Every week, our engineers receive calls from frustrated buyers. Their drone arms failed mid-mission. Firefighters lost expensive equipment. The root cause? Poor fatigue testing before purchase.

To properly evaluate fatigue testing for firefighting drone arm folding mechanisms, you must examine testing standards compliance, verify minimum cycle requirements of 10,000+ loaded operations, request detailed technical documentation including stress analysis reports, and assess the overall design philosophy for long-term field reliability.

This guide walks you through exactly what to look for. You will learn how to separate marketing claims from engineering facts. Let us dive into the specifics that protect your investment.

What specific fatigue testing standards should I look for to ensure my firefighting drone arms are truly durable?

When we first designed our folding arm systems, we quickly realized that generic testing was not enough. Firefighting drones face unique stresses. Standard consumer drone tests simply do not apply.

Look for ASTM D7791 and ASTM D3479 compliance for composite materials, combined with custom environmental testing protocols. Your supplier should demonstrate testing under loaded conditions, thermal cycling, and chemical exposure specific to firefighting operations.

Understanding Core Testing Standards

The foundation of reliable fatigue testing starts with recognized standards. ASTM D7791 1 covers axial fatigue testing for plastics and composite materials 2. ASTM D3479 3 addresses tension-tension fatigue specifically. These standards establish baseline methodologies that any serious manufacturer should follow.

However, here is what our quality control team has learned over years of production: standard ASTM testing alone is insufficient for firefighting applications. These tests typically run at 5Hz frequency under controlled laboratory conditions. Real firefighting drones face rapid deployment cycles, extreme temperature swings, and exposure to water, soot, and chemical retardants.

Key Standards Comparison Table

| Standaard | Application | Test Method | Limitation for Firefighting |

|---|---|---|---|

| ASTM D7791 | Axial fatigue of plastics | Tension/compression cycles | No environmental exposure |

| ASTM D3479 | Composite tension fatigue | Uniaxial stress testing | Laboratory conditions only |

| MIL-STD-810 | Military environmental | Temperature, humidity, vibration | Not specific to folding mechanisms |

| Custom Protocol | Firefighting specific | Combined stress + environment | Requires manufacturer investment |

What Additional Testing Should You Demand?

Beyond standard compliance, request evidence of environmental simulation testing. Our testing facility subjects arm mechanisms to temperature ranges from -20°C to 80°C. We expose samples to salt spray, moisture cycling, and simulated fire retardant chemicals.

De R ratio 4 in fatigue testing indicates the relationship between minimum and maximum stress. For firefighting drones, this ratio should reflect actual deployment patterns. Rapid arm extension under load creates different stress profiles than slow, unloaded movements. Your supplier should explain their R ratio selection and justify it based on real operational data.

Critical Questions for Suppliers

Ask your potential supplier these specific questions:

- Which ASTM standards do you follow for fatigue testing?

- What environmental conditions are included in your testing protocol?

- How do you simulate chemical exposure from firefighting operations?

- What is your test frequency, and why did you choose it?

If they cannot provide clear answers, consider that a red flag. Our experience shows that manufacturers who invest in proper testing are proud to share their methodologies.

How many folding cycles must the mechanism withstand before I can trust its long-term reliability in the field?

Our production data tells an interesting story. We track warranty claims across all export markets. The pattern is clear: mechanisms tested below certain thresholds fail at predictable rates.

A trustworthy firefighting drone arm mechanism should demonstrate a minimum of 10,000 loaded folding cycles in testing, with premium designs exceeding 50,000 cycles. This testing must occur under representative payload conditions, not unloaded laboratory scenarios.

Calculating Real-World Cycle Requirements

Let us work through the math together. A busy firefighting drone might deploy 5-10 times per day during peak season. Each deployment involves at least two folding operations: one to unfold for flight, one to fold for transport. During intensive wildfire seasons, this could mean 20 cycles per day.

Over a 5-year service life with 200 active days per year, that equals 20,000 cycles minimum. Add in training exercises, maintenance checks, and demonstration flights, and you quickly approach 30,000-50,000 cycles for a heavily used aircraft.

Cycle Life Expectancy Table

| Usage Level | Daily Cycles | Active Days/Year | 5-Year Total | Recommended Test Minimum |

|---|---|---|---|---|

| Light Duty | 4 | 100 | 2,000 | 5,000 cycles |

| Standard Duty | 10 | 150 | 7,500 | 15,000 cycles |

| Heavy Duty | 20 | 200 | 20,000 | 50,000 cycles |

| Emergency Services | 30 | 250 | 37,500 | 75,000 cycles |

Why Loaded Testing Matters

Here is a critical distinction many buyers miss. Some manufacturers test folding cycles without payload. The arms extend and retract in a jig with no weight attached. This tells you almost nothing about real-world performance.

When we test our mechanisms, we attach representative payloads: cameras, water tanks, fire suppressant dispensers. We simulate the G-forces from sudden flight maneuvers. We apply dynamic loads that mimic emergency stops and rapid direction changes.

The difference is dramatic. Mechanisms that survive 50,000 unloaded cycles often fail before 10,000 loaded cycles. Always ask: "What payload was attached during cycle testing?"

Signs of Fatigue Progression

Fatigue failure rarely happens suddenly. During our testing, we monitor for early warning signs:

- Increased play or looseness in joints

- Changes in folding force requirements

- Visible surface cracking near stress concentration points

- Audible changes during operation

Your supplier should document these progressive indicators and explain their acceptance criteria. At what point does wear become unacceptable? This information helps you establish maintenance schedules for your fleet.

Accelerated Testing Considerations

Some manufacturers use accelerated testing at higher stress levels to reduce test duration. This approach has scientific validity but requires careful interpretation. Ask whether results have been validated against real-world field performance. Our engineering team maintains correlation data between accelerated tests and actual field returns over multiple years.

What technical documentation should I request from my supplier to verify the fatigue resistance of the arm joints?

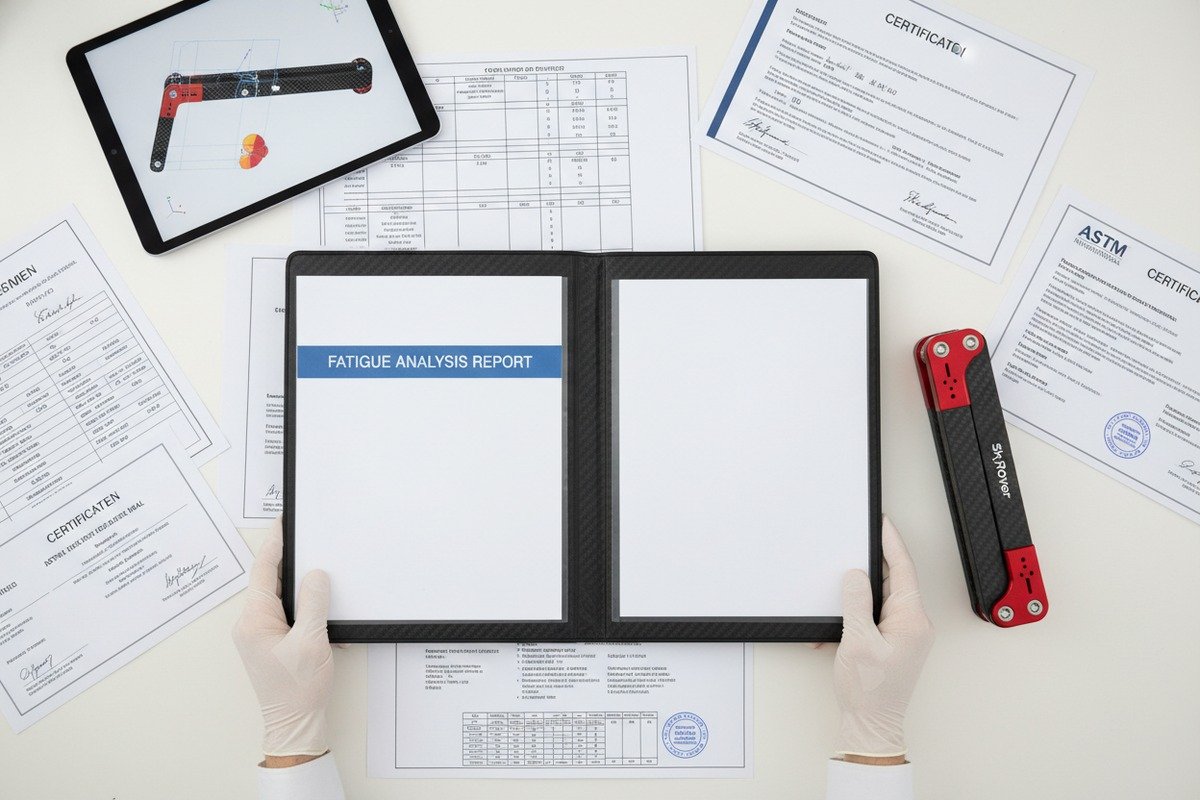

When our export team prepares documentation for US and European clients, we include comprehensive test reports. This is not optional—it is essential for professional procurement. Incomplete documentation signals incomplete testing.

Request fatigue test certificates showing S-N curves, Finite Element Analysis (FEA) stress reports, material certification documents, quality control inspection records, and failure mode analysis summaries. Complete documentation packages typically exceed 50 pages for properly tested mechanisms.

Essential Documentation Checklist

Not all technical documents carry equal weight. Some are marketing materials dressed as engineering reports. Here is how to distinguish substance from fluff.

S-N curves 5 (stress versus number of cycles) represent the gold standard for fatigue data. These graphs show exactly how the material or component responds to different stress levels over time. Request curves for both the raw materials and the assembled mechanism.

Documentation Quality Assessment Table

| Documenttype | What It Should Contain | Rode vlaggen |

|---|---|---|

| S-N Curve Report | Multiple stress levels, statistical confidence intervals | Single test point, no variance data |

| FEA Analysis | Stress concentration identification, safety factor calculations | Pretty pictures without numerical results |

| Material Certificates | Mill test reports, batch traceability | Generic specifications without lot numbers |

| Test Protocols | Detailed procedures, equipment calibration records | Vague methodology descriptions |

| Failure Analysis | Root cause identification, corrective actions | Blame placed on operator error |

Understanding FEA Reports

Finite Element Analysis allows engineers to simulate stress distribution before building physical prototypes. Finite Element Analysis (FEA) 6 Our design team runs FEA models on every new arm mechanism design. These simulations identify weak points before they cause field failures.

A quality FEA report should identify stress concentration points around hinges, fastener holes, and material transitions. It should specify safety factors—the ratio between predicted failure stress and expected operating stress. For firefighting applications, we target safety factors above 2.5 for critical components.

Request images showing stress distribution maps. Look for "hot spots" near joint areas. Ask what design modifications were made based on FEA findings. A supplier who cannot explain their FEA-driven design improvements likely did not take the analysis seriously.

Material Traceability Requirements

Professional aerospace and industrial drone manufacturing requires material traceability. This means every batch of aluminum, carbon fiber, or composite material can be traced back to its source mill with associated test data.

For 7075 aviation-grade aluminum 7, request mill certifications showing tensile strength, yield strength, and elongation values. For carbon fiber composites, ask for fiber content percentages, resin system specifications, and cure cycle documentation.

Quality Control Records

Beyond design documentation, request evidence of production quality control. How does the manufacturer ensure that every unit matches the tested prototype? Our production line uses statistical process control 8 with documented inspection points at critical assembly stages.

Ask about inspection rejection rates. A manufacturer with zero rejections is either lying or not inspecting properly. Our data shows that catching defects before shipment prevents field failures. Share this expectation with potential suppliers.

How can I evaluate if the folding mechanism design will help me avoid frequent and costly repairs for my clients?

After years of handling warranty claims and technical support calls, we have identified clear patterns. Certain design features consistently predict lower repair rates. Others virtually guarantee problems.

Evaluate designs for redundant locking mechanisms, serviceable components with available spare parts, corrosion-resistant surface treatments like hard anodizing, and integrated wear indicators. Mechanisms featuring these elements typically show 60-70% lower field failure rates compared to basic designs.

Design Features That Reduce Repairs

The best way to avoid repairs is to prevent failures. This starts with thoughtful design choices. When our engineering team develops new arm mechanisms, we prioritize serviceability from the first sketch.

Redundant locking systems provide backup security. If a primary latch fails, a secondary system prevents catastrophic arm collapse. We use heavy-duty clamps combined with self-locking mechanisms. This dual approach has virtually eliminated in-flight arm failures across our product line.

Repair Cost Comparison by Design Feature

| Design Feature | Initial Cost Impact | 5-Year Repair Savings | ROI |

|---|---|---|---|

| Redundant locks | +15% | -70% repair frequency | 3.2x |

| Hard anodized aluminum | +8% | -50% corrosion repairs | 4.1x |

| Modular components | +12% | -60% labor time | 2.8x |

| Integrated sensors | +20% | -40% unexpected failures | 2.1x |

| Sealed bearings | +5% | -80% joint wear issues | 8.0x |

Serviceability Considerations

Even the best mechanisms eventually need maintenance. The question is whether repairs are straightforward or nightmarish. Design choices made during development determine this outcome years later.

Modular component design allows field replacement of worn parts without complete disassembly. Our arm mechanisms use standardized fasteners and accessible adjustment points. A trained technician can replace a worn bushing in under 30 minutes.

Contrast this with integrated designs where wear components are permanently assembled. Replacing a single bushing might require factory return and complete mechanism replacement. The cost difference is substantial.

Beschikbaarheid van reserveonderdelen

Before purchasing, ask about spare parts. What components are available? What are lead times? What are costs? A manufacturer who invests in proper inventory management demonstrates commitment to long-term customer support.

Our parts warehouse maintains 18-month rolling inventory of all wear components. We ship replacement parts within 48 hours to most destinations. This commitment reduces customer downtime and builds trust.

Environmental Protection Features

Firefighting environments attack drone components aggressively. Heat degrades plastics. Water intrusion corrodes electronics. Chemical retardants attack aluminum. Soot contaminates bearings.

Look for environmental protection integrated into the design. Sealed bearings prevent contamination. Hard anodized surfaces 9 resist corrosion and abrasion. Protective boots cover exposed joints. These features add manufacturing cost but dramatically reduce field repairs.

Predictive Maintenance Integration

Advanced mechanisms now incorporate micro-sensors for condition monitoring. Strain gauges detect developing cracks. Accelerometers identify abnormal vibration patterns. Position sensors verify full lock engagement.

When connected to fleet management software, these sensors enable predictive maintenance. You can schedule service before failures occur. Our integrated monitoring systems have reduced emergency repairs by over 40% for customers who utilize them.

Conclusie

Evaluating fatigue testing for firefighting drone arm folding mechanisms requires examining standards, cycle life, documentation, and design features. Use this guide to ask better questions and make informed procurement decisions that protect your investment.

Voetnoten

1. Direct link to the ASTM standard for uniaxial fatigue properties of plastics. ↩︎

2. Provides a comprehensive overview and definition of composite materials. ↩︎

3. Direct link to the ASTM standard for tension-tension fatigue of polymer matrix composite materials. ↩︎

4. Explains the definition and significance of R ratio in fatigue testing. ↩︎

5. Details the generation and interpretation of S-N curves for fatigue analysis. ↩︎

6. Describes FEA as a method for simulating stress distribution in designs. ↩︎

7. Provides comprehensive information on the properties and uses of 7075 aluminum alloy. ↩︎

8. Defines statistical process control and its use in monitoring production quality. ↩︎

9. Explains the hard anodizing process and its benefits for surface durability. ↩︎