We often see clients worried about reliability when sourcing equipment for mission-critical operations. mission-critical operations 1 Safety depends on trusting your hardware completely.

You must verify component manufacturing dates against the final assembly date and inspect physical wear on connectors. Requesting milliohm meter readings for motors and checking battery cycle counts in the management software ensures no prior usage exists before delivery.

Let’s explore the practical steps you can take to verify your new equipment.

What visible signs of wear on motors and connectors should I look for during inspection?

During our final assembly checks in Chengdu, we reject any part with even microscopic imperfections to ensure longevity.

Inspect motor windings for discoloration indicating heat stress and check connectors for insertion marks or scratches on gold-plated pins. Additionally, look for stripped screw heads or dust accumulation in cooling vents, which are clear indicators of previous refurbishment or heavy use.

When you first unbox a firefighting drone, the physical condition of the hardware tells a story that paperwork might hide. In our factory, we train our quality control team to look for "micro-evidence" of usage. quality control team 2 A drone might look pristine on the outside, especially if the supplier has replaced the outer shell. However, the internal mechanical components are much harder to mask if they have seen previous action. internal mechanical components 3

Inspecting the Propulsion System

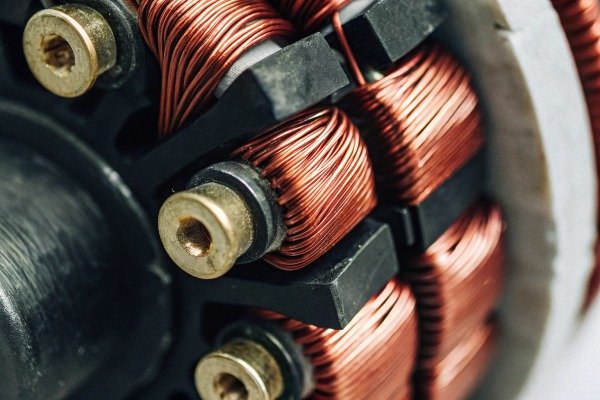

The motors are the heart of your drone. On our black quadcopters with the X-shape arm configuration, the motors are exposed and easy to inspect. You should look closely at the copper windings inside the motor bell. copper windings 4

- Winding Color: Brand-new copper windings should have a bright, consistent orange-gold color. If you see dark spots, brown discoloration, or a "burned" look, the motor has likely been subjected to high heat from previous flights.

- Bearing Noise: Spin the propeller mount gently by hand. A new motor should be silent and smooth. A gritty feeling or a faint clicking sound suggests the bearings are worn or have ingested dust, which is common in refurbished units that were not properly serviced.

- Mounting Screws: Look at the screws holding the motors to the arms. If the paint on the screw heads is chipped or if the metal looks stripped, someone has removed and reattached those motors. In a factory setting, we use precision torque drivers that do not damage the screw heads.

Connector and Port Analysis

Connectors are the most frequent point of failure in refurbished drones. Every time a cable is plugged in and removed, it leaves a microscopic trace.

- Gold Plating: Inspect the gold-plated pins on the battery terminals and gimbal ports. Virgin connectors will be flawless. If you see linear scratches or dull patches on the gold plating, that component has been mated multiple times.

- USB and Data Ports: Check the area around the USB-C or data ports on the flight controller. contrôleur de vol 5 "Misses" (scratches around the port where a plug didn't go in straight) are a sign of human use. A factory-fresh unit typically only has one or two insertion cycles for programming and testing.

The Chassis and Hardware

Our SkyRover units feature a distinct bright orange top casing for visibility. While this plastic is durable, it is also a canvas for evidence.

- Cooling Vents: Use a flashlight to look inside the cooling vents of the main body. Dust accumulation on the internal heatsinks is a smoking gun for a used unit. It is nearly impossible to fully clean dust out of a heat sink without disassembling the electronics entirely.

- Gimbal Mounts: The vibration dampeners (rubber balls or silicone pads) holding the camera underneath should be firm and free of cracks. Aged rubber becomes brittle or develops micro-cracks, indicating the unit sat in a warehouse or was flown for many hours.

Comparison Table: Factory New vs. Refurbished Signs

| Composant | Factory New Condition | Signs of Refurbishment/Use |

|---|---|---|

| Motor Windings | Bright, consistent copper color. | Darkened, brownish, or inconsistent color due to heat. |

| Screw Heads | Pristine paint, sharp edges. | Paint chips, stripped metal, signs of tool slippage. |

| Battery Pins | Flawless gold plating. | Vertical scratches, dullness, or carbon buildup. |

| Cooling Vents | clean, dust-free internals. | Gray dust accumulation on fans or heatsinks. |

| Amortisseurs en caoutchouc | Flexible, uniform color. | Brittle texture, micro-cracks, or fading. |

How can I use component serial numbers to trace the actual manufacturing date of the parts?

We track every electronic speed controller and flight computer in our internal database to prevent inventory aging issues.

Compare the date codes printed on Printed Circuit Board Assemblies (PCBAs) with the drone’s final assembly certificate. If internal components show manufacturing dates significantly older than the drone’s production date, the supplier likely used recycled or legacy inventory.

Tracing the genealogy of your drone’s components is one of the most effective ways to expose a refurbished unit. Suppliers who refurbish drones often take a crash-damaged unit, put it in a new shell, and sell it as new. While the shell is new, the electronics inside might be two or three years old. This poses a significant risk for firefighting operations where component reliability is non-negotiable. opérations de lutte contre l'incendie 6

Decoding PCBA Markings

Almost every Printed Circuit Board Assembly (PCBA) inside a drone has a manufacturing date code. You may need to remove the top orange casing to see the main flight controller or the Electronic Speed Controllers (ESCs). Contrôleurs électroniques de vitesse 7

- The Format: Most electronics manufacturers use a YYWW format (Year/Week) or a YYYYMMDD stamp. For example, a code reading "2345" means the board was manufactured in the 45th week of 2023.

- The Discrepancy Test: If your drone was delivered in June 2024, but the internal flight controller is stamped with a date from 2021, you have a problem. In our production line, inventory turnover is rapid. A gap of more than 6-8 months between component manufacture and final assembly is rare for a high-volume manufacturer. A multi-year gap strongly suggests the part was salvaged from an older unit.

Cross-Referencing with Manufacturer Databases

As a buyer, you should record the serial numbers of the major sub-systems, not just the drone's main hull.

- The "Frankenstein" Drone: A legitimate factory unit will have serial numbers that are sequential or batched together. In a refurbished "Frankenstein" drone, the motor serial numbers might be from completely different production batches.

- Verify Online: Many major component suppliers (like those who make the specific thermal sensors or high-end flight controllers) allow you to check warranty status online. If you input a serial number and see that the warranty expired last year, or that the component was "Activated" two years ago, the supplier has sold you used goods.

The "Gray Market" Risk and Capacitor Aging

Why does the date matter if the part still works? Electronic components, specifically capacitors, have a shelf life. Electronic components 8

- Electrolytic Capacitors: These components can dry out over time, especially if they have been subjected to heat cycles in a previous drone. An old ESC with aged capacitors may fail under the heavy load of a firefighting mission, causing the drone to fall from the sky.

- Firmware Mismatches: Older hardware often cannot run the latest firmware efficiently. If you find that your "new" drone struggles to update to the latest safety features, check the hardware version on the mainboard. safety features 9 It might be an obsolete revision that was discontinued years ago.

Common Date Code Locations and Formats

| Composant | Typical Location of Date Code | Common Format | Panneau d'avertissement |

|---|---|---|---|

| Contrôleur de vol | Printed directly on the PCB or on a sticker near the main processor. | YYWW (e.g., 2402) | Date is >1 year older than delivery date. |

| ESC (Speed Controller) | On the capacitor or the flat side of the PCB. | YYYY-MM (e.g., 2023-11) | Mismatch between the 4 ESCs (different batches). |

| Rotule/Caméra | On the ribbon cable or the rear metal casing of the sensor. | QR Code or Serial String | Serial number shows "Activated" status online. |

| Batterie | On the back label or embedded in the smart chip. | DDMMYYYY | Cycle count > 0 despite "new" label. |

Can I detect previous usage history by analyzing the drone's initial flight logs and system data?

Our software engineers program the flight controllers to log every second of operation starting from the very first test bench run.

Connect the aircraft to its diagnostic software to review the internal “black box” logs for flight hours predating your receipt. Brand new units should show zero user flights and single-digit battery cycles, with only brief factory test records visible.

Digital forensics is often the smoking gun that proves a supplier is dishonest. While a supplier can polish a scratched casing or replace a propeller, wiping the deep-level system logs of an industrial drone is difficult and often overlooked by refurbishers. When we export our SkyRover drones, the only data on the system is from our specific Quality Assurance (QA) flight test in Xi'an.

Analyzing Battery Management System (BMS) Data

The smartest component in modern drones is often the battery. Industrial drone batteries record their own history.

- Cycle Count: This is the most critical metric. A "Cycle" is defined as one full charge and discharge. A brand-new battery should have a cycle count of 0 or 1 (due to factory activation). If you see a cycle count of 15, 50, or 100, that battery is used.

- Cell Deviation: In the battery software tab, look at the voltage of each individual cell. In a new battery, all cells should be perfectly balanced (e.g., 4.20V, 4.20V, 4.20V). If you see significant deviation (e.g., 4.20V, 4.15V, 4.05V), the battery chemistry is degrading, which happens after repeated use or poor storage.

Internal Flight Log Review

Most industrial flight controllers maintain an internal "Black Box" that records flight events.

- Ghost Flights: Connect the drone to the assistant software on your PC. Look at the flight records. If you see GPS coordinates corresponding to a location you have never been to—perhaps a field in another country or a different state—that is proof of previous ownership.

- Timestamp Analysis: Check the dates of the logs. If the drone was supposedly manufactured in May 2024, but there are error logs or flight records from December 2023, the flight controller is second-hand.

- Total Flight Time: There is a "Total Mileage" or "Total Hours" counter deep in the system settings. A factory test flight usually lasts 5 to 15 minutes. If the total flight time reads 20 hours, the unit is refurbished.

Error Code History

Refurbished drones are often built from "crashed" units. Sometimes, the damage history is preserved in the error logs.

- Critical Failures: Look for past flags like "Motor Obstructed," "Impact Detected," or "Barometer Error." If these errors appear in the history log with timestamps predating your purchase, it indicates the sensors were involved in an incident.

- Persistent Errors: Sometimes, a refurbished sensor will still throw intermittent errors. If you see a recurring "Compass Error" immediately upon unboxing, it is likely a damaged component that was not replaced during the refurbishment process.

Investigating System Data: A Checklist

- Download the Assistant Software: Install the manufacturer's diagnostic tool.

- Connect via USB: Use a high-quality data cable.

- Navigate to "Battery Info": Check "Times Charged" or "Cycle Count." Target: < 2.

- Navigate to "Data Log" or "Black Box": Sort logs by date. Target: Only recent QA dates.

- Check "Total Flight Distance": Target: < 5km (allowance for factory testing).

- Review "Module Status": Ensure all serial numbers match the physical stickers.

What specific quality control reports should I ask the supplier for to prove all components are brand new?

Before we ship any unit to the US or Europe, we generate a comprehensive data packet that validates the integrity of every subsystem.

Demand component-level Certificates of Conformance (CoC) for critical systems like the thermal camera and flight controller. Also, request a fresh radiometric calibration certificate for the payload to prove the sensor has not suffered pixel degradation from prior exposure.

Paperwork is your legal shield and your technical verification. Many buyers simply accept a generic "Quality Passed" sticker on the box. However, for industrial firefighting drones, you need granular proof. We always advise our clients to stipulate specific documentation requirements in their purchase contracts. If a supplier hesitates to provide these, it is a red flag.

The Certificate of Conformance (CoC)

A general warranty is not the same as a CoC. A Certificate of Conformance is a formal document certifying that the specific serial number you received meets all original manufacturing standards and is brand new.

- Component Level: Do not just ask for a CoC for the "Drone." Ask for a CoC for the Contrôleur de vol, the CSE, and the Moteurs.

- Traceability: The CoC should list the specific batch numbers. This creates a paper trail. If a motor fails later, we can trace it back to the specific batch of copper wire used. A refurbisher cannot provide this because they do not know the origin of their salvaged parts.

Thermal Camera Calibration Reports

For firefighting drones, the thermal camera (mounted underneath the black fuselage) is the most expensive and sensitive component. caméra thermique 10

- Radiometric Calibration: Thermal sensors degrade if looked at the sun or high-intensity heat sources for too long (a common occurrence in used firefighting drones). A brand-new sensor comes with a factory calibration certificate dated close to your purchase.

- Pixel Dead Count: The report should certify that there are zero dead pixels. Used sensors often develop "stuck" pixels that show up as white or black dots on the screen, which can be dangerous when trying to identify hotspots in a fire.

Factory Acceptance Test (FAT) Checklists

You should ask for a copy of the actual "End of Line" test report. This is not a blank template, but the actual sheet filled out by the technician who tested your specific drone.

- Values, Not Just Checkmarks: A real FAT report contains data. Instead of just a checkmark next to "GPS Test," it should say "Satellites Locked: 18, Signal Strength: Strong." Instead of "Motor Test: Pass," it might list "Idle Current: 1.2A."

- Technician Sign-off: It should include the name or ID of the QA engineer and the date. This proves that a human actually verified the drone before it was placed in the box. Refurbished units often lack this specific data because they are batch-tested quickly without detailed logging.

Essential Documents for Verification

- Bill of Materials (BOM) Validation: A document listing the serial numbers of all major sub-components (Arms, Motors, Camera, Flight Controller) matching the physical unit.

- Battery Safety Test Report: Proof that the specific battery batch passed UN38.3 (transport safety) and capacity testing.

- Payload Calibration Data: Date-stamped radiometric data for the thermal camera.

- Flight Test Log Output: A printed summary of the final test flight parameters (duration, max altitude reached, hover stability).

Conclusion

Determining if your firefighting drone uses refurbished parts requires a mix of physical inspection, digital forensics, and documentation review. By checking for physical wear on connectors, verifying PCBA date codes, analyzing flight logs for ghost data, and demanding rigorous Certificates of Conformance, you protect your department from the risks of unreliable equipment. Always insist on transparency—your safety depends on it.

Notes de bas de page

1. NIST provides standards for response robots used in mission-critical environments. ︎

2. ISO 9001 is the global standard for quality management systems in manufacturing. ︎

3. NASA documentation on mechanical components and structural integrity for aerospace systems. ︎

4. Technical documentation on motor winding technology from a leading motor manufacturer. ︎

5. IEEE standards and research regarding flight controller reliability and architecture. ︎

6. News report on the increasing use of drones in modern firefighting operations. ︎

7. General background on the function and components of ESCs in drones. ︎

8. University research lab specializing in the reliability and packaging of electronic components. ︎

9. FAA guidance on drone safety features and operations for fire departments. ︎

10. Explanation of radiometric thermal imaging from a leading sensor manufacturer. ︎