When our engineering team first started exporting firefighting drones to US fire departments, we quickly learned that meeting NFPA standards is not optional—it’s essential public safety sUAS 1. Many procurement managers face confusion when suppliers claim compliance but lack proper documentation. This gap between marketing claims and actual certification creates real risks for fire departments and their communities.

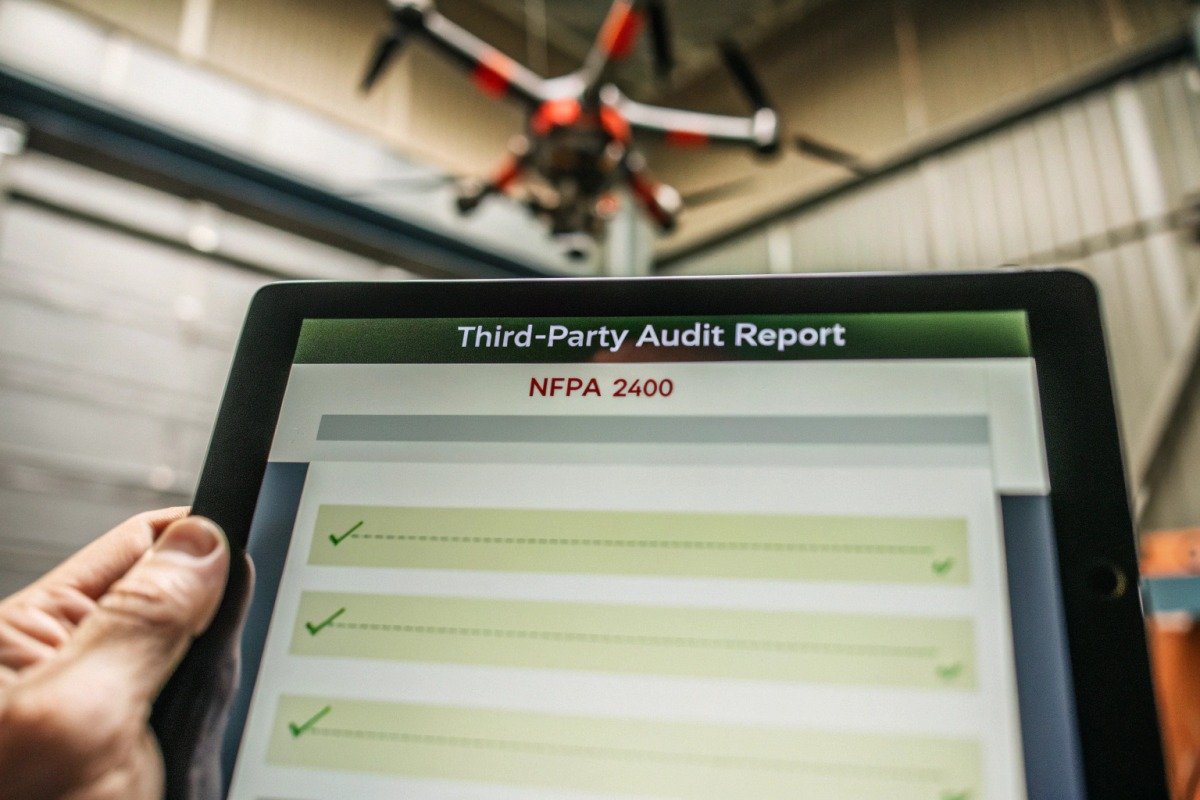

To verify if firefighting drone suppliers meet US NFPA standards, you must request formal documentation proving NFPA 2400 compliance, audit pilot training curricula against Chapter 5 requirements, validate hardware durability ratings, and confirm maintenance protocols align with Chapter 6 specifications. Third-party audit reports provide the strongest verification.

This guide breaks down exactly what to check and how to spot suppliers who genuinely meet these critical safety standards. Let’s walk through each verification step.

How do I verify that my supplier's firefighting drone certifications actually align with NFPA requirements?

When we work with US distributors, they often arrive with a list of certification questions that reveal how confusing this landscape can be. Some suppliers wave generic safety certificates, but those rarely address the specific demands of public safety drone operations. The problem is real: without proper verification, fire departments risk deploying equipment that fails when lives depend on it.

To verify supplier certifications align with NFPA requirements, request a formal Certificate of Conformance citing NFPA 2400 specifically, demand third-party audit reports, cross-reference training materials with Chapter 5 Job Performance Requirements, and confirm FAA Part 107 compliance documentation exists alongside any BVLOS waivers.

Understanding NFPA 2400 as the Foundation

NFPA 2400 2 serves as the primary US standard for small unmanned aircraft systems in public safety operations. Released in 2019, it functions as a "three-in-one" standard covering program development, professional qualifications, and maintenance requirements. This standard applies to fire departments using drones for suppression support, search and rescue, thermal imaging 3, hazmat response, and post-fire assessments.

Many buyers confuse NFPA 2400 with other standards. NFPA 1710 covers response times. NFPA 402 addresses aircraft fires. Neither applies to drone procurement verification. Always confirm your supplier references NFPA 2400 specifically.

What Documents to Request

| Document Type | What It Should Include | Red Flags |

|---|---|---|

| Certificate of Conformance | Explicit NFPA 2400 citation, date, scope | Generic "public safety ready" claims only |

| Third-Party Audit Report | Independent testing lab name, test dates, specific chapters addressed | Self-certified documents without external validation |

| FAA Compliance Proof | Part 107 certificate, any BVLOS waivers | Missing Remote ID documentation |

| Training Curriculum | Chapter 5 JPR alignment, RPIC and VO modules | Generic pilot training without public safety focus |

Verifying Personnel Qualification Alignment

Chapter 5 of NFPA 2400 defines Job Performance Requirements for Remote Pilots in Command and Visual Observers. Your supplier's training programs must match these requirements. RPIC personnel need qualifications covering final flight authority, mission planning, and risk assessment. Visual Observers must maintain line-of-sight duties exclusively.

Ask suppliers if their training holds Pro Board accreditation. This accreditation links directly to NFPA 2400 Chapter 5.2.2 requirements. Without it, training certificates carry less weight.

Cross-Referencing FAA Requirements

NFPA 2400 mandates compliance with FAA regulations 4 but doesn't replace them. Your supplier must demonstrate both NFPA and FAA compliance exist together. The FAA issued its first Beyond Visual Line of Sight waiver for firefighting in 2021. If your operations require BVLOS capability, verify your supplier supports this waiver process with proper documentation.

What specific engineering tests should I request to confirm my drone's durability in high-heat environments?

Our production floor runs continuous durability testing because we understand what happens when drones fail during active fire operations. The thermal stress, particulate exposure, and electromagnetic interference at fire scenes create conditions that destroy consumer-grade equipment. Yet some suppliers skip these tests entirely, hoping buyers won't ask the right questions.

Request documentation of IP55 or higher ingress protection testing, thermal cycling tests simulating 150°C+ ambient exposure, wind resistance validation at 39+ ft/s, motor stress tests under payload, and battery thermal runaway prevention certification. NIST 2022 standardized test protocols provide the most reliable benchmark.

Essential Durability Specifications

Fire scenes subject drones to extreme conditions. Radiant heat from structure fires can exceed 1000°C at the source. Smoke particles clog motors and sensors. Turbulent air from fire-generated convection creates unpredictable flight conditions. Your supplier must prove their equipment survives these challenges.

| Test Category | Minimum Requirement | Testing Standard |

|---|---|---|

| Ingress Protection | IP55 rating minimum | IEC 60529 |

| Heat Resistance | Continuous operation at 60°C ambient | NIST sUAS Test Methods |

| Wind Resistance | Stable flight at 39 ft/s (27 mph) | MIL-STD-810G Method 506.6 |

| Flight Duration | 50+ minutes under payload | Manufacturer specification with third-party validation |

| Operational Range | 5+ miles effective control | FCC Part 15/47 compliance |

Thermal Imaging Sensor Validation

Firefighting drones rely heavily on thermal imaging for hotspot detection, victim location, and structural assessment. NFPA 1801 provides performance requirements for thermal imaging cameras used in structural firefighting. While this standard originally targeted handheld devices, its image quality and heat resistance requirements offer useful benchmarks.

Ask your supplier these questions about thermal sensors:

- What temperature range does the sensor detect?

- At what ambient temperature does image quality degrade?

- How does smoke density affect detection accuracy?

- What is the sensor's minimum detectable temperature difference?

Battery Safety Under Fire Conditions

In our experience testing battery systems, thermal management becomes critical near fire scenes. Lithium batteries 5 face increased thermal runaway risk when ambient temperatures rise. Your supplier's battery charging and storage systems must comply with NFPA 1 (Fire Code) and NFPA 70 (National Electrical Code).

Request documentation showing:

- Battery management system thermal cutoff specifications

- Charging system fire containment features

- Storage cabinet compliance with NFPA 1 Chapter 52

- Cell-level thermal runaway propagation prevention

NIST 2022 Testing Framework

The National Institute of Standards and Technology 6 released standardized test methods for public safety sUAS in 2022. These tests provide objective benchmarks for comparing different supplier claims. Ask if your supplier has completed NIST testing protocols and request the resulting data sheets.

Can my drone manufacturer provide the technical documentation I need for US regulatory compliance?

When we prepare export shipments to US clients, documentation preparation often takes longer than manufacturing. The regulatory landscape demands specific paperwork that many overseas suppliers simply don't understand. Missing documents create customs delays, compliance gaps, and liability exposure that hurt both suppliers and buyers.

Yes, qualified manufacturers must provide FAA Part 107 compliance documentation, Remote ID integration certificates, FCC radio frequency authorization, NFPA 2400 conformance statements, battery safety certifications per NFPA 1 and NFPA 70, maintenance schedule templates aligned with Chapter 6, and data security protocols meeting implied NFPA 2400 information integrity standards.

Core Documentation Package Requirements

US regulatory compliance requires documentation from multiple agencies. FAA governs flight operations. FCC controls radio frequencies. NFPA sets public safety equipment standards. Your supplier must navigate all three simultaneously.

| Agency/Standard | Required Documentation | Purpose |

|---|---|---|

| FAA | Part 107 compliance certificate, Remote ID registration, BVLOS waiver (if applicable) | Flight legality |

| FCC | Part 15 or Part 47 equipment authorization | Radio frequency compliance |

| NFPA 2400 | Conformance statement, Chapter 6 maintenance templates | Public safety operations |

| NFPA 1/70 | Battery system compliance certificates | Fire prevention in storage/charging |

| DOT | Lithium battery shipping documentation (UN3481) | Import/transport safety |

Maintenance Documentation Standards

Chapter 6 of NFPA 2400 establishes maintenance requirements for public safety drones. Your supplier must provide maintenance schedule templates, digital logging systems, and inspection checklists that meet these requirements. Fire departments face accountability requirements that consumer drone maintenance programs don't address.

Key maintenance documentation includes:

- Pre-flight inspection checklists specific to firefighting payload

- Motor hour tracking and replacement schedules

- Firmware update logs with version control

- Calibration records for thermal sensors

- Battery cycle counts and health monitoring data

Data Security and Sovereignty

NFPA 2400's operational standards imply requirements for information integrity. Fire department operations generate sensitive data including building layouts, personnel positions, and incident details. Your supplier must demonstrate:

- End-to-end encryption 7 for flight data transmission

- Data storage location documentation (critical for government contracts)

- Access control protocols for operational footage

- Audit trails for data access and modification

Many procurement managers overlook data security until contract negotiations. Suppliers headquartered in different countries may store data on servers subject to foreign government access. Clarify data sovereignty early.

Import Process Support

Experienced export suppliers understand US customs requirements. We maintain documentation packages specifically formatted for US import processes. Your supplier should provide:

- Commercial invoices with proper HTS codes 8

- Country of origin certificates

- Packing lists with serial numbers

- Technology classification documentation (EAR99 or ECCN)

How can I assess if a supplier has the R&D capability to customize firefighting drones for my specific NFPA needs?

Our engineering team receives customization requests weekly—different payload configurations, modified flight envelopes, specialized software integrations. Some requests are straightforward. Others require significant R&D investment. The challenge for procurement managers is distinguishing suppliers with genuine development capability from those who simply resell standardized products with modified labels.

Assess supplier R&D capability by reviewing their engineering team size and credentials, requesting case studies of previous customization projects, evaluating their prototyping timeline and process, examining their software development infrastructure, and verifying their ability to provide ongoing firmware updates and technical support post-purchase.

Evaluating Engineering Team Capability

Genuine R&D capability requires specific expertise. Flight controller programming, thermal sensor integration, and rugged housing design each demand specialized knowledge. Ask suppliers directly about their engineering team composition.

| Capability Area | Required Expertise | Verification Questions |

|---|---|---|

| Flight Control | Aerospace/controls engineering | What flight controller platform do you use? Can you modify PID parameters? |

| Thermal Integration | Electro-optical engineering | Have you integrated sensors other than DJI Zenmuse? |

| Structural Design | Mechanical engineering with composites experience | What materials do you use for high-heat exposure frames? |

| Software Development | Embedded systems programming | Do you develop firmware in-house or license it? |

| Regulatory Compliance | Quality assurance with standards experience | Who manages your NFPA compliance documentation? |

Case Study Evaluation

Request specific examples of previous customization work. Generic capability claims mean little without evidence. Strong suppliers can provide:

- Before/after specifications showing modifications made

- Timeline from request to delivery

- Testing data validating customization performance

- Client references willing to discuss experience

At our facility, we maintain a portfolio of customization projects specifically for procurement discussions. This transparency builds trust and demonstrates genuine capability.

Prototyping and Iteration Process

Customization projects require iteration. Initial designs rarely perform perfectly. Your supplier needs a structured prototyping process that includes:

- Concept review and feasibility assessment

- Initial prototype with performance benchmarks

- Testing against target specifications

- Revision cycles with clear documentation

- Final validation before production

Ask about typical revision cycles. Suppliers who claim first prototypes always succeed may be overpromising.

Post-Purchase Support Infrastructure

Customization creates long-term support obligations. Modified firmware needs updates. Custom components require replacement parts. Your supplier must demonstrate:

- Ongoing firmware update capability

- Spare parts manufacturing or sourcing

- Remote diagnostic support systems

- On-site technical support availability (where practical)

- Documentation updates as modifications evolve

Intellectual Property Considerations

Custom developments raise IP questions. Clarify early:

- Who owns design modifications?

- Can you share specifications with other suppliers?

- What NDA requirements apply?

- How are software modifications licensed?

Conclusion

Verifying firefighting drone suppliers against NFPA standards protects your investment and the communities your equipment serves. Request specific documentation, validate engineering capabilities, and never accept marketing claims without third-party verification. Your due diligence today prevents operational failures tomorrow.

Footnotes

1. Training and information on small unmanned aircraft systems for public safety personnel. ↩︎

2. Official NFPA standard for small unmanned aircraft systems in public safety. ↩︎

3. Explains thermal imaging technology and its applications in various fields. ↩︎

4. FAA guidance and resources for public safety UAS operations. ↩︎

5. OSHA guidance on health and safety hazards associated with lithium-ion batteries. ↩︎

6. Official website of the US government’s measurement science and standards agency. ↩︎

7. Explains the concept and importance of end-to-end encryption for secure communication. ↩︎

8. Found authoritative replacement on the official U.S. International Trade Commission website for HTS. ↩︎