When our production team first encountered EU customs delays, we realized compliance documentation was the hidden bottleneck. Many buyers face the same frustration—products stuck at borders because charger certifications were incomplete or unverifiable.

To verify EU LVD compliance for agricultural drone battery chargers, request the EU Declaration of Conformity, technical files with risk assessments, and test reports from accredited laboratories. Confirm the charger operates within 50-1000V AC or 75-1500V DC range and carries authentic CE marking with proper traceability documentation.

This guide walks you through exactly what documents to demand, how to spot fake certifications, and which standards prevent costly delays. Let’s dive into the specifics.

What specific documents should I request from my supplier to prove LVD compliance for drone chargers?

Our export team has learned that incomplete documentation causes 80% of customs issues. Many suppliers provide only surface-level certificates. This leaves buyers exposed to import rejections and legal liability.

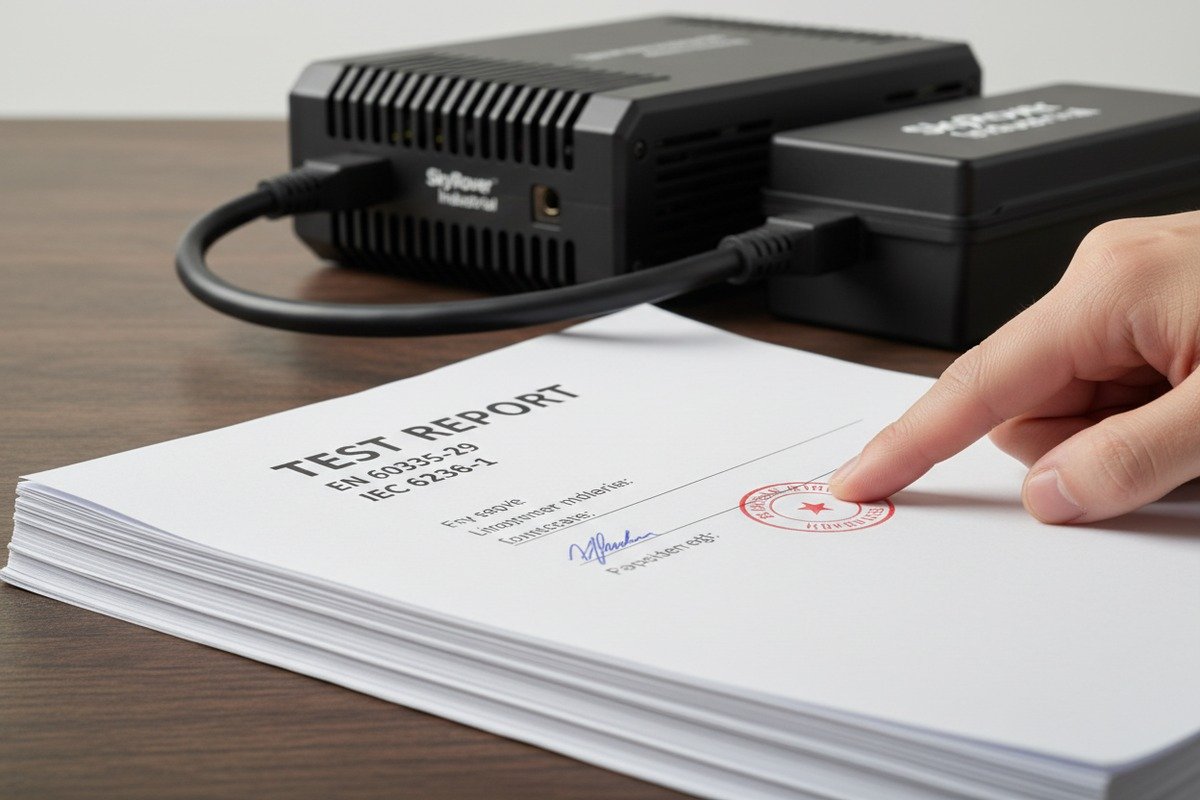

Request these core documents: EU Declaration of Conformity signed by the manufacturer, complete technical file including design specifications and risk assessment, test reports from accredited laboratories referencing harmonized standards like EN 60335 or IEC 62368-1, and traceability records linking the charger model to specific compliance testing.

The EU Declaration of Conformity

This single-page document is your primary proof of compliance. The manufacturer signs it, taking full legal responsibility. Every legitimate Declaration of Conformity must include:

- Manufacturer's name and address

- Product identification (model number, serial number range)

- Reference to Directive 2014/35/EU (LVD) 1

- List of harmonized standards applied

- Signature of authorized representative

- Date of issue

If your supplier cannot produce this document within 24 hours, consider it a red flag. We keep all Declarations of Conformity accessible in digital format for immediate sharing.

Technical File Contents

The technical file is your deep documentation layer. It proves the manufacturer actually performed safety engineering—not just paperwork.

| Tipo de documento | Objetivo | Red Flag if Missing |

|---|---|---|

| Design drawings | Shows electrical layout | Cannot verify safety design |

| Risk assessment | Documents hazard analysis | No proof of safety evaluation |

| Test reports | Confirms standard compliance | No third-party verification |

| Component list | Identifies critical parts | Cannot trace quality |

| User manual | Instructions for safe use | Liability exposure |

Test Reports from Accredited Labs

Generic test reports mean nothing. Demand reports from laboratories accredited under ISO 17025 2 and recognized by EU member states. The report must reference specific harmonized standards.

For agricultural drone chargers, look for testing against:

- EN 60335-1 (general safety requirements)

- EN 60335-2-29 3 (battery chargers)

- IEC 62368-1 (audio/video and IT equipment)

Our engineering team always requests the laboratory's accreditation certificate alongside test reports. This dual verification prevents accepting fraudulent documentation.

How can I verify that the CE marking and LVD test reports for my agricultural drone chargers are authentic?

In our years of exporting to Europe, we have seen counterfeit certifications damage buyer relationships. Fake documents look professional but collapse under scrutiny. Your reputation depends on catching fraud before products ship.

Verify authenticity by cross-checking laboratory accreditation numbers against ILAC or national accreditation body databases, contacting the testing laboratory directly to confirm report numbers, examining CE marking for correct proportions and placement, and requesting notified body involvement records if applicable to your charger type.

Spotting Fake CE Markings

The CE marking has specific legal dimensions. The letters must be at least 5mm tall and maintain exact proportions. Counterfeit markings often appear:

- Too small or incorrectly proportioned

- Using wrong fonts or stylized designs

- Placed on packaging only, not on the product itself

- Missing from the charger's rating label

Real CE markings appear directly on the product, on the packaging, and in accompanying documents. All three locations must show consistency.

Laboratory Verification Steps

Follow this process to confirm test reports are genuine:

- Extract the lab name from the test report header

- Search ILAC database (ilac.org) for member accreditation bodies

- Check national accreditation body (e.g., DAkkS for Germany, UKAS for UK)

- Contact the laboratory directly using contact information from official sources—not from the report itself

- Provide the report number and ask for verification

We perform this verification on every new supplier relationship. It takes one hour but prevents months of problems.

Understanding Accreditation Marks

| Accreditation Body | País | Database Link | Recognition |

|---|---|---|---|

| DAkkS | Alemania | dakks.de | Full EU recognition |

| UKAS | United Kingdom | ukas.com | EU recognized |

| COFRAC | Francia | cofrac.fr | Full EU recognition |

| CNAS | China | cnas.org.cn | ILAC MRA 4 signatory |

Reports from ILAC MRA (Mutual Recognition Arrangement) signatory laboratories hold equal validity across EU member states. Our testing partners maintain CNAS accreditation with ILAC recognition, ensuring our reports satisfy EU authorities.

Document Cross-Referencing

Authentic documentation creates a traceable chain. The Declaration of Conformity references specific test reports. Test reports reference specific harmonized standards. Standards reference specific safety requirements.

Any break in this chain signals potential fraud. Ask your supplier to explain how each document connects to the others. Legitimate manufacturers answer this question instantly. Fraudulent suppliers hesitate or provide vague responses.

Which safety standards must my drone battery charger meet to ensure it passes EU customs without delays?

Our shipments have taught us that customs officers check specific standard references. Missing the right standards means your charger sits in a warehouse while competitors deliver. Preparation eliminates delays.

Agricultural drone battery chargers must meet harmonized standards under LVD including EN 60335-2-29 for battery chargers or IEC 62368-1 for IT equipment. Additionally, comply with EMC Directive 2014/30/EU standards like EN 55032 and EN 55035. For chargers with wireless features, Radio Equipment Directive standards under EN 301 489 series apply.

Core LVD Harmonized Standards

Not all standards carry equal weight at customs. Officers look for specific EN standard numbers on your Declaration of Conformity. The most commonly accepted standards for drone battery chargers include:

| Standard Number | Standard Title | Application |

|---|---|---|

| EN 60335-1 | Household appliances – General requirements | Base safety standard |

| EN 60335-2-29 | Battery chargers | Direct application |

| IEC 62368-1 5 | Audio/video, IT equipment safety | Modern alternative |

| EN 62311 | EMF exposure assessment | Human safety near charger |

Our R&D team designs chargers specifically to meet EN 60335-2-29 requirements. This standard addresses battery-specific hazards like thermal runaway, overcharging, and reverse polarity protection.

EMC Directive Requirements

LVD compliance alone is insufficient. The EMC Directive 2014/30/EU 6 runs parallel and applies to all electrical equipment. Your charger must:

- Not emit electromagnetic interference affecting other devices

- Operate normally when exposed to external electromagnetic fields

For agricultural settings, EMC compliance matters greatly. Farm equipment generates significant electromagnetic noise. Your charger must function reliably despite this interference.

Key EMC standards include:

- EN 55032 (emission limits)

- EN 55035 (immunity requirements)

- EN 61000-3-2 (harmonic current emissions)

- EN 61000-3-3 (voltage fluctuations)

Radio Equipment Directive Considerations

Modern "smart" chargers with WiFi, Bluetooth, or cellular connectivity trigger Radio Equipment Directive (RED) 2014/53/EU 7 requirements. This adds another compliance layer many manufacturers overlook.

If your charger includes:

- Remote monitoring via app

- Fleet management connectivity

- Firmware update capability via wireless

- GPS tracking integration

Then RED compliance is mandatory. Our connected charger models undergo additional testing against EN 301 489 series for radio equipment EMC and EN 300 328 for 2.4 GHz band equipment.

The 2026 Deadline Factor

Regulation (EU) 2019/945 8 requires all civilian drones on the EU market to comply by January 1, 2026. This regulation treats the drone and its accessories as a system. Charger compliance directly affects whether your complete drone system can legally enter the market.

Start compliance verification now. Testing and documentation typically require 2-4 months. Our production planning accounts for this timeline on every new charger model.

How does LVD compliance impact the long-term reliability and safety of my industrial drone fleet?

When we design chargers at our facility, safety compliance and product reliability are inseparable. Cutting corners on LVD compliance creates chargers that fail faster and create liability exposure. Your fleet investment deserves proper protection.

LVD compliance directly improves fleet reliability by requiring protection against electric shock, thermal hazards, and mechanical failures. Compliant chargers include overcurrent protection, overvoltage safeguards, thermal cutoffs, and proper insulation—all features that extend battery life and prevent field failures that ground your aircraft.

Safety Features That Extend Equipment Life

LVD compliance forces manufacturers to implement protective circuits. These circuits protect both operators and equipment. A well-designed charger includes:

- Overcurrent protection: Prevents damage from power surges

- Overvoltage protection: Stops charging before battery damage occurs

- Thermal monitoring: Cuts power if temperature exceeds safe limits

- Short circuit protection: Prevents catastrophic failures

- Reverse polarity protection: Protects against connection errors

Our agricultural drone chargers incorporate all these features as baseline requirements, not optional extras. The compliance mandate ensures consistent protection across our product line.

Battery Life Extension Through Proper Charging

LVD-compliant chargers must match the battery chemistry they service. For agricultural drones using LiPo or Li-ion batteries, this means:

| Charging Parameter | Non-Compliant Risk | Compliant Charger Behavior |

|---|---|---|

| Cell balancing | Uneven wear, reduced capacity | Active balancing during charge |

| Temperature monitoring | Thermal runaway risk | Automatic shutoff above 45°C |

| Charge termination | Overcharging damage | Precise voltage cutoff |

| Current regulation | Stress on battery cells | Constant current/constant voltage profile |

Proper charging extends battery lifespan by 30-50%. Over a fleet of 10 agricultural drones, this translates to significant cost savings and reduced downtime.

Field Reliability Under Harsh Conditions

Agricultural operations stress equipment beyond typical commercial use. Dust, moisture, temperature extremes, and vibration challenge charger durability. LVD compliance testing addresses many of these factors through:

- Ingress protection requirements

- Thermal stress testing

- Mechanical impact resistance

- Insulation integrity verification

Our chargers undergo environmental testing beyond minimum compliance requirements. We simulate real agricultural conditions—including exposure to pesticide residue and high humidity—because our customers operate in these environments daily.

Liability Protection for Operators

When a charger fails and causes damage, the compliance documentation chain determines liability. Operators using LVD-compliant chargers from verifiable sources have clear recourse. Those using non-compliant equipment bear responsibility for incidents.

Documentation you should maintain includes:

- Purchase records with supplier identification

- Declaration of Conformity copies

- Maintenance logs

- Incident reports if any failures occur

This documentation protects your business and supports insurance claims if incidents occur. Our customer support team helps buyers establish proper record-keeping systems.

Total Cost of Ownership Perspective

Cheap non-compliant chargers cost more over time. Factor in:

- Replacement costs from premature failures

- Battery damage from improper charging

- Downtime during critical spraying windows

- Potential liability from safety incidents

- Customs delays and rejection costs

Investing in verified LVD-compliant chargers from the start eliminates these hidden costs. Our customers report significantly lower total ownership costs compared to competitors who initially purchased cheaper alternatives.

Conclusión

LVD compliance verification protects your investment and ensures smooth EU market access. Request complete documentation, verify laboratory accreditation, and understand applicable standards before purchasing agricultural drone chargers.

Notas al pie

1. Official text of the Low Voltage Directive. ↩︎

2. Replaced HTTP 404 with an authoritative and accessible page from ANAB (ANSI National Accreditation Board) providing information on ISO/IEC 17025. ↩︎

3. Describes the safety standard for battery chargers. ↩︎

4. Explains the mutual recognition arrangement for accreditation bodies. ↩︎

5. Describes the safety standard for audio/video and IT equipment. ↩︎

6. Official text of the Electromagnetic Compatibility Directive. ↩︎

7. Official text of the Radio Equipment Directive. ↩︎

8. Official EU regulation concerning unmanned aircraft systems (drones). ↩︎