When we adjust our flight controllers in Xi’an, we know US farmers face unique challenges. Generic imports often fail to meet local needs, causing frustration and operational downtime.

To determine supplier cooperation, assess their willingness to customize software interfaces for imperial units, integrate US-compliant hardware for FAA regulations, and provide a transparent roadmap for replacing restricted components to meet evolving market standards.

Finding a partner who adapts to your market is crucial, so let’s examine the specific indicators of a responsive manufacturer.

Does the manufacturer offer software development support to adapt the user interface for American farmers?

Our software engineers frequently rewrite code to match American workflow habits and units. A rigid interface frustrates operators, increases training time, and ultimately hurts your brand’s resale value.

A cooperative supplier will provide an Open API or SDK for local integration, offer a clear timeline for imperial unit conversion, and demonstrate compatibility with major US ag-tech platforms like Climate FieldView.

The Importance of Software Localization

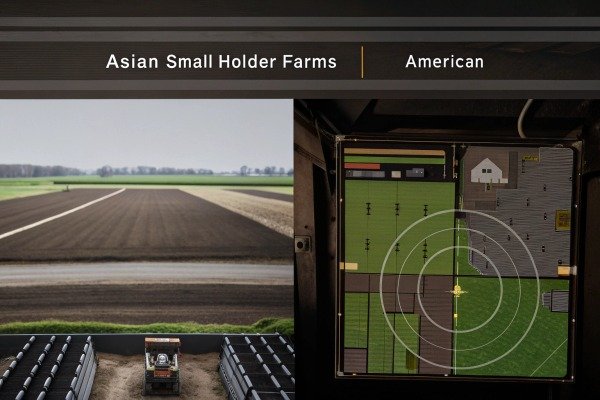

Agricultural drones are data-gathering tools, not just flying machines. If the software logic is hard-coded for Asian small-holder farms, it will fail on massive American acreages. You need to verify if the supplier treats software as a finished static product or a living ecosystem.

When we collaborate with US clients, the first hurdle is often unit conversion. It is not enough to simply change the label from "liters" to "gallons." The underlying logic for flow rates, battery consumption curves, and area planning must be recalibrated for Imperial units. Keizerlijke eenheden 1 A supplier willing to do this shows deep commitment.

Key Software Features to Audit

You should ask specific technical questions about their development environment. Are they willing to open their SDK (Software Development Kit)? An open SDK allows you to build your own proprietary app on top of their flight control system. This is a massive competitive advantage. It prevents you from being locked into a generic app that looks identical to your competitor’s.

Furthermore, consider data sovereignty. US farmers are increasingly protective of their yield data. You must ask if the supplier can configure the drone to send data to US-based servers (like AWS US East) AWS US East 2 rather than default servers in Asia.

Integration with US Ag-Tech

American agriculture runs on interconnected platforms. A drone that operates in a silo is less valuable. Ask the supplier if they have experience parsing data formats compatible with John Deere Operations Center John Deere Bedrijfscentrum 3 or Trimble John Deere Bedrijfscentrum 4. If they look confused, they have not localized their product. If they say, "We can write a script for that," they are a partner worth keeping.

Assessing Software Flexibility

Use this table to grade potential suppliers during your initial discussions.

| Feature Category | Basic Supplier (Avoid) | Cooperative Partner (Preferred) |

|---|---|---|

| Unit System | Metric only (forced conversion) | Native Imperial support in UI/Logic |

| Data Hosting | Fixed foreign servers | Option for local US server hosting |

| API/SDK Access | Closed/Proprietary | Open SDK for custom app development |

| Map Source | Generic (e.g., Baidu/AMap) | Google Maps/Mapbox integration |

| Updates | Infrequent, generic bugs only | Frequent, responsive to US regulations |

Will the supplier agree to modify hardware components to ensure compliance with US aviation regulations?

While assembling frames in our factory, we often swap specific modules for our American partners. Ignoring FAA rules risks grounding your entire fleet indefinitely and invites legal penalties.

Suppliers committed to US compliance will proactively integrate FAA-approved Remote ID modules, offer component swapping for NDAA alignment, and provide documented proof of FCC certification for all radio transmission parts.

Navigating the Regulatory Hardware Landscape

Hardware compliance is the biggest barrier to entry in the US market. Standard off-the-shelf drones from China often lack the specific modules required by the FAA. A supplier who says "it should work" is a liability. You need a supplier who says, "We have tested this specific module for Part 89 compliance Part 89 compliance 5."

Remote ID is non-negotiable. The drone must broadcast its location and ID. ID op afstand 6 Many generic flight controllers do not have this built-in. A cooperative supplier will agree to integrate a US-approved Remote ID module directly into the CAN bus system CAN bus system 7, rather than forcing you to tape a third-party module on top of the drone.

De NDAA-factor

The National Defense Authorization Act (NDAA) restricts federal agencies from buying drones National Defense Authorization Act 8 with critical components from certain countries. Even for private commercial use, many large US farms prefer NDAA-compliant tech to future-proof their investment.

You must determine if the supplier is willing to "sanitize" their supply chain for you. This means checking if they are willing to replace a video transmission module or a flight controller with a component from a non-restricted country (like the US or Taiwan) during assembly. We often perform this "hybrid assembly" for high-level clients. It costs more, but it ensures market access.

Radio Frequency and FCC Rules

In China, radio transmission power limits are different. Using a Chinese standard radio in the US might be illegal due to interference or lack of FCC certification. A supplier focused on localization will provide FCC IDs for their remote controllers and telemetry links. If they ask you to "just fly it," they are not serious about the US market.

Hardware Compliance Checklist

Before placing an order, run through these hardware requirements.

| Compliance Area | Vereiste | Supplier Action Needed |

|---|---|---|

| FAA Remote ID | Broadcast ID/Location | Integrate compliant module (e.g., specific chipsets) |

| FCC-certificering | Radio Frequency limits | Provide valid FCC ID for controller & air unit |

| Anti-Collision | Night flight lighting | Install FAA-compliant anti-collision strobe lights |

| NDAA (Optional) | Secure supply chain | Swap restricted comms/flight control modules |

How can I evaluate the R&D team's capability to implement custom spray systems or payload changes?

We love it when clients challenge our engineering team with unique crop requirements. Standard sprayers often drift or miss targets in complex field environments, reducing efficacy.

Evaluate R&D capability by requesting a specific, minor payload modification test; a capable supplier will produce a prototype or CAD adjustment quickly, demonstrating engineering agility rather than simple resale rigidity.

Testing Engineering Agility

Many "manufacturers" are actually just assemblers of standard kits. They cannot change the design because they do not own the molds or the code. To test a supplier, ask for a modification. For example, ask if they can change the nozzle layout to accommodate a specific boom width used in US row crops.

If they reply with "MOQ is 1000 units for that change," they are a rigid factory. If they reply with "Let us check with our engineer" and return with a CAD drawing or a 3D printed prototype within a week, you have found a true R&D partner. This agility is vital because US agriculture is diverse. You might need granular spreaders for cover crops one month and ultra-low volume sprayers for orchards the next.

Customizing for US Inputs

US farmers use different chemical formulations than farmers in Asia. Some US herbicides are thicker or more corrosive. Standard pumps might fail. A supplier willing to cooperate on localization will agree to test your specific chemical compatibility with their seals and pumps.

We often ship samples of US-standard nozzles (like TeeJet) to our factory nozzles (like TeeJet) 9 to ensure our threading fits perfectly. If a supplier refuses to use standard US fittings (NPT threads vs. metric), your customers will struggle to find replacement parts at their local hardware store. This small detail is a huge indicator of localization mindset.

Payload Modularity

The ability to swap payloads is a key selling point. Can the drone switch from a spray tank to a granular spreader in under five minutes? Can it carry a multispectral camera for crop scouting?

Ask for a demonstration of the payload release mechanism. A good R&D team designs for modularity. They should be able to provide you with the pin-out data for the payload port, allowing you to develop your own custom payloads in the future.

R&D Competency Signs

Look for these specific responses during your technical interviews.

- Positive Sign: "We can adjust the pump pressure curves in the firmware to match that viscosity."

- Positive Sign: "Send us the dimensions of the sensor you want to mount, and we will design a bracket."

- Negative Sign: "This is the standard model. We cannot change it."

- Negative Sign: "You can try to modify it yourself, but it voids the warranty."

What specific signs during negotiation indicate a supplier is truly open to joint development and OEM branding?

During late-night calls with US buyers, we prioritize long-term engineering roadmaps over quick sales. Transactional vendors vanish when you need technical evolution or support.

True partners agree to OEM branding with custom manuals, assign dedicated engineers for technical troubleshooting, and transparently discuss supply chain modifications to mitigate distinct geopolitical risks during the contract phase.

Moving Beyond the Logo

OEM (Original Equipment Manufacturer) services often stop at printing your logo on the shell. This is superficial. True localization involves "white-labeling" the entire user experience.

During negotiation, ask if they will provide the source files for the user manual. You need to rewrite the manual in native English, not "Chinglish," and add US-specific safety warnings. A supplier who shares editable InDesign or Word files is transparent. A supplier who sends a locked PDF is protective and uncooperative.

Direct Access to Engineering

One of the strongest signs of partnership is access to the technical team. In a standard sales relationship, you only talk to a salesperson. In a joint development partnership, we create a group chat involving your product manager and our lead engineer.

If the supplier hesitates to let you speak to their engineers, be wary. It implies they are either outsourcing the tech or they do not trust you. Direct communication is essential for troubleshooting bugs that only appear in the US field environment.

The Localization Roadmap

Ask the supplier for their "Localization Roadmap." This document should outline their plans for the US market over the next 12 to 24 months.

- Are they planning to open a US service center?

- Are they stocking spare parts in a Los Angeles warehouse?

- Are they applying for US patents? US patents 10

A supplier with a roadmap is investing in your success. A supplier without one is just exporting surplus inventory.

Evaluating Partnership Potential

Use this matrix to judge if the supplier is ready for a strategic alliance.

| Evaluatiecriteria | Transactional Vendor | Strategic OEM Partner |

|---|---|---|

| Branding | Sticker logo only | Full custom color, manual, & startup screen |

| Communication | Sales rep only | Direct line to engineering leads |

| Onderdelen | Order on demand (long wait) | Helps set up local US parts inventory |

| Exclusivity | Sells to anyone | Open to territorial protection discussions |

| Problem Solving | Blames user error | Collaborative root-cause analysis |

Conclusie

Sourcing the right drone involves verifying deep localization capabilities, from software unit conversion to FAA hardware compliance. A willing partner adapts their engineering to your reality, ensuring long-term market success.

Voetnoten

1. Historical and technical context for the Imperial measurement system. ↩︎

2. Information on AWS regional infrastructure for data sovereignty compliance. ↩︎

3. Documentation for integrating agricultural data with John Deere’s platform. ↩︎

4. Official product page for the specific ag-tech platform mentioned. ↩︎

5. Official FAA page detailing Part 89 Remote ID regulations. ↩︎

6. Official FAA resource for Remote ID compliance requirements for UAS. ↩︎

7. ISO standard for CAN bus communication in road vehicles and machinery. ↩︎

8. Background on US federal restrictions for drone components and procurement. ↩︎

9. Official website of the specific nozzle manufacturer mentioned. ↩︎

10. Official government website for United States patents. ↩︎