Every season, our production team receives urgent calls from distributors IP67-rated seals 1. Their batteries caught fire during storage. The damage costs thousands. Worse, it destroys trust with their customers.

To verify fire safety standards for agricultural drone battery storage boxes, you must demand third-party certifications like UL 2054 or IEC 62133, request thermal abuse test reports, confirm materials meet non-flammable ratings, and verify pressure relief mechanisms are properly rated for lithium battery containment.

This guide walks you through every step. You will learn exactly what to ask suppliers, which documents to request, and how to test materials yourself. Let us begin with certifications.

What specific fire safety certifications should I require from my drone battery box supplier?

When we ship battery storage boxes to our US and European customers, certification questions come first. Buyers want proof. They need documentation that satisfies their local regulators and protects their business.

Require UL 2054 for battery pack safety, UL 9540A for thermal runaway testing, IEC 62133 for secondary lithium cells, and NFPA 855 compliance for installation standards. These certifications prove your storage box has passed rigorous third-party fire safety evaluations.

Understanding Key Certification Standards

Not all certifications carry equal weight. Some focus on the battery itself. Others cover the storage container. You need both types for complete protection.

UL 2054 2 addresses the safety of battery packs. It tests for overcharging, short circuits, and crush damage. UL 9540A specifically evaluates thermal runaway fire propagation 3. This test matters most for storage boxes because it shows whether a fire in one cell will spread.

IEC 62133 4 is the international equivalent. European buyers often prefer this standard. It covers similar safety parameters but follows European testing protocols.

Certification Comparison Table

| Certification | Issuing Body | Primary Focus | Geographic Preference |

|---|---|---|---|

| UL 2054 | UL Solutions | Battery pack safety | North America |

| UL 9540A | UL Solutions | Thermal runaway propagation | North America |

| IEC 62133 | International Electrotechnical Commission | Secondary lithium cell safety | Europe, Asia |

| NFPA 855 5 | National Fire Protection Association | Installation and storage standards | North America |

| UN 38.3 6 | United Nations | Transport safety testing | Global |

What Documents to Request

Ask your supplier for the actual test reports, not just certificates. A certificate confirms testing occurred. The report shows what happened during tests. Our engineering team always reviews full reports before approving any component supplier.

Request the following documents:

- Original certification certificates with expiration dates

- Complete test reports showing pass/fail results

- Material safety data sheets 7 for enclosure components

- Quality control inspection records

Red Flags to Watch

Some suppliers show outdated certificates. Others present certificates for different product models. We have seen competitors use certificates from completely different manufacturers. Always verify the certificate number directly with the issuing body.

How can I test the heat resistance and durability of the battery storage materials?

Our quality control lab runs material tests daily. We learned early that supplier claims often differ from reality. Testing materials yourself reveals the truth before problems occur in the field.

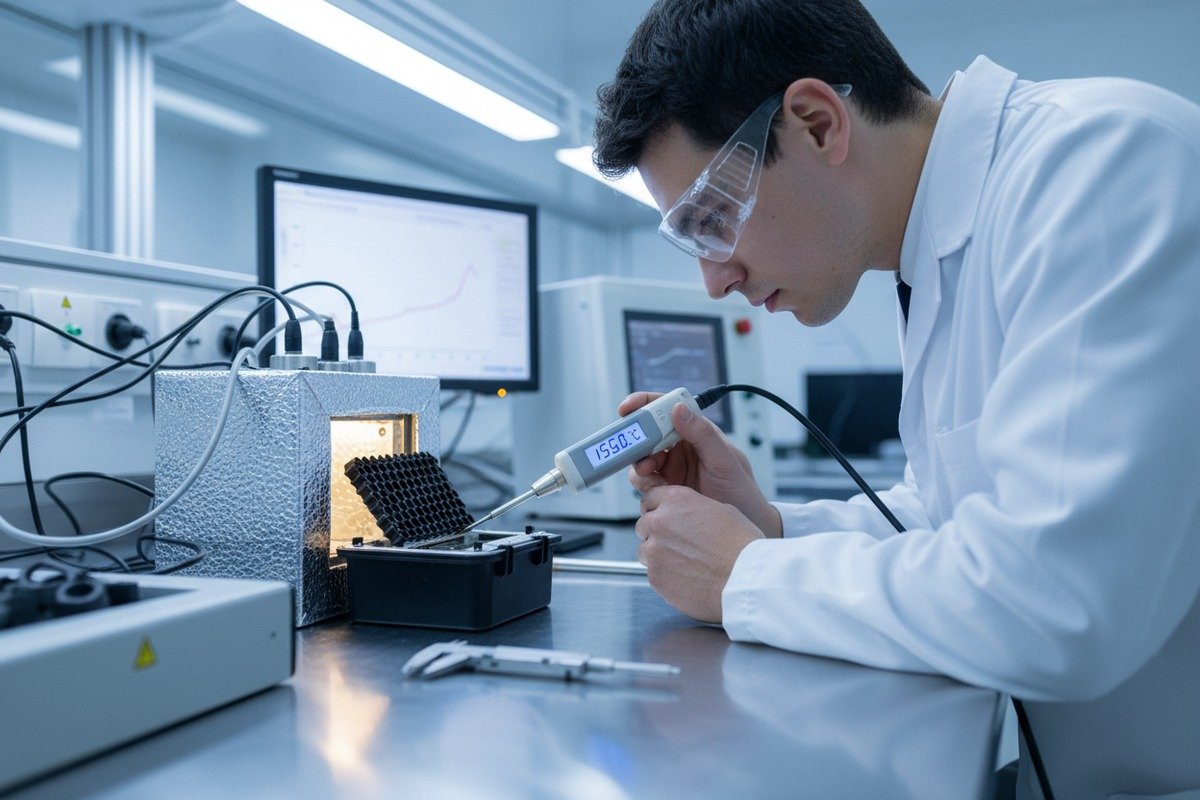

Test heat resistance by exposing material samples to temperatures exceeding 150°C for extended periods, checking for deformation or combustion. Verify durability through drop tests, pressure cycling, and chemical exposure tests using common agricultural substances like pesticides and fertilizers.

Simple Heat Resistance Tests

You do not need expensive laboratory equipment for basic verification. A calibrated oven and temperature probe provide essential data. Heat samples to 150°C and hold for 30 minutes. Quality materials show no visible change. Poor materials warp, discolor, or emit fumes.

For more rigorous testing, increase temperature to 200°C. This simulates conditions during thermal runaway events. The storage box must contain heat at these temperatures without structural failure.

Material Testing Protocol

| Test Type | Method | Pass Criteria | Equipment Needed |

|---|---|---|---|

| Heat resistance | 150°C exposure for 30 minutes | No deformation or discoloration | Calibrated oven, thermocouple |

| Flame resistance | Direct flame application for 10 seconds | Self-extinguishing within 5 seconds | Butane torch, timer |

| Impact durability | 1-meter drop test on concrete | No cracks or seal damage | Concrete surface, measuring tape |

| Chemical resistance | 24-hour immersion in pesticide solution | No material degradation | Glass container, sample pesticide |

| Seal integrity | IP65 water spray test | No water ingress | Pressurized water source |

Durability Under Agricultural Conditions

Agricultural environments are harsh. Dust, humidity, chemical residues, and temperature swings stress storage boxes constantly. Our field testing includes exposure to common pesticides, fertilizers, and cleaning agents.

Submerge material samples in diluted pesticide solution for 24 hours. Quality materials show no swelling, cracking, or surface degradation. This test reveals whether agricultural chemicals will compromise your storage box over time.

Pressure Relief Verification

Thermal runaway produces gas rapidly. Storage boxes must vent this gas safely without explosive failure. Check that pressure relief valves are present and properly rated.

Our engineers test valves by pressurizing empty boxes to rated limits. The valve should open smoothly and close properly when pressure normalizes. Valves that stick or fail to reseat create ongoing safety risks.

Can my supplier provide the necessary fire-safety documentation for my local import regulations?

When our export team prepares shipments to the United States and Europe, documentation takes significant time. Customs authorities reject incomplete paperwork. Worse, improper documentation can lead to seized shipments and regulatory penalties.

Qualified suppliers must provide UN 38.3 transport test summaries, material safety data sheets, certificates of conformity to destination country standards, and detailed technical specifications showing compliance with local fire codes like NFPA 855 or EN standards.

Essential Import Documentation

Different countries require different documents. However, some documents are universally expected. UN 38.3 test summaries are mandatory for international lithium battery shipment. Without this document, your shipment will not clear customs.

Material Safety Data Sheets describe chemical compositions and hazard classifications. Customs officials use these to determine proper handling requirements and storage restrictions at ports.

Documentation Requirements by Region

| Region | Required Documents | Additional Requirements |

|---|---|---|

| United States | UN 38.3 summary, MSDS, UL certificates, DOT shipping declaration | NFPA 855 compliance letter for commercial storage |

| European Union | UN 38.3 summary, MSDS, CE marking documentation, IEC certificates | REACH compliance declaration for chemical content |

| Canada | UN 38.3 summary, MSDS, ULC certificates | Transport Canada dangerous goods documentation |

| Australia | UN 38.3 summary, MSDS, SAA approval | Electrical safety compliance statement |

Questions to Ask Your Supplier

Before placing orders, ask these specific questions:

- Can you provide the original UN 38.3 test report, not just the summary?

- Which laboratory conducted your certification testing?

- Have you exported to my destination country before?

- Can you provide reference contacts from previous customers in my region?

- What support do you offer if customs rejects documentation?

Our customer service team maintains documentation packages tailored to each major export market. We update these packages whenever regulations change. This proactive approach prevents delays for our distributors.

Working with Customs Brokers

Experienced customs brokers know local requirements intimately. Before importing, consult a broker familiar with drone and battery equipment. They can review supplier documentation and identify gaps before shipment.

We recommend sending documentation to your broker for pre-clearance review. This small step prevents expensive delays and storage fees at ports.

What safety features should I look for to prevent thermal runaway during long-distance shipping?

Shipping agricultural drone batteries across oceans takes weeks. Temperature fluctuations, vibration, and handling impacts stress batteries throughout transit. Our logistics partners report that most battery incidents occur during shipping, not during normal use.

Look for storage boxes with integrated temperature monitoring, shock-absorbing internal compartments, individual cell isolation barriers, automatic venting systems, and IP67-rated seals. These features prevent thermal runaway triggers and contain events if they occur during transit.

Critical Safety Features Explained

Thermal runaway begins when one cell overheats. Heat transfers to adjacent cells. The reaction cascades until all cells fail catastrophically. Breaking this chain requires physical barriers between cells and heat-absorbing materials.

Quality storage boxes include intumescent materials. These expand when heated, creating insulating barriers that slow heat transfer. This buys time for detection systems to alert handlers and for venting systems to release pressure safely.

Safety Feature Checklist

| Feature | Purpose | Verification Method |

|---|---|---|

| Cell isolation barriers | Prevent thermal propagation between cells | Visual inspection of internal compartments |

| Intumescent materials | Create expanding heat barriers during thermal events | Request material specifications and test data |

| Pressure relief valves | Safely vent gases during thermal runaway | Check valve rating and test operation |

| Temperature indicators | Show if box experienced dangerous temperatures | Confirm indicator type and sensitivity range |

| Shock absorption | Protect cells from impact damage during handling | Drop test empty box and inspect for damage |

| IP67 sealing | Prevent moisture ingress that causes shorts | Conduct water spray or immersion test |

Temperature Monitoring Solutions

Modern storage boxes offer integrated monitoring. Sensors track internal temperature continuously. Some systems transmit data wirelessly, allowing remote monitoring during shipping.

At minimum, require irreversible temperature indicators. These simple devices change color permanently when temperatures exceed safe thresholds. Upon delivery, check indicators immediately. Color change indicates the shipment experienced dangerous conditions.

Preparing Batteries for Safe Shipping

Storage box features matter. But proper preparation matters equally. Store batteries at 40-60% charge before shipping. This reduces energy available if thermal runaway occurs.

Ensure all batteries pass visual inspection before packing. Swollen, damaged, or previously overheated batteries present elevated risks during transit. Our quality control team rejects any battery showing physical abnormalities.

Choosing Shipping Partners Wisely

Not all carriers handle lithium batteries properly. Select carriers with dangerous goods certifications and temperature-controlled options. Request documentation of their battery handling procedures.

We partner with carriers who maintain climate-controlled warehouses at transit points. This prevents temperature extremes during the most vulnerable periods of international shipping.

Conclusion

Verifying fire safety standards protects your investment, your customers, and your business reputation. Demand proper certifications, test materials yourself, ensure documentation meets import requirements, and select storage boxes with comprehensive safety features. Your diligence prevents disasters.

Footnotes

1. Wikipedia offers a clear explanation of the IP Code, including IP67 ratings. ↩︎

2. UL Solutions is the authoritative source for UL 2054 standard information. ↩︎

3. Wikipedia provides a comprehensive overview of thermal runaway in batteries. ↩︎

4. The International Electrotechnical Commission is the issuing body for IEC standards. ↩︎

5. NFPA is the official source for information on the NFPA 855 standard. ↩︎

6. IATA provides essential guidelines for UN 38.3 compliance for air transport of lithium batteries. ↩︎

7. OSHA is a primary government source for information on Safety Data Sheets (formerly MSDS). ↩︎