When our production team first started shipping firefighting drones 1 to international leasing companies, we quickly learned that procurement managers face a maze of technical questions. The wrong supplier choice can lock you into years of poor service and equipment failures.

To evaluate firefighting drone suppliers for DaaS financial leasing, verify their technical support infrastructure, assess engineering customization capabilities, confirm export certifications and documentation, and examine product durability alongside spare parts availability. These four pillars protect your leasing investment and ensure operational continuity throughout the lease term.

This guide walks you through each critical evaluation step technical support infrastructure 2. We will share practical checklists, comparison tables, and insider knowledge from years of manufacturing and exporting industrial drones to DaaS operators worldwide.

How can I verify if a firefighting drone manufacturer provides the technical support my DaaS fleet requires?

In our experience supporting leasing fleets across Europe and the United States, technical support gaps create the biggest headaches for DaaS operators modular hardware architecture 3. A drone sitting idle means lost revenue and angry end-users.

Verify technical support by requesting documented response time guarantees, checking for 24/7 remote diagnostic capabilities, confirming dedicated support staff for leasing partners, and reviewing case studies from existing DaaS customers. Strong suppliers offer tiered support levels with clear escalation paths and on-site assistance options.

Why Technical Support Matters More in DaaS Models

Unlike outright purchases, DaaS leasing means you carry the responsibility for uptime software development kits 4. Your clients—fire departments, government contractors, third-party service providers—expect equipment to work every time. When a thermal imaging camera 5 fails during a wildfire response, there is no time for slow email exchanges.

Our engineering team learned this lesson early. We now maintain dedicated support engineers assigned to each major leasing partner. This model ensures continuity and faster issue resolution.

Key Technical Support Elements to Evaluate

You need to examine several support components before signing any contract.

| Support Element | What to Verify | Red Flags |

|---|---|---|

| Response Time SLA | Written guarantee of initial response within 4 hours | Vague promises like "as soon as possible" |

| Remote Diagnostics | Real-time telemetry access and remote firmware updates | No cloud connectivity or diagnostic portal |

| Spare Parts Stocking | Regional warehouses with critical components | All parts ship from overseas only |

| On-Site Support | Availability of technicians in your operating region | Support limited to headquarters country |

| Training Resources | Video libraries, webinars, and certification programs | One-time training with no ongoing education |

Questions to Ask Potential Suppliers

Start with direct questions during your evaluation calls. Ask how many DaaS customers they currently support. Request references you can contact. Find out if they have support staff in your time zone.

When we work with new leasing partners, we provide a dedicated Slack or Teams channel. This gives them instant access to our technical team. Not all manufacturers offer this level of integration.

Testing Support Before Committing

Consider a pilot program before committing to a full fleet lease. Order a small batch and intentionally test the support system. Submit tickets. Track response times. Evaluate the quality of solutions provided.

This real-world testing reveals more than any sales presentation. It also gives you negotiating leverage for better support terms in your final contract.

What engineering capabilities should I look for when customizing drones for my financial leasing business?

Our R&D department has collaborated with leasing companies to develop custom payload mounts, specialized firmware, and white-label branding solutions. These customizations can differentiate your fleet in a competitive market.

Look for suppliers offering modular hardware architecture, open software development kits, in-house engineering teams for custom integrations, and experience with white-label OEM programs. The best partners collaborate on design from concept through production and provide ongoing engineering support for future modifications.

Understanding Customization Levels

Not all customization requests are equal. Some involve simple cosmetic changes. Others require deep engineering work. Understanding these levels helps you set realistic expectations.

| Customization Level | Examples | Typical Timeline | Engineering Complexity |

|---|---|---|---|

| Cosmetic | Custom colors, logo placement, branded packaging | 2-4 weeks | Low |

| Configuration | Pre-set flight parameters, custom controller mapping | 3-6 weeks | Low to Medium |

| Hardware Integration | Third-party sensor mounting, custom payload brackets | 6-12 weeks | Medium |

| Software Development | Custom app features, API integrations, unique flight modes | 8-16 weeks | High |

| Ground-Up Design | Entirely new airframe or propulsion system | 6-12 months | Very High |

Critical Engineering Capabilities

When we evaluate requests from leasing partners, we assess several core capabilities.

First, look for modular design philosophy. Drones built with modularity allow easier upgrades and repairs. This matters enormously for leasing operations where equipment cycles through multiple end-users.

Second, verify software development resources. Can the supplier modify flight controller firmware? Do they offer APIs for integration with incident command systems? Our team maintains a full software stack that we customize for different market requirements.

Third, confirm prototyping and testing facilities. Reputable manufacturers have in-house testing rigs, environmental chambers, and flight test areas. Ask for a virtual factory tour if you cannot visit in person.

OEM and White-Label Considerations

Many DaaS operators want their own branding on the equipment. This creates a stronger market position and builds customer loyalty to your brand rather than the manufacturer's brand.

When we provide OEM services, we remove all original branding and apply custom logos, colors, and packaging. We also modify startup screens and app interfaces to reflect the partner's brand identity.

However, white-labeling involves more than just stickers. Ensure the supplier understands your market positioning. Discuss warranty terms, support branding, and how technical documentation will be presented to end-users.

Evaluating Past Customization Projects

Request a portfolio of previous custom projects. Ask detailed questions about the engineering challenges and how they were solved. Strong suppliers will share case studies demonstrating their problem-solving capabilities.

Pay attention to timeline accuracy. Did previous projects deliver on schedule? What caused delays? How did the supplier communicate throughout the process?

How do I ensure my supplier has the export certifications and documentation needed for my international leasing contracts?

When we calibrate our export documentation processes, we always consider the end-user's regulatory environment. A missing certificate can delay your shipment by weeks and create costly customs complications.

Ensure your supplier maintains current export licenses, provides NDAA compliance documentation for U.S. government contracts, offers CE marking for European markets, supplies complete technical files and test reports, and has established relationships with freight forwarders experienced in drone shipments. Request sample documentation packages before placing orders.

Understanding Regional Certification Requirements

Different markets demand different certifications. The United States, European Union, and other regions each have unique requirements.

| Market | Key Certifications | Documentation Required | Compliance Considerations |

|---|---|---|---|

| United States | FCC, NDAA Compliance 6, Blue sUAS listing | FCC test reports, component origin certificates | Government contracts require NDAA compliance; DJI products increasingly restricted |

| European Union | CE Marking 7, EU Drone Regulations | Declaration of Conformity, technical files | New EU drone classes (C0-C4) affect operations |

| United Kingdom | UKCA Marking | Post-Brexit equivalent of CE documentation | Separate from EU requirements since 2021 |

| Australia | RCM Compliance | Supplier declaration, test evidence | Focus on radio equipment standards |

The NDAA Compliance Challenge

For DaaS operators targeting U.S. government contracts, NDAA compliance has become non-negotiable. Section 848 of the NDAA prohibits federal agencies from using drones manufactured by certain foreign entities.

Our production lines are documented to demonstrate component sourcing. We provide full bill-of-materials transparency and origin certificates for critical electronics. This level of documentation takes time to compile but opens access to lucrative government leasing contracts.

Some leasing companies make the mistake of assuming all Chinese-manufactured drones are non-compliant. The reality is more nuanced. Compliance depends on specific component sourcing and corporate ownership structures, not simply country of origin.

Essential Export Documents

A complete export documentation package should include several key items.

Commercial invoices must accurately describe the products with HS codes. Packing lists detail exact contents of each shipment. Certificates of origin verify manufacturing location. Technical specifications support customs classification.

Beyond basic shipping documents, you need compliance certificates. These include radio frequency test reports for FCC and CE. They include safety test results. They include any government-specific certifications required by your end markets.

Building Supplier Relationships for Smooth Customs

Experienced suppliers have established relationships with freight forwarders who specialize in drone shipments. These specialists understand the unique challenges of shipping lithium batteries and radio equipment.

Ask your potential supplier about their standard shipping arrangements. Do they have preferred freight partners? What is their success rate with customs clearance? Have they experienced significant delays or seizures?

We maintain door-to-door delivery services specifically because customs complications can destroy delivery timelines. Our logistics team tracks every shipment and intervenes quickly when issues arise.

Red Flags in Export Documentation

Watch for suppliers who cannot provide documentation samples before your first order. Be cautious of vague answers about compliance status. Question any reluctance to discuss component sourcing.

Strong suppliers proactively share their certification portfolios. They understand that documentation transparency builds trust and reduces your procurement risk.

What should I check regarding product durability and spare parts availability to protect my leasing investment?

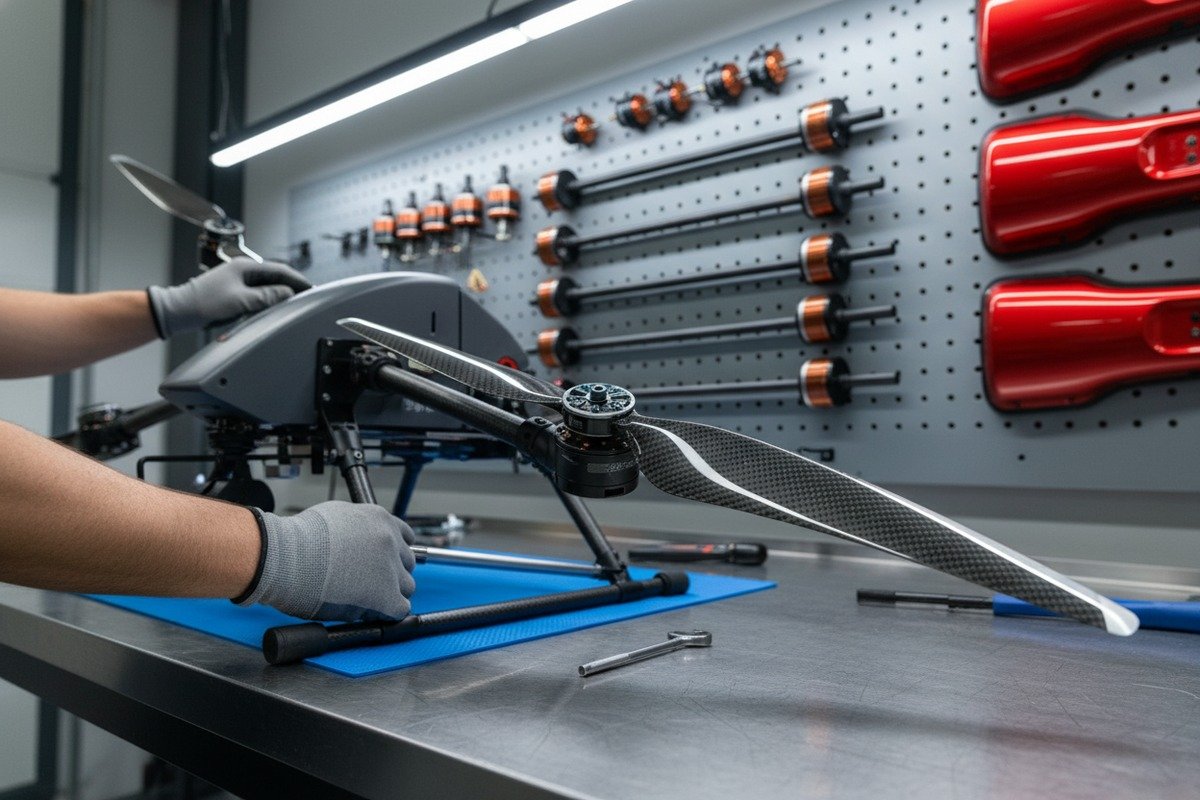

Our quality control team tests every firefighting drone in extreme temperature chambers and high-humidity environments before shipment. This durability focus comes from understanding that leasing equipment faces harder use than owner-operated equipment.

Check durability by requesting MTBF (Mean Time Between Failures) data, reviewing IP ratings for water and dust resistance, examining frame materials and construction quality, and verifying warranty terms specific to commercial use. For spare parts, confirm regional stocking locations, lead times for critical components, pricing structures, and supplier commitment to long-term parts availability.

Why Durability Matters More for Leased Equipment

Leased firefighting drones face unique stress factors. End-users may not treat equipment as carefully as owners would. Training periods mean more beginner mistakes. High turnover of operators increases accident risk.

Firefighting applications add environmental challenges. Heat exposure, smoke particulates, water spray, and rough landing zones all accelerate wear. Equipment designed for consumer photography will not survive long in these conditions.

When we design firefighting drones, we specify military-grade connectors, reinforced landing gear, and sealed electronics compartments. These features cost more initially but dramatically reduce maintenance frequency.

Key Durability Specifications to Verify

| Specification | Minimum Standard | Premium Standard | What It Means |

|---|---|---|---|

| IP Rating | IP43 | IP55 or higher | Protection against water jets and dust intrusion |

| Operating Temperature | -10°C to 40°C | -20°C to 50°C | Ability to function in extreme conditions |

| Frame Material | Engineering plastic | Carbon fiber composite | Impact resistance and weight optimization |

| Motor Class | Brushless standard | Industrial-grade sealed | Longevity under continuous heavy use |

| Propeller Mount | Quick-release plastic | Reinforced metal hub | Reliability under vibration and stress |

Spare Parts Strategy for Leasing Operations

Spare parts availability can make or break your leasing business. A grounded drone generates no revenue but continues costing you money.

Critical components include propellers, motors, batteries, and electronic speed controllers. These items fail most frequently and ground drones until replaced. Secondary components like camera gimbals, landing gear, and shell pieces affect functionality but may allow limited operations.

Ask potential suppliers about their parts stocking strategy. Do they maintain inventory in your region? What are typical lead times? Will they guarantee parts availability for the expected life of your lease contracts?

Cost Structure Considerations

Parts pricing affects your total cost of ownership significantly. Some suppliers use low initial drone prices but charge premium rates for replacement parts. This razor-and-blade model can devastate leasing profitability.

Request a complete price list for all spare parts before committing. Calculate expected replacement costs based on industry failure rates. Include these projections in your financial modeling.

Our approach provides transparent parts pricing from the start. We believe fair parts costs build long-term partnerships rather than extracting maximum short-term profit.

Warranty Terms for Commercial Use

Standard consumer warranties often exclude commercial applications. Read warranty terms carefully. Look for specific coverage of commercial or leasing use cases.

Strong suppliers offer extended warranty options designed for fleet operators. These may include coverage for accidental damage, expedited replacement programs, and dedicated warranty support channels.

Negotiate warranty terms as part of your supplier agreement. For volume commitments, many manufacturers will customize warranty coverage to fit your business model.

Conclusion

Evaluating firefighting drone suppliers for DaaS financial leasing 9 requires systematic assessment across technical support, engineering capabilities, export documentation, and product durability. Use the frameworks and checklists provided to protect your leasing investment and build profitable long-term partnerships.

Footnotes

1. Replaced with an authoritative Wikipedia article on drones in wildfire management. ↩︎

2. Discusses best practices for IT infrastructure support, relevant to maintaining drone fleets. ↩︎

3. Defines modular hardware architecture and its benefits in system design. ↩︎

4. Explains what SDKs are, their components, and benefits for developers. ↩︎

5. Explains how thermal imaging cameras work and their various applications. ↩︎

6. Addresses NDAA compliance for drones, including restrictions and cleared lists. ↩︎

7. Official government guidance on CE marking requirements and its significance. ↩︎

8. Explains IP ratings, their meaning, and importance for product protection. ↩︎

9. Explains the Drones as a Service (DaaS) model, including its financial aspects and benefits. ↩︎