During our years on the production line, we have seen European buyers struggle with one recurring problem IP67+ ratings 1. They invest in powerful agricultural drones, only to find the folding mechanisms fail after one harsh season. This wastes money and damages trust with farmers who depend on reliable equipment.

To properly evaluate agricultural drone folding designs for European farmers, focus on five critical areas: folding mechanism type (arm-folding, upward-folding, or cross-folding), material durability with IP67+ ratings, transport dimensions fitting European farm vehicles, joint maintenance accessibility, and EU regulatory compliance including CE marking and EASA requirements.

Below, we break down each evaluation criterion. You will learn practical testing methods and key specifications that separate reliable designs from problematic ones.

How can I verify if a drone's folding mechanism is durable enough for the intensive European farming season?

When we test folding mechanisms in our quality control lab, we see massive variation in durability CE marking 2. Some joints fail after 50 cycles. Others last thousands of deployments. European farming seasons demand equipment that survives months of daily use without breakdown EASA requirements 3.

Verify folding mechanism durability by conducting 100+ cycle stress tests, checking for injection-molded joints over welded alternatives, confirming IP67 waterproofing ratings, and examining corrosion-resistant coatings. Request supplier fatigue test reports and inspect joint play after simulated wet-field conditions.

Understanding Folding Mechanism Types

Not all folding designs offer equal durability. Our engineering team has identified three main categories, each with distinct strengths and weaknesses injection-molded joints 4.

Arm-folding systems like those on the DJI T30/T10 reduce overall size by up to 80%. The arms pivot inward along a single axis. This simplicity means fewer moving parts and failure points. However, the hinge bearings must handle significant stress during spray operations.

Upward-folding designs such as the H160 8-axis configuration fold arms vertically. This protects the propellers and motors during transport. The trade-off is a taller folded profile that may not fit all storage spaces.

Cross-folding mechanisms like the HF F20 combine multiple fold directions. This achieves compact dimensions but introduces more joints that require inspection.

Key Durability Testing Methods

Before committing to a supplier, request these specific tests:

| Test Type | Minimum Standard | Why It Matters |

|---|---|---|

| Fold cycle endurance | 500+ cycles without joint play | European seasons require 200+ deployments |

| Wet condition unfold | 10 cycles in simulated rain | Morning dew and sudden showers are common |

| Load-bearing test | 1.5x maximum payload weight | Safety margin for real-world conditions |

| Temperature cycling | -10°C to +40°C range | Covers spring frost to summer heat |

| Vibration resistance | 2 hours at operational frequency | Motor vibration accelerates wear |

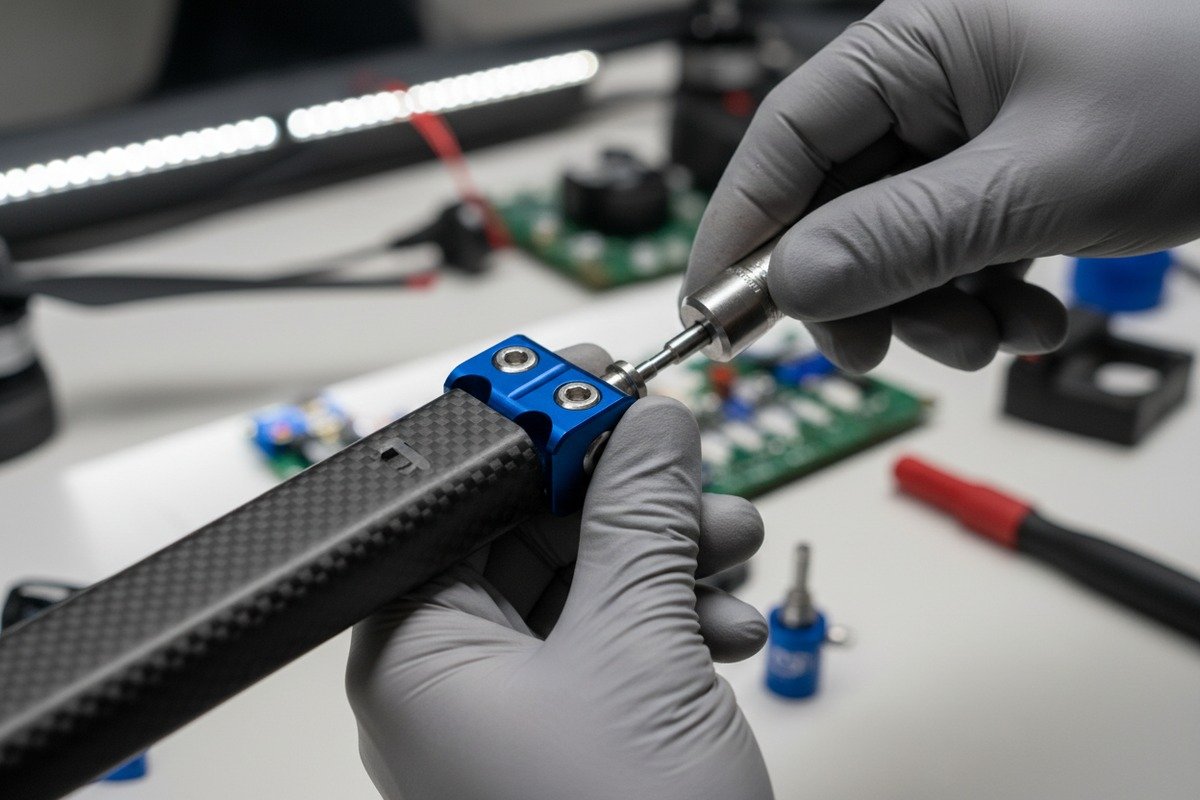

Material Quality Indicators

When we source components for our production, we prioritize injection-molded parts over cast alternatives. Injection molding creates more consistent internal structures with fewer air pockets that could become crack initiation points.

Look for these material specifications:

- Carbon fiber reinforced polymers 5 for arm tubes

- Anodized aluminum for hinge pins

- Stainless steel fasteners throughout

- Sealed bearing assemblies 6 in all rotating joints

The IP67 rating deserves special attention. This means the drone survives temporary immersion in water. For agricultural drones exposed to pesticides, fertilizers, and cleaning procedures, this protection is essential. The DJI T30 core module carries IP67 certification, setting a useful benchmark.

Corrosion Resistance Testing

European agricultural chemicals attack unprotected metals aggressively. Request samples exposed to common herbicides and fungicides. After 48 hours of exposure, check for:

- Discoloration on aluminum surfaces

- Swelling of polymer components

- Stiffness changes in rubber seals

- Any visible pitting on steel parts

Our quality team rejects any joint design showing degradation in these tests. Your European farmer customers cannot afford mid-season failures due to chemical corrosion.

Which folding design will best help my customers transport large agricultural drones across narrow rural roads?

Our export team regularly hears from European distributors about transport challenges. Many farms connect via single-lane roads. Storage happens in centuries-old barns with low doorways. The folding design directly determines whether a drone fits these real constraints.

For European rural transport, arm-folding designs achieving 70-80% size reduction work best. Target folded dimensions under 1200mm length to fit standard pickup beds and SUV cargo areas. Cross-folding systems like the HF F20 (775x765x777mm folded) excel for tight storage, while upward-folding suits larger transport vehicles.

Dimension Comparison Across Popular Models

Understanding exact measurements helps you match drones to customer vehicle fleets. Here is how leading models compare:

| Model | Unfolded Dimensions (mm) | Folded Dimensions (mm) | Size Reduction |

|---|---|---|---|

| DJI T30 | 2858x2685x790 | 1170x670x857 | ~80% |

| HF F20 | 1397x1397x765 | 775x765x777 | ~69% |

| DJI T10 | 1676x1870x665 | 1030x530x765 | ~75% |

| ABZ L30 | 2400x2400x750 | 1100x650x800 | ~78% |

Vehicle Compatibility Considerations

European farms typically use these transport options:

Pickup trucks with bed dimensions around 1500-2000mm length can accommodate most folded agricultural drones. The DJI T30 folded length of 1170mm leaves room for batteries and support equipment.

SUVs and estate cars with cargo areas of 1000-1400mm length require more compact folding. The HF F20 at 775mm length fits even smaller vehicles, making it ideal for contractors visiting multiple farms daily.

Trailers offer flexibility but add complexity. If your customers prefer trailer transport, upward-folding designs work well since height matters less than footprint.

Weight Distribution in Folded State

A poorly balanced folded drone creates handling difficulties. When we design mounting solutions, we consider center of gravity placement.

The spray tank location significantly affects folded balance. Center-mounted tanks between the arms maintain stability. Wing-mounted tanks shift weight toward extremities, making the package awkward to lift.

Recommend customers invest in custom foam inserts or mounting brackets. These prevent shifting during transport and protect folding joints from impact damage.

Protection During Transit

Folded drones still need protection from road vibration and accidental impacts. Check these design elements:

- Propeller guards that remain in place when folded

- Camera and sensor covers integrated into the folding sequence

- Nozzle caps preventing contamination and damage

- Landing gear that absorbs shocks without transmitting force to folded arms

Some manufacturers offer transport cases designed for specific models. While adding cost, these cases dramatically reduce transit damage. The investment typically pays back after preventing just one repair.

Quick Deploy Requirements

European farmers value speed. Every minute spent unfolding means less productive spray time. We benchmark competitive designs against these targets:

| Operation | Target Time | Notes |

|---|---|---|

| Complete unfold | Under 60 seconds | Single operator, no tools |

| Propeller installation | Under 30 seconds | Quick-release preferred |

| Battery insertion | Under 15 seconds | Slide mechanism faster than latches |

| Pre-flight check completion | Under 2 minutes | Automated self-test ideal |

| Complete fold for transport | Under 90 seconds | Reverse of deployment |

Designs requiring tools or multiple operators for basic deployment lose competitiveness in the European market. Your customers need drones that one person can ready for flight within five minutes of arrival.

What features should I look for to ensure the folding joints don't lead to frequent maintenance issues for my clients?

When our service team analyzes warranty returns, folding joint failures account for significant repair costs. European farmers cannot wait weeks for parts during critical spray windows. Selecting designs with maintainability built in prevents these problems.

Ensure low-maintenance folding joints by selecting designs with tool-free access panels, standardized fastener sizes, visible wear indicators, grease fittings for lubrication, and modular replacement parts. Prioritize suppliers offering European service networks with parts availability under 48 hours.

Maintenance Access Design Elements

The best folding joint designs anticipate maintenance needs. During our design reviews, we evaluate these accessibility features:

Tool-free inspection panels let operators check joint condition without specialized equipment. Snap-fit covers work better than screwed panels for daily inspections.

Visible wear indicators show when components approach replacement thresholds. Color-coded markings that reveal underlying material when surface coating wears away provide clear signals.

Standardized fasteners across all joints simplify field repairs. A drone requiring five different wrench sizes creates unnecessary complexity. The best designs use no more than two fastener sizes throughout the folding system.

Common Joint Failure Modes

Understanding how joints fail helps you evaluate prevention features:

| Failure Mode | Cause | Prevention Feature |

|---|---|---|

| Bearing seizure | Contamination ingress | Sealed bearing assemblies |

| Pin wear | Insufficient lubrication | Grease fittings with schedule |

| Housing crack | Impact damage | Reinforced impact zones |

| Locking mechanism slip | Spring fatigue | Positive mechanical locks |

| Corrosion binding | Chemical exposure | Dissimilar metal isolation |

Lubrication System Requirements

Agricultural drones operate in dusty, chemical-laden environments. Proper lubrication extends joint life dramatically.

Look for these lubrication features:

- Zerk fittings 7 allowing grease injection without disassembly

- Clear lubrication schedules in maintenance documentation

- Compatible lubricant specifications resistant to agricultural chemicals

- Wipers or seals preventing contamination of lubricated surfaces

We recommend clients establish 50-hour lubrication intervals for joints without sealed bearings. This simple practice prevents most wear-related failures.

Spare Parts Availability

European customers need rapid parts access. When evaluating suppliers, investigate:

European warehouse locations reduce shipping time from weeks to days. Ask if the manufacturer stocks folding joint components in EU facilities.

Parts commonality across model ranges simplifies inventory. If hinge pins share specifications between the 20L and 30L models, distributors can stock fewer part numbers.

Modular replacement units speed repairs. A complete joint assembly that swaps in minutes beats rebuilding individual components in the field.

Predictive Maintenance Integration

Advanced folding designs incorporate sensors monitoring joint health. While adding cost, these systems prevent unexpected failures:

- Strain gauges detecting abnormal loading patterns

- Temperature sensors identifying bearing friction increases

- Position encoders confirming complete lock engagement

- Cycle counters triggering maintenance alerts

The 2025-2026 trend points toward AI-enhanced monitoring. These systems learn normal operating patterns and flag deviations before they become failures. For high-end European operations, this technology offers compelling value.

Service Network Evaluation

Beyond the drone itself, evaluate the supplier's service capabilities:

| Service Factor | Minimum Standard | Preferred Level |

|---|---|---|

| Parts shipping to EU | Under 7 days | Under 48 hours |

| Technical support hours | Business hours CET | 24/7 availability |

| Repair documentation | English PDF manuals | Video tutorials |

| Training availability | Online courses | In-person EU sessions |

| Warranty coverage | 12 months | 24 months with extension options |

Our service agreements with European distributors include dedicated parts inventory. This ensures their customers never wait more than two days for critical folding joint components.

How does the folding structure affect the flight stability and spray precision required by high-end European farms?

Our flight test pilots notice immediate differences between folding designs when conducting precision spray trials. European vineyards and orchards demand centimeter-level accuracy. Any structural flex or vibration from folding joints degrades performance.

Folding structures affect flight stability through arm rigidity, weight distribution, and vibration transmission. High-end European applications require locked joints achieving over 95% of fixed-arm stiffness, symmetric weight balance within 2% tolerance, and vibration damping preventing resonance. RTK positioning only performs optimally when the airframe remains stable.

Structural Rigidity Requirements

When arms fold, the locking mechanism must eliminate all play. Even small amounts of joint looseness create problems:

Angular deflection under spray payload causes uneven nozzle patterns. If one arm droops 2 degrees more than others, spray distribution becomes asymmetric.

Vibration amplification occurs when loose joints resonate with motor frequencies. This creates oscillations that confuse stabilization systems and reduce GPS accuracy.

Control system compensation for flexible structures consumes processing power and reduces response time. Rigid airframes allow more aggressive flight control tuning.

Testing Rigidity in Folding Designs

Request these test results from potential suppliers:

| Test | Acceptable Result | Excellent Result |

|---|---|---|

| Static deflection under load | Under 5mm at arm tip | Under 2mm at arm tip |

| Natural frequency | Above 15 Hz | Above 25 Hz |

| Joint play after 100 cycles | Under 0.5 degrees | Under 0.1 degrees |

| Torsional stiffness | Over 80% of welded equivalent | Over 95% of welded equivalent |

Weight Balance Considerations

European terrain includes slopes, terraces, and uneven orchard floors. Drones must maintain stability across varied attitudes. Folding designs affect weight balance in several ways:

Asymmetric folding sequences can leave one side heavier during deployment. This creates momentary instability during takeoff.

Component placement within folded packages shifts center of gravity. Designs keeping heavy items central perform better.

Payload mounting points must maintain balance as tank contents deplete. The best designs place spray tanks at the geometric center.

Spray Precision Impact Factors

High-end European farms expect these precision levels:

- Position accuracy: Under 10cm with RTK correction

- Spray width consistency: Within 5% of target

- Flow rate variation: Under 3% across all nozzles

- Height maintenance: Within 20cm of target above canopy

Folding structures that flex or vibrate make these targets difficult to achieve. Our testing shows that poorly designed folding joints can degrade positioning accuracy by 30-50%.

Terrain Following Capability

European vineyards feature dramatic elevation changes. Drones must adjust altitude continuously while maintaining spray height. This requires:

Rapid sensor response from terrain-following radar 8 or lidar. Structural vibration creates noise in these sensors.

Stable platform for accurate height measurement. Arms that oscillate produce false readings.

Consistent spray geometry regardless of pitch and roll angles. Rigid structures maintain nozzle orientation.

Obstacle Avoidance Integration

Modern agricultural drones include omnidirectional radar 9 for obstacle detection. The DJI systems exemplify this trend. Folding affects obstacle avoidance through:

Sensor mounting stability ensuring consistent detection angles. Vibrating mounts create blind spots.

Radar reflection patterns from the drone's own structure. Poorly designed folding mechanisms can create false returns.

Response time requirements for autonomous avoidance. Flexible structures take longer to execute evasive maneuvers.

Performance Comparison: Folding vs. Fixed

For complete transparency, here is how folding designs typically compare to fixed-arm alternatives:

| Performance Metric | Fixed Arm | Quality Folding | Economy Folding |

|---|---|---|---|

| Structural rigidity | 100% baseline | 90-98% | 70-85% |

| Maximum payload | Highest | 5-10% reduction | 15-25% reduction |

| Vibration level | Lowest | 10-20% higher | 30-50% higher |

| Maintenance interval | Longest | 10-20% shorter | 30-40% shorter |

| Transport convenience | Poorest | Excellent | Good |

For European farms with adequate transport capacity, the rigidity advantages of fixed arms deserve consideration. However, most operations benefit more from folding convenience, provided quality joints maintain adequate stiffness.

Conclusion

Evaluating agricultural drone folding designs requires attention to durability, transport dimensions, maintenance accessibility, and flight stability. By testing mechanisms thoroughly and matching specifications to European farming conditions, you can source equipment that builds lasting customer relationships. Our team remains available to discuss specific requirements for your market.

Footnotes

1. Explains the IEC 60529 standard for ingress protection against dust and water. ↩︎

2. Official EU information on CE marking requirements for products sold in the European Economic Area. ↩︎

3. Official EASA regulations and framework for drone and UAS operations in Europe. ↩︎

4. Discusses the advantages of injection molding for producing precise and durable parts. ↩︎

5. Provides a comprehensive overview of the properties and applications of CFRPs. ↩︎

6. Explains the benefits of sealed bearings in preventing contamination and extending service life. ↩︎

7. Describes the purpose and function of Zerk fittings in lubrication systems. ↩︎

8. Explains how terrain-following radar enables aircraft to maintain constant altitude above ground. ↩︎

9. Discusses the application of omnidirectional radar for obstacle detection in drones. ↩︎

10. Details Real-Time Kinematic (RTK) GPS technology for highly accurate positioning data. ↩︎