In our experience testing various spraying systems at our Chengdu facility, we often see buyers focus solely on tank capacity while overlooking the critical mechanics of atomization mechanics of atomization 1. You might have faced the frustration of uneven chemical application or clogged lines in the middle of a busy season. These issues usually stem from not asking the right technical questions about the nozzle system before purchase.

To properly evaluate atomization, you must ask for the specific Volume Median Diameter (VMD) at various flow rates and rotational speeds (RPM). Do not accept a generic micron range; instead, request a correlation chart showing how droplet size changes with motor speed, and verify the system’s ability to maintain a consistent droplet spectrum (Relative Span) to ensure effective crop coverage.

Below, we break down the specific inquiries you need to make to ensure you invest in a drone that delivers precise, reliable results.

What specific questions should I ask about the adjustable droplet size range to suit different crops?

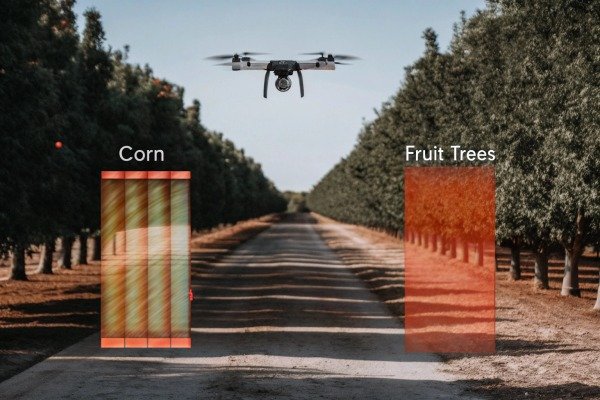

When we collaborate with our US partners on custom firmware, we prioritize the ability to fine-tune motor speeds because different crops demand different droplet physics droplet physics 2. If you do not clarify the adjustability range upfront, you risk buying a machine that works well for corn but fails miserably on sensitive fruit trees.

You should ask for a detailed performance curve that maps the disc rotational speed (RPM) to the resulting Volume Median Diameter (VMD) in microns. Specifically, inquire about the minimum and maximum achievable droplet sizes (e.g., 50–250 µm) and confirm that the drone’s flight controller allows you to input specific target sizes that the system automatically maintains during flight.

When you are negotiating with a supplier, the term "adjustable" can be vague. Many basic drones have a manual dial or a fixed setting that requires physical changes to the hardware. In modern high-end agricultural drones, like the SkyRover series we develop, adjustability should be software-defined and precise.

To get the real truth about a drone's capabilities, you need to dig into the relationship between the Brushless Motor RPM and the Liquid Flow Rate.

Understanding the Physics of the Disc

Centrifugal nozzles work by spinning a disc at high speeds—often between 10,000 and 20,000 RPM. The centrifugal force shreds the liquid into droplets. The faster the disc spins, the smaller the droplets. However, if you increase the flow rate (pump more liquid) without increasing the spin speed, the droplets get larger.

You need to ask the vendor if their system compensates for this. If you fly faster, the pump pumps more liquid. Does the nozzle spin faster to keep the droplet size the same? This is a "closed-loop" control system. If the drone lacks this, your spray quality will fluctuate wildly during the flight.

The Critical "VMD" Metric

Do not just ask "how small is the mist?" Ask for the VMD (Volume Median Diameter). This is the standard engineering metric.

- VMD: The midpoint where half the volume of spray is in smaller droplets and half is in larger ones.

If a vendor cannot provide a VMD chart, they likely have not tested their equipment professionally. You want to see data that proves the drone can handle the specific requirements of your target crops.

Recommended Droplet Sizes for Different Applications

Use the following table to guide your questions. Ask the vendor if their nozzle can effectively hit all these targets:

| Crop / Application | Recommended VMD (microns) | Why this matters? |

|---|---|---|

| Insecticides on Wheat/Rice | 100 – 150 µm | Needs fine mist to stick to thin leaves and stems. |

| Herbicides (Systemic) | 200 – 300 µm | Larger drops prevent drift to neighboring crops. |

| Fungicides on Fruit Trees | 80 – 120 µm | Requires very fine mist to penetrate deep into the canopy. |

| Liquid Fertilizer | 250 – 400 µm | Coarse drops reduce evaporation and leaf burn. |

Control Interface

Finally, ask to see the software interface. When we design our Ground Control Station (GCS) software, we ensure the user can select "Coarse," "Medium," or "Fine," or input a specific micron value.

- Bad Answer: "You can adjust the voltage manually."

- Good Answer: "The app lets you set the droplet size in microns, and the flight computer adjusts the RPM automatically."

This distinction is often the difference between a hobby-grade toy and a professional industrial tool.

How do I verify the nozzle's capability to handle high-viscosity liquids without clogging?

Our repair team frequently receives units with burned-out motors caused by users trying to spray thick wettable powders wettable powders 3 through systems designed only for water. To avoid downtime and expensive repairs, you must verify the fluid dynamics of the system before you sign the purchase order.

Ask the specific viscosity limit (in centipoise/cP) of the nozzle and pump system, and verify if the atomizing disc utilizes a serrated edge or specialized geometry to process wettable powders. You must also confirm that the fluid channels are wide enough to prevent sediment buildup and request video evidence of the drone successfully spraying high-density mixtures like lime sulfur or heavy fertilizers.

One of the main selling points of centrifugal nozzles over traditional pressure nozzles is their resistance to clogging. However, not all centrifugal nozzles are created equal. The market is flooded with cheap plastic copies that look like high-end units but fail the moment you introduce a thick slurry.

The "Powder" Test

Many agricultural inputs, especially in organic farming or heavy fertilization, come as Wettable Powders (WP) of Suspension Concentrates (SC). When mixed with water, these do not form a perfect solution; they form a suspension.

- Het risico: In a poorly designed nozzle, the centrifugal force separates the solid particles from the water before they leave the disc. The water sprays out, but the powder packs into the rim of the disc, turning into a concrete-like solid that unbalances the motor.

Question to Ask: "Does the atomization disc have a self-cleaning design or open-channel geometry that prevents powder accumulation?"

Pump Compatibility

The nozzle is only half the battle. You must also ask about the pump.

- Diaphragm Pumps: Common, but can struggle with very thick fluids.

- Peristaltic Pumps: Best for durability and high viscosity. They squeeze the tube rather than touching the liquid.

- Impeller Pumps: High flow, but can be damaged by abrasive powders.

When we build our heavy-lift drones, we often specify peristaltic pumps for clients using aggressive chemicals. You should ask the vendor which pump type pairs with their centrifugal nozzle.

Verifying Viscosity Claims

A vendor might say, "Yes, it handles fertilizer." That is too vague. Use this checklist to verify their claims:

| Functie | What to Ask / Look For | Waarschuwingstekens |

|---|---|---|

| Fluid Channel Diameter | "What is the minimum internal diameter of the tubing and nozzle feed?" | Tubing smaller than 6mm often clogs with thick fluids. |

| Motor Torque | "What is the torque rating of the nozzle motor?" | Small, low-torque motors will stall if the fluid is too heavy (drag increases). |

| Material | "Is the disc made of carbon fiber, aluminum, or plastic?" | Cheap plastic wears down quickly with abrasive powders. |

| Testing | "Can you show me a video of it spraying a 1.3g/ml density liquid?" | If they refuse or show only water testing, be skeptical. |

Real-world Scenario: Lime Sulfur

Lime sulfur is notoriously thick and sticky Lime sulfur 4. If you plan to use this, specific inquiry is mandatory. Ask if the manufacturer suggests a specific cleaning protocol after using such chemicals. A good system is easy to disassemble. If you need a screwdriver and 20 minutes to take the nozzle apart for cleaning, your operational efficiency will plummet. We design our SkyRover nozzles to be "tool-free" detachable for this exact reason.

What details should I confirm regarding spray uniformity and crop canopy penetration?

We often see farmers confused when their crops show uneven growth despite using expensive automated drones. In our field analyses, we usually find that while the drone flew the correct path, the spray curtain was inconsistent, missing the lower leaves entirely.

Inquire about the “Relative Span” or Coefficient of Variation (CV) of the droplet spectrum to ensure the nozzle produces uniform sizes rather than a mix of ineffective mist and wasteful large drops. Furthermore, ask for field data demonstrating the effective spray width at different flight altitudes and how the rotor downwash field interacts with the spray pattern to drive chemicals into the lower canopy.

Uniformity is the hidden metric of efficiency. If you spray 10 liters per hectare, but 50% of it lands on the top leaves and 0% reaches the bottom, you have wasted your money.

The Problem of "Relative Span"

In any spray, you get a range of droplet sizes. range of droplet sizes 5

- Ideal: All droplets are exactly 100 microns.

- Reality: You get some at 50, some at 100, some at 200.

De Relative Span (RS) measures this spread. A lower number is better.

- High RS (Bad): You have many tiny droplets (drift risk) and many huge droplets (runoff/waste).

- Low RS (Good): Most droplets are near the target size.

Question to Ask: "What is the Relative Span value of your nozzle at standard operating RPM? Is it below 1.0?"

If the vendor doesn't know what Relative Span is, they are likely just assembling parts, not engineering a solution.

Canopy Penetration and Downwash

Centrifugal nozzles create a horizontal spray pattern (like a flat plate) horizontal spray pattern 6. This is different from pressure nozzles that shoot down. Therefore, centrifugal systems rely heavily on the propeller downwash (the wind from the drone's motors) to push the mist down into the crop.

This interaction is complex. If the nozzle is placed too far from the propeller, the mist floats away. If it's too close, it gets sucked up into the props.

- Orchards: You need high penetration. The droplets must be pushed through thick leaves.

- Field Crops: You need even coverage without flattening the crop.

Evaluating Spray Width Data

Vendors often exaggerate spray width. They might say "6 meters width!" but that might include the thin, ineffective edges.

You need to ask for the Effective Spray Width. This is the width where the chemical concentration is sufficient to kill the pest.

Table: Evaluating Uniformity and Penetration Data

| Metrisch | What to Ask For | Good Benchmark |

|---|---|---|

| Druppeldichtheid | "How many droplets per cm² reach the bottom of a soy/wheat plant?" | >15 droplets/cm² (fungicide/insecticide). |

| CV (Coefficient of Variation) | "What is the CV across the spray boom?" | < 15% is excellent; > 25% leads to striping. |

| Overlap Strategy | "What track spacing do you recommend to ensure uniform overlap?" | Typically, track spacing should be 80-90% of the effective width. |

H3: The "Hollow Center" Issue

Some centrifugal setups create a "hollow" cone pattern where no spray lands directly under the drone. We address this by angling the nozzles or overlapping the spray patterns of multiple rotors. Ask the vendor: "Does the nozzle arrangement cover the area directly beneath the fuselage, or will I need to fly tighter overlaps to cover the gap?"

How should I inquire about the anti-drift performance of the atomization system in windy conditions?

During our export operations to Europe, we face strict environmental regulations regarding chemical drift environmental regulations 7, which has forced us to rigorously optimize our algorithms. environmental regulations regarding chemical drift 8 If you ignore wind performance, you risk not only wasting chemicals but also facing legal liability for damaging neighboring properties.

You must ask if the drone’s flight control system actively monitors wind speed and automatically increases the droplet size (coarsening) to reduce drift potential in real-time. Additionally, request specific data on the “drift distance” of their standard droplets at wind speeds of 3–5 m/s, and verify if the drone supports off-center nozzle configurations to counteract crosswinds.

Drift is the number one enemy of aerial application. aerial application 9 Centrifugal nozzles are often criticized for drift because they can produce very fine mist. However, smart technology can mitigate this.

The Physics of Drift

Small droplets fall slower. A 50-micron droplet can float for hundreds of meters in a light breeze. A 300-micron droplet falls like a stone.

The Trade-off: Small droplets give better coverage; large droplets give better safety.

Active vs. Passive Anti-Drift

- Passive: The user manually selects a coarser setting before takeoff because it feels windy.

- Active (Smart): The drone has an anemometer (wind sensor) or estimates wind via GPS/IMU data. It detects a 4 m/s gust and instantly slows down the spinning disc to make droplets larger and heavier.

Question to Ask: "Does your flight controller have dynamic RPM adjustment based on ground speed and wind resistance?"

Flight Path and Buffer Zones

Drift isn't just about the nozzle; it's about the flight plan. Advanced systems allow you to set "Buffer Zones" where the drone Buffer Zones 10 automatically switches to a special "Anti-Drift Mode" (low altitude, high flow, coarse droplet).

Ask the vendor about their software capabilities:

- Boundary Safety: Can I program the drone to spray only when flying into the wind near boundaries?

- Cut-off Speed: How fast do the nozzles shut off when the drone stops? Centrifugal nozzles can drip if not equipped with rapid-stop valves.

Troubleshooting Drift Issues

If you are evaluating a demo unit, look for these red flags:

| Observation | Diagnose | Question to Vendor |

|---|---|---|

| Mist swirling up into props | Vortices are capturing the spray. | "Is the nozzle vertical position adjustable to escape the rotor tip vortices?" |

| Visible cloud drifting >10m | Droplets are too fine (<100µm). | "What is the minimum RPM setting? Can I lock it to prevent fine misting?" |

| Uneven settling | Crosswind effect. | "Does the drone crab (fly sideways) to compensate for wind, and does the spray system adjust?" |

The "Hoisting" Effect

At high flight speeds (over 6-7 m/s), the air resistance can shatter droplets further or lift them up (hoisting).

Vraag: "What is the maximum flight speed recommended before atomization quality degrades due to wind shear?"

At SkyRover, we typically recommend capping speed at 5-6 m/s for high-precision work, even if the drone can fly faster. The vendor should be honest about these physical limits.

Conclusie

Asking the right questions about atomization—specifically regarding VMD adjustability, viscosity management, uniformity, and drift control—shifts the conversation from simple price negotiation to ensuring long-term operational success. By demanding data on droplet spectrums and verifying the integration between software and hardware, you ensure that the drone you purchase is not just a flying machine, but a precision agricultural tool capable of delivering chemicals effectively and safely.

Voetnoten

1. Refers to the scientific principles of spray formation and droplet breakup. ↩︎

2. Explains how droplet size affects interaction with different crop surfaces. ↩︎

3. Defines the specific pesticide formulation type that causes clogging. ↩︎

4. Identifies the specific high-viscosity chemical compound mentioned. ↩︎

5. USDA research publication discussing droplet size measurement and VMD in agricultural spraying. ↩︎

6. Describes the specific distribution geometry of centrifugal nozzles. ↩︎

7. Links to official government standards regarding chemical application compliance. ↩︎

8. Official EPA regulations regarding the management of pesticide spray drift. ↩︎

9. General overview of aerial application techniques in agriculture. ↩︎

10. Defines the designated safety areas required for drift mitigation. ↩︎