When our production lines run 24/7, ensuring every agricultural drone performs identically becomes a real challenge ISO 9001 certifications 1. Buyers often receive units with varying sensor accuracy or flight stability, causing costly field failures.

To verify automated production consistency, request factory audit reports showing Statistical Process Control data, demand batch sampling tests on 10-20% of units, review ISO 9001 certifications, and conduct field trials comparing performance metrics like NDVI variance, spray uniformity, and GPS accuracy across multiple drones from the same order.

This guide walks you through practical verification methods we use daily NDVI variance 2. You will learn exactly what to ask suppliers and how to test drones before committing to bulk orders.

How can I verify that my supplier's automated production line ensures consistent drone quality?

When we calibrate flight controllers 3 on our assembly floor, we track every adjustment digitally. Many buyers struggle to know if their supplier does the same. Without verification, you risk receiving drones that look identical but perform differently.

Verify production consistency by requesting Statistical Process Control reports showing defect rates below 1%, touring the factory virtually or in person, checking for ISO 9001 certification, and demanding sample units from different production batches for comparative testing before placing bulk orders.

Understanding Statistical Process Control in Drone Manufacturing

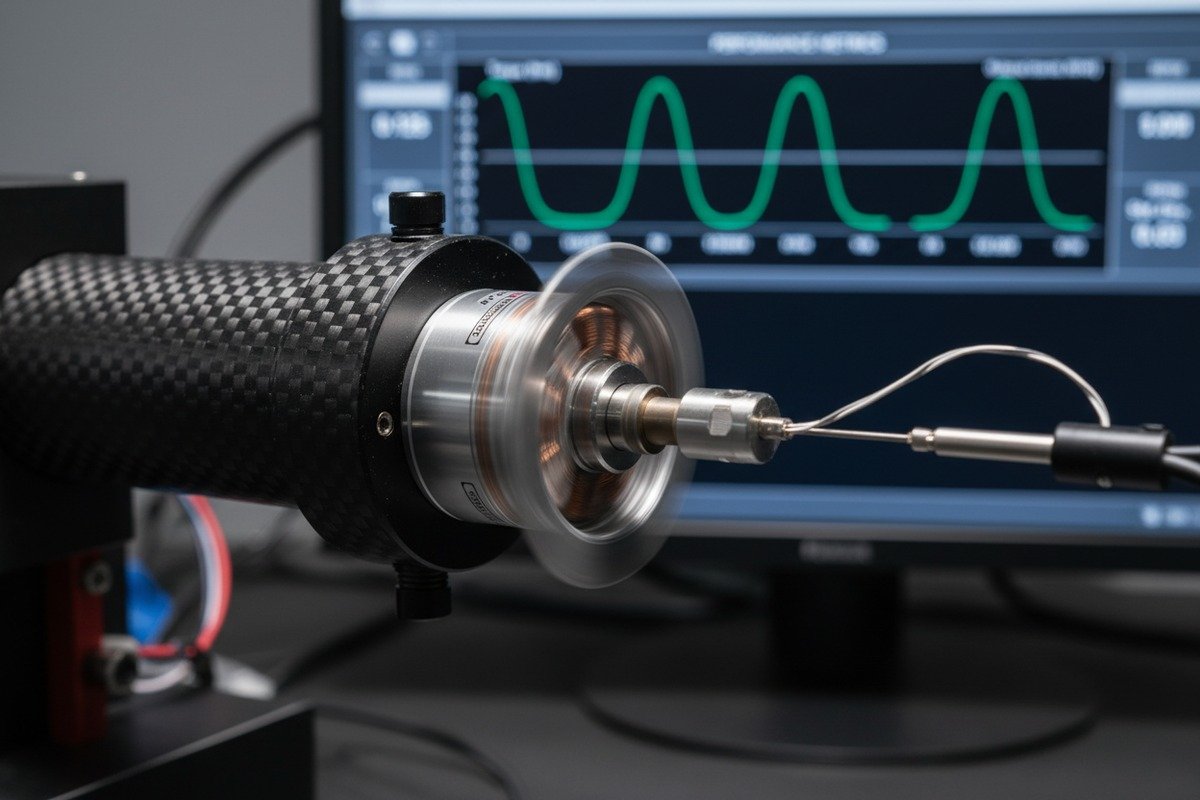

Statistical Process Control 4, or SPC, tracks every measurement during production. Our engineers monitor over 50 data points per drone. These include motor torque, frame alignment, and sensor calibration values.

A reliable supplier shares SPC dashboards with buyers. Look for control charts showing measurements stay within tight limits. If values swing wildly, consistency suffers.

Key Metrics to Request from Suppliers

| Metric | Acceptable Range | Why It Matters |

|---|---|---|

| Defect Rate | Below 1% | Indicates overall quality control effectiveness |

| Motor RPM Variance | ±2% | Affects flight stability and hover precision |

| Frame Weight Tolerance | ±50 grams | Impacts battery life and payload capacity |

| Sensor Calibration Drift | Below 5% | Ensures accurate crop monitoring data |

| Battery Cell Matching | ±0.05V | Extends battery lifespan and prevents failures |

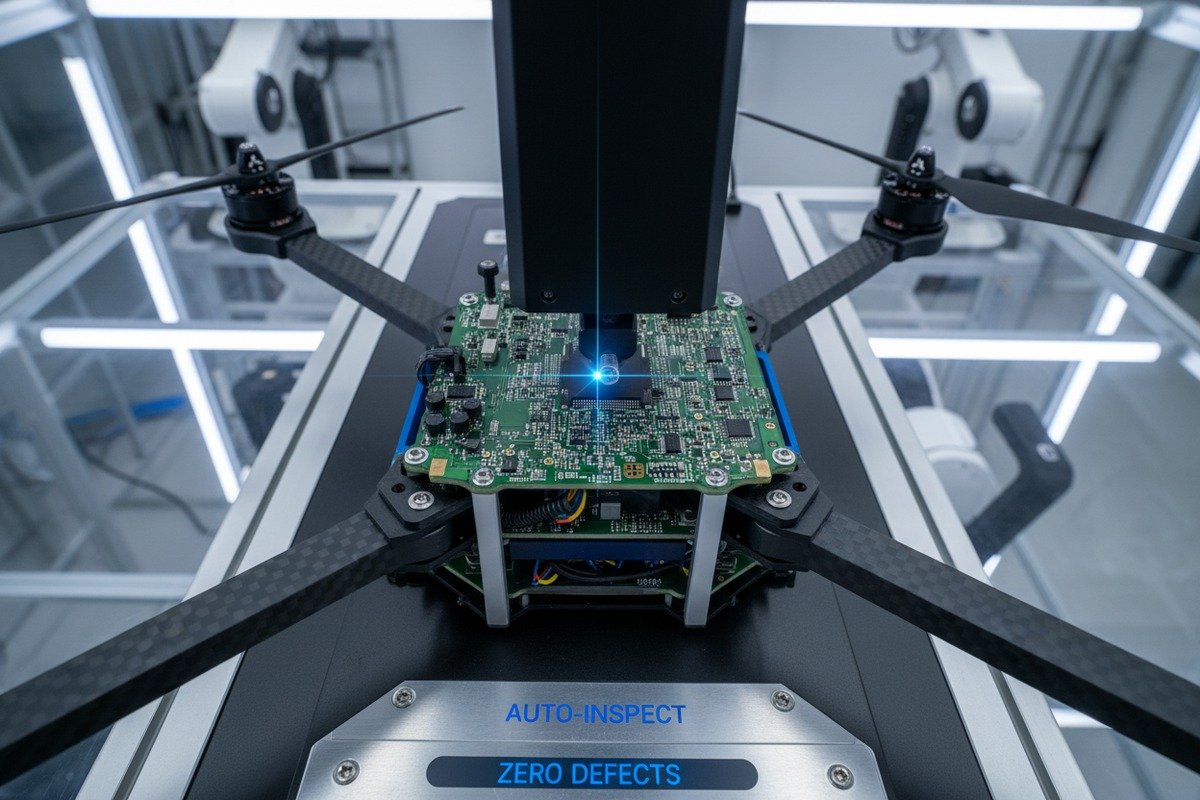

Evaluating Assembly Line Automation Levels

Not all automation equals quality. Some factories automate only packaging. Others automate critical steps like soldering and calibration.

Ask your supplier these questions:

- Which assembly steps use robots?

- How do you calibrate sensors automatically?

- What happens when a unit fails automated inspection?

Our facility uses robotic arms for propeller mounting. This eliminates human error that causes vibration issues. We also use automated optical inspection 5 to check every solder joint.

Batch Testing Before Bulk Orders

Never trust a single sample. Request three to five units from different production batches. Test them side by side. Measure:

- Hover stability at various altitudes

- GPS lock time and accuracy

- Spray pattern uniformity

- Battery discharge rates

If results vary more than 5%, question the supplier's consistency claims.

What documentation should I request to confirm the factory's automated quality control processes?

In our experience exporting to the US and Europe, documentation gaps cause the biggest delays. Customs officials and end users both demand proof of quality. Without proper papers, your shipment sits in port.

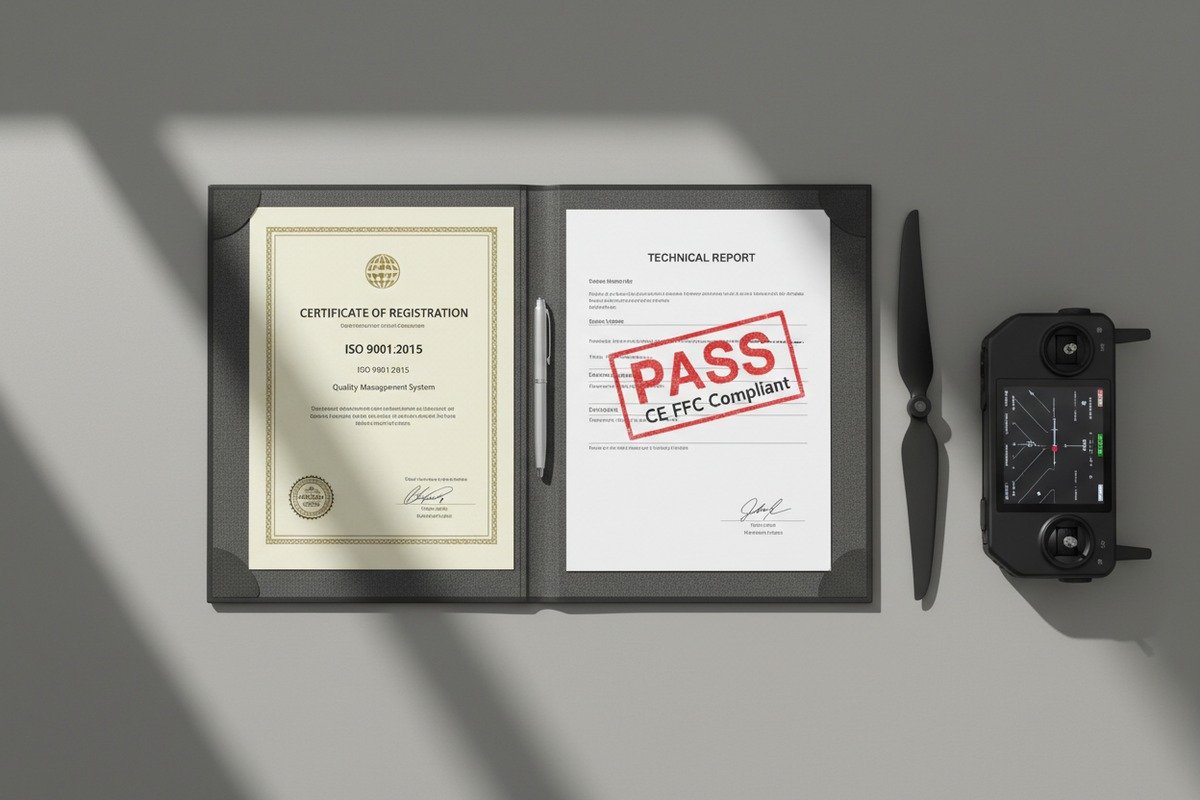

Request ISO 9001 quality management certificates, CE/FCC compliance documents, SPC reports with control charts, calibration certificates for test equipment, incoming material inspection records, and final assembly test reports showing pass/fail criteria for each drone unit.

Essential Certifications for Agricultural Drones

Certifications prove third parties verified the factory's claims. Do not accept self-declarations alone.

| Certification | Issuing Body | What It Verifies |

|---|---|---|

| ISO 9001:2015 | Accredited registrars | Quality management system effectiveness |

| CE Marking | EU notified bodies | Compliance with European safety standards |

| FCC Part 15 | Federal Communications Commission | Radio frequency emissions within limits |

| RoHS | Testing laboratories | Hazardous substance restrictions |

| IP Rating | Independent labs | Dust and water resistance claims |

Reading Quality Control Reports Correctly

Many suppliers send impressive-looking reports. But numbers without context mean nothing.

When reviewing SPC reports, check these elements:

- Date ranges covering recent production

- Sample sizes large enough to be meaningful

- Upper and lower control limits clearly defined

- Actions taken when limits were exceeded

Our quality team generates daily reports. We share monthly summaries with buyers. This transparency builds trust.

Traceability Documentation

Every component should trace back to its source. This matters when problems appear later.

Ask for:

- Bill of materials with supplier names

- Incoming inspection records for batteries and sensors

- Lot numbers linking components to specific drones

- Test records tied to serial numbers

Blockchain-based traceability systems 6 are emerging. These create immutable records. Some suppliers now offer QR codes linking to full production histories.

Calibration Certificates for Test Equipment

Your supplier's measurements are only valid if their equipment is accurate. Request calibration certificates for:

- Multimeters and oscilloscopes

- Torque testers

- GPS simulators

- Spray volume measurement devices

Certificates should come from accredited calibration laboratories 7. Check expiration dates. Expired calibrations invalidate all test results.

How do I ensure that every agricultural drone in my bulk order meets the same performance standards?

Our engineers have found that field performance varies more than factory tests suggest. Environmental factors, firmware versions, and operator skill all play roles. Smart buyers define clear acceptance criteria upfront.

Ensure uniform performance by establishing written acceptance criteria covering flight time, GPS accuracy, spray rate variance, and sensor resolution. Conduct acceptance testing on a random 10-20% sample. Use standardized test protocols and document results with photos and data logs for dispute resolution.

Creating Clear Acceptance Criteria

Vague requirements lead to disputes. Specify exact numbers.

| Performance Parameter | Minimum Acceptable Value | Test Method |

|---|---|---|

| Flight Time (full payload) | 20 minutes | Timed hover at 10m altitude |

| GPS Horizontal Accuracy | ±3 cm with RTK | 10-point coordinate comparison |

| Spray Rate Variance | Below 5% | Calibrated catch cups across swath |

| NDVI Consistency | Variance below 2% | Same field, same time, multiple units |

| Maximum Wind Resistance | 8 m/s | Hover stability test with anemometer |

Implementing Acceptance Testing Protocols

Random sampling catches problems statistical reports miss. Here is our recommended approach:

- Select 10-20% of units randomly

- Assign unique test IDs

- Run identical test sequences

- Record all data electronically

- Compare results against criteria

- Document any failures with evidence

If more than 2% of samples fail, reject the entire batch. This sounds harsh. But accepting inconsistent products costs more in field failures and reputation damage.

Third-Party Testing Services

Independent testing removes bias. Services like agrifoodTEF specialize in agricultural drone validation.

Benefits include:

- Standardized testing protocols

- Calibrated equipment

- Unbiased reporting

- Expert recommendations

Testing fees add cost. But they often pay for themselves by catching problems early. One client saved $50,000 by rejecting a batch that passed supplier inspection but failed independent spray uniformity tests.

Firmware and Software Version Control

Identical hardware means nothing if software differs. Verify:

- All units run the same firmware version

- AI algorithms are identical

- Calibration parameters match

- Flight controller settings are standardized

Request a configuration dump from each tested unit. Compare files byte by byte. Even small differences can cause behavioral variations.

Post-Delivery Performance Monitoring

Verification does not end at delivery. Track field performance over time.

Set up a simple monitoring system:

- Log flight hours per unit

- Record any error codes

- Document maintenance actions

- Compare spray efficiency across units

Patterns reveal which drones came from problematic batches. This data helps negotiate warranty claims and future orders.

Can I request a virtual factory audit to see how automation impacts the durability of my drones?

When we upgraded our welding robots last year, product durability improved by 15%. But buyers only see results, not the process. Virtual audits bridge this gap. They show exactly how automation affects the drones you receive.

Yes, most professional drone manufacturers now offer virtual factory audits via live video tours. Request real-time footage of automated welding, stress testing stations, environmental chambers, and quality checkpoints. Ask to see specific production steps that affect durability, like frame assembly and waterproofing.

What Virtual Audits Can Reveal

Virtual audits work when done right. They show:

- Actual automation levels versus marketing claims

- Cleanliness and organization of production areas

- Real-time quality checks happening on the floor

- Worker training and supervision practices

- Equipment condition and maintenance status

Schedule audits during active production. Empty factories hide problems. Ask to see specific serial numbers being built.

Key Production Steps Affecting Durability

Focus your audit on these durability-critical processes:

| Process | Automation Impact | What to Observe |

|---|---|---|

| Frame Welding | Reduces weak joints | Consistent bead patterns, no spatter |

| Motor Mounting | Ensures proper torque | Calibrated torque tools, verification steps |

| Conformal Coating | Protects electronics | Even coverage, no missed areas |

| Vibration Testing | Catches loose parts | Every unit tested, failure handling |

| IP Rating Verification | Confirms water resistance | Actual submersion tests, not just claims |

Stress Testing Observation

Durability comes from surviving stress. Watch these tests live:

Vibration Testing: Units mount on shaker tables simulating flight. Look for test duration of at least 30 minutes. Shorter tests miss fatigue issues.

Environmental Chambers: Temperature cycling between -20°C and +50°C reveals material weaknesses. Humidity testing at 95% confirms corrosion resistance.

Drop Testing: Controlled drops from 1 meter simulate handling damage. Frames should survive without cracks.

Motor Endurance: Continuous running at maximum RPM for hours. Our motors run 48-hour tests before passing.

Digital Twin Technology

Advanced factories use digital twins. Digital Twin Technology 8 These virtual copies of each drone track production data permanently.

Ask if your supplier offers:

- Unique digital records for each serial number

- Production parameter storage

- Predictive maintenance recommendations

- Historical performance tracking

Digital twins help diagnose problems months later. They prove whether a failure came from production defects or field damage.

Audit Checklist for Buyers

Use this checklist during virtual audits:

- Can you see date/time stamps proving live footage?

- Are workers following documented procedures?

- Is testing equipment visibly calibrated?

- Do rejected units get clearly segregated?

- Can you request views of specific serial numbers?

- Are environmental controls (temperature, humidity) visible?

- Does automation cover critical quality steps?

Document everything with screenshots. These become evidence if quality disputes arise later.

Comparing Virtual and Physical Audits

Virtual audits have limits. They cannot replace physical presence entirely.

| Aspect | Virtual Audit | Physical Audit |

|---|---|---|

| Cost | Low (no travel) | High (flights, hotels) |

| Time Required | 2-4 hours | 1-3 days |

| Detail Level | Moderate | High |

| Supplier Preparation | Easier to stage | Harder to hide issues |

| Random Inspection | Limited | Full access |

| Relationship Building | Minimal | Strong |

For orders over $100,000, consider physical audits. For smaller orders, virtual audits provide reasonable assurance at lower cost.

Conclusion

Verifying automated production consistency protects your investment and reputation. Request SPC data, proper certifications, and batch samples. Conduct acceptance testing using clear criteria. Use virtual audits to observe durability-critical processes. These steps ensure every agricultural drone in your order performs reliably in the field.

Footnotes

1. TÜV SÜD is an authoritative body for ISO 9001 certification, explaining its importance. ↩︎

2. Fieldmargin provides a clear explanation of NDVI analysis and its interpretation in agriculture. ↩︎

3. Grepow offers a comprehensive guide to drone flight controllers and their functions. ↩︎

4. Wikipedia provides a widely accepted and accessible definition and explanation of Statistical Process Control. ↩︎

5. ZEISS provides a detailed explanation of automated optical inspection (AOI) in manufacturing. ↩︎

6. IBM explains how blockchain-based traceability systems work in supply chain management. ↩︎

7. Transcat defines accredited calibration laboratories and their importance for quality assurance. ↩︎

8. IBM provides a clear explanation of what a digital twin is and how it works. ↩︎