Every week, our engineering team receives calls from frustrated buyers. Their agricultural drones failed mid-flight. Motors burned out. Crops went unsprayed. The culprit? Substandard Electronic Speed Controllers 1 that looked good on paper but collapsed under real field conditions.

To verify top-tier ESC quality for agricultural drones, examine current ratings at 1.2-1.5x motor peak draw, confirm IP67+ waterproofing certifications, request manufacturer quality control documentation including test reports, and evaluate long-term engineering support availability. These four pillars separate reliable ESCs from costly failures.

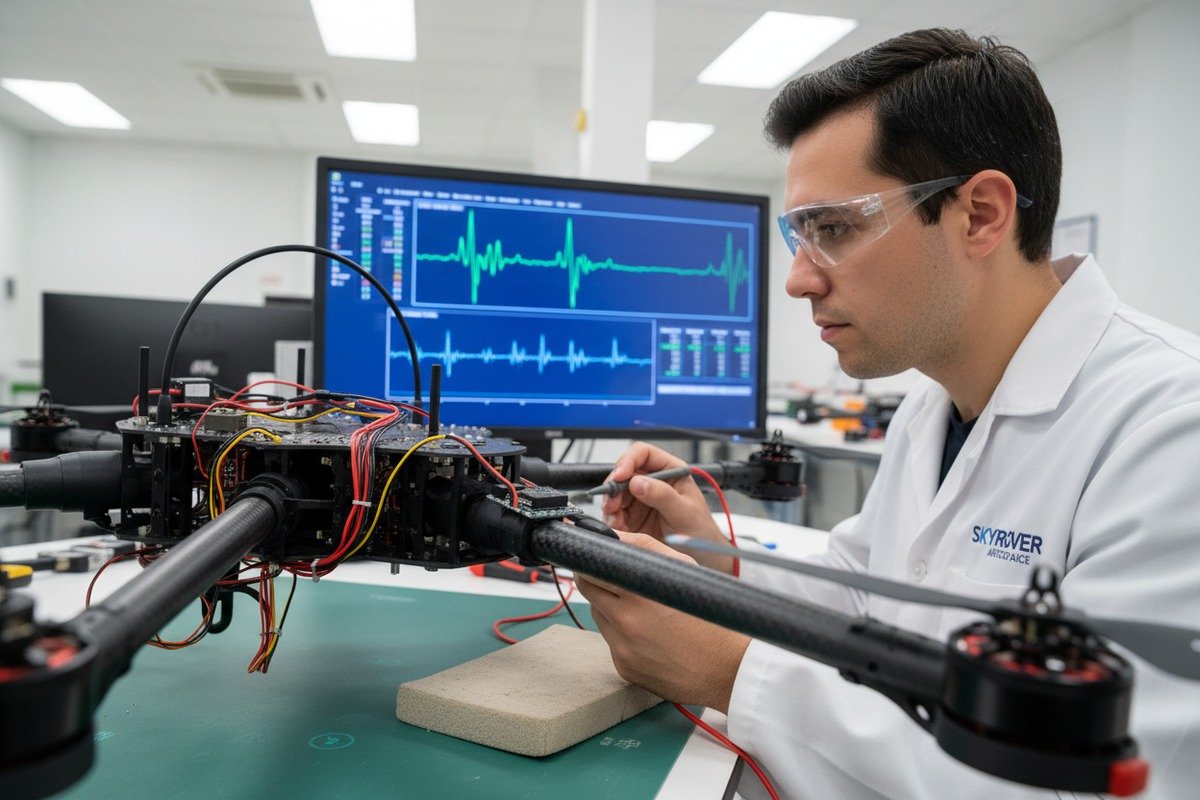

Let me walk you through exactly what our quality control team checks before any ESC enters our production line. These same criteria will help you source components that survive harsh agricultural environments.

What technical benchmarks should I look for to ensure ESC stability under heavy agricultural payloads?

Our testing facilities have seen ESCs from dozens of suppliers. Some perform beautifully in lab conditions. Then they overheat at 60% load in actual field operations. The gap between specification sheets and real-world performance is where most procurement mistakes happen.

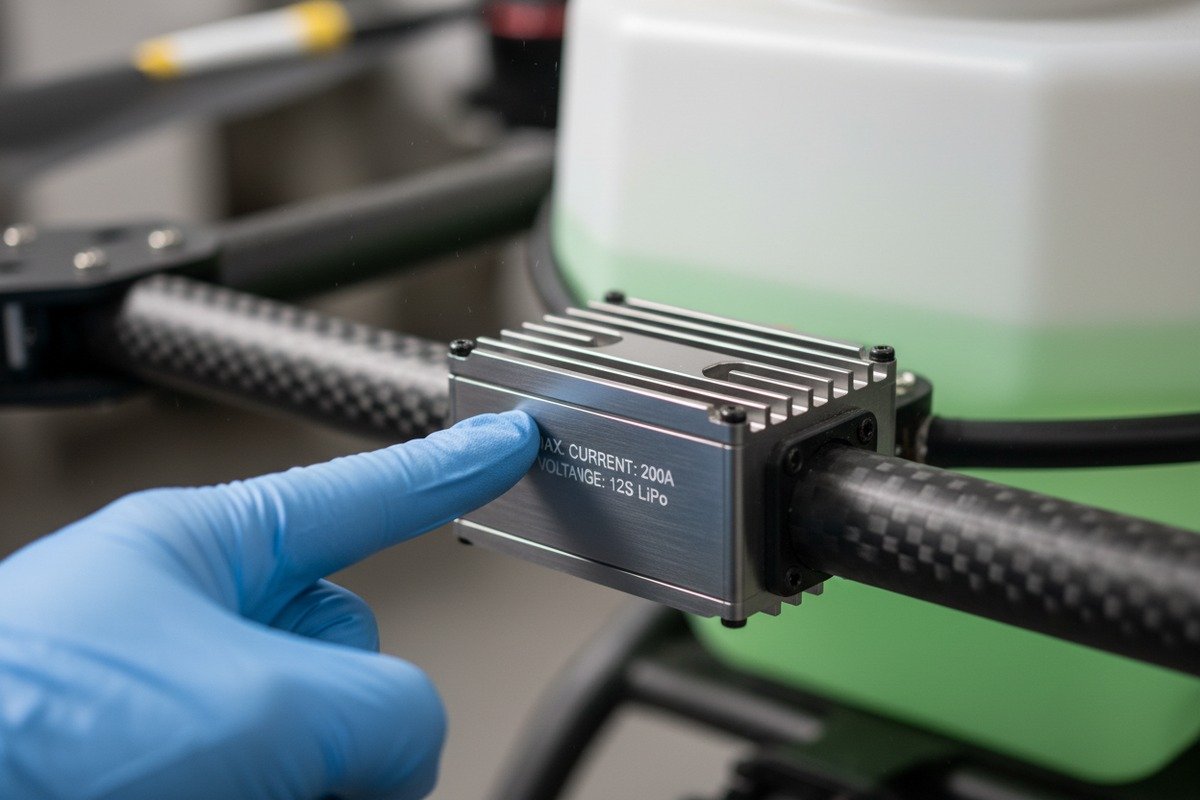

Look for ESCs with continuous current ratings at least 1.2-1.5 times your motor's peak draw, voltage compatibility matching your battery configuration (typically 12S-14S for heavy sprayers), and FOC control protocols for smooth torque delivery under variable payload conditions.

Understanding Current and Voltage Specifications

The most critical benchmark is current handling capacity. When our engineers design power systems for 17-18kg per-axis thrust configurations, we never match ESC ratings exactly to motor specifications. This leaves zero safety margin.

Consider this practical example. A motor drawing 80A at peak load needs a 100A ESC minimum. For heavy agricultural sprayers carrying 20-30 liters of liquid, motors often spike to 120A during rapid altitude adjustments. Your ESC must handle these surges without thermal shutdown.

| Payload Category | Recommended Motor Peak | Minimum ESC Rating | Optimal ESC Rating |

|---|---|---|---|

| Light Scout (5kg) | 40A | 50A | 60A |

| Medium Sprayer (15kg) | 80A | 100A | 120A |

| Heavy Sprayer (30kg) | 120A | 150A | 180A |

Voltage compatibility is equally important. Agricultural drones typically run 12S (44.4V) or 14S (51.8V) battery configurations. Mismatched voltage ratings cause immediate component failure. Always verify the ESC's S-rating matches your entire power system.

FOC vs Traditional Control Protocols

Field-Oriented Control technology has transformed ESC performance in agricultural applications. When we calibrate flight controllers at our facility, FOC-equipped ESCs consistently deliver smoother motor response and better efficiency.

Traditional BLHeli ESCs work adequately for basic multispectral imaging drones. However, spraying operations demand precise torque control. Liquid payloads shift constantly during flight. FOC algorithms adjust motor output in real-time, preventing the oscillations that waste battery life and reduce spray accuracy.

| Control Protocol | Best Application | Efficiency Gain | Calibration Complexity |

|---|---|---|---|

| BLHeli_S | Scout drones, light payloads | Baseline | Bajo |

| BLHeli_32 | Medium payloads, general use | 5-10% | Medio |

| FOC | Heavy sprayers, precision work | 10-20% | Más alto |

Thermal Management Requirements

Heat kills ESCs faster than any other factor in agricultural operations. Our production line rejects any ESC design without proper thermal management. Look for these specific features:

Low-ESR capacitors 2 rated at 440μF or higher absorb voltage spikes effectively. These components reduce electrical noise and prevent the sudden surges that damage sensitive circuits. Synchronous rectification improves efficiency by reducing heat generation during power conversion.

Physical cooling matters too. Quality ESCs feature aluminum heat sinks or direct motor mounting for heat dissipation. Avoid plastic housings that trap heat during extended spray missions.

How can I verify that the ESCs are properly protected against the moisture and chemicals used in my spraying operations?

In our experience exporting to the US and European markets, chemical exposure causes more ESC failures than any electrical issue. Pesticides, herbicides, and fertilizers create corrosive environments that destroy unprotected electronics within weeks.

Verify ESC protection by confirming IP67 or higher waterproof ratings, requesting specific chemical resistance certifications, inspecting conformal coating on circuit boards, and checking for sealed connector designs that prevent moisture ingress during high-humidity field operations.

IP Rating Decoded for Agricultural Use

IP ratings 3 tell you exactly what environmental protection an ESC offers. The two-digit code covers dust and water resistance separately. For agricultural drones, both matter equally.

The first digit rates dust protection. Agricultural fields generate constant particulate matter. Soil dust, crop residue, and dried chemical particles penetrate unsealed electronics. Demand IP6X ratings, indicating complete dust-tight sealing.

The second digit rates water resistance. Agricultural spraying creates constant moisture exposure. Morning dew, rainfall, and spray drift all threaten electronic components. IP67 4 means immersion protection to 1 meter depth. IPX8 offers even deeper protection for wash-down cleaning.

| Clasificación IP | Dust Protection | Water Protection | Agricultural Suitability |

|---|---|---|---|

| IP54 | Limited dust protection | Splash resistant | Not recommended |

| IP65 | Dust tight | Low-pressure jets | Minimum acceptable |

| IP67 | Dust tight | Immersion to 1m | Recommended standard |

| IP68 | Dust tight | Extended immersion | Premium protection |

Chemical Resistance Beyond Waterproofing

Standard waterproofing fails against agricultural chemicals. Water-based IP testing does not replicate the corrosive properties of concentrated pesticides. When our quality team evaluates suppliers, we specifically request chemical resistance documentation.

Conformal coating 5 provides the critical barrier. This protective layer covers PCB components completely, blocking chemical penetration. Quality coatings resist pH levels from 3 to 11, covering the range of common agricultural chemicals.

Connector sealing deserves special attention. The junction between ESC and motor wiring creates vulnerability points. Look for gold-plated connectors with silicone gaskets. These resist corrosion far better than standard copper connections.

Practical Field Testing Methods

Lab certifications provide baseline assurance. Real-world validation confirms actual performance. Our engineering team uses specific field tests that you can request from any supplier.

Humidity chamber testing exposes ESCs to 95% humidity at elevated temperatures for 48-72 hours. This accelerated test reveals moisture ingress problems that appear after months of field use.

Chemical spray exposure testing applies diluted agricultural chemicals directly to sealed ESCs. Post-test inspection should show zero penetration to internal components.

What quality control documentation should I request from a manufacturer to guarantee ESC long-term reliability?

Our production records show that thorough documentation review prevents 80% of component quality issues. Manufacturers with rigorous quality systems produce documentation willingly. Those who hesitate often have something to hide.

Request batch-specific test reports showing current/voltage performance curves, certification documents for CE/FCC/ISO 21384-3 compliance, material traceability records for critical components, and failure mode analysis data demonstrating long-term reliability under agricultural operating conditions.

Essential Certification Requirements

Certification standards vary by destination market. When we prepare export shipments to the United States, our documentation packages include specific compliance evidence that serious buyers expect.

CE marking confirms European safety and electromagnetic compatibility standards. FCC certification verifies radio frequency compliance for US markets. ISO 21384-3 6 addresses unmanned aircraft systems specifically, covering design and manufacturing quality.

Beyond regulatory compliance, industry-specific certifications matter. Agricultural drone certifications from bodies like the FAA Safety Assurance Council demonstrate manufacturer commitment to professional applications.

| Certificación | Cobertura | Relevance to ESC Quality |

|---|---|---|

| Marcado CE | EU safety/EMC | Electromagnetic interference control |

| FCC | US radio emissions | Signal integrity with flight controller |

| ISO 21384-3 | UAS design/manufacturing | System-level quality management |

| RoHS | Hazardous materials | Component material quality |

| REACH | Chemical substances | Environmental compliance |

Test Reports and Performance Data

Generic specification sheets tell you what an ESC should do. Batch-specific test reports prove what it actually does. Quality manufacturers test every production batch against defined parameters.

Current draw curves show ESC performance across the operating range. Look for smooth, linear response from zero to maximum load. Irregular curves indicate component quality variations or calibration issues.

Thermal performance data reveals heat management effectiveness. Request temperature measurements at 50%, 75%, and 100% continuous load over 30-minute test cycles. Quality ESCs maintain stable temperatures without thermal throttling.

Traceability and Material Documentation

Component traceability becomes critical when problems occur. If ESCs fail in the field, you need to identify affected batches and arrange replacements quickly. Quality manufacturers maintain complete records.

MOSFET transistors 7, the primary switching components in ESCs, vary significantly in quality. Request datasheets identifying specific MOSFET manufacturers and part numbers. Established semiconductor suppliers like Infineon, ON Semiconductor, and STMicroelectronics indicate quality commitment.

Capacitor specifications require similar scrutiny. As mentioned earlier, low-ESR capacitors rated at 440μF minimum prevent voltage spikes. Documentation should identify capacitor brands and verify ESR ratings.

How do I assess if the ESC manufacturer provides the engineering support and spare parts I need for long-term maintenance?

When we speak with procurement managers from US agricultural companies, one concern dominates all others. What happens when something breaks? The lowest-price ESC becomes the most expensive choice when failures halt operations during critical spraying windows.

Assess manufacturer support by verifying spare parts availability with guaranteed lead times under 2 weeks, confirming technical support channels including remote diagnostics capability, requesting warranty terms covering 12-24 months of agricultural use, and evaluating firmware update policies for ongoing performance optimization.

Spare Parts Availability Assessment

Rapid replacement capability determines your operational continuity. Agricultural spraying schedules cannot wait for 6-week international shipping. Quality suppliers maintain regional inventory or partner with local distributors.

Request specific information about parts availability. How many ESC units does the manufacturer keep in stock? What is the standard lead time for replacement orders? Do they offer expedited shipping options for urgent needs?

Modular ESC designs facilitate field repairs. Look for plug-and-play configurations that minimize recalibration requirements after component swaps. Our integrated power systems allow motor-ESC assemblies to be replaced entirely, reducing field repair time to minutes instead of hours.

Technical Support Infrastructure

Remote diagnostic capability saves time and money. Modern ESCs with telemetry features transmit performance data to flight controllers. Quality manufacturers provide software tools that analyze this data and identify problems before failures occur.

Evaluate support channel availability. Email response times should not exceed 24 hours for technical questions. Phone or video support for urgent issues demonstrates serious commitment to customer success.

Training resources indicate long-term partnership orientation. Manufacturers who provide calibration guides, troubleshooting flowcharts, and integration documentation invest in customer success beyond the initial sale.

| Support Element | Minimum Standard | Premium Standard |

|---|---|---|

| Email Response | 48 hours | 24 horas |

| Spare Parts Lead Time | 4 weeks | 2 weeks |

| Warranty Period | 12 meses | 24 meses |

| Actualizaciones de firmware | Anual | Trimestral |

| Technical Documentation | Basic manual | Complete integration guide |

Warranty and Long-Term Reliability

Warranty terms reveal manufacturer confidence in product quality. ESCs failing within 12 months indicate manufacturing defects or design flaws. Extended warranties of 18-24 months demonstrate reliability commitment.

Examine warranty exclusions carefully. Some manufacturers void warranties for agricultural use despite marketing products for that application. Others exclude chemical exposure damage, making coverage meaningless for spraying drones.

Predictive maintenance 8 integration represents the cutting edge of ESC support. Advanced telemetry systems track component degradation over time, alerting operators before failures occur. This proactive approach minimizes operational disruptions and extends equipment lifespan.

Conclusión

Verifying top-tier ESC quality requires systematic evaluation across technical specifications, environmental protection, documentation quality, and long-term support infrastructure. Apply these criteria consistently, and your agricultural drone fleet will deliver reliable performance season after season.

Notas al pie

1. Defines the core electronic component discussed throughout the article regarding drone propulsion. ↩︎

2. Explains how low Equivalent Series Resistance in capacitors improves efficiency and reduces heat. ↩︎

3. Official page from the International Electrotechnical Commission defining the standard used. ↩︎

4. Defines the IP67 standard for protection against dust and water immersion. ↩︎

5. Describes a protective polymeric film applied to circuit boards to shield against environmental conditions. ↩︎

6. Specifies an international standard for safe commercial Unmanned Aircraft Systems (UAS) operations. ↩︎

7. Explains MOSFETs as powerful switches used to control high currents efficiently in ESCs. ↩︎

8. authoritative business/tech definition of the maintenance strategy discussed in the context of support. ↩︎