Every week on our production floor, we see procurement managers struggle with one costly mistake: accepting motor lifespan claims at face value Mean Time Between Failures (MTBF) 1. The result? Drones fail mid-season, spraying windows close, and crops suffer.

To verify centrifugal nozzle motor lifespan, request lab test reports showing Mean Time Between Failures (MTBF) data, cross-reference with documented real-world flight hours from existing users, physically inspect seals and bearings, and demand salt spray test certifications meeting ASTM B117 standards from your supplier.

This guide breaks down exactly what our engineering team has learned from years of manufacturing and exporting agricultural drones. Let’s walk through the verification process step by step.

How can I verify the manufacturer's lab test data and real-world flight hours for these nozzle motors?

When we ship drones to distributors in the US and Europe, the first question they ask concerns proof of durability. Lab data sounds impressive, but numbers without context mean nothing.

Verify motor lifespan by requesting MTBF certificates with test conditions specified, full load test reports showing temperature curves, and documented flight hour logs from reference customers. Cross-check lab data against field performance by asking for maintenance records from similar climate operations.

Understanding Lab Test Reports

Lab tests simulate real-world stress. However, not all tests are equal. When our engineers validate motors, we run them under specific conditions that mirror agricultural use.

Ask your supplier these questions:

- What load percentage was used during testing?

- What ambient temperature and humidity levels were simulated?

- How long did continuous operation tests run?

A quality supplier will provide full load test reports. These show motor temperature under maximum stress. If temperature exceeds 120°C consistently, expect reduced lifespan.

Key Data Points to Request

| Type de document | Ce qu'il prouve | Red Flag If Missing |

|---|---|---|

| MTBF Certificate | Average hours before failure | Supplier cannot quantify durability |

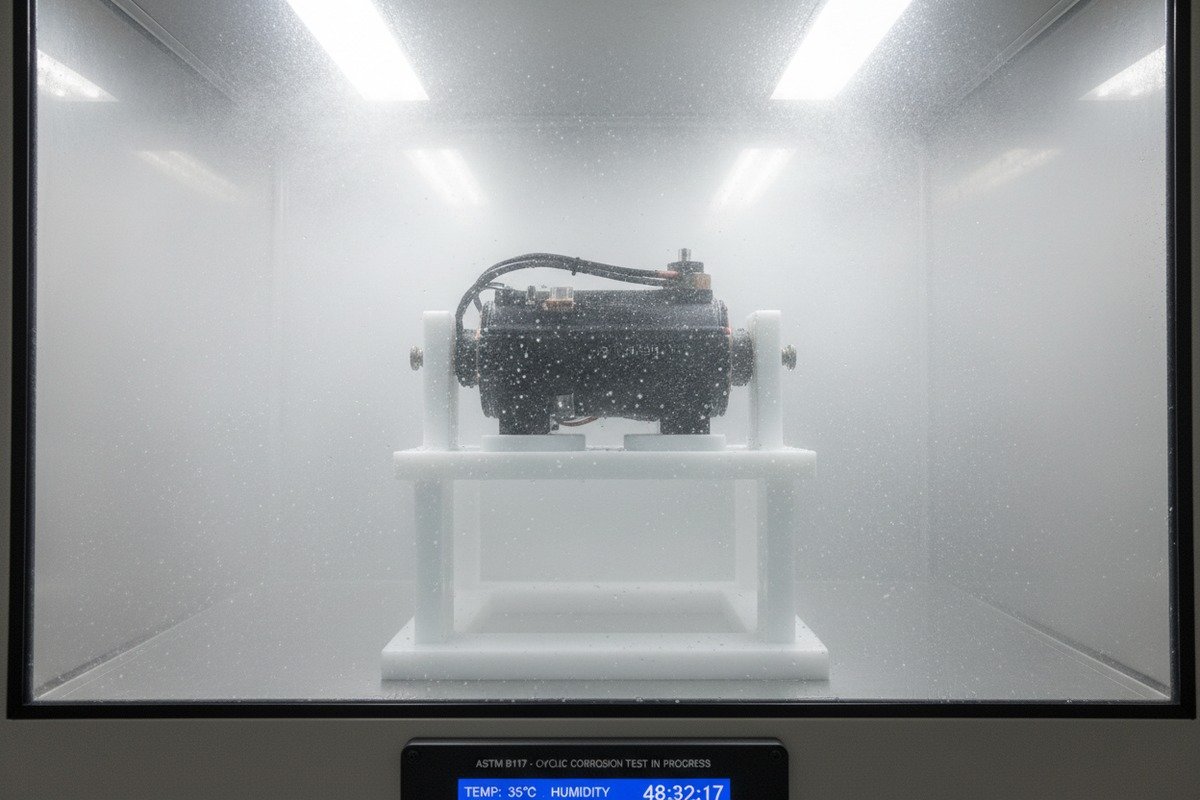

| Salt Spray Test 2 (ASTM B117) | Corrosion resistance | Motor will fail in humid/coastal areas |

| Full Load Test Report | Temperature stability | Overheating risk unknown |

| Dynamic Balance Certificate | Vibration control | Premature bearing wear likely |

| Flight Hour Logs | Real-world performance | No field validation exists |

Cross-Referencing Real-World Data

Lab conditions differ from rice paddies and orchards. We always recommend asking for reference contacts. Speak directly with operators using the same motors in similar environments.

Questions for reference customers:

- How many flight hours before first motor replacement?

- What maintenance schedule do they follow?

- Have they experienced unexpected failures?

In our experience exporting to coastal regions, motors without proper corrosion protection fail 20-50% faster than lab predictions suggest. Real-world humidity and salt exposure accelerate wear significantly.

Warning Signs in Documentation

Beware of suppliers who only provide marketing brochures. Genuine test data includes specific numbers, test dates, and laboratory identification. Generic statements like "long-lasting" or "durable" without data should raise concerns.

Our quality control team rejects motors if documentation lacks test condition specifics. Your procurement standards should be equally strict.

What specific motor build quality features should I look for to ensure long-term durability in my agricultural operations?

On our assembly line, we see the difference quality components make. Two motors can look identical externally. Internally, one lasts 1500 hours while the other fails at 400.

Look for industrial-grade brushless DC motors with ceramic or stainless steel bearings, corrosion-resistant windings, IP45-IP55 ratings, and high-quality magnets resistant to demagnetization. Verify the motor operates at 80-87.5% efficiency under typical loads to prevent overheating and premature wear.

Motor Type Selection

Industrial agricultural applications demand brushless DC motors 3. These outperform brushed alternatives significantly. Here's why:

Brushless motors eliminate brush friction. No brushes mean no brush replacement. They also run cooler and more efficiently.

When we design our spraying drones, we select motors rated for 10,000+ theoretical hours. However, centrifugal nozzle applications reduce this due to chemical exposure.

Critical Build Quality Indicators

| Composant | Quality Indicator | Expected Lifespan Impact |

|---|---|---|

| Bearings | Ceramic > Stainless > Brass | Ceramic: 3-5x longer than brass |

| Windings | Corrosion-resistant coating | 30-50% longer in humid conditions |

| Magnets | High-grade neodymium | Resists demagnetization under heat |

| Housing | Aluminum alloy with coating | Prevents external corrosion |

| Shaft | Hardened steel | Reduces wear from spinning disc |

Bearing Quality Matters Most

Bearings determine motor longevity more than any other component. In centrifugal nozzles, the shaft spins at high speeds continuously. Poor bearings fail fast.

When we calibrate our centrifugal systems, we test bearing smoothness manually. The shaft should spin freely without grinding or resistance. Any roughness indicates quality issues.

Ceramic bearings 4 cost more but last 3-5 times longer than brass alternatives. For high-intensity operations, this investment pays off quickly.

Efficiency and Load Considerations

Motors operating outside their optimal efficiency range wear faster. The sweet spot is 80-87.5% efficiency under normal agricultural loads.

Ask your supplier for efficiency curves 5. If the motor runs at 95% capacity during standard spraying operations, it will overheat. Overheating degrades winding insulation and bearing lubrication.

Our engineering team sizes motors with 20-30% headroom above typical operational loads. This buffer prevents stress damage during demanding applications.

Material Quality for Agricultural Exposure

Pesticides are corrosive. Humidity accelerates this corrosion. Motors need protection against both.

Look for:

- Epoxy-coated windings

- Stainless steel or ceramic contact surfaces

- Sealed bearing enclosures

- Corrosion-resistant housing materials

Motors without these features may work fine initially. After 200-300 hours of pesticide exposure, corrosion begins degrading performance.

How do I evaluate if the motor's sealing and cooling systems are sufficient for my harsh field environments?

When we test drones for export to humid rice-growing regions, sealing and cooling become critical. Motors that perform well in dry climates fail quickly in tropical conditions.

Evaluate sealing by checking IP ratings (minimum IP45 for agricultural use), inspecting gasket quality at all entry points, and verifying cable gland integrity. Assess cooling by reviewing thermal management design, airflow pathways, and heat dissipation features like aluminum housings or integrated heat sinks.

Understanding IP Ratings

Indices IP 6 indicate protection against dust and water. For agricultural drones, minimum IP45 is essential. IP55 provides better protection for wet conditions.

| Indice IP | Dust Protection | Water Protection | Suitability |

|---|---|---|---|

| IP44 | Protected from objects >1mm | Splash resistant | Indoor/dry only |

| IP45 | Protected from objects >1mm | Low-pressure jets | Standard agricultural |

| IP54 | Dust protected | Splash resistant | Dusty environments |

| IP55 | Dust protected | Low-pressure jets | Humid/wet conditions |

| IP65 | Dust tight | Low-pressure jets | Extreme conditions |

Physical Sealing Inspection

When we receive motors from our suppliers, our quality team inspects every seal point. You should conduct similar inspections.

Check these areas:

- Motor housing seams for gaps

- Cable entry points for proper glands

- Shaft seal where it exits the motor

- Any ventilation openings for protective covers

Run your finger along seams. Any gap allows dust and moisture entry. Even microscopic openings cause problems over hundreds of flight hours.

Cooling System Evaluation

Agricultural drone motors generate significant heat. Without adequate cooling, temperatures exceed safe thresholds quickly.

Look for these cooling features:

Passive cooling: Aluminum housings dissipate heat naturally. Fins or ribbed surfaces increase heat dissipation area.

Active cooling: Some designs include small fans or airflow channels. These move heat away from critical components.

Thermal monitoring: Quality ESCs include temperature sensors. These alert operators before damage occurs.

Our drones use ESCs that cut power if motor temperature exceeds 120°C. This protection prevents permanent damage but also indicates the motor is working too hard.

Environmental Stress Testing

Ask suppliers about environmental testing protocols. Quality manufacturers test beyond standard conditions.

Questions à poser :

- Has the motor been tested in salt spray environments?

- What humidity levels were used during testing?

- How does the motor perform after dust exposure?

Motors destined for coastal agricultural areas need salt spray testing per ASTM B117 standards 7. Without this validation, corrosion failures are likely within one to two seasons.

Field Environment Matching

Match motor specifications to your specific conditions. A motor perfect for California almond orchards may fail quickly in Louisiana rice paddies.

Consider:

- Average humidity in your operating region

- Dust levels during typical operations

- Chemical types being sprayed

- Operating temperature ranges

When we customize drones for different export markets, we adjust sealing and cooling specifications accordingly. Your procurement process should include similar environmental matching.

What technical documentation should I request from my supplier to guarantee the motor's lifespan meets my procurement standards?

Before we ship any drone order, our documentation package includes everything a professional buyer needs. Your supplier should provide equally comprehensive materials.

Request MTBF/TBO certificates, salt spray test results (ASTM B117), full load test reports, efficiency curves, IP rating certificates, dynamic balancing reports, material certifications, warranty terms specifying hour limits, and if available, blockchain-verified component provenance for critical parts.

Liste de contrôle des documents essentiels

Create a standardized documentation request for all suppliers. This ensures consistent evaluation across potential vendors.

| Document Category | Specific Documents | Objectif |

|---|---|---|

| Performance Testing | MTBF certificate, TBO specifications | Quantifies expected lifespan |

| Environmental Testing | Salt spray test, humidity test, dust test | Validates durability claims |

| Quality Certification | ISO certificates, material specs | Confirms manufacturing standards |

| Operational Data | Efficiency curves, temperature limits | Enables proper usage planning |

| Warranty Documentation | Hour limits, coverage terms, exclusions | Protects your investment |

| Traceability | Component origin, batch numbers | Enables quality tracking |

Understanding MTBF and TBO

MTBF (Mean Time Between Failures) indicates average operational hours before failure. TBO (Time Between Overhaul) specifies when maintenance is required.

For agricultural centrifugal nozzle motors, expect:

- Industrial grade: 800-1500 hours MTBF

- Consumer grade: 300-500 hours MTBF

- DJI reference standard: 700 hours recommended replacement

These numbers assume proper maintenance. Without regular cleaning and inspection, actual lifespan decreases significantly.

Warranty Terms Analysis

Warranty documentation reveals supplier confidence in their products. Analyze terms carefully.

Red flags in warranty terms:

- No hour-based coverage limits specified

- Exclusions for "agricultural use" or "chemical exposure"

- Requirements for authorized service only (unavailable in your region)

- Very short coverage periods (under 6 months)

Strong warranty indicators:

- Specific hour guarantees (e.g., 500 flight hours)

- Coverage for agricultural applications explicitly stated

- Parts availability guarantees

- Clear replacement procedures

Emerging Documentation Standards

Blockchain verification 8 for component provenance is becoming available. This technology creates tamper-proof records of manufacturing quality, material sourcing, and service history.

While not yet standard, suppliers offering blockchain-verified documentation demonstrate commitment to transparency. Ask if this option exists.

Building Your Procurement File

Organize documentation systematically. For each potential supplier, create a file containing:

- Initial specification sheets

- Test certificates and reports

- Reference customer contacts

- Warranty terms

- Communication records

This file becomes valuable if disputes arise later. It also enables comparison between suppliers during evaluation.

Verification of Documentation Authenticity

Unfortunately, fraudulent documentation exists. Verify authenticity when possible.

Verification methods:

- Contact testing laboratories directly to confirm certificates

- Check ISO certification databases for supplier listings

- Request original documents rather than copies

- Look for consistent formatting and professional presentation

Our quality assurance team catches falsified documents regularly. Inconsistent dates, missing laboratory details, and generic language indicate potential fraud.

Conclusion

Verifying centrifugal nozzle motor lifespan requires systematic evaluation of lab data, build quality, environmental protection, and documentation. Request specific certifications, inspect physical components, and always cross-reference supplier claims with real-world user experiences.

Notes de bas de page

1. Replaced with an authoritative Wikipedia page explaining MTBF. ︎

2. Replaced with an authoritative Wikipedia page explaining the Salt Spray Test. ︎

3. Details the advantages and characteristics of brushless DC motors for industrial applications. ︎

4. Highlights the benefits of ceramic bearings for extending motor lifespan and improving efficiency. ︎

5. Explains how to interpret motor efficiency curves for optimal motor selection and performance. ︎

6. Provides a detailed explanation of IP ratings for dust and water protection. ︎

7. Defines ASTM B117 as the benchmark standard for salt spray corrosion testing. ︎

8. Replaced with a clear and concise explanation of blockchain verification. ︎