Picture this: a 2,000°F inferno rages through a warehouse thermal insulation materials 1. Human firefighters cannot enter. Our engineering team faced this exact challenge when developing drones that survive such extremes.

Evaluating firefighting drone heat dissipation requires testing thermal insulation materials, monitoring internal temperatures during controlled heat exposure up to 392°F for 10 minutes, assessing active cooling system performance, and conducting real-world flight simulations near actual flames to verify survival time and component integrity.

This guide breaks down the exact methods we use and recommend for testing heat resistance aerogel materials 2. You will learn what materials work best, how cooling systems perform, and what to ask your supplier.

How can I accurately test the heat dissipation limits of a firefighting drone in extreme environments?

When we calibrate our thermal testing chambers at the factory, temperature consistency matters most thermal runaway 3. Many buyers receive drones that fail in real fires because testing was inadequate.

Accurate testing requires controlled chamber exposure at temperatures up to 200°C (392°F), open-flame trials at firefighter training facilities, component-level isolation tests, and tracking metrics like time-to-overheat, heat flux penetration, and sensor accuracy under thermal stress.

Controlled Chamber Testing Methods

Our quality control team runs every firefighting drone through a heat chamber before shipment. The chamber maintains steady temperatures. We start at 100°C and increase to 200°C over 30 minutes. Internal sensors record component temperatures every 5 seconds.

The key metrics we track include:

- Time until internal temperature exceeds safe limits

- Heat flux penetration through insulation layers

- Cooling system activation timing

- Flight controller response accuracy

Open-Flame Trial Protocols

Chamber tests alone are not enough. Real fires behave differently. We partner with firefighter training facilities to run open-flame trials. Drones fly at various distances from controlled burns. We measure:

| Test Parameter | Measurement Method | Acceptable Range |

|---|---|---|

| Surface temperature | Thermocouple arrays | Below 150°C |

| Internal electronics temp | Embedded sensors | Below 60°C |

| Flight stability | IMU data logging | Less than 5° drift |

| Sensor accuracy | Cross-reference thermal cameras | Within 2°C variance |

| Survival duration | Timer from flame exposure | Minimum 10 minutes |

Component-Level Isolation Testing

We also test individual parts separately. Batteries go into heat chambers alone. Flight controllers face thermal stress without airflow. This reveals weak points before full assembly.

Using CFD Simulations for Predictive Modeling

Computational Fluid Dynamics simulations 4 save time and money. Our engineers model heat flow around the drone body digitally. This predicts problem areas before we build physical prototypes. CFD shows where heat accumulates and where cooling needs improvement.

For buyers evaluating suppliers, ask to see CFD analysis reports. Suppliers who use simulation tools understand thermal engineering deeply. Those who skip this step often deliver products that fail unexpectedly.

What specific cooling technologies should I look for to protect my drone's internal electronics from overheating?

Our R&D department spent two years testing cooling technologies from aerospace and automotive industries. Not all solutions work equally well for drones. Weight and power consumption limit options.

Look for multi-layered thermal insulation using aerogel materials, reflective aluminum coatings for radiant heat rejection, active cooling systems like CO2 evaporative mechanisms, and thermoelectric cooling units that maintain protective air layers around critical electronics.

Passive Cooling Technologies

Passive systems require no power. They work continuously without draining batteries. The main passive technologies include:

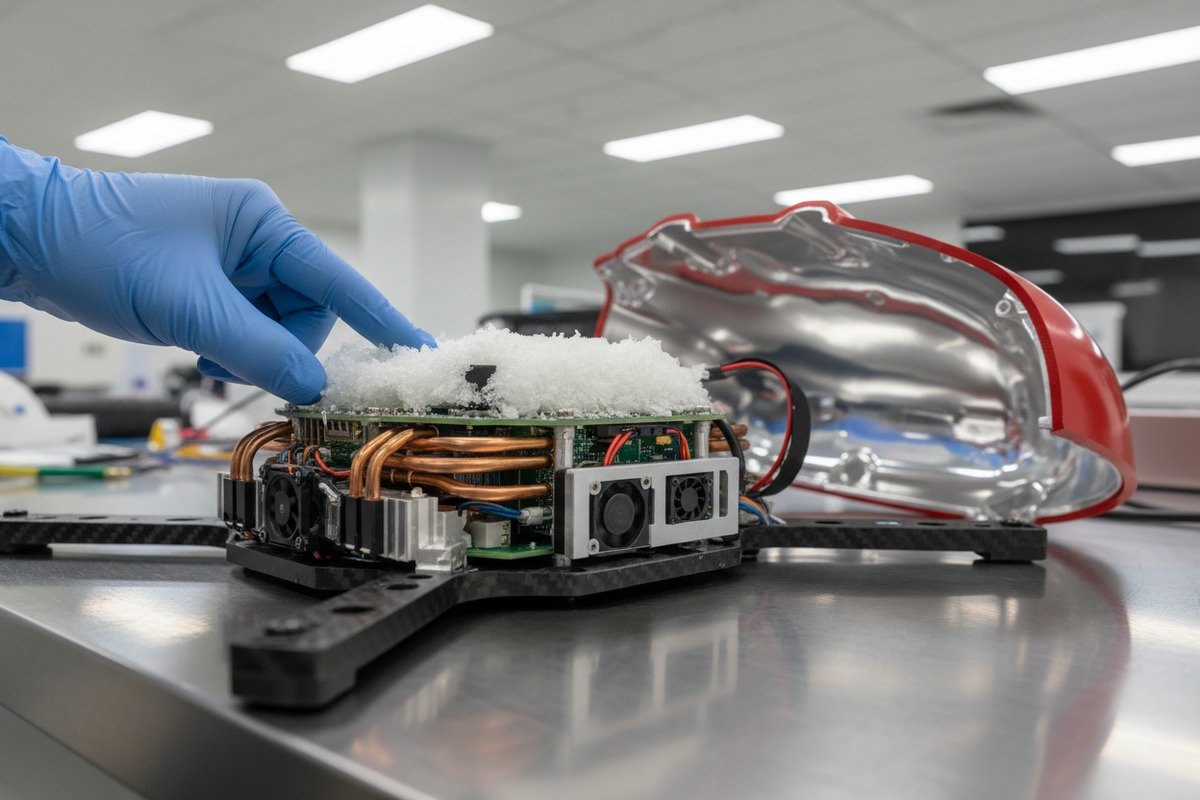

Aerogel Insulation: Polyimide and glass fiber-reinforced aerogels provide exceptional insulation. They weigh almost nothing. A 5mm layer of aerogel equals 50mm of traditional insulation. We wrap all critical electronics in aerogel blankets.

Reflective Aluminum Coatings: Thin aluminum layers reflect radiant heat away from the drone. reflective aluminum coatings 5 This technology comes from spacecraft design. Our yellow and red housing covers include embedded reflective layers.

High-Temperature Polymers: Carbon fiber frames and heat-resistant plastics form the outer shell. These materials withstand direct heat better than standard drone bodies.

Active Cooling Technologies

Active systems consume power but provide superior cooling. The trade-off involves reduced flight time versus better heat protection.

| Cooling Technology | Power Consumption | Weight Added | Cooling Capacity | Best For |

|---|---|---|---|---|

| CO2 evaporative | Low (pressurized canister) | 200-400g | Excellent short-term | High-intensity exposures |

| Thermoelectric | Medium (5-15W) | 150-300g | Good sustained | Prolonged missions |

| Liquid cooling loops | High (20-40W) | 500-800g | Excellent sustained | Heavy payload operations |

| Forced air | Low (3-8W) | 50-100g | Moderate | General protection |

CO2 Evaporative Cooling: Inspired by human sweat, this system releases small amounts of liquid CO2 that evaporate and absorb heat. The FireDrone prototype from Imperial College London uses this approach. Our own systems incorporate similar technology.

Thermoelectric Cooling: These solid-state devices pump heat away from electronics using electrical current. They create a protective air layer between hot exterior surfaces and sensitive components.

Choosing the Right Combination

No single technology works perfectly alone. Our firefighting drones combine multiple approaches:

- Aerogel wrapping around batteries and flight controllers

- Aluminum-coated external housing

- Thermoelectric cooling 6 for sustained operations

- CO2 backup for emergency high-heat situations

When evaluating suppliers, request detailed specifications on each cooling layer. Ask what happens when one system fails. Redundancy matters in extreme environments.

How will extreme heat affect my drone's battery performance and total flight time during a fire mission?

In our experience exporting firefighting drones to US fire departments, battery questions come up constantly. Heat is the enemy of lithium batteries. Performance drops faster than most buyers expect.

Extreme heat reduces battery capacity by 20-40%, shortens total flight time significantly, accelerates chemical degradation, and may cause thermal runaway if internal temperatures exceed 60°C. High-temperature tolerant batteries with enhanced thermal management are essential for fire missions.

How Heat Affects Battery Chemistry

Lithium-ion and lithium-polymer batteries 7 perform best between 20-25°C. Above 40°C, chemical reactions accelerate. This creates several problems:

- Reduced Capacity: A battery rated for 30 minutes at room temperature may only deliver 18-24 minutes at 50°C

- Accelerated Degradation: High heat permanently damages battery cells, reducing total lifespan

- Thermal Runaway Risk: Above 60°C internal temperature, batteries may catch fire or explode

- Voltage Sag: Hot batteries cannot deliver full current, affecting motor performance

Battery Specifications for Firefighting Drones

| Specification | Standard Drone Battery | Fire-Rated Battery | Why It Matters |

|---|---|---|---|

| Operating temp range | -10°C to 40°C | -20°C to 60°C | Wider range handles fire environments |

| Thermal cutoff | 50°C | 70°C | Higher threshold prevents premature shutdown |

| Cell chemistry | Standard LiPo | High-temp LiPo or LiFePO4 | More stable at elevated temperatures |

| Insulation | Basic housing | Aerogel wrapping | Protects cells from external heat |

| BMS protection | Basic | Advanced thermal monitoring | Prevents dangerous conditions |

Real-World Flight Time Expectations

We tell buyers to expect 30-40% reduction in flight time during fire missions. A drone rated for 45 minutes in normal conditions may fly only 27-32 minutes near flames. Planning must account for this reduction.

Battery Management Strategies

Our drones include several battery protection features:

Active Monitoring: The battery management system tracks cell temperatures continuously. If any cell exceeds 55°C, the system alerts the operator and can initiate automatic return-to-home.

Thermal Isolation: Batteries sit inside insulated compartments separate from other heat-generating components like motors and ESCs.

Rapid Swap Design: Quick-release battery bays allow fast changes. Fire departments can cycle multiple batteries during extended operations.

Pre-Cooling Protocols: For planned missions, we recommend keeping spare batteries in cooled containers until needed.

When purchasing firefighting drones, verify battery specifications carefully. Ask for test data showing actual flight times at elevated temperatures, not just room-temperature ratings.

Can my manufacturer provide custom engineering support to optimize heat dissipation for my specific climate requirements?

Our export team regularly works with US buyers who operate in Arizona deserts, Florida humidity, or California wildfire zones. Each environment presents unique challenges. Standard products rarely meet every need.

Reputable manufacturers offer custom engineering support including thermal modeling for your specific climate, modified insulation configurations, adapted cooling system specifications, extended testing protocols, and ongoing technical consultation to optimize heat dissipation for regional requirements.

What Custom Engineering Support Includes

When we work with distributors and government contractors, custom support involves several phases:

Initial Consultation: We review your operating environment in detail. Temperature ranges, humidity levels, altitude, and typical mission durations all affect thermal design. Arizona operations face different challenges than Pacific Northwest deployments.

Thermal Modeling: Our engineers create custom CFD simulations for your conditions. This identifies where standard designs may fail and where modifications help most.

Prototype Development: For significant customizations, we build test units with your specifications. These undergo full thermal testing before production approval.

Field Validation: We support on-site testing at your facilities. This ensures the drone performs as expected in real conditions, not just laboratory simulations.

Questions to Ask Your Supplier

Before committing to a supplier, verify their engineering capabilities:

- Do you have in-house thermal engineering staff?

- Can you provide CFD simulation reports for my operating conditions?

- What testing facilities do you own versus outsource?

- How long does custom thermal optimization typically take?

- What documentation do you provide for modified designs?

- Do you offer on-site technical support for deployment?

- What warranty terms apply to customized products?

Cost and Timeline Expectations

Custom engineering adds cost and time. Budget appropriately:

| Service Level | Timeline | Typical Cost Impact | What's Included |

|---|---|---|---|

| Standard product | 2-4 weeks | Base price | Factory thermal configuration |

| Minor modifications | 4-8 weeks | +10-20% | Adjusted insulation, software tuning |

| Significant customization | 8-16 weeks | +25-50% | Custom cooling systems, modified frame |

| Full custom development | 16-32 weeks | +100-200% | Ground-up thermal design for unique requirements |

Long-Term Support Considerations

Heat dissipation systems degrade over time. Aerogel loses effectiveness after repeated thermal cycles. Cooling components wear out. Good suppliers provide:

- Replacement insulation materials

- Spare cooling system components

- Firmware updates for thermal management algorithms

- Technical support for field issues

- Training for maintenance staff

Our team at SkyRover maintains long-term relationships with buyers. We provide remote diagnostic support, ship replacement parts with reasonable lead times, and offer periodic system reviews to ensure continued performance.

Conclusion

Evaluating firefighting drone heat dissipation requires comprehensive testing, understanding of cooling technologies, realistic battery expectations, and strong supplier support. Choose partners who demonstrate genuine engineering capability and provide ongoing technical assistance.

Footnotes

1. Comprehensive guide on properties of thermal insulation materials. ↩︎

2. Wikipedia is an authoritative source providing a comprehensive overview of aerogel materials. ↩︎

3. Authoritative explanation of thermal runaway in batteries from a safety research institute. ↩︎

4. Wikipedia is an authoritative source and the content accurately defines Computational Fluid Dynamics. ↩︎

5. This article provides a detailed explanation of the uses and advantages of aluminum coatings, including their reflective properties. ↩︎

6. Authoritative government explanation of how thermoelectric coolers work. ↩︎

7. Clearly explains the differences and characteristics of both battery types. ↩︎