When our production team first encountered RoHS compliance requirements 1, the complexity surprised us. Many importers face the same confusion. You want durable, high-performance agricultural drones. But hidden hazardous substances in components can block your shipments at customs and damage your reputation.

Essential RoHS compliance details include verifying the EU Declaration of Conformity referencing Directive 2015/863, obtaining third-party test reports for all ten restricted substances, confirming component-level compliance for batteries and circuit boards, and maintaining complete documentation for customs clearance and market access.

This guide breaks down everything you need to know. We will cover certification verification, performance impacts, and legal risks. Let’s dive into the specifics.

Why is RoHS compliance critical for my agricultural drone import business?

Our engineers have seen shipments held at ports for weeks due to missing compliance documents. The financial losses are significant. If you plan to import agricultural drones into Europe or sell to environmentally conscious markets, RoHS compliance is not optional.

RoHS compliance is critical because agricultural drones qualify as electrical and electronic equipment under EU Directive 2011/65/EU. Without proper certification, your products face customs seizure, market access denial, substantial fines, and mandatory product recalls that can destroy your business reputation.

Understanding RoHS Directive Scope

Agricultural drones fall under Category 11 of RoHS 2, known as the "open scope" category. This means any electrical or electronic equipment not covered by other categories must comply. Our hexacopter drones contain multiple regulated components: circuit boards, solders, wiring, and battery systems.

The directive restricts ten hazardous substances:

| Substance | Maximum Concentration | Common Drone Components |

|---|---|---|

| Lead (Pb) | 0.1% | Solders, circuit boards |

| Mercury (Hg) | 0.1% | Switches, relays |

| Cadmium (Cd) | 0.01% | Plating, pigments |

| Hexavalent Chromium | 0.1% | Coatings, corrosion protection |

| PBB | 0.1% | Plastic housings |

| PBDE | 0.1% | Flame retardants |

| DEHP | 0.1% | Cable insulation |

| BBP | 0.1% | Plasticizers |

| DBP | 0.1% | Adhesives |

| DIBP | 0.1% | Coatings |

The CE Mark Connection

RoHS compliance is mandatory for CE-markering 2. Without CE marking, you cannot legally place agricultural drones on the European market. Our quality control team always verifies both certifications together. They work as a package.

Financial Consequences of Non-Compliance

The costs of non-compliance extend beyond fines. Consider these scenarios from our industry experience:

- Customs seizure means storage fees accumulate daily

- Product recalls require shipping costs and customer refunds

- Market access denial halts all European sales

- Reputation damage affects future partnerships

Many importers underestimate these risks. They focus on product features and forget regulatory requirements. This approach fails consistently.

How do I verify the authenticity of a Chinese supplier's RoHS certification?

In our experience exporting to European markets, we have seen many buyers deceived by fake certifications. Fraudulent documents look convincing. However, simple verification steps can protect your investment and business relationships.

Verify RoHS certification authenticity by requesting the complete EU Declaration of Conformity referencing Directive 2015/863, demanding third-party test reports from accredited laboratories, cross-checking laboratory accreditation through official databases, and conducting surprise component testing on received products.

Essential Documents to Request

When our export team prepares compliance packages, we include specific documents. You should demand the same from any supplier:

| Documenttype | Wat controleren? | Rode vlaggen |

|---|---|---|

| EU-conformiteitsverklaring | References Directive 2015/863 4 | Generic statements, missing directive numbers |

| Third-party Test Reports | Accredited laboratory stamp | Internal testing only, expired reports |

| Material Declarations | Component-level compliance | Incomplete supplier chain data |

| Bill of Materials | Full material composition | Missing subcomponent information |

Verifying Laboratory Accreditation

Not all test reports carry equal weight. Accredited laboratories follow ISO 17025 standards 5. You can verify accreditation through national databases. In China, CNAS (China National Accreditation Service) maintains the official registry.

Our recommendation: request test reports from internationally recognized laboratories. SGS, TÜV, and Bureau Veritas maintain consistent standards globally. These reports rarely face challenges at customs.

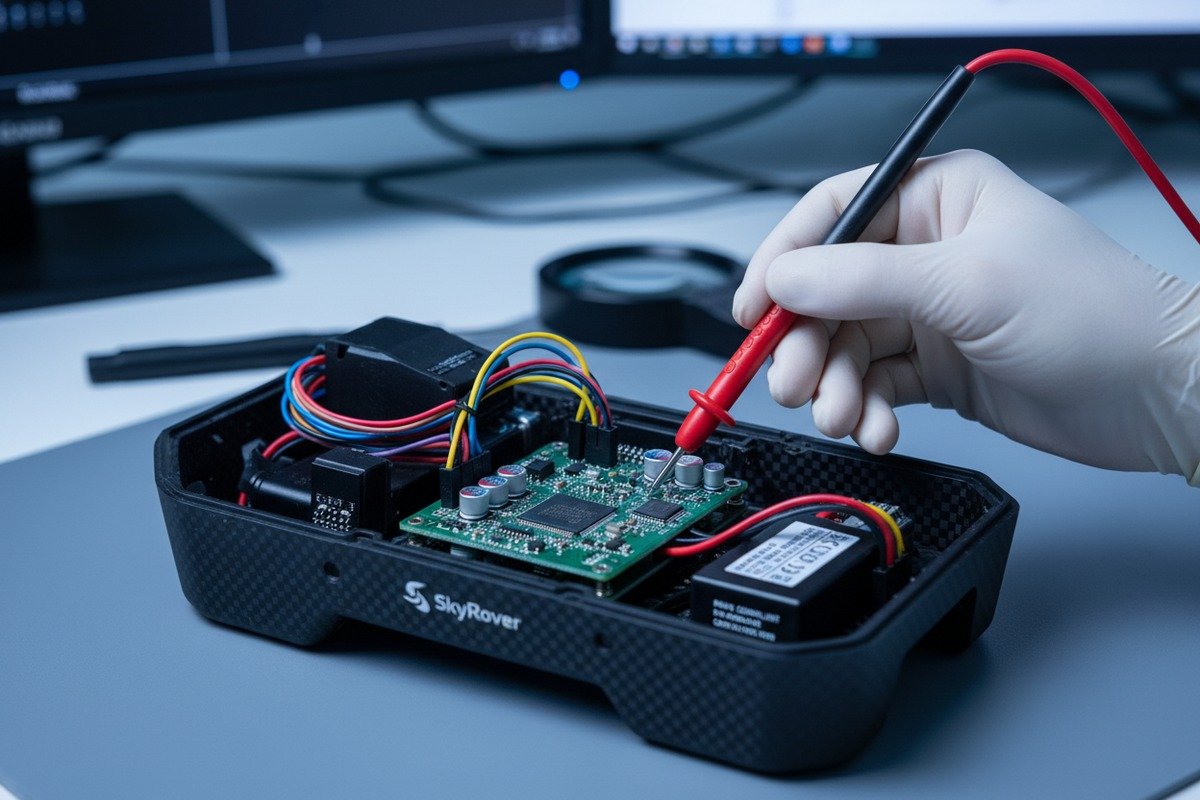

Supply Chain Due Diligence

RoHS compliance must extend throughout the supply chain. A drone contains hundreds of components from different suppliers. Each component must meet restrictions. Our procurement team maintains compliance records for every material entering our production line.

Ask your supplier these questions:

- Who supplies your circuit boards?

- What solder formulations do you use?

- Where do your plastics originate?

- Can you provide material safety data sheets?

Legitimate suppliers answer confidently. Hesitation indicates potential compliance gaps.

On-Site Verification Options

For large orders, consider factory audits. Our facility welcomes customer inspections. We show our testing equipment, material storage, and documentation systems. Suppliers who refuse inspections raise immediate concerns.

Third-party audit services specialize in Chinese manufacturing verification. They understand local practices and common compliance shortcuts. The investment protects against much larger losses.

Will RoHS-compliant components affect the durability and performance of my drones?

When we calibrate our flight controllers and test propulsion systems, component quality matters enormously. Early lead-free solders 6 caused reliability concerns in electronics. However, technology has advanced significantly. Modern RoHS-compliant components meet demanding performance standards.

RoHS-compliant components do not negatively affect agricultural drone durability or performance when properly selected and manufactured. Modern lead-free solders, compliant battery chemistries, and approved plastics deliver equivalent or superior reliability compared to older restricted materials in harsh agricultural environments.

Evolution of Lead-Free Soldering

Early concerns about lead-free solders were valid. Tin whisker formation and joint reliability presented challenges. Our production engineers studied these issues extensively. Current solder alloys solve most historical problems.

| Solder Type | Composition | Performance Characteristics |

|---|---|---|

| Traditional (restricted) | Sn63/Pb37 | Low melting point, excellent wetting |

| SAC305 (compliant) | Sn96.5/Ag3.0/Cu0.5 | Higher strength, good fatigue resistance |

| SAC387 (compliant) | Sn95.5/Ag3.8/Cu0.7 | Superior thermal cycling performance |

| Innolot (compliant) | SAC + additives | Enhanced reliability for harsh environments |

Agricultural drones operate in challenging conditions. Temperature extremes, vibration, and humidity stress electronic connections. Our testing shows modern compliant solders withstand these stresses effectively.

Battery Performance Considerations

Agricultural drone batteries require high energy density and cycle life. RoHS compliance affects certain battery component materials. However, lithium polymer and lithium-ion chemistries already avoid most restricted substances.

Our battery systems comply with multiple regulations:

- RoHS restrictions on hazardous substances

- UN38.3 transport safety certification

- IEC 62133 battery safety standards

The combination ensures both regulatory compliance and operational reliability. Flight times and payload capacities remain unaffected by RoHS requirements.

Plastic Housing Durability

Flame retardants in plastic housings faced significant reformulation after RoHS. Some early alternatives performed poorly. Current compliant formulations provide:

- Equivalent UV resistance

- Similar impact strength

- Adequate flame retardancy

- Good chemical resistance

Our carbon fiber frames avoid most plastic concerns entirely. The structural components use inherently compliant materials. Only minor elements require verification.

Long-Term Reliability Data

After producing agricultural drones for several years, our warranty data provides insights. Return rates for RoHS-compliant units match or improve upon historical baselines. Component failures show no correlation with compliance status.

The key factor is manufacturing quality, not material compliance. Properly processed compliant materials perform excellently. Shortcuts in any material create problems.

What legal risks do I face if my drone shipment lacks proper RoHS documentation at customs?

Our export documentation team works closely with customs brokers worldwide. We have witnessed shipments from other suppliers detained for months. The legal and financial consequences escalate rapidly. Understanding these risks helps you prepare adequately.

Legal risks for inadequate RoHS documentation include immediate customs seizure and detention, substantial administrative fines reaching hundreds of thousands of euros, mandatory destruction orders for non-compliant goods, market surveillance actions against your company, and potential criminal liability for repeated violations.

Immediate Customs Actions

European customs authorities actively enforce RoHS requirements. When documentation gaps appear, several actions follow:

| Customs Action | Tijdlijn | Your Costs |

|---|---|---|

| Documentation request | Day 1-3 | Administrative time |

| Shipment hold | Day 3-14 | Storage fees, demurrage |

| Laboratory testing | Week 2-6 | Testing costs, extended storage |

| Release decision | Week 6-12 | Accumulated fees |

| Destruction order | Week 12+ | Disposal fees, product loss |

Storage fees alone can reach thousands of euros weekly. Extended holds destroy profitability even before fines apply.

Financial Penalties Structure

EU member states set their own penalty structures. Germany, France, and the Netherlands enforce aggressively. Fines vary by violation severity:

- First offense documentation gaps: €10,000 – €50,000

- Substantive compliance failures: €50,000 – €200,000

- Repeated violations: €200,000 – €500,000+

- Criminal prosecution possible for intentional violations

These penalties apply per shipment, not per company. Multiple detained shipments multiply exposure rapidly.

Market Surveillance Consequences

Customs detention triggers market surveillance notifications. Your company enters enforcement databases. Future shipments face enhanced scrutiny. Business reputation suffers with distributors and end customers.

RAPEX (Rapid Alert System for Non-Food Products) 7 publishes non-compliance cases publicly. Competitors and customers see these notifications. Recovery from public compliance failures takes years.

EASA Regulatory Integration

Drone-specific regulations increasingly integrate environmental compliance. EASA C-class markings will require comprehensive conformity. RoHS compliance forms part of this framework. Non-compliant drones may face operational restrictions beyond import barriers.

Forward-thinking importers establish compliance systems now. Retrofitting systems after regulatory changes proves more expensive and disruptive.

Protecting Your Business

Our recommendation: invest in compliance verification before shipping. The costs are minimal compared to enforcement consequences. Request complete documentation packages. Verify laboratory accreditation. Conduct periodic sample testing.

When our team prepares export shipments, we include all required documents. Customs clearance proceeds smoothly. Your business deserves the same protection.

Conclusie

RoHS compliance protects your agricultural drone import business from costly enforcement actions. Verify supplier certifications thoroughly. Demand complete documentation before shipment. The investment in compliance prevents far greater losses from customs detention and market access denial.

Voetnoten

1. Provides a comprehensive guide to RoHS regulations and requirements. ↩︎

2. Explains the purpose and requirements of CE marking in the EU. ↩︎

3. Defines the scope of products covered by the RoHS directive. ↩︎

4. Links directly to the official EU delegated directive (RoHS 3). ↩︎

5. Provides an overview of the international standard for testing and calibration laboratories. ↩︎

6. Discusses the development and characteristics of lead-free solder alloys. ↩︎

7. Explains the EU’s rapid alert system for unsafe consumer products. ↩︎