Every year, our engineering team receives urgent calls from US buyers who discovered their newly purchased drones cannot handle American fire suppressants US wildland fire standards 1. The payload tanks corrode. The release gates fail. The retardant clogs the delivery mechanism. These problems cost thousands in repairs and delay critical firefighting operations.

To verify firefighting drone delivery systems for US fire suppressants, you must confirm chemical compatibility with EPA-approved retardants, request engineering documentation for payload release mechanisms, check FAA and IAB certifications, and conduct pre-shipment suppressant drop tests with manufacturers who understand US wildland fire standards.

This guide walks you through each verification step Phos-Chek retardants 2. We will cover delivery mechanism compatibility, engineering documentation requirements, customization processes, and essential certifications. Let us start with the most technical challenge first.

How do I verify that the drone's delivery mechanism is fully compatible with standard US fire suppressants?

When our engineers first tested US fire retardants on standard industrial drone tanks, we discovered unexpected chemical reactions. The foam concentrate ate through certain plastics. Some retardants left residue that jammed release gates. These failures taught us exactly what buyers must verify before purchasing.

Verify delivery mechanism compatibility by testing tanks with specific US suppressants like Phos-Chek retardants, checking material certifications for chemical resistance, conducting static drop tests, and confirming the release gate operates smoothly after repeated suppressant exposure over minimum 50 cycles.

Understanding US Fire Suppressant Types

The United States uses specific fire suppressants that differ from those in other markets. Your drone must handle each type without degradation.

| Suppressant Type | Common US Brands | Key Compatibility Concerns |

|---|---|---|

| Long-term retardants | Phos-Chek LC95, FireTrol 931 | High salt content corrodes aluminum; requires stainless steel or polymer tanks |

| Class A foam concentrates | Phos-Chek WD881, Silvex | Attacks certain plastics; needs HDPE or fluoropolymer-lined containers |

| Gel suppressants | Barricade, ThermoPel | High viscosity clogs narrow release gates; needs minimum 3-inch openings |

| Water enhancers | FireIce, WetWater | Generally compatible but may leave mineral deposits |

Material Certification Requirements

Request material certificates for every component that contacts suppressants. The tank body should be 316 stainless steel 3 or chemical-resistant HDPE. Seals and gaskets need EPDM or Viton rubber rated for pH levels between 4 and 10. Release gate mechanisms require corrosion-resistant coatings.

Our production line uses double-wall tank construction. The inner wall contacts the suppressant. The outer wall provides structural support. This design prevents leakage even if the inner wall develops minor wear.

Conducting Your Own Compatibility Tests

Before accepting any shipment, request that manufacturers perform these tests:

- Fill the tank with your specific US suppressant

- Let it sit for 72 hours at elevated temperature

- Operate the release gate 50 times

- Inspect all seals for swelling or deterioration

- Check for discoloration or material breakdown

We provide video documentation of these tests to our US buyers. You should demand the same from any supplier.

Drop Accuracy After Suppressant Exposure

Chemical exposure affects mechanical precision. Gates that operated smoothly with water may stick or delay after retardant exposure. Test drop accuracy by measuring release timing before and after suppressant contact.

The acceptable variance is under 0.5 seconds. Greater delays compromise targeting accuracy during actual firefighting operations.

What engineering documentation should I request to confirm the reliability of the drone's payload release system?

Our export department has learned that US buyers face strict liability requirements. When a drone fails during a wildfire response, documentation determines who bears responsibility. Without proper engineering records, you cannot defend your purchasing decision or pursue warranty claims.

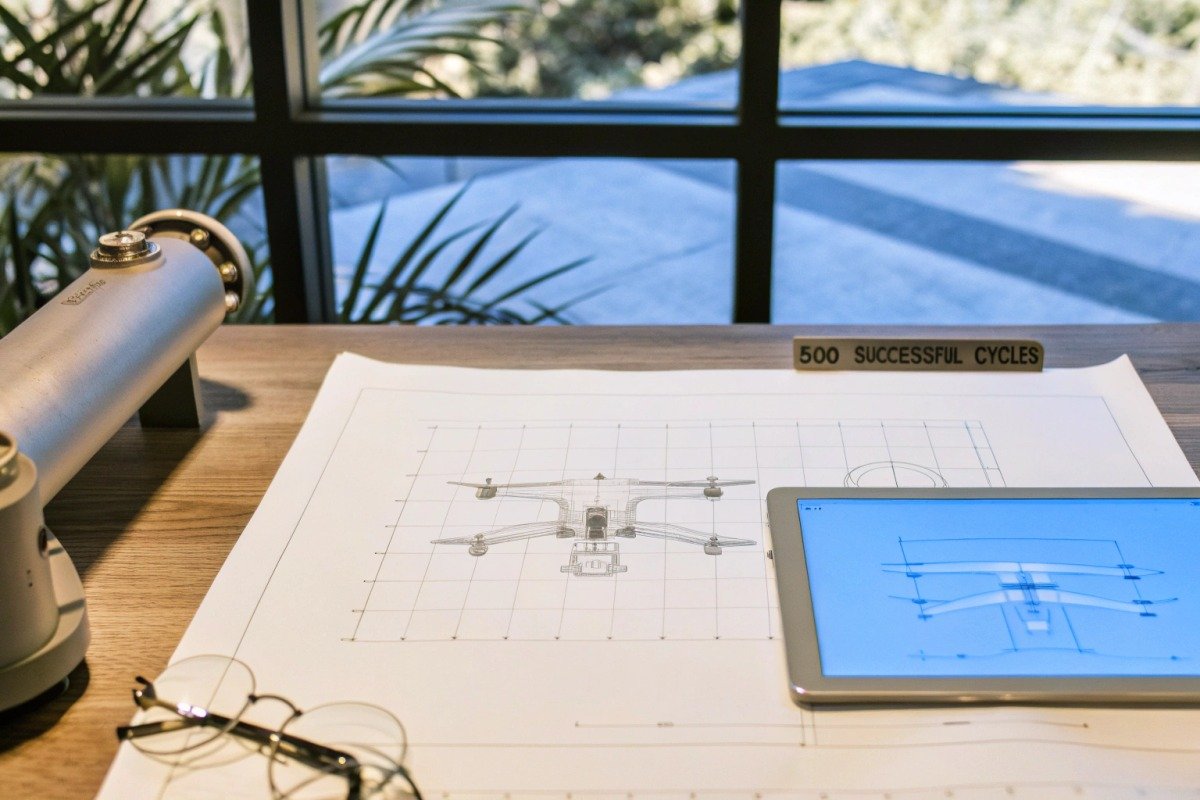

Request payload release system documentation including mechanical drawings with tolerances, fatigue test reports showing minimum 500 cycle reliability, FMEA analysis identifying failure modes, material certifications for all components, and quality control inspection records from production.

Essential Documentation Package

Every reliable manufacturer maintains these documents. Request them before placing any order.

| Document Type | What It Contains | Why You Need It |

|---|---|---|

| Mechanical Assembly Drawings | Component dimensions, materials, tolerances | Verify parts meet specifications; enable local repairs |

| Fatigue Test Report 4 | Cycle counts, failure points, safety margins | Confirms system survives repeated use |

| FMEA (Failure Mode Effects Analysis) | Identified risks, severity ratings, countermeasures | Shows manufacturer understands potential problems |

| Material Certificates | Chemical composition, heat treatment, supplier info | Proves components meet claimed specifications |

| QC Inspection Records | Measurements, pass/fail results, inspector signatures | Documents manufacturing quality |

Understanding Fatigue Test Reports

The release mechanism experiences stress during every drop operation. Each cycle includes pressurization, gate actuation, payload release, and system reset. Quality manufacturers test these systems to destruction.

Look for reports showing at least 500 successful cycles without failure. Better systems exceed 1,000 cycles. The report should identify the specific failure mode that eventually occurred—whether seal degradation, motor burnout, or structural fatigue.

When we test our payload systems, we document the exact cycle where performance begins degrading. This information helps you plan maintenance schedules.

Failure Mode Analysis Matters

FMEA documents reveal how seriously a manufacturer considers safety. FMEA analysis 5 The analysis should cover scenarios like:

- Power loss during release operation

- Partial gate opening

- Sensor failure causing premature release

- Communication breakdown with ground control

- Structural failure under maximum payload

Each failure mode needs an assigned severity rating and countermeasure. If the manufacturer cannot provide this analysis, they have not thoroughly engineered their system.

Quality Control Traceability

Request records showing how your specific unit was inspected. Serial numbers should trace back to production batch records. Inspection data should include dimensional measurements, leak testing results, and functional verification.

This traceability becomes critical if problems occur after delivery. You can determine whether the issue stems from manufacturing defects or operational damage.

How can I collaborate with a manufacturer to customize the delivery system for my specific firefighting mission requirements?

When a California fire department contacted us last year, they needed drones capable of dropping gel suppressant in narrow canyon terrain. Off-the-shelf systems could not meet their requirements. Through collaborative development, we created a solution that worked for their specific mission. This process taught us how effective customization partnerships should function.

Collaborate with manufacturers by first documenting your operational requirements in detail, then requesting a technical feasibility assessment, agreeing on development milestones with acceptance criteria, maintaining regular engineering communication throughout production, and conducting joint testing before final delivery.

Defining Your Mission Requirements

Before approaching any manufacturer, document exactly what you need. Vague requirements produce vague solutions. Specific requirements enable precise engineering.

| Requirement Category | Questions to Answer | Example Specification |

|---|---|---|

| Payload capacity | Maximum weight per flight? | 50 kg suppressant minimum |

| Drop precision | Acceptable targeting variance? | Within 3 meters of GPS coordinates |

| Environmental conditions | Wind speed, temperature, altitude limits? | Operational to 25 mph wind, -10°C to 50°C |

| Suppressant types | Which specific products will you use? | Phos-Chek LC95, Class A foam |

| Flight duration | Minimum time with full payload? | 25 minutes with 50 kg payload |

| Control range | Maximum distance from operator? | 5 km BVLOS capability |

The Technical Feasibility Assessment

After receiving your requirements, manufacturers should provide a feasibility assessment within two weeks. This document explains what is achievable, what requires development, and what falls outside current capabilities.

Our engineering team produces assessments that include:

- Analysis of each requirement against current product capabilities

- Identified gaps requiring custom development

- Estimated development timeline and costs

- Technical risks and mitigation strategies

- Alternative approaches if primary solutions prove impractical

Reject manufacturers who promise everything without detailed analysis. Honest assessments protect both parties.

Development Milestone Structure

Successful customization projects use clear milestones with acceptance criteria.

Phase 1: Design Review

- Manufacturer presents detailed design concept

- Customer reviews and provides feedback

- Agreement on final design specifications

Phase 2: Prototype Development

- Manufacturer builds working prototype

- Initial testing against specifications

- Customer inspection and preliminary acceptance

Phase 3: Testing and Validation

- Full performance testing with actual suppressants

- Documentation of all test results

- Resolution of any specification deviations

Phase 4: Production and Delivery

- Manufacturing of final units

- Quality inspection before shipment

- Installation support and training

Maintaining Engineering Communication

Weekly technical calls prevent misunderstandings. Assign engineers from both sides who can discuss details directly. Translation services help when language barriers exist, but nothing replaces having technical experts communicate regularly.

We schedule video calls showing work in progress. Customers see their systems being built. This transparency builds confidence and catches problems early.

What certifications must I verify to ensure the drone delivery system meets US safety and import standards?

Our export team deals with US customs requirements daily. We have seen shipments detained for missing documentation. We have helped customers navigate FAA authorization processes. This experience revealed which certifications actually matter and which just look impressive on paper.

Verify FAA Part 107 or COA eligibility, NDAA compliance for government contracts, FCC equipment authorization for radio systems, DOT hazmat shipping compliance if applicable, and for wildland fire use specifically, confirm the system can meet USDA Forest Service Interagency Airtanker Board testing requirements.

FAA Regulatory Requirements

The FAA governs all drone operations in US airspace. Your certification pathway depends on how you will use the drone.

| Operation Type | Required Authorization | Key Requirements |

|---|---|---|

| Commercial operations under 55 lbs | Part 107 | Remote pilot certificate, registration, operational limits |

| Public agency operations | Certificate of Authorization (COA) | Agency application, safety case, operational procedures |

| Beyond visual line of sight | Part 107 waiver | Demonstrated safety mitigations, specific route approval |

| Operations near wildfires | TFR authorization | Coordination with incident command, aerial supervision clearance |

Part 107 certification belongs to the pilot, not the drone. However, your drone must meet airworthiness standards. The manufacturer should provide documentation supporting FAA registration and operational compliance.

NDAA Compliance for Government Sales

If you sell to US government agencies or their contractors, Section 848 of the National Defense Authorization Act 6 restricts certain foreign-manufactured drones. NDAA-compliant systems must demonstrate:

- No covered telecommunications equipment

- Supply chain transparency

- Manufacturing outside prohibited countries or with approved components

We provide NDAA compliance statements with our government-eligible products. These documents detail component origins and manufacturing locations.

Interagency Airtanker Board Process

For wildland firefighting applications, the USDA Forest Service Interagency Airtanker Board 7 (IAB) evaluates aircraft and delivery systems. Understanding this process helps you prepare.

Testing Phases:

- Pre-evaluation: Contact SDTDC Program Leader, submit application, agree on costs

- Static ground tests: 10-15 days evaluating tank integrity and gate operation

- Drop tests: 10-15 flying days plus 2-4 weeks analysis

- Final review: Draft report, proponent comments, IAB recommendation

The proponent pays all evaluation costs. Self-testing does not substitute for official IAB evaluation, but preliminary testing helps ensure your system will pass.

Import Documentation Requirements

Beyond operational certifications, you need documentation for customs clearance:

- Commercial invoice with accurate product descriptions

- Packing list matching actual shipment contents

- Country of origin documentation

- FCC authorization for radio equipment

- Any applicable export licenses from origin country

We prepare complete documentation packages for our US shipments. This preparation prevents customs delays that could leave you without equipment during fire season.

Conclusion

Verifying firefighting drone delivery systems requires systematic attention to chemical compatibility, engineering documentation, customization processes, and regulatory certifications. Work with manufacturers who understand US requirements and provide transparent documentation. Your due diligence today prevents costly failures during tomorrow's fire emergencies.

Footnotes

1. NWCG provides national interagency standards for wildland fire management and operations. ↩︎

2. Official manufacturer site for Phos-Chek fire retardants, a common US suppressant. ↩︎

3. Wikipedia article on marine-grade stainless steel, which extensively covers 316 stainless steel. ↩︎

4. ASTM International is a globally recognized standards organization for materials and fatigue testing. ↩︎

5. ASQ provides authoritative resources and information on Failure Mode and Effects Analysis (FMEA). ↩︎

6. DHS discusses Section 848 of the NDAA and its restrictions on foreign-manufactured drones. ↩︎

7. Official USDA Forest Service page for the Interagency Airtanker Board (IAB) and its mission. ↩︎

8. Official FAA website detailing regulations for commercial drone operations under Part 107. ↩︎