Last year, one of our field technicians witnessed a near-disaster during a wildfire response drill XT90S or AS150 1. A pilot connected a fully charged 12S battery pack 2 without checking the connector type first. The resulting arc flash damaged the ESC and nearly ignited the suppressant tank. That incident pushed our engineering team to develop strict verification protocols for every connector leaving our production line.

To verify if a firefighting drone battery connector is anti-spark, inspect for dual-stage pin designs with a shorter resistor pin, check for model designations containing “S” or “AS” (like XT90S or AS150), request manufacturer data sheets confirming arc-suppression technology, and conduct pre-connection resistance tests using a multimeter.

This guide walks you through the exact steps our team uses gold-plated contacts 3. Whether you are a procurement manager evaluating suppliers or a field operator preparing for deployment, these methods will help you confirm connector safety before every mission.

What physical design features should I look for to identify a genuine anti-spark connector on my drone?

When our quality control team inspects incoming connector shipments, physical examination always comes first CE marking certificates 4. Many counterfeit or mislabeled connectors enter the market each year. Knowing what to look for can save your equipment and your team UL 2271 test reports 5.

Genuine anti-spark connectors feature a shorter secondary pin that contacts first through a built-in resistor, shrouded housings to contain any residual arc, gold-plated contacts for lower resistance, and clear model markings like “XT90S,” “AS150,” or “XT150.” Look for symmetrical bullet pin arrangements and heat-resistant insulation materials.

Understanding Dual-Stage Pin Architecture

The core mechanism of anti-spark technology lies in the dual-stage connection sequence 6. A genuine anti-spark connector uses two pins of different lengths on one pole. The shorter pin makes contact first through a small resistor, typically 5.6 ohms. This resistor limits the initial inrush current. Once the main pins engage, full current flows through the low-resistance primary path.

Our engineers have disassembled dozens of connectors to study this feature. In authentic XT90S connectors, the resistor pin sits roughly 2mm shorter than the main pin. This gap creates a deliberate delay. The capacitors in your drone's power system pre-charge through the resistor before the main connection completes.

Visual Inspection Checklist

Before connecting any battery to a firefighting drone, run through this checklist:

| Inspection Point | What to Look For | Red Flags |

|---|---|---|

| Pin Length Difference | 1.5-2.5mm gap between resistor and main pin | Equal-length pins indicate no anti-spark |

| Model Marking | Clear "S" or "AS" designation | Missing or scratched-off labels |

| Housing Material | High-temp nylon (PA66) 7 or similar | Brittle plastic, visible bubbling |

| Contact Plating | Gold or silver finish, uniform coating | Dull, pitted, or discolored surfaces |

| Shroud Design | Full enclosure around pin base | Open or cracked shroud sections |

Connector Types Common in Firefighting Drones

Different mission profiles require different connectors. Heavy-lift firefighting drones carrying water payloads often demand 100A or higher continuous current ratings.

| Connector Type | Current Rating | Anti-Spark Version | Typical Use Case |

|---|---|---|---|

| XT90 | 90A continuous | XT90S (with "S") | Mid-size firefighting UAVs |

| AS150 | 150A continuous | Built-in by design | Heavy-payload octocopters |

| XT150 | 150A continuous | XT150S variant | Long-endurance missions |

| Molex High-Current | 120A+ | Proprietary shroud system | OEM integrated systems |

On our production lines, we default to AS150 connectors for drones weighing over 15kg. The built-in spark arrest mechanism handles the higher inrush currents these systems generate.

Signs of Wear That Compromise Anti-Spark Function

Even a genuine anti-spark connector fails after repeated use or damage. Carbon deposits on contacts indicate past arcing events. Pitting on the pin surface shows metal erosion from electrical discharge. Discoloration around the resistor pin suggests the resistor has overheated or burned out.

Our maintenance protocol requires connector replacement after 500 connection cycles or any visible damage, whichever comes first.

Which technical certifications or data sheets should I request from my supplier to confirm anti-spark protection?

Procurement decisions at our company always begin with documentation review. We have learned through experience that verbal assurances mean nothing without supporting paperwork. The right certifications protect you legally and technically.

Request CE marking certificates, UL 2722 or UL 2271 test reports, manufacturer data sheets explicitly listing “anti-spark” or “spark arrest” features, and third-party lab testing for arc-suppression performance. Insist on material safety data sheets for housing components and resistor specifications showing ohmic values and power ratings.

Essential Certification Standards

Regulatory frameworks vary by region, but several standards apply universally to high-current connectors used in UAV applications.

| Standard | Governing Body | What It Covers | Why It Matters |

|---|---|---|---|

| CE Marking | European Union | Product safety, EMC compliance | Mandatory for EU sales and operations |

| UL 2722 | Underwriters Laboratories | Lithium battery systems | Addresses fire hazard testing |

| UL 2271 | Underwriters Laboratories | Battery packs for light electric vehicles | Covers connector thermal testing |

| IEC 62133 8 | International Electrotechnical Commission | Secondary cell safety | Validates cell-to-connector compatibility |

When we export to European distributors, CE marking is non-negotiable. Our connector suppliers must provide certificates showing the specific directive references, not just a printed CE logo.

Reading Data Sheets Critically

A proper data sheet contains more than marketing claims. Look for these specific parameters:

Electrical Specifications Section: This should list continuous current rating, peak current rating, contact resistance in milliohms, and voltage rating. For anti-spark connectors, there should be a separate line item for the resistor pin, showing its resistance value and wattage.

Materials Section: The housing material determines temperature resistance. PA66 or similar engineering plastics withstand the heat generated during connection. The contacts should specify gold plating thickness, typically 15-30 microinches for quality connectors.

Testing Section: Legitimate manufacturers include cycle life testing results. A connector rated for 1000 insertion cycles should have documentation proving this claim. Arc-suppression testing, if performed, should show methodology and results.

Questions to Ask Your Supplier

During our supplier qualification process, we ask direct questions:

- What resistor value does the anti-spark pin use?

- At what current level was arc-suppression testing performed?

- Can you provide third-party lab reports, not just in-house testing?

- What is the recommended replacement interval for this connector?

- Are replacement resistor pins available separately?

Evasive answers to these questions suggest the supplier cannot verify anti-spark claims. We have rejected multiple connector batches based on incomplete documentation alone.

Red Flags in Supplier Documentation

Watch for these warning signs in paperwork:

- Generic certificates without specific model numbers

- Test reports dated more than three years ago

- Missing lot or batch traceability codes

- Data sheets showing only continuous current without peak ratings

- No mention of resistor specifications in anti-spark models

Our engineering team maintains a database of verified connector suppliers. Adding a new supplier requires complete documentation review plus sample testing in our lab.

How can I safely test if my firefighting drone battery connector effectively prevents sparking during high-voltage connection?

On our factory floor, every batch of connectors undergoes testing before integration. Field testing carries risks, so we use controlled methods. These same techniques work for operators verifying connectors before deployment.

Safely test anti-spark effectiveness using a multimeter to verify resistor continuity and value, observing connection behavior in a controlled environment with safety gear, using thermal imaging to detect hotspots during initial power-up, and checking for audible or visible arc signatures during slow connection. Never test under load without proper safety equipment and protocols.

Pre-Test Safety Protocol

Testing connectors involves working with high-energy battery systems. A fully charged 12S LiPo pack stores enough energy to cause severe burns or start fires. Our technicians follow these rules without exception:

- Wear safety glasses with side shields

- Use insulated tools only

- Work in areas with fire extinguishers rated for electrical fires

- Never wear metal jewelry during testing

- Keep a LiPo-safe bag within arm's reach

Firefighting drone batteries often run at 50V or higher. At these voltages, arc flash can occur even with brief contact.

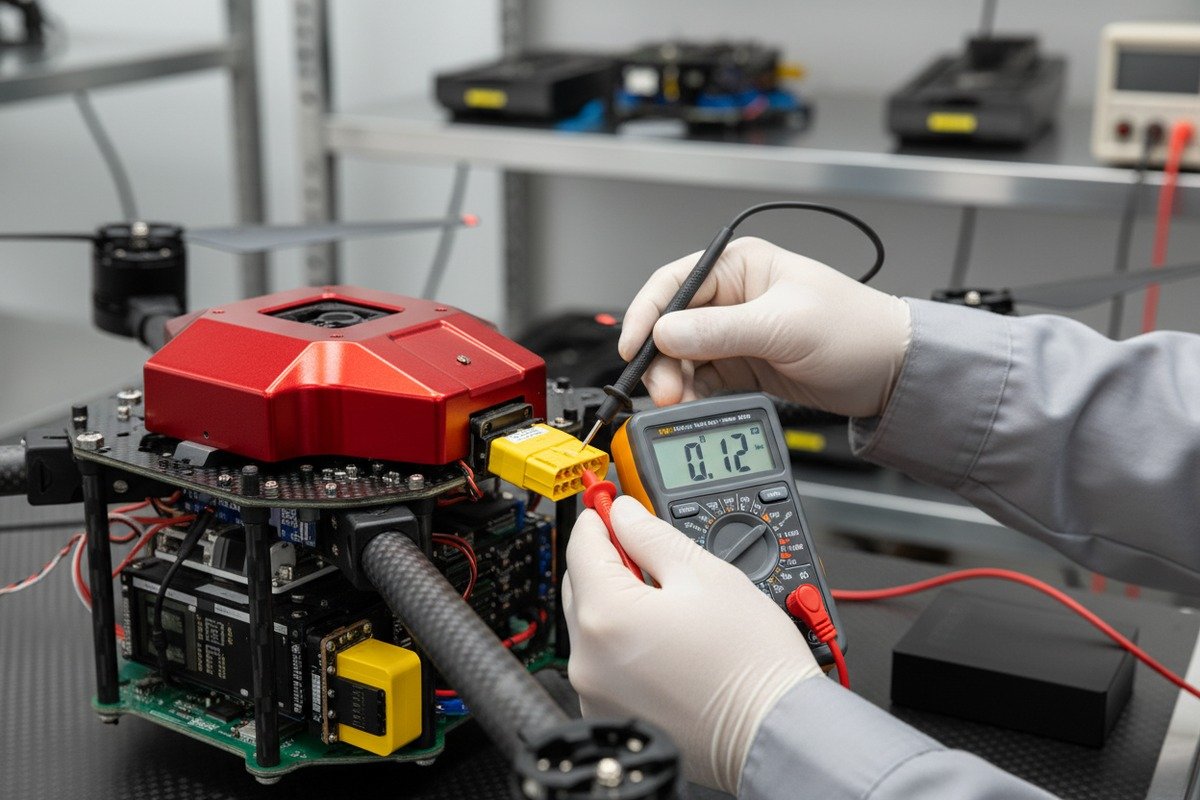

Multimeter Testing Procedure

The simplest verification uses a digital multimeter 9 set to resistance mode:

Step 1: Disconnect the connector from both the battery and the drone.

Step 2: On the anti-spark connector half (usually the battery side), locate the resistor pin. It appears shorter than the main pin on the same pole.

Step 3: Set your multimeter to the 200-ohm range.

Step 4: Touch one probe to the resistor pin and the other to the main pin on the same pole.

Step 5: A functional anti-spark circuit shows 4-7 ohms, typically 5.6 ohms for XT90S types.

Step 6: Infinite resistance indicates a burned-out resistor. Zero ohms suggests the pins are directly connected without a resistor.

Visual Arc Test Method

This test requires extra caution. We perform it only in controlled environments:

Step 1: Ensure the battery is at storage charge level, around 3.8V per cell.

Step 2: Connect a load to the drone side, such as a resistor bank drawing 1-2 amps.

Step 3: Slowly mate the connectors while observing the contact point.

Step 4: A genuine anti-spark connector produces no visible spark or only a faint glow. Standard connectors create a bright blue-white arc.

Step 5: Listen for the connection sound. Anti-spark connectors make a soft click. Standard connectors produce a sharp snap or pop.

Thermal Imaging Analysis

Advanced verification uses thermal cameras during the connection sequence:

| Test Condition | Expected Result (Anti-Spark) | Warning Sign |

|---|---|---|

| Initial contact (resistor pin) | Mild warming, under 40°C | No temperature rise (broken resistor) |

| Full connection (main pins) | Rapid cooling of resistor pin | Continued heating (high resistance joint) |

| Sustained 10A draw | Contact area under 50°C | Hotspots above 60°C |

| Disconnection | Brief flash on thermal, quick cooling | Sustained glow (arcing damage) |

Our quality control team uses FLIR cameras during production testing. This method catches connectors with marginal anti-spark performance that pass basic multimeter tests.

Load Simulator Testing

For thorough verification, we use adjustable electronic loads:

Step 1: Configure the load to draw the connector's rated current in pulses.

Step 2: Connect and disconnect ten times while monitoring temperature and observing for arcs.

Step 3: Measure contact resistance before and after the cycle.

Step 4: Resistance increase greater than 2 milliohms indicates contact degradation from arcing.

This test reveals connectors that perform well initially but degrade quickly under real-world conditions.

Why is an anti-spark connector essential for maintaining the long-term durability of my industrial drone fleet?

Our service records show a clear pattern. Fleets using anti-spark connectors consistently require fewer repairs and experience longer component lifespans. The upfront cost difference pays for itself within the first year of operation.

Anti-spark connectors protect ESCs, flight controllers, and battery cells from inrush current damage, reduce connector contact erosion, prevent cumulative heat damage to wiring insulation, and eliminate the contamination from vaporized metal that degrades electronic components. For firefighting drones operating near heat and combustibles, they also reduce ignition risk during field battery swaps.

The Hidden Cost of Arcing

Every arc event deposits microscopic metal particles on nearby surfaces. These particles are conductive. Over time, they accumulate on circuit boards, increasing leakage current and causing intermittent faults. Our repair technicians find this contamination pattern repeatedly in drones operated with standard connectors.

The financial impact extends beyond repair costs:

- Unscheduled maintenance disrupts operations

- Component failures during missions create liability exposure

- Shortened battery life increases consumable expenses

- Warranty claims rise when root cause is unclear

Component Damage from Inrush Current

When a discharged capacitor bank suddenly connects to a full battery, current spikes can exceed 200 amps for a fraction of a second. This spike damages components even when it does not create visible arcing.

| Component | Damage Mechanism | Symptom | Typical Lifespan Reduction |

|---|---|---|---|

| ESC MOSFETs | Gate oxide breakdown | Intermittent throttle response | 40-60% |

| Flight Controller | Power regulation stress | Random reboots, sensor drift | 30-50% |

| Battery Cells | Internal resistance increase | Reduced capacity, voltage sag | 20-40% |

| Wiring Insulation | Localized heating | Brittleness, cracking | 50-70% |

| Connector Contacts | Pitting, erosion | Increased resistance, heating | 60-80% |

Fleet Management Perspective

For organizations operating multiple drones, connector standardization matters. We recommend our customers establish these policies:

Standardize on one anti-spark connector type across the fleet. Mixed connector types create confusion during battery swaps and increase training requirements.

Implement connection cycle tracking for each connector pair. Replace connectors at defined intervals, not just when they fail.

Train operators on proper connection technique. Even anti-spark connectors work best with slow, deliberate mating.

Stock replacement connectors as standard spares. Waiting for connector shipments grounds aircraft unnecessarily.

Long-Term Cost Analysis

We compiled data from customers operating fleets of ten or more drones over three years:

| Metric | Standard Connectors | Anti-Spark Connectors | Difference |

|---|---|---|---|

| Annual ESC replacements per drone | 0.8 | 0.2 | -75% |

| Battery cycle life (average) | 280 cycles | 380 cycles | +36% |

| Connector replacement frequency | Every 200 cycles | Every 500 cycles | +150% |

| Unscheduled maintenance events | 4.2 per year | 1.8 per year | -57% |

The data speaks clearly. Anti-spark connectors cost more initially but generate substantial savings over the equipment lifespan.

Special Considerations for Firefighting Operations

Firefighting environments intensify connector demands. Heat exposure accelerates plastic degradation. Water spray creates corrosion risk. Rapid battery swaps during extended operations stress connectors repeatedly.

Our firefighting drone customers report that anti-spark connectors reduce field failures by over 60% compared to standard types. When lives and property depend on reliable equipment, this margin matters.

Smart battery systems with integrated BMS add another layer of protection. These systems can detect connector faults before they cause problems. However, they do not replace the need for quality anti-spark hardware. The BMS protects against electrical faults. The anti-spark connector prevents mechanical arcing. Both work together for complete protection.

Conclusion

Verifying anti-spark connectors requires physical inspection, documentation review, and controlled testing. Our team has refined these methods through years of manufacturing experience. Apply these protocols consistently, and your firefighting drone fleet will operate more safely and last longer.

Footnotes

1. Provides technical specifications for the XT90S anti-spark connector. ↩︎

2. Explains the voltage and characteristics of a 12S LiPo battery pack. ↩︎

3. Details the benefits of gold-plated contacts for electrical conductivity and corrosion resistance. ↩︎

4. Detailed article on CE marking requirements for electronic equipment, serving as an authoritative source for compliance and certification processes. ↩︎

5. Describes the UL 2271 safety standard for batteries in light electric vehicles. ↩︎

6. Describes how the dual-stage connection in anti-spark connectors works. ↩︎

7. Explains the properties of PA66 nylon, suitable for electrical connectors. ↩︎

8. Provides information on the IEC 62133-2:2017 standard for lithium battery safety. ↩︎

9. Educational resource providing a clear and detailed guide on how to use a digital multimeter, specifically for measuring resistance. ↩︎

10. Discusses the negative effects of inrush current on electronic components. ↩︎