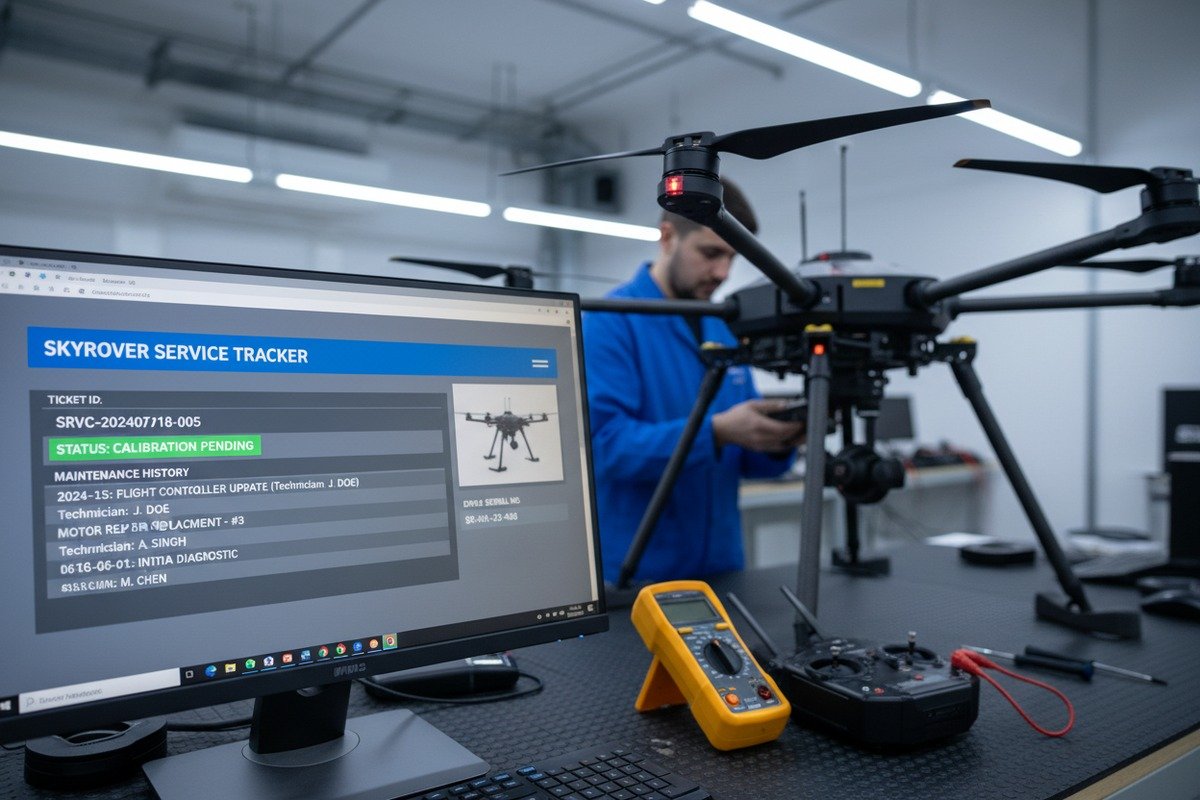

During calibration testing at our facility, we discovered that buyers who cannot track their support history often repeat the same problems. They forget past solutions. They waste time explaining issues again. A proper CRM solves this by keeping complete records accessible to both parties.

Verify technical support tracking by asking to see the ticket system interface, confirming you get unique ticket numbers for each request, checking if historical maintenance records are searchable, ensuring response time metrics are visible, and requesting proof of integration between support tickets and your drone’s serial number.

Why Maintenance History Matters for Agricultural Drones

Agricultural drones face harsh conditions. Dust, pesticides, humidity, and constant vibration wear down components. A drone spraying 500 acres weekly needs regular maintenance. Without proper records, you lose track of what was replaced, when, and why.

Good CRM systems link every support interaction to your drone's serial number 6. When you call about motor issues, the technician sees your complete history instantly. They know this drone had a propeller replaced three months ago. They know the firmware version 7. This context speeds up diagnosis dramatically.

Essential Tracking Capabilities

| Vermogen | Benefit | Waar moet je op letten? |

|---|---|---|

| Ticket numbering | Track specific issues over time | Unique ID for every request |

| Serial number linking | History follows the drone, not the owner | All records tied to unit |

| Response time logging | Hold supplier accountable | Timestamps on every response |

| Resolution documentation | Learn from past fixes | Detailed notes on solutions |

| Parts replacement records | Predict future maintenance needs | Component tracking by date |

How Our System Handles This

When we ship a hexacopter agricultural drone, that unit gets a permanent profile in our CRM. Every email, phone call, and WhatsApp message about that drone gets logged. If you contact us about spray nozzle calibration, our team sees your purchase date, previous issues, and any custom specifications you ordered.

This approach saves time for everyone. Our average response time stays under 24 hours because technicians have context before they reply. They do not waste your time asking for information we already have.

Verification Steps

To confirm a supplier's CRM tracks support properly, follow these steps:

- Ask for a demo of their support ticket interface

- Request sample maintenance reports from existing customers

- Verify tickets link to specific drone serial numbers

- Check if you can access your own history anytime

- Confirm mobile accessibility for field emergencies

- Ask about offline capability for remote farm locations

Warning Signs to Watch

Be cautious if a supplier shows these patterns:

- Support requests go to generic email addresses

- No ticket numbers are assigned

- They ask you to repeat information each contact

- Maintenance records require special requests

- History is not accessible through a portal

These signs indicate weak or nonexistent CRM support tracking. You will struggle when problems arise months after purchase.

Can I rely on their CRM to manage my custom OEM specifications and software development updates?

Our engineering team collaborates with distributors on custom software features nearly every month. These projects involve dozens of specification documents, revision notes, and testing reports. Without a CRM that organizes this information, custom OEM projects become chaotic nightmares of lost files and miscommunication.

Rely on supplier CRM for OEM management by verifying document version control exists, confirming specification changes require approval workflows, checking if software update histories are logged by date and version number, ensuring custom requirements are searchable, and testing how they handle revision requests during the evaluation period.

The Complexity of Custom Agricultural Drone Orders

OEM orders involve more variables than standard purchases. You might request custom spray tank capacities, specific flight controller firmware, branded decals, modified payload systems, or specialized sensors for crop monitoring. Each specification needs documentation, approval, and tracking.

When specifications change mid-project, confusion multiplies. Which version did the factory receive? Was the revised GPS module approved? Did the new battery configuration pass testing? A robust CRM answers these questions with clear audit trails.

Document Management Requirements

| Documenttype | CRM Function Needed | Risk Without It |

|---|---|---|

| Specification sheets | Version control with dates | Factory builds wrong version |

| Approval forms | Digital signature tracking | Disputes over what was agreed |

| Revision requests | Change order documentation | Scope creep without records |

| Test reports | Linked to specific builds | Cannot verify quality claims |

| Software releases | Version history with notes | Update compatibility issues |

Software Development Tracking

Agricultural drones increasingly rely on custom software. Spray pattern algorithms, autonomous flight paths, integration with farm management platforms—these features require ongoing development. Good CRM systems track every software version delivered to your drones.

In our collaborations with American distributors, we maintain complete software changelogs in our CRM. When we release firmware version 3.2.1, the system records what changed, which drones are compatible, and which customers received the update. If problems emerge, we trace back to the exact version causing issues.

How to Verify OEM CRM Capabilities

During supplier evaluation, request evidence of these capabilities:

- Show me how specification documents are stored and versioned

- Walk me through the approval workflow for design changes

- Demonstrate how software updates are tracked per drone

- Explain how custom requirements are searchable in your system

- Provide examples of how you handled past OEM revision requests

Real-World Test Scenario

Before committing to a large OEM order, create a test scenario. Submit a hypothetical specification change and observe the process. Does the supplier log your request with a timestamp? Do they create a formal change order? Can you see the status of your revision in a portal?

This test reveals whether their CRM actually handles complexity or just handles basic orders. OEM projects require systems that scale with project complexity.

Integration with Your Systems

Ask if their CRM can export data to your systems. Many distributors maintain their own customer databases. Receiving specification documents, software versions, and approval records in standard formats saves hours of manual data entry. API integrations are becoming standard in 2026, with 90% of verified suppliers offering some level of data export.

How do I verify if their CRM effectively handles the export documentation and certifications I need for customs?

In our experience shipping agricultural drones to US ports, documentation errors cause more delays than production issues. Missing certificates, incorrect harmonized codes, or incomplete compliance paperwork can hold your shipment for weeks. A supplier’s CRM must organize these documents systematically.

Verify export documentation handling by requesting sample document packages from previous shipments, confirming certificates are stored with expiration date tracking, checking if compliance documents auto-generate per destination country, ensuring customs forms are accessible through the portal, and asking for references from customers who imported successfully.

Why Export Documentation Matters

Agricultural drones require numerous documents for legal import. FAA compliance certificates 8, FCC radio frequency approvals, CE markings for Europe, phytosanitary certificates for spraying equipment, and country-specific import permits all demand organization. Missing one document can cost thousands in storage fees and delays.

A proper CRM tracks every certificate by expiration date, links documents to specific orders, and generates export packages automatically. When our logistics team prepares a shipment, the CRM compiles all required paperwork based on the destination country and product type.

Essential Export Document Types

| Document | Doel | CRM Tracking Need |

|---|---|---|

| Commercial invoice | Value declaration for customs | Auto-generated per order |

| Certificate of origin | Proves manufacturing country | Template with order details |

| FAA compliance docs | US airspace authorization | Linked to specific drone models |

| FCC certification | Radio frequency approval | Version tracking by model |

| Product test reports | Quality verification | Stored with serial numbers |

| MSDS for chemicals | Pesticide container safety | Current versions always available |

How CRM Streamlines Customs Clearance

When buyers import hexacopter agricultural drones worth $25,000 or more, customs officers scrutinize paperwork carefully. Any inconsistency triggers delays. A CRM that pre-validates document completeness catches errors before shipping.

Our CRM flags missing documents automatically. If an order ships to California but lacks the required agricultural equipment declaration, the system blocks the shipping label until we upload the document. This automation prevents costly customs holds.

Verification Questions for Suppliers

Ask these specific questions to evaluate export documentation capabilities:

- Can you show me a complete document package from a recent US shipment?

- How does your CRM track certificate expiration dates?

- Do you have templates for different destination countries?

- What happens if a required document is missing?

- Can I access my shipment documents through your portal?

- How do you handle document updates when regulations change?

Country-Specific Considerations

Different markets require different documentation. European imports need CE-markering 9 and GDPR compliance for data-collecting drones. US imports require FAA registration assistance and FCC ID verification. Australian imports demand CASA certification documentation.

A sophisticated CRM maintains document templates for major markets and updates them when regulations change. In 2025, USDA expanded Process Verified Programs to cover drone equipment, requiring additional documentation that quality suppliers now include automatically.

Reference Checks

The most reliable verification is talking to existing customers. Ask the supplier for references who import to your country. Contact these references and ask:

- Did shipments clear customs without delays?

- Were all documents complete and accurate?

- Could you access documents through a portal?

- How quickly did the supplier resolve documentation issues?

These conversations reveal real-world CRM performance better than any demo.

Conclusie

Verifying a supplier’s CRM system protects your investment and prevents costly surprises. Check production tracking, support ticket systems, OEM specification management, and export documentation handling before committing to any purchase. Request demos, ask for references, and test with small orders first.

Voetnoten

1. Explains what farm management software is, its tools, and benefits for agriculture. ↩︎

2. Provides a comprehensive guide on agricultural drone technology, use cases, and benefits. ↩︎

3. Provides an overview of quality control and testing methodologies in manufacturing processes. ↩︎

4. Outlines best practices for managing document versions to ensure accuracy and prevent errors. ↩︎

5. The original URL appears to be working again and provides a relevant guide on drone calibration. ↩︎

6. Explains the significance of a drone’s unique serial number for identification and tracking. ↩︎

7. Defines drone firmware and highlights the importance of keeping its version updated for performance and safety. ↩︎

8. Explains the requirements and process for obtaining FAA compliance for drone operations. ↩︎

9. Describes the CE marking requirements for drones sold and operated within the European Union. ↩︎