Every week, our engineering team receives calls from US distributors worried about one thing: NDAA compliance DOD Blue sUAS Cleared List 1. The fear is real. One wrong component can block your government contract forever.

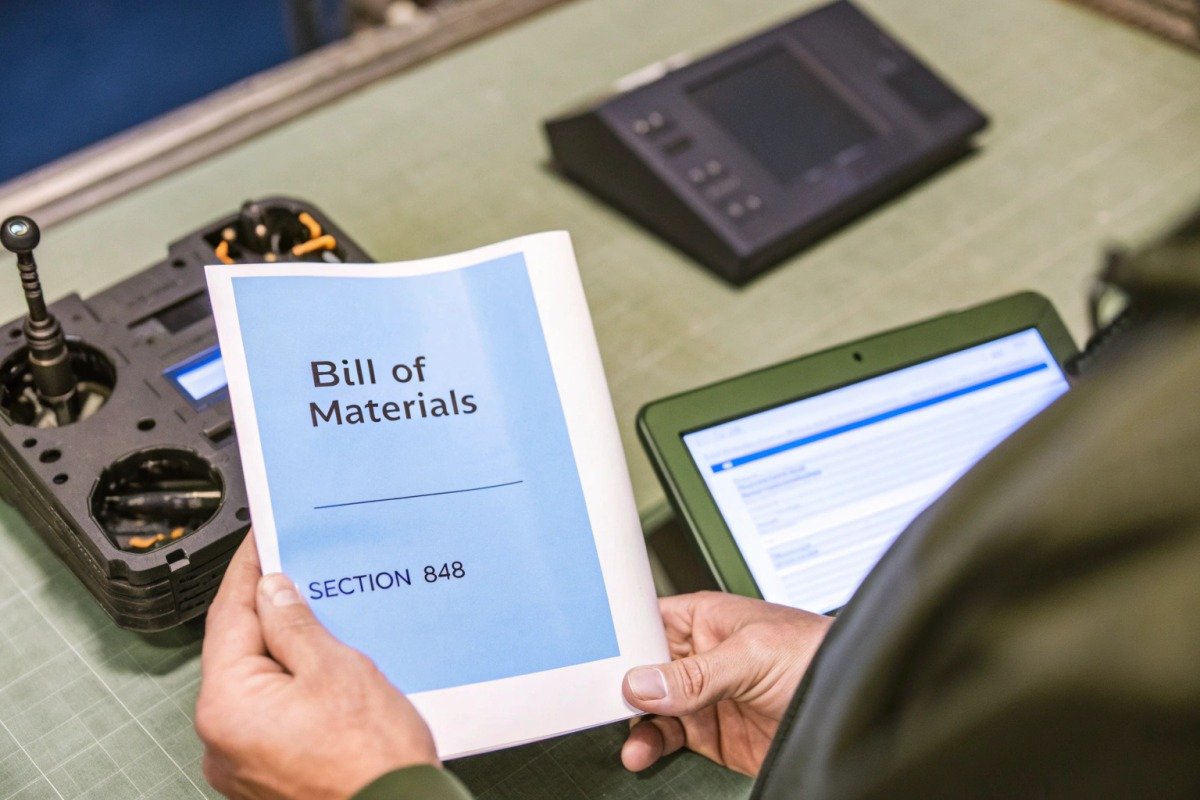

To verify NDAA compliance for firefighting drones from Chinese suppliers, request complete bills of materials, check the DOD Blue sUAS Cleared List, demand FCC certifications, audit component origins against Section 848 restrictions, and obtain written declarations confirming no covered foreign entity involvement in critical parts like cameras, radios, and flight controllers.

Let me walk you through exactly what our team has learned from years of exporting to the US market Commerce Entity Lists 2. The rules are strict, but they are not impossible to navigate.

What specific documentation should I request from a Chinese supplier to prove my firefighting drones are NDAA compliant?

When our export team prepares shipments for US government contractors, documentation becomes everything. Missing one certificate can delay your entire project by months.

Request a complete bill of materials with component origins, FCC authorization documents, manufacturer declarations of non-affiliation with covered foreign entities, supply chain audit reports, and written NDAA compliance certifications specifically referencing Section 848 and ASDA requirements for each critical component.

Essential Documents Checklist

The documentation process starts with understanding what US regulations actually require. Section 848 of the FY2020 NDAA 3 bans DOD purchases of UAS from covered foreign countries. The American Security Drone Act 4 expands this to all federal projects. Your documentation must prove your drones fall outside these restrictions.

Our production facility maintains a standard documentation package for all US-bound orders. Here is what you need to request:

| Document Type | Purpose | Why It Matters |

|---|---|---|

| Bill of Materials (BOM) | Lists every component and origin country | Proves critical parts avoid covered entities |

| FCC Authorization | Confirms radio equipment meets US standards | Required for legal operation in US |

| Manufacturer Declaration | Written statement of non-affiliation | Legal protection against future audits |

| Supply Chain Audit Report | Third-party verification of component sources | Independent proof of compliance |

| NDAA Compliance Certificate | Direct reference to relevant sections | Shows supplier understands regulations |

Understanding Critical vs. Non-Critical Components

Not all components face the same scrutiny. The NDAA focuses on data-transmitting parts. Motors and propellers are currently considered low-risk. Cameras, flight controllers, radios, and data links face strict review.

When we design firefighting drones, we separate components into two categories. Critical components include anything that stores, processes, or transmits data. These must come from non-covered sources. Mechanical components like frames and rotors have more flexibility.

Red Flags in Supplier Documentation

Watch for vague language in compliance documents. Phrases like "assembled in USA" or "designed domestically" mean nothing without component-level proof. Our team always provides specific manufacturing locations for each critical part.

A legitimate compliance certificate will reference:

- NDAA Section 848 specifically

- ASDA Sections 1824-1825

- FAR prohibition on covered foreign entities

- FCC Covered List status

If your supplier cannot explain these references, find another supplier.

How can I verify that the internal components and software of my imported drones meet US federal security standards?

Our engineers spend significant time testing component security before any drone leaves our facility. The internal architecture matters more than the external branding.

Verify internal compliance by requesting component-level certifications, demanding source code access for critical software, checking processor and radio chip origins against Commerce Entity Lists, requiring encrypted data transmission protocols, and confirming cloud services use US-based or allied servers.

Breaking Down Internal Component Categories

Every firefighting drone contains hundreds of parts. Focus your verification on these critical systems:

| Component Category | Security Concern | Verification Method |

|---|---|---|

| Flight Controller | Data processing and storage | Check chip manufacturer origin |

| Camera System | Image capture and transmission | Verify sensor and processor sources |

| Radio Transmitter | Communication interception risk | Confirm FCC authorization |

| GPS Module | Location data sensitivity | Check for non-covered chipsets |

| Data Link | Real-time transmission security | Verify encryption standards |

| Software/Firmware | Backdoor vulnerabilities | Request source code audit rights |

Software Verification Challenges

Software presents unique verification problems. Code can be updated remotely. Backdoors can hide in firmware. Our development team addresses this through several methods.

First, we provide firmware source code access to serious buyers. This allows independent security audits. Second, we disable automatic update features for government-contract drones. Third, we use open-source flight controller platforms where possible.

The 2026 regulatory environment will likely expand NDAA definitions to include AI algorithms and cloud services. Start preparing now. Ask your supplier about data routing. Where do flight logs go? Who can access telemetry data?

Practical Testing Procedures

You can verify some compliance claims yourself. Use network monitoring tools during drone operation. Check for unexpected data transmissions. Our team recommends:

- Operate the drone in isolated network environments

- Monitor all outbound data packets

- Verify encryption on all transmissions

- Check connection attempts to foreign servers

- Test offline operation capabilities

A compliant firefighting drone should operate fully without internet connection. If your drone requires cloud connectivity for basic functions, investigate further.

What steps should I take to audit a manufacturer's supply chain for restricted parts before placing my order?

In our Xi'an headquarters, supply chain management takes up an entire department. We track every component from raw material to finished drone. Your supplier should offer the same transparency.

Audit supply chains by requesting Tier-1 and Tier-2 supplier lists, verifying component manufacturers against Commerce Entity Lists, conducting factory visits or third-party inspections, checking for Blue sUAS program participation, and requiring contractual guarantees with penalty clauses for compliance violations.

The Multi-Tier Supply Chain Problem

Most drones contain components from dozens of suppliers. A Chinese manufacturer might use Korean cameras, American chips, and Japanese motors. Each tier adds complexity.

Here is how our supply chain works:

| Tier Level | Example | Audit Requirement |

|---|---|---|

| Tier 0 | Final drone assembly | Factory location and ownership |

| Tier 1 | Major subsystems (camera, flight controller) | Component manufacturer verification |

| Tier 2 | Chips and sensors inside subsystems | Semiconductor origin confirmation |

| Tier 3 | Raw materials and basic parts | Country of origin documentation |

Most NDAA violations happen at Tier 1 or Tier 2. A flight controller might be assembled in Taiwan but use a processor from a covered entity. Dig deeper than surface-level claims.

Conducting Effective Supplier Audits

Factory visits remain the gold standard for verification. Our facility welcomes customer inspections. We show production lines, component storage, and quality control processes.

If you cannot visit personally, hire third-party inspection services. Companies like SGS, Bureau Veritas, and Intertek offer supply chain audits. Request specific focus on NDAA compliance.

During audits, check for:

- Physical component labels matching documentation

- Inventory records showing supplier invoices

- Quality control logs with batch numbers

- Separate storage for US-market components

Building Contractual Protections

Smart procurement requires contractual safeguards. Include these clauses in purchase agreements:

- Compliance warranty: Supplier guarantees NDAA compliance with specific section references

- Audit rights: Buyer can inspect facilities and records with reasonable notice

- Penalty provisions: Financial consequences for compliance failures

- Replacement obligations: Supplier must replace non-compliant components at their cost

- Indemnification: Supplier assumes liability for regulatory violations

Our standard contracts include all five provisions. Any supplier refusing these terms raises immediate concerns.

Can I partner with a supplier to develop a custom firefighting drone that satisfies my government client's NDAA requirements?

Custom development is where our engineering team truly excels. Working directly with US clients, we have built compliant firefighting systems from the ground up.

Yes, partnering with a Chinese supplier for custom NDAA-compliant firefighting drones is possible by specifying approved component sources upfront, using open-source flight platforms, selecting US or allied-nation critical parts, maintaining full supply chain documentation, and building compliance verification into every development milestone.

Structuring a Compliant Development Partnership

The key to custom development is building compliance into the design phase. Retrofitting non-compliant drones rarely works. Start clean.

Our typical custom development process includes:

| Phase | Compliance Activities | Deliverables |

|---|---|---|

| Requirements | Define acceptable component sources | Approved vendor list |

| Design | Select compliant parts for critical systems | Component specifications with origin data |

| Prototyping | Verify each component meets requirements | Compliance checklist per part |

| Testing | Confirm no unauthorized data transmission | Security audit report |

| Production | Maintain documented supply chain | Full traceability records |

| Delivery | Provide compliance certification package | All required documentation |

Selecting Compliant Components for Custom Builds

For firefighting applications, certain components require special attention. Thermal cameras must handle extreme heat while remaining compliant. Here are common solutions:

Flight Controllers: Open-source platforms like PX4 or ArduPilot 5 allow full code inspection. These can run on compliant hardware from US or European manufacturers.

Cameras: FLIR 6 and other US thermal imaging companies offer compliant sensors. Integration requires engineering work but eliminates compliance concerns.

Radios: US-made radio systems exist but cost more than Chinese alternatives. Factor this into project budgets.

Batteries: Current NDAA restrictions focus on electronics, but Section 842 phases in battery restrictions starting 2028. Plan ahead.

Cost Implications of Custom Compliant Development

Honest conversation about costs matters. Custom NDAA-compliant drones cost more than off-the-shelf Chinese alternatives. Our experience shows:

- Critical component substitutions add 30-50% to material costs

- Engineering time for compliance documentation adds 10-15% to development costs

- Extended supply chain management increases overhead

- Third-party audits require additional budget

However, these costs are investments. A compliant drone opens government contract opportunities that non-compliant products cannot access. The math usually favors compliance for serious US market players.

Long-Term Partnership Benefits

Working with a manufacturer on custom development creates advantages beyond single orders. Our long-term partners receive:

- Priority access to new compliant components

- Faster turnaround on documentation updates

- Joint responses to regulatory changes

- Shared compliance monitoring resources

The NDAA landscape will continue evolving. Battery restrictions arrive in 2028. Software definitions may expand in 2027. A strong supplier relationship helps you adapt quickly.

Conclusion

NDAA compliance for firefighting drones requires thorough documentation, careful component verification, supply chain audits, and strategic partnerships. Work with suppliers who understand these requirements and can prove compliance at every level.

Footnotes

1. Official Defense Innovation Unit portal for the Blue sUAS Cleared List. ↩︎

2. Official U.S. Department of Commerce page explaining the Entity List and its purpose. ↩︎

3. Provides the official text of the law prohibiting foreign-made UAS procurement by the DOD. ↩︎

4. Provides the official legislative text expanding drone restrictions to all federal projects. ↩︎

5. Official website for PX4, a leading open-source flight control software for drones. ↩︎

6. Official website of a leading manufacturer of thermal imaging cameras, relevant for drone applications. ↩︎