When our engineers designed the latest hexacopter series, they faced a critical challenge from European distributors. Sudden gusts during spray missions caused costly chemical drift 1 and mission failures across farms from France to Poland.

To evaluate agricultural drone wind resistance for Europe’s variable climate, you must combine wind tunnel testing, real-world field trials, and CFD simulations. Check manufacturer ratings against Beaufort Scale levels 4-6, verify gust recovery times under 500 milliseconds, and ensure the drone maintains stable yaw, pitch, and roll control in sustained winds up to 15 m/s.

This guide walks you through practical evaluation methods, key engineering features, and verification steps. Whether you import drones for resale or operate your own fleet, understanding wind resistance saves money and prevents operational disasters.

How do I determine the maximum wind speed my agricultural drone can safely handle in gusty conditions?

Our flight test team spends weeks in varied wind conditions before any drone leaves the factory. Yet we still receive questions from European partners about real-world limits versus spec sheet numbers. The gap between lab ratings and field performance frustrates many operators.

Your agricultural drone's safe maximum wind speed depends on three factors: the manufacturer's sustained wind rating, gust recovery capability, and payload configuration. Most professional agricultural drones handle 10-15 m/s sustained winds, but gusts exceeding 10 m/s can destabilize flight. Always verify ratings through independent field testing with an anemometer at drone operating height.

Understanding Wind Ratings and the Beaufort Scale

Manufacturers express wind resistance differently. Some use meters per second. Others use miles per hour or Beaufort Scale 2 levels. This inconsistency confuses buyers. Here is a quick reference table:

| Beaufort Level | Wind Speed (m/s) | Wind Speed (km/h) | Typical Conditions | Drone Safety |

|---|---|---|---|---|

| Level 3 | 3.4-5.4 | 12-19 | Gentle breeze, leaves move | Safe for all drones |

| Level 4 | 5.5-7.9 | 20-28 | Moderate breeze, dust rises | Safe for most ag drones |

| Level 5 | 8.0-10.7 | 29-38 | Fresh breeze, small trees sway | Caution required |

| Level 6 | 10.8-13.8 | 39-49 | Strong breeze, large branches move | Professional drones only |

| Level 7 | 13.9-17.1 | 50-61 | Near gale, whole trees move | Not recommended |

Most agricultural operations should stay within Level 4-5 conditions. At Level 6, even robust industrial drones experience increased battery drain and reduced spray accuracy.

Gust Recovery Time Matters More Than Peak Ratings

A drone rated for 15 m/s sustained winds may fail in 8 m/s gusts. Why? Gusts change direction and intensity within seconds. The IMU and flight controller must react in milliseconds. When we calibrate our flight controllers, we measure recovery time after sudden 5 m/s gusts from multiple angles.

Good agricultural drones recover position within 200-500 milliseconds. Poor designs take over one second. During that delay, spray patterns drift and GPS positioning errors compound.

Payload Changes Everything

An empty drone handles wind better than a loaded one. Our testing shows a 25-liter liquid payload reduces effective wind resistance by 15-20%. The shifting liquid creates additional instability. Granular payloads like seeds behave differently. They do not slosh but add static weight.

Before each mission, calculate your actual wind tolerance:

- Start with manufacturer's maximum rating

- Subtract 2-3 m/s for full payload

- Subtract another 1-2 m/s for gusty conditions

- This gives your practical safe limit

What specific engineering features should I look for to ensure my drone remains stable during unpredictable European weather?

During production runs at our facility, we test every stabilization component individually before final assembly. European weather patterns demand engineering solutions that consumer drones simply cannot provide. The Mistral winds in southern France and Atlantic storms hitting Ireland require specific design approaches.

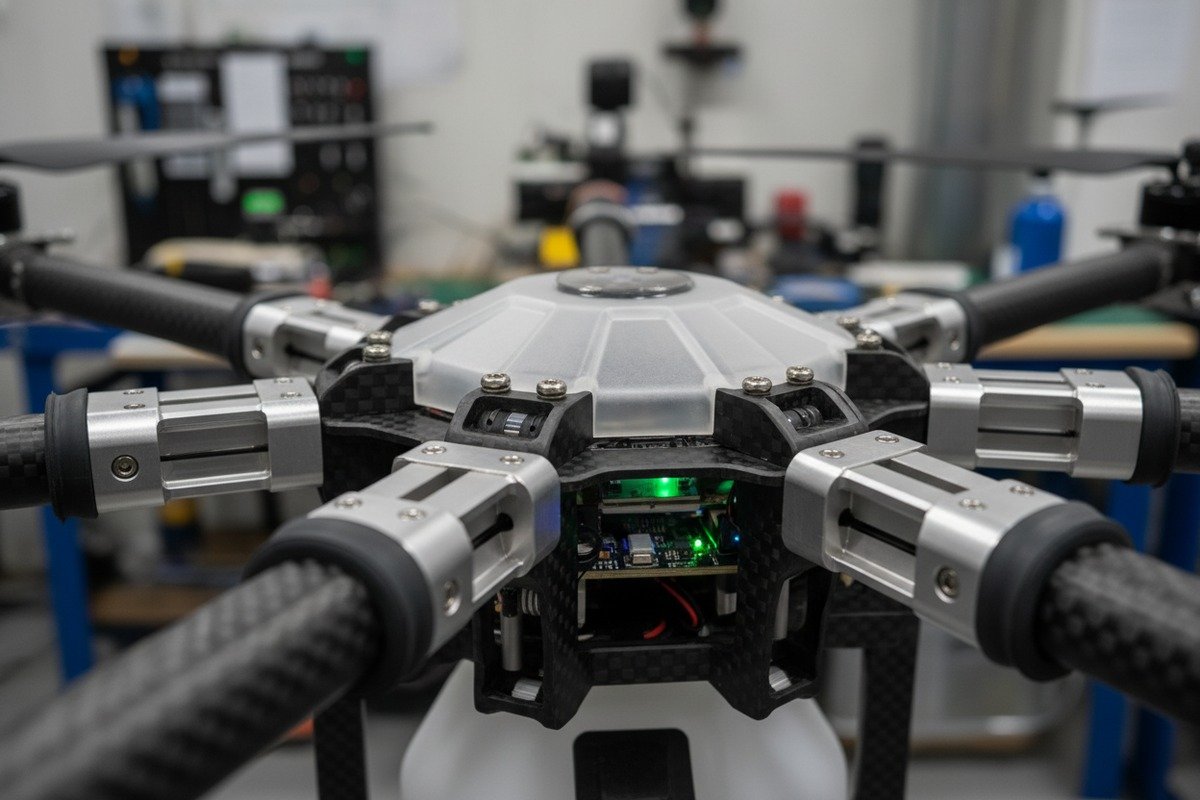

Look for six key features: hexacopter or octocopter redundancy, carbon fiber frames with low drag profiles, IMU sensors with 1000Hz+ update rates, AI-assisted flight controllers with predictive gust compensation, modular payload systems for balance adjustment, and weatherproofed electronics rated IP54 or higher. These features combined enable stable operation in Europe's challenging microclimates.

Frame Design and Rotor Configuration

The number and arrangement of motors directly impacts wind resistance. Quadcopters struggle in gusty conditions because losing stability on any axis quickly compounds. Hexacopters provide redundancy. If one motor underperforms, the other five compensate.

| Configuration | Wind Stability | Redundancy | Typical Use Case |

|---|---|---|---|

| Quadcopter | Moderate | None | Light surveying |

| Hexacopter | High | Single motor failure | Agricultural spraying |

| Octocopter | Very High | Dual motor failure | Heavy payload operations |

Our hexacopter designs position motors at 60-degree intervals. This creates balanced thrust vectors that counteract wind from any direction. The carbon fiber arms resist flexing under stress, maintaining propeller plane alignment.

IMU and Flight Controller Performance

The Inertial Measurement Unit 3 detects orientation changes. Cheap IMUs update 200-400 times per second. Professional agricultural drones need 1000Hz or faster. At 1000Hz, the controller detects a 10 m/s gust within one millisecond.

Modern AI-assisted controllers go further. They predict gusts based on initial pressure changes. When our engineers integrated machine learning algorithms 4, gust response improved by 40%. The drone starts compensating before the full gust arrives.

Propeller Efficiency in Headwinds

CFD-optimized propellers reduce drag by up to 30% compared to standard designs. This matters because headwinds effectively reduce available thrust. A drone with 50% thrust margin in calm air may have only 20% margin in a 10 m/s headwind.

Look for propellers with:

- Variable pitch angles optimized for agricultural speeds

- Carbon fiber construction to resist deformation

- Low-noise profiles that also indicate efficient airflow

Weather Resistance Ratings

Europe's climate includes humidity, rain, and temperature swings. Electronics must survive morning dew and afternoon heat. IP54 rating 5 means protection against dust and splashing water. IP65 handles direct water jets.

| IP Rating | Dust Protection | Water Protection | Suitability |

|---|---|---|---|

| IP43 | Limited | Light spray | Indoor only |

| IP54 | Complete | Splashing | Fair weather ops |

| IP65 | Complete | Direct jets | All-weather ops |

| IP67 | Complete | Brief immersion | Extreme conditions |

For European agricultural use, IP54 is minimum. IP65 is recommended for regions with frequent rain like the UK, Netherlands, and Ireland.

How can I verify that a manufacturer's wind resistance ratings meet the strict safety standards required for my import business?

When we prepare export documentation for European distributors, we include test reports from independent laboratories. But we know many manufacturers inflate specifications. Your import business depends on accurate ratings. Failed products damage your reputation and create liability issues.

Verify manufacturer wind ratings through three methods: request third-party test certificates from recognized laboratories, conduct your own field trials using calibrated anemometers and RTK position logging, and cross-reference claims against EASA operational guidelines. Independent wind tunnel tests or documented field trials at Beaufort Level 5-6 conditions provide the most reliable verification.

Third-Party Certification Options

Independent testing laboratories provide objective verification. In Europe, several organizations offer drone performance testing:

- TÜV Rheinland (Germany) – comprehensive drone testing

- Bureau Veritas (France) – industrial equipment certification

- SGS (Switzerland) – multi-standard compliance testing

Request specific test reports showing:

- Wind speed during testing

- Duration of sustained wind exposure

- Gust intensity and frequency

- Position deviation measurements

- Battery consumption rates

Be wary of manufacturers who only provide internal test data. Ask for the testing methodology. Legitimate tests follow standardized protocols.

Field Verification Protocol

If third-party certification is unavailable, conduct your own verification. Here is a practical protocol:

Step 1: Choose a test day with steady winds of 8-12 m/s at ground level. Use a calibrated anemometer mounted at planned flight altitude.

Step 2: Program a simple hover test at 10 meters altitude. Record position data via RTK GPS with centimeter accuracy 6.

Step 3: Measure position deviation over 5 minutes. Professional drones should maintain position within 1-2 meters.

Step 4: Execute spray pattern tests. Mark ground targets and measure actual spray distribution against programmed paths.

Step 5: Monitor battery consumption. Compare to calm-day baselines. Wind resistance claims are invalid if battery drain exceeds 30% increase.

EASA Compliance Considerations

European Aviation Safety Agency regulations 7 set operational boundaries. Drones operating in the "specific" category require operational authorization. This includes most commercial agricultural applications.

EASA does not directly certify wind resistance. However, your Operational Authorization application must include:

- Risk assessment for weather conditions

- Operating limitations including wind speed limits

- Pilot training requirements for adverse weather

Importing drones that cannot meet declared specifications creates regulatory risk. If an accident occurs during high winds, investigators will compare actual performance to claimed specifications.

Red Flags in Manufacturer Claims

Watch for these warning signs:

- Wind ratings without specifying sustained versus gust

- No mention of payload impact on ratings

- Identical ratings across different models

- Refusal to provide test methodology

- Ratings exceeding industry norms without explanation

Current industry standards for professional agricultural drones range from 12-15 m/s sustained wind resistance. Claims of 20+ m/s should require exceptional evidence.

Will frequent operation in high-wind environments increase my long-term maintenance costs or affect my drone's flight endurance?

Our service department tracks warranty claims by region. Drones operating in coastal Scotland and the Netherlands show different wear patterns than those in sheltered Spanish valleys. The correlation between wind exposure and maintenance needs is clear from our data.

Yes, frequent high-wind operations significantly increase maintenance costs and reduce flight endurance. Expect 20-40% higher motor wear, 15-25% shorter battery lifespan, and 30% more frequent propeller replacements. Flight endurance decreases 10-20% in sustained 10 m/s winds due to increased power demands. Budget accordingly and implement preventive maintenance schedules.

Motor and ESC Wear Patterns

Motors work harder in wind. Constant thrust adjustments create heat cycles that degrade bearings and windings. Electronic Speed Controllers also suffer increased stress.

| Component | Calm Operation Lifespan | High-Wind Operation Lifespan | Cost Impact |

|---|---|---|---|

| Brushless Motors 8 | 500+ flight hours | 350-400 flight hours | +25-40% replacement frequency |

| ESCs | 800+ flight hours | 600-700 flight hours | +15-25% replacement frequency |

| Propellers | 200 flight hours | 140-160 flight hours | +25-40% replacement frequency |

| Batteries | 300 cycles | 220-260 cycles | +15-25% replacement frequency |

These figures come from aggregated service data across European deployments. Actual results vary based on wind intensity and frequency.

Battery Degradation in Windy Conditions

Batteries drain faster in wind. More current flow generates more heat. Heat accelerates chemical degradation. A battery rated for 300 charge cycles may only achieve 220-260 cycles with regular high-wind use.

Beyond cycle count, capacity fades faster. After 100 cycles in high-wind operations, expect 85-90% original capacity versus 92-95% in calm operations.

Strategies to extend battery life:

- Never discharge below 20% in windy conditions

- Allow batteries to cool before recharging

- Store partially charged during off-season

- Rotate batteries to distribute wear evenly

Preventive Maintenance Schedule Adjustments

Standard maintenance intervals assume mixed conditions. For high-wind European operations, compress schedules:

- Motor inspection: Every 50 flight hours instead of 100

- Bearing replacement: Every 150 flight hours instead of 300

- ESC thermal inspection: Every 75 flight hours instead of 150

- Frame stress inspection: Every 100 flight hours instead of 200

Document all inspections. This protects your warranty claims and demonstrates due diligence for insurance purposes.

Flight Endurance Calculations

Wind reduces flight time through two mechanisms. First, the drone uses more power to maintain position. Second, headwind segments of programmed paths take longer.

In calm conditions, a 25-liter agricultural drone might achieve 15-18 minutes flight time. In 10 m/s sustained winds, expect 12-15 minutes. Planning for 20% reduced endurance is practical.

Optimize routes to minimize headwind segments. Flying perpendicular to wind direction maintains more consistent ground speed than directly into or with the wind.

Conclusion

Evaluating agricultural drone wind resistance for Europe's variable climate requires understanding specifications, verifying claims, and planning for long-term costs. Test before you trust, verify independently, and budget for increased maintenance in challenging wind environments.

Footnotes

1. Explains what pesticide drift is, its causes, and potential impacts on health and environment. ↩︎

2. Provides a clear definition and table for the Beaufort Wind Scale and its associated conditions. ↩︎

3. Replaced HTTP 403 with an authoritative Wikipedia page defining Inertial Measurement Units. ↩︎

4. Discusses how machine learning algorithms are optimized to improve drone maneuverability and power efficiency. ↩︎

5. Explains the IP54 rating, detailing its protection against dust and water splashes. ↩︎

6. Explains how RTK GPS enhances positioning to achieve centimeter-level accuracy for drone mapping. ↩︎

7. Provides official information and a comprehensive framework for drone regulations across EU member states. ↩︎

8. Replaced HTTP 404 with an authoritative Wikipedia page defining Brushless DC electric motors. ↩︎