When we discuss specifications with clients at our Xi’an headquarters, we often notice they overlook the one component that keeps them grounded.

You must ask about the specific battery capacity in mAh, the rated runtime at maximum screen brightness, support for external hot-swappable batteries, and the total charging time required to reach full capacity.

Let’s explore the critical questions you need to ask to ensure your operations run smoothly.

What is the actual operating time I can expect from the remote controller on a single charge?

Our flight test engineers frequently report that bright high-definition screens 1, high-definition screens consume power much faster than laboratory estimates suggest.

Request the actual operating time with the screen set to 100% brightness, as field work requires high visibility. Standard ratings often assume indoor lighting, but real-world sunlight cuts runtime significantly.

Understanding the difference between "marketing specs" and "field reality" is crucial for your daily planning. When manufacturers list battery life, they often test under ideal conditions with low screen brightness and minimal background processes. However, in the field, you are fighting against the sun. To see the screen clearly, you must crank the brightness up to the maximum level, often exceeding 1000 nits. This single action can cut the advertised battery life in half.

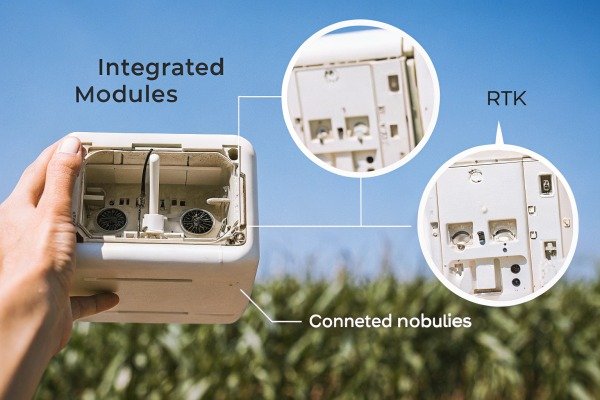

The Impact of Integrated Modules

Beyond the screen, other power-hungry components are running inside the controller. If you are using RTK (Real-Time Kinematic) positioning for centimeter-level accuracy Real-Time Kinematic 2 RTK (Real-Time Kinematic) positioning 3, or if the controller has a built-in 4G/5G modem for data transmission, the power draw increases further. You need to ask the supplier how these specific modules affect the runtime. Does the 6-hour rating account for RTK being active?

Idle Time vs. Active Time

Another factor to consider is the "idle" time. During a typical spraying operation, the drone spends time on the ground being refilled with liquid or having its flight battery swapped. The remote controller usually stays on during this process to maintain the connection. You should ask if the controller has an efficient "sleep" or "standby" mode that preserves power during these 8-10 minute refill intervals. If the controller drains power just as fast while the drone is on the ground, your effective workday shortens.

Real-World Expectations

Below is a breakdown of how different factors impact the theoretical battery life versus what you will likely experience in the field.

| Operating Condition | Estimated Power Draw | Expected Runtime (Typical 5000mAh Battery) |

|---|---|---|

| Indoor / Lab Test | Low (Screen 30% brightness, WiFi off) | 6.0 – 7.0 Hours |

| Standard Field Use | Medium (Screen 70%, standard GPS) | 4.0 – 5.0 Hours |

| High Performance | High (Screen 100%, RTK on, 4G on) | 2.5 – 3.5 Hours |

| Extreme Conditions | Very High (Max brightness + Extreme Heat >40°C) | < 2.5 Hours |

By asking for the "High Performance" runtime figures, you avoid unpleasant surprises in the middle of a job.

Can I easily swap the remote controller battery or use an external power bank in the field?

In our experience designing long-endurance systems, we know that a fixed internal battery eventually becomes a bottleneck for professional operators.

Verify if the controller supports hot-swappable external batteries or standard USB-PD power banks. This feature allows continuous operation without shutting down the system or pausing specifically for recharging.

For commercial operators, time is money. If your remote controller dies, the entire spraying operation stops, regardless of how many charged flight batteries you have ready for the drone. This is why the power architecture of the remote controller is a vital discussion point.

Internal vs. External Power Sources

Some controllers rely solely on an internal, non-removable battery. While this makes the device sleeker and more water-resistant, it limits you to the internal capacity. Once it is empty, you are tethered to a charger. You should ask if the manufacturer offers a "hybrid" power solution. Many advanced agricultural remotes now feature a slot for an external battery (often the same type used in other accessories) or a secure port for a high-capacity power bank.

The Value of Hot-Swapping

The "hot-swap" capability is a game-changer. This means you can attach a fresh external battery while the internal battery keeps the remote running. You never have to power down, disconnect from the drone, or reboot your mission software. This seamless transition is critical when managing complex mission plans that might be lost or require reloading if the remote shuts down completely.

Compatibility with Standard Gear

You should also inquire about the charging interface. Does it use a proprietary connector, or does it use a standard USB-C port with Power Delivery (PD) protocol Power Delivery (PD) protocol 4? Power Delivery 5 If it supports USB-PD, you can use generic, high-quality power banks (like those used for laptops) to power the remote in an emergency. This flexibility can save a workday if you forget the specific proprietary batteries.

| Feature | Internal Only Battery | Hybrid (Internal + External) |

|---|---|---|

| Runtime Limit | Fixed (e.g., 4 hours) | Unlimited (with enough spares) |

| Downtime | Must stop to charge | Zero (Hot-swap capable) |

| Waterproofing | Generally easier to seal (IP67) | Harder to seal ports (IP54) |

| Weight | Lighter | Heavier due to extra mount |

| Field Flexibility | Low | High |

Asking these questions helps you determine if the system is built for the casual user or the intensive commercial operator.

How long will I need to wait for the remote controller to recharge between flights?

We constantly refine our charging protocols because we understand that waiting for equipment to charge kills productivity during the busy harvest season.

Determine the exact recharge duration using both standard adapters and high-speed fast chargers. A controller should ideally regain enough power for several flights within just 30 minutes of charging.

Charging speed is just as important as battery capacity. If a remote controller takes four hours to charge but only lasts three hours in the sun, you have a negative energy balance. You will eventually run out of power, even if you charge during lunch breaks.

Fast Charging Protocols

When speaking with suppliers, do not just ask "How long does it take to charge?" Instead, ask "What is the maximum wattage the charging port accepts?" A modern controller should support at least 65W fast charging. This allows the battery to go from 0% to 100% in roughly two hours, or more importantly, from 20% to 80% in about 45 minutes. This rapid boost allows you to recover significant runtime during short breaks or while moving between fields.

Charging While Operating

Another critical question is whether the remote supports pass-through charging 6 "pass-through charging." Can you plug the remote into a power source (like a USB port on a generator or a truck's 12V outlet) and continue flying? Some lower-end electronics overheat if used while charging, causing the screen to dim or the processor to throttle. Confirming that the thermal design supports simultaneous charging and operation ensures you have a backup plan if the battery gets low mid-flight.

Generator Compatibility

In agricultural settings, clean grid power is rare. You are likely charging off a portable generator or an inverter in a truck. Ask the manufacturer if their chargers are sensitive to the "dirty power" (voltage fluctuations) typical of field generators. Robust industrial chargers should handle these fluctuations without damaging the remote's sensitive internal circuits.

Here is a comparison of charging scenarios you might encounter:

| Charging Method | Power Output | Estimated Charge Time (0-100%) | Note |

|---|---|---|---|

| Standard USB Port | 5V / 2A (10W) | 6+ Hours | Too slow for field use |

| Standard Wall Plug | 12V / 1.5A (18W) | 4-5 Hours | Overnight charging only |

| Fast Charger (PD) | 20V / 3.25A (65W) | ~2 Hours | Recommended for daily use |

| While Operating | Varies | Slower net gain | Prevents drain, generates heat |

Clarifying these details ensures your ground station keeps pace with your flight operations.

How many charge cycles will the remote controller battery last before I need to replace it?

Through years of monitoring our components in heavy-use markets like the US, we track exactly how long lithium cells maintain their peak performance lithium cells 7.

Inquire about the rated cycle life, typically around 500 to 1,000 cycles, before capacity drops below 80%. Also, ask if the battery is user-replaceable or requires factory service.

Batteries are consumables. They are chemical systems that degrade over time. For an agricultural drone that might fly every day for months during the season, the remote controller accumulates charge cycles rapidly. charge cycles 8

Understanding Cycle Life

A "cycle" is one full discharge and recharge. If you discharge 50% and recharge, that is half a cycle. Ask the specific question: "What is the cycle life until 80% health?" Once a battery drops below 80% of its original capacity, the voltage can become unstable, leading to sudden shutdowns—a pilot's nightmare. If the manufacturer claims a standard consumer grade (300-500 cycles), you might need to replace the battery after just one or two busy seasons. Industrial-grade cells should offer 800-1000+ cycles.

Serviceability and Replacement

This is a major hidden cost. Some remote controllers are sealed units. If the battery dies, you must ship the entire controller to a service center, potentially leaving you without equipment for weeks. Other designs feature a battery compartment that is accessible by removing a few screws, allowing you to buy a spare part and replace it yourself.

- Sealed Unit: High IP rating (waterproof), but high maintenance downtime.

- User-Replaceable: Low downtime, but requires care with seals to maintain waterproofing.

Environmental Degradation

Agricultural work involves extremes. High heat (leaving the remote in a truck cab) and freezing cold (early morning starts) accelerate battery aging. Ask if the battery has a built-in heater for cold weather or advanced thermal management for heat. A Battery Management System (BMS) that actively balances cells Battery Management System (BMS) 9 can significantly extend the usable life of the pack. Battery Management System 10

You need to know the Total Cost of Ownership (TCO). If a remote lasts 5 years but needs a $200 battery service every year, that cost adds up.

Conclusion

Asking these critical questions ensures your ground equipment matches the endurance of your aerial fleet, preventing costly downtime during the peak season.

Footnotes

1. Authoritative definition of high-definition display standards. ↩︎

2. General background on the RTK positioning technique used in agricultural drones. ↩︎

3. Technical explanation of RTK technology by an industry leader. ↩︎

4. Official standard specification for USB Power Delivery. ↩︎

5. Official specification for the USB Power Delivery protocol mentioned in the charging section. ↩︎

6. Explanation of pass-through charging technology by a major manufacturer. ↩︎

7. Government resource explaining lithium battery technology. ↩︎

8. Industry standards for testing battery cycle life and safety performance. ↩︎

9. Technical definition of BMS by a technology leader. ↩︎

10. Overview of BMS functions in managing and protecting battery packs. ↩︎