Watching a drone crash due to a failed lock is a nightmare we work hard to prevent on our assembly floor.

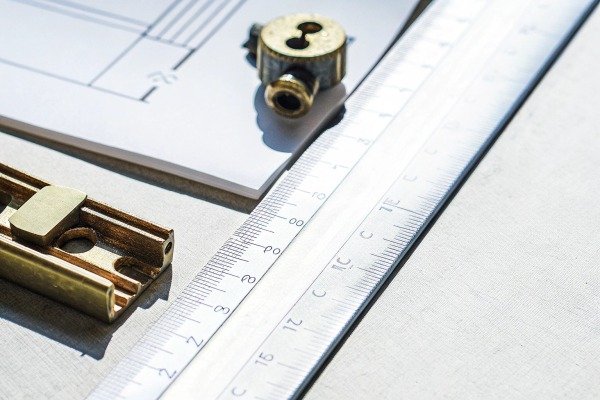

To evaluate arm locking safety, inspect the mechanism for secondary safety latches that prevent accidental disengagement precision CNC machining 1. Test the joint’s resistance to vibration by checking for play, verify the use of CNC-machined aluminum over plastic, and ensure the design includes wear-resistant components to handle heavy payload stresses.

Let’s explore the critical details that keep your drone airborne and your investment safe.

How can I ensure the arm locking mechanism won't loosen due to intense flight vibrations?

In our flight testing facility, we have seen how high-frequency vibrations can undo even tight bolts high-frequency vibrations 2 if not properly secured.

You must verify that the locking system features anti-loosening designs such as nylon-insert lock nuts or tension-based clamps. Check for tolerance precision in the pivot points, as any initial gap or movement will worsen rapidly under the stress of heavy spraying operations.

Agricultural Agricultural drones 3 drones operate in a unique environment compared to photography drones Anodization 4. They carry heavy liquid payloads that slosh around, creating dynamic shifts in weight. This, combined with the high torque of heavy-lift motors, generates intense high-frequency vibrations that travel through the frame. If an arm lock is not designed to dampen or resist these forces, it will eventually work itself loose.

The Role of Precision Tolerance

When we inspect locking joints, the first thing we look for is "play." This refers to any wiggle room in the joint when the arm is in the locked position. You should be able to shake the arm firmly without feeling any clicking or movement at the hinge. If there is even a millimeter of play when the drone is new, that gap will widen quickly.

Vibration acts like a hammer on these gaps. Over time, the metal fatigues, and the locking force diminishes. metal fatigues 5 High-quality drones use precision CNC machining to ensure the male and female parts of the joint fit perfectly. This tight fit creates friction that naturally resists vibration.

Anti-Loosening Features

Beyond the fit, the mechanical fasteners must have anti-loosening properties. Simple screws are not enough. You want to see:

- Nylon-insert nuts (Nyloc): These prevent nuts from backing off under vibration.

- Thread-locking compounds: Chemical adhesives applied to threads during assembly.

- Tension-adjustable clamps: These allow you to re-tighten the mechanism as parts wear down over time.

Assessing Wear Patterns

Vibration causes friction, and friction causes wear. A poor locking mechanism will show signs of metal dust or scraping after just a few flights. This is a red flag. The best systems use durable inserts or washers at the friction points to prevent the aluminum arm from grinding directly against the steel locking pin.

Vibration Safety Checklist

Use the table below to assess the vibration resistance of a potential drone purchase.

| Feature to Inspect | Por qué es importante | Safety Rating Impact |

|---|---|---|

| Zero-Play Fit | Prevents "hammering" effect at the joint. | Critical |

| Adjustable Tension | Allows maintenance to tighten loose locks. | Alto |

| Nyloc Nuts | Prevents fasteners from vibrating off. | Alto |

| Rubber Dampeners | Absorbs high-frequency motor noise. | Medio |

| Steel Bushings | Prevents aluminum wear at pivot points. | Alto |

Should I prioritize a threaded sleeve or a buckle design for maximum safety?

When designing our SkyRover series, we debated endlessly between the speed of buckles and the security of threaded sleeves.

Threaded sleeves generally offer superior security and vibration resistance for heavy-lift drones, as they tighten under load. However, buckle designs provide faster setup times. For maximum safety in agricultural operations, prioritize threaded sleeves or buckles that include an integrated secondary locking pin.

The debate between threaded sleeves (collars) and buckle clamps (quick-release) is common in the industry. Both have their place, but they serve different operational needs and safety profiles. Understanding the mechanics of each will help you choose the right tool for your specific farming operations.

The Case for Threaded Sleeves

Threaded sleeves are often considered the "gold standard" for safety in heavy-lift aviation. The mechanism involves a large nut that screws over the folding joint, physically encasing the hinge.

- Structural Integrity: Once tightened, the sleeve becomes a structural part of the arm. It distributes stress evenly around the entire circumference of the tube.

- Vibration Resistance: Threads have a large surface area of friction. It takes a significant amount of force to unscrew a sleeve, especially if it has a rubber O-ring to provide tension.

- Fail-Safe Nature: Even if a threaded sleeve loosens slightly, gravity and the upward thrust of the props often keep the arm in an upward, locked position relative to the sleeve.

The downside is speed. It takes time to screw and unscrew four or six arms every time you move fields.

The Case for Buckle Clamps

Buckle clamps, similar to those found on bicycle seats or tripods, are designed for speed. They use a cam lever to apply pressure.

- Efficiency: You can deploy a drone in seconds. This is vital for operators covering many small, scattered fields.

- Visual Confirmation: You can easily see if a lever is open or closed.

However, buckles rely entirely on tension. If the tension screw loosens, the clamp provides zero holding force. We have also seen buckles snag on clothing or branches, potentially popping open if not secured by a secondary pin.

Which is Safer for You?

If you are flying massive payloads (over 40 liters) where safety is the absolute priority, the threaded sleeve is harder to beat. The sheer mass of a fully loaded drone puts immense strain on the joints. A threaded sleeve handles this shear force better than a buckle pin. However, modern high-end buckles now come with locking buttons that prevent the lever from lifting. If you choose a buckle design, this feature is non-negotiable.

Comparison of Locking Mechanisms

| Característica | Threaded Sleeve (Collar) | Buckle Clamp (Quick-Release) |

|---|---|---|

| Setup Speed | Slow (requires turning) | Fast (flip lever) |

| Vibration Security | Excellent (high friction) | Moderate (needs tuning) |

| Visual Safety Check | Harder to verify at a distance | Easy to see lever position |

| Wear & Tear | Low (threads last long) | Medium (cam surfaces wear) |

| Snag Risk | Low (smooth profile) | Medium (lever sticks out) |

| Ideal para | Heavy payloads (>30L) | Rapid deployment (<30L) |

What materials should I look for to guarantee the long-term durability of the folding joint?

We reject many suppliers because their metal alloys corrode too quickly when exposed to common pesticides used in American fields.

Prioritize locking mechanisms made from CNC-machined aviation-grade aluminum (7075 or 6061) or stainless steel. Avoid standard plastics for load-bearing parts. Ensure the materials are treated with anodization or anti-corrosion coatings to withstand exposure to harsh agricultural chemicals and fertilizers.

The material of your arm lock is the only thing standing between a successful mission and a catastrophic mid-air structural failure. In agricultural settings, mechanical strength is not the only requirement; chemical resistance is equally important. chemical resistance 6

The Problem with Plastic

In our testing, we found that plastic composites, while lightweight, often fail in agricultural environments. Plastics are susceptible to:

- UV Degradation: Long days in the sun make plastic brittle.

- Chemical Reaction: Certain solvents in pesticides can soften or crack plastic housings.

- Fatigue: Plastic deforms under constant load (creep), causing the lock to loosen over time.

For a professional tool, the main locking knuckle should never be plastic.

Aviation-Grade Aluminum

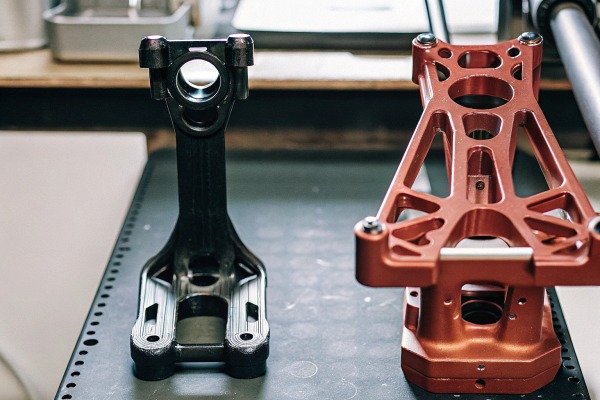

The industry standard for high-quality drones is aviation-grade aluminum, specifically 7075 or 6061 alloys.

- 7075 Aluminum: This alloy contains zinc and is incredibly strong, comparable to some steels, but lightweight. It is the best choice for the high-stress pivot pins and locking hooks.

- CNC Machining: Look for parts that are "CNC machined" rather than "cast." Cast aluminum can have internal air bubbles and is more brittle. Machined parts are cut from a solid block, ensuring consistent density and strength.

Corrosion Resistance is Key

Your drone will be covered in water, fertilizers, and pesticides. Many of these chemicals are corrosive. Many of these chemicals are corrosive 7 If the locking mechanism rusts, it may seize up (making it impossible to fold) or weaken until it snaps.

When evaluating a drone, ask about the surface treatment. Anodization is a process that thickens the natural oxide layer on aluminum parts, making them harder and resistant to corrosion. Stainless steel parts (like pins and springs) should be rated 304 or 316 for rust resistance.

Carbon Fiber Integration

While the lock itself is metal, it attaches to a carbon fiber arm. The interface between the metal lock and the carbon tube is a stress point. We inspect this bond rigorously. High-quality manufacturing uses industrial-grade adhesives and rivets to ensure the metal lock doesn't twist off the carbon tube.

Does the system include a secondary safety latch to prevent accidental unlocking?

Our engineering team insists on redundancy because we know that human error happens during rushed mornings on the farm.

A robust agricultural drone must include a secondary safety latch or a redundant locking pin. This backup system physically blocks the primary mechanism from opening during flight, even if the main clamp fails or is bumped, ensuring the arm remains rigid under load.

In aviation, redundancy is life. The concept of a "single point of failure" is something engineers try to eliminate. single point of failure 8 If a primary lock fails and there is nothing else to hold the arm, the drone falls. A secondary safety latch acts as that critical backup.

Types of Secondary Safety Mechanisms

There are several ways manufacturers implement this:

- Safety Pins: A simple steel pin that slides through the lock handle. The handle physically cannot be lifted unless the pin is removed. This is simple and effective.

- Spring-Loaded Buttons: On buckle designs, you often have to press a button while lifting the lever. This prevents a branch or a strap from accidentally flipping the lever open.

- Interference Fit: Some designs use a physical block that must be rotated out of the way before the main lock can engage or disengage.

Why Redundancy Matters for FAA Compliance

If you are operating in the United States under a Part 137 certificate Part 137 certificate 9 (for aerial application), you are responsible for the safe operation of the aircraft. During an inspection or when applying for exemptions (like the 44807 exemption for heavy drones) 44807 exemption 10, demonstrating safety features is crucial.

A secondary lock shows that the aircraft is designed to mitigate risk. It prevents "uncommanded configuration changes" (i.e., the drone folding itself up in mid-air). This is not just about protecting the hardware; it is about protecting people on the ground and preventing chemical spills.

Visual Confirmation

A good secondary lock also serves as a visual indicator. For example, if the safety pin cannot be inserted, it means the primary lock is not fully closed. This helps the pilot perform a pre-flight check more effectively. If the pin is in, the drone is safe. If it's not, do not fly.

Evaluating Safety Latch Features

| Característica | Descripción | Benefit |

|---|---|---|

| Passive Engagement | The safety latch clicks in automatically when locked. | Removes human error of forgetting to lock it. |

| Tool-Less Operation | Can be operated with gloves on. | Essential for field work. |

| High Visibility | Painted red or bright orange. | Easy to check during pre-flight inspection. |

| Tethered Components | Pins are attached to the frame with a wire. | Prevents losing small safety parts in the field. |

Conclusión

Evaluating the arm locking mechanism is about ensuring reliability under the harsh reality of farm work. By prioritizing vibration-resistant designs, durable materials like CNC aluminum, and redundant safety latches, you protect your investment and ensure safe, compliant operations.

Notas al pie

1. ISO standard for general tolerances in machining, ensuring precision in mechanical joint components. ↩︎

2. Provides scientific background on the nature of vibrations mentioned in the article. ↩︎

3. Example of a major manufacturer’s heavy-lift agricultural drone documentation. ↩︎

4. Official definition from the Aluminum Anodizers Council. ↩︎

5. Defines the specific material failure mode caused by vibration. ↩︎

6. Global organization providing guidance on pesticide management and equipment safety. ↩︎

7. Explains the electrochemical process used to protect metals from the corrosive chemicals mentioned. ↩︎

8. Authoritative definition of this engineering risk concept. ↩︎

9. Official FAA guidance for agricultural aircraft operations. ↩︎

10. Official FAA guidance on statutory requirements for operating heavy unmanned aircraft systems. ↩︎