We understand the immense pressure you face when a drone is grounded during a critical mission. At our factory, we see firsthand how vital reliable components are for your fleet's uptime, and we know that standard consumer warranties simply cannot support the intensity of firefighting operations.

You should request a minimum 12-month or 500-hour warranty for motors and flight controllers, covering manufacturing defects and thermal stress failures. Crucially, negotiate for "Advance Replacement" to ship spares within 48 hours and ensure coverage includes protection against chemical ingress from firefighting foams.

To help you navigate these negotiations and protect your investment, we have broken down the specific terms and clauses you need to secure from your supplier.

What is the standard warranty period for industrial drone motors?

In our testing labs, we push motors to their limits to ensure they withstand extreme heat, yet we know standard policies often fail to reflect this reality. You need coverage that matches the high-intensity demands of your daily operations.

Standard industrial warranties typically cover motors for 6 to 12 months. However, for high-intensity firefighting operations, you should negotiate usage-based terms, such as 200 to 500 hours of flight time, to account for the rapid wear caused by heavy payloads and high-temperature environments.

The Disconnect Between Calendar Days and Flight Hours

When we design industrial drones for firefighting, we calculate the lifespan of brushless motors based on operating cycles and thermal load, not calendar days. A motor sitting on a shelf for a year is very different from one that has flown 100 missions carrying fire extinguishing bombs.

brushless motors 1

Most standard contracts offer a "12-month warranty," which sounds sufficient on paper. However, this is often a trap for high-utilization users like fire departments. If your fleet flies daily, you might hit the mechanical wear limit of a bearing within three months. If the warranty is strictly time-based, you are covered. But if the supplier includes a "normal wear and tear" exclusion clause without defining flight hours, they can deny your claim by stating the motor was "overused."

mechanical wear 2

Negotiating a Hybrid Warranty Model

To protect your interests, we recommend pushing for a hybrid warranty model. This combines a calendar duration with a flight-hour cap. For example, "12 months or 300 flight hours, whichever comes first." This aligns the warranty with the actual mechanical life of the component.

Furthermore, you must address the "Thermal Stress Clause." Firefighting drones often operate near large fires where ambient temperatures are high. Standard motors are rated for specific temperature ranges. If a motor fails because the air intake was sucking in 50°C air, a standard warranty might void the claim due to "environmental abuse." You need a clause that explicitly covers failures resulting from operating within the manufacturer's stated high-temperature limits, ensuring you aren't penalized for doing your job.

ambient temperatures 3

Critical Component Warranty Comparison

Below is a comparison of what a standard consumer warranty offers versus what you should demand for industrial firefighting applications.

| Característica | Standard Consumer Warranty | Recommended Industrial Firefighting Warranty |

|---|---|---|

| Duration Basis | Time-only (e.g., 12 months) | Hybrid (e.g., 12 months or 500 hours) |

| Thermal Coverage | Void if overheated | Covers operation within rated high-temp limits |

| Wear & Tear | Excludes bearings/moving parts | Includes bearings up to specified hour limit |

| Ingress Protection | Void if water/dust damage found | Covers failure despite rated IP rating (e.g., IP54) |

| Proof of Failure | Visual inspection only | Flight log (Black Box) data analysis |

By clarifying these terms upfront, you avoid disputes later. We always advise our clients to look at the "MTBF" (Mean Time Between Failures) data we provide and base the warranty hours on that figure.

Mean Time Between Failures 4

Does the warranty cover replacement parts and shipping costs?

We often see clients surprised by hidden shipping fees and long wait times when returning defective units to China. Clear terms regarding logistics and costs are essential to prevent unexpected expenses when you need repairs fast.

Most basic warranties cover the cost of replacement parts but exclude shipping fees. You must explicitly negotiate "two-way shipping" coverage for warranty claims and ensure the agreement includes a guaranteed stock of critical spares like propellers and arms to avoid supply chain delays.

The Hidden Cost of International Returns

When we export drones to the United States or Europe, the logistics of warranty returns can be the biggest friction point. A replacement motor might only cost $150, but shipping a heavy drone back to our factory in Chengdu for diagnosis can cost over $500 and take weeks.

Standard warranty terms usually state "Ex Works" or "FOB" for returns, meaning you pay to ship the broken part to the factory, and sometimes you even pay for the return shipping of the repaired unit. For a procurement manager, this is unacceptable. You should negotiate for DDP (Entrega con derechos pagados) terms on warranty replacements, where the supplier bears the cost of shipping the replacement part to your door.

Securing a Spare Parts List and Lead Time Guarantee

Beyond just the cost, time is your most valuable asset. A warranty is useless if the replacement part takes six weeks to arrive. We strongly suggest that before you sign a contract, you require the supplier to provide a comprehensive Spare Parts List (BOM) with associated lead times.

You should ask: "If a motor fails, do you have it in stock, or do you need to manufacture it?"

For critical components like motors, ESCs (Electronic Speed Controllers), and arms, you should negotiate an "Advance Replacement" agreement. This means that once you provide digital proof of failure (photos or logs), the supplier ships the replacement immediately, without waiting to receive the broken part first.

Recommended Spare Parts Strategy

We recommend structuring your procurement to include a "Crash Kit" or "Maintenance Kit" upfront, with a warranty clause that replenishes this kit.

| Categoría de componentes | Typical Lead Time (No Stock) | Recommended Stock Strategy | Warranty Negotiation Goal |

|---|---|---|---|

| Hélices | 1-2 semanas | Keep 2 sets per drone on-site | Consumable (usually not covered), buy in bulk |

| Motores | 2-4 Weeks | Keep 1 spare per 4 motors | Advance replacement within 48 hours |

| Controlador de vuelo | 2-4 Weeks | No stock needed (low failure rate) | Priority shipping if failure occurs |

| Arms/Landing Gear | 3-5 Weeks | Keep 1 set on-site | Coverage for structural defects |

The "Right to Repair" Clause

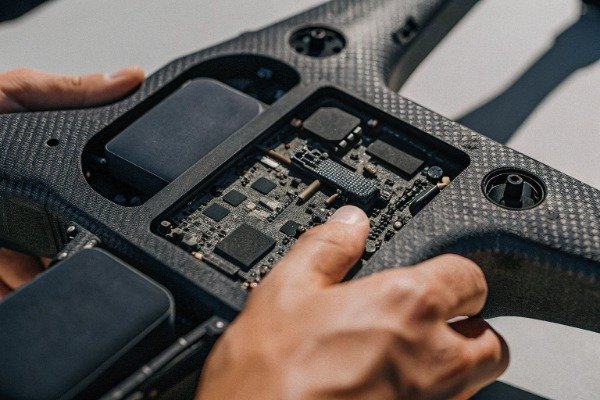

Another critical aspect is your ability to repair the drone yourself. Many warranties are void if the "warranty seal" is broken. However, shipping a drone back to China for a simple motor swap is inefficient.

warranty seal 5

You should negotiate a clause that allows "Certified In-house Repair." This allows your technicians to replace specific parts (like motors or arms) using OEM components without voiding the warranty on the rest of the system (like the flight controller). We often provide training videos to our distributors to facilitate this, as it saves time for everyone.

Our software engineers spend weeks debugging flight algorithms, so we understand that code errors can be just as fatal as hardware failure. You need assurance that software glitches won't leave your fleet grounded without recourse.

flight algorithms 6

Suppliers typically handle software claims by providing remote firmware patches or updates rather than hardware replacement. Ensure your warranty mandates free lifetime updates for stability bugs and requires the use of flight log data to objectively prove system failure versus pilot error.

Distinguishing Between Hardware and Software Failures

In the industrial drone sector, the line between a "bad motor" and a "software glitch" is often blurred. For instance, if a drone suddenly drops from the sky, was it a motor seizure or a flight controller command error?

Standard warranties often have a "hardware only" focus. They might say, "We warrant the physical goods." If the crash was caused by a firmware bug that shut down the motors mid-flight, a strict hardware warranty might deny the claim because the physical motor itself wasn't defective—it just received a bad command.

You must ensure your warranty covers "System Integration Failures." This means if the software causes a hardware crash, the hardware damage is covered.

The Role of Flight Logs (Black Box Data)

This is the single most important tool in warranty claims. Every industrial drone we manufacture records detailed flight logs. When a claim arises, the first thing we ask for is this data.

flight logs 7

However, disputes happen. A supplier might claim, "The logs show you flew too aggressively," while you know it was a stability failure. To protect yourself, negotiate a clause that mandates "Objective Log Analysis."

- Data Ownership: Ensure you have the right to access and interpret the logs yourself or via a third party.

- Dispute Resolution: If there is a disagreement on the log interpretation, agree on a neutral third-party expert or a standardized analysis protocol.

Firmware Updates and Long-Term Support

Software is never finished; it evolves. A firefighting drone bought in 2024 needs to work in 2027.

- Bug Fixes: The warranty must guarantee free patches for any safety-critical bugs for the lifetime of the product.

- Feature Updates: While new features might cost extra, stability updates should always be free.

- Compatibility: Ensure that if you update the ground station software, the flight controller firmware will still be supported.

Software Warranty Checklist

| Tipo de problema | Standard Supplier Response | What You Should Negotiate |

|---|---|---|

| Firmware Bug Crash | "Pilot Error" until proven otherwise | "System Failure" coverage including hardware repair |

| Update Bricking | Return to factory for reset | Remote desktop support to unbrick immediately |

| Feature Glitch | Wait for next scheduled update | Hotfix provided within 7 days for critical bugs |

| Map/Geo-fencing | Not covered | Updates to unlock No-Fly Zones for emergency auth |

By treating software as a critical component equal to the motor, you ensure that "invisible" failures don't become expensive visible costs.

Can I purchase an extended warranty for the flight control system?

We design our flight controllers to last, but the unpredictable nature of fire scenes adds risk that standard terms can't cover. Extended coverage offers peace of mind for long-term deployments and budget predictability.

Yes, many manufacturers offer extended warranties for flight control systems, often extending coverage up to three years. These plans frequently include "crash replacement" options for non-warranty accidents and priority technical support, which is essential for maintaining fleet readiness during peak fire seasons.

The Economics of Extended Warranties

Is an extended warranty worth it? For a consumer drone, maybe not. For a $20,000 firefighting drone, absolutely. The flight controller is the brain of the aircraft. If it fails out of warranty, the replacement cost is high, but the reconfiguration cost is even higher.

When we offer extended warranties, we aren't just selling insurance on the hardware; we are selling Acuerdos de Nivel de Servicio (SLA).

A standard warranty gives you a repair. An extended warranty should give you priority.

- Priority Queue: Your repair ticket jumps to the front of the line.

- Loaner Units: Some premium extended plans include a loaner drone while yours is being fixed.

"Crash Replacement" vs. Standard Warranty

This is a vital distinction. A standard warranty only covers manufacturing defects. If you fly into a tree because of smoke blinding the sensors, that is not a defect. It is an accident.

Extended warranties often function like "Hull Insurance." You pay a deductible (e.g., $500), and we replace the drone regardless of whose fault the crash was. For firefighting departments, where risks are high and "pilot error" is often just "operational hazard," this coverage is indispensable.

Hull Insurance 8

Future-Proofing Your Fleet

Industrial drones have a longer service life than consumer electronics. You might plan to use this fleet for 3 to 5 years.

- Obsolescence Protection: An extended warranty can sometimes guarantee parts availability. If we stop making that specific flight controller version, an extended warranty obligates us to provide a compatible upgrade or solution.

- Transferability: If you sell your older drones to a smaller department to upgrade your fleet, check if the extended warranty is transferable. This increases the resale value of your assets.

Evaluating the Cost

Typically, an extended warranty costs 10-15% of the hardware price per year.

- Scenario A (No Extended Warranty): Flight controller fails in Year 2. Cost: $2,000 for part + $500 labor + 3 weeks downtime.

- Scenario B (With Extended Warranty): Cost: $0 deductible + Priority Shipping + 3 days downtime.

If your department cannot afford downtime, the extended warranty is not an expense; it is an operational necessity.

Electronic Speed Controllers 9

Conclusión

Securing robust warranty terms for motors and flight controllers ensures your firefighting fleet remains operational and cost-effective. Focus on usage-based coverage, advance replacements, and comprehensive software support to minimize risk.

Ex Works 10

Notas al pie

1. Defines the specific type of electric motor used in industrial drones. ↩︎

2. Explains the physical degradation process affecting drone bearings. ↩︎

3. Provides context on environmental conditions that impact drone operation. ↩︎

4. Explains the reliability metric used to calculate warranty hours. ↩︎

5. References federal guidelines regarding warranty void stickers and repairs. ↩︎

6. Explains the complex software logic governing drone stability. ↩︎

7. Describes the data recording system used for accident investigation. ↩︎

8. Contextualizes the type of coverage compared to standard warranties. ↩︎

9. Describes the critical component responsible for regulating motor speed. ↩︎

10. Defines the international shipping term determining cost responsibility. ↩︎