At SkyRover, we frequently see clients struggle to choose between strict budget constraints and mission-critical specifications. Failing to balance these factors often leads to operational failures during emergencies, risking both equipment and safety.

Balancing performance and cost requires prioritizing mission-critical specifications like thermal resolution, flight endurance, and IP ratings over non-essential features. Buyers must calculate the Total Cost of Ownership (TCO), including maintenance, training, and batteries, rather than focusing solely on the initial sticker price to ensure long-term operational reliability.

Let’s break down the financial and technical trade-offs to help you make an informed decision for your fleet.

What Are the Hidden Costs of Choosing Cheaper Firefighting Drone Models?

We often repair budget drones that failed in high-heat environments because their components couldn’t handle the stress. Saving money upfront frequently results in expensive downtime when lives and property are at risk.

Cheaper firefighting drones often incur significant hidden costs through frequent battery replacements, lower durability requiring expensive repairs, and lack of modularity. Additionally, the downtime caused by system failures during critical missions creates operational vacancies that far exceed the savings from a lower initial purchase price.

![]()

When evaluating procurement options, the sticker price is often just the tip of the iceberg. In our manufacturing experience, we have analyzed the lifecycle costs of various industrial drones. A lower upfront cost usually implies compromises in component quality, which manifests as financial leaks later in the product’s life.

The "Disposable Drone" Syndrome

Entry-level drones often lack the modular design found in mid-to-high-end industrial models. If a motor arm breaks on a cheap unit, you might have to replace the entire airframe. In contrast, professional industrial drones are designed for component-level repair. This difference drastically changes your long-term budget. A $5,000 drone that needs total replacement after a minor crash is more expensive than a $15,000 drone that requires a $200 repair part.

Battery Lifespan and Management

One of the most overlooked costs is battery management. Cheaper drones often use lower-grade lithium cells with fewer charge cycles (often 200-300 cycles). High-end enterprise drones utilize intelligent batteries rated for 500+ cycles with self-heating capabilities for cold weather.

Consider this comparison of estimated costs over a three-year period for a single unit:

| Cost Category | Budget Model (Entry-Level) | Enterprise Model (Mid/High-End) | Impact on Operations |

|---|---|---|---|

| Initial Purchase | $10,000 | $25,000 | Lower barrier to entry vs. higher capex. |

| Battery Replacements (3 Years) | $6,000 (3 sets/year) | $3,000 (1 set/year) | Frequent downtime for budget models. |

| Maintenance & Repairs | $4,500 (Frequent failures) | $1,500 (Scheduled service) | Unpredictable costs for budget models. |

| Downtime Cost (Estimated) | $10,000 (Missed missions) | $2,000 (Minimal downtime) | Operational vacancy risks contracts. |

| Total 3-Year Cost | $30,500 | $31,500 | Costs equalize, but performance differs. |

The Cost of Operational Vacancy

For procurement managers, the most dangerous hidden cost is "operational vacancy." If a fire department relies on a drone that malfunctions due to poor heat shielding, they lose situational awareness. The cost of a fire spreading because the commander lacked aerial thermal data dwarfs the price of the drone. Reliable equipment acts as an insurance policy against mission failure.

How Do High-End Flight Controllers Impact Long-Term Maintenance Expenses?

In our R&D labs, we test various flight controllers rigorously under simulated heavy loads. Unstable controllers cause crashes, leading to skyrocketing repair bills that frustrate procurement managers and ground fleets.

High-end flight controllers significantly reduce long-term maintenance expenses by providing superior stability, redundancy, and precise telemetry data. These advanced systems minimize pilot error and crash risks, thereby lowering insurance premiums and reducing the frequency of costly hull replacements compared to basic consumer-grade controllers.

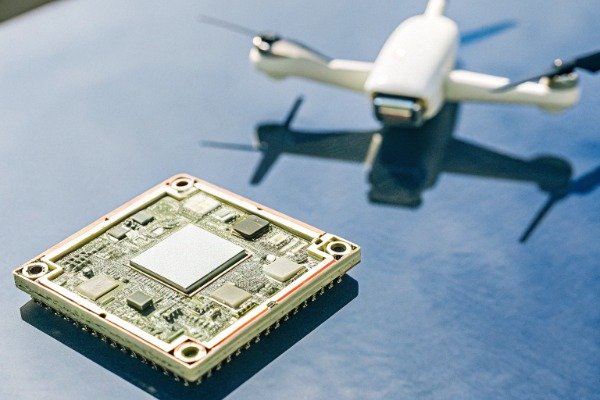

The flight controller (FC) is the brain of the drone. In industrial applications, specifically firefighting, the FC must process data from multiple sensors while battling high winds, thermal updrafts from fires, and electromagnetic interference.

electromagnetic interference 1

Redundancy is Not a Luxury

Standard consumer drones operate on a single IMU (Inertial Measurement Unit) and compass. If that sensor fails due to magnetic interference—common near heavy machinery or steel structures—the drone may "fly away" or crash. High-end flight controllers feature triple redundancy. This means they have three sets of sensors. If one disagrees with the others, the system automatically switches to the backup without the pilot even noticing.

From a maintenance perspective, this redundancy is a massive cost saver. A crash caused by sensor failure usually results in a "total loss" of the airframe and the expensive payload (camera). By investing in a high-end FC, you are effectively buying insurance against hardware failure.

Stability Reduces Wear and Tear

Advanced algorithms in premium flight controllers manage motor output more efficiently. They smooth out the flight, reducing vibration. High vibration is the enemy of electronics and mechanical joints.

- Low-end FC: Constant micro-corrections and jitter lead to premature motor bearing failure and stress cracks in the frame.

- High-end FC: Smooth flight paths reduce physical stress on the airframe, extending the lifespan of motors and structural components.

Telemetry and Predictive Maintenance

Modern industrial flight controllers log detailed data. At SkyRover, we use this data to help clients perform predictive maintenance. The FC can alert the pilot if a motor is drawing slightly more current than usual, indicating a potential blockage or bearing issue before it fails mid-flight.

| Característica | Standard Flight Controller | High-End Industrial Flight Controller | Maintenance Implication |

|---|---|---|---|

| IMU Redundancy | Single (1x) | Triple (3x) | Prevents crashes from sensor errors. |

| Vibration Damping | Software only | Hardware + Software | Extends life of frame and motors. |

| Interference Shielding | Minimal | Aluminum/Copper Shielding | Prevents "flyaways" in urban areas. |

| Blackbox Logging | Limitado | Comprehensive | Allows for precise error diagnosis. |

Can I Negotiate Better Pricing for Bulk Orders Without Sacrificing Payload Capacity?

When we negotiate with distributors, volume matters, but we advise caution against squeezing manufacturing costs too hard. Pushing prices too low often forces suppliers to cut corners on critical payload components like sensors.

Total Cost of Ownership 2

You can negotiate better pricing for bulk orders by focusing on volume discounts for accessories like batteries and charging stations rather than the airframe itself. This strategy preserves the budget for high-capacity payloads while lowering the overall cost per unit through economies of scale.

frequency-hopping transmission systems 3

Negotiation is an art, especially when dealing with complex machinery like firefighting drones. Many procurement managers make the mistake of asking for a flat percentage discount on the entire unit. However, the profit margins on the core airframe and high-end thermal sensors are often slim for manufacturers who maintain strict quality control.

IP rating 4

Where to Squeeze, Where to Yield

If you demand a 20% price cut on the drone unit, a manufacturer might be forced to switch to cheaper motors or a lower-grade carbon fiber to meet your price target. This compromises the payload capacity and safety. Instead, target the high-margin items.

Negotiable Items:

- Batteries: These are consumables. Manufacturers can often offer "buy 10 get 2 free" deals or significant bulk discounts.

- Ground Control Stations: Screens and controllers have flexible pricing.

- Training: Ask for free remote training or extended technical support packages instead of hardware discounts.

- Kits de repuestos: Negotiate for a comprehensive "crash kit" (propellers, landing gear) to be included at no cost.

The "White Label" Advantage

If you are a large distributor or a government contractor, consider OEM (Original Equipment Manufacturer) services. At SkyRover, we often work with clients who want customized branding. By committing to a larger volume under an OEM agreement, you can often secure a better per-unit price because it guarantees a production run for the factory. This allows us to purchase raw materials in bulk, passing the savings to you without downgrading the specs.

Strategic Procurement Framework

When approaching a supplier, use a "Total Package" negotiation strategy. Do not just ask for the drone price. Ask for the price of the "Operational Year."

- Wrong Ask: "Can you lower the price of the drone by $1,000?"

- Right Ask: "If we commit to 10 units, can you include 20 extra batteries and extend the warranty to 2 years at the current price?"

This approach ensures you get the high-performance payload capacity you need (because you didn’t devalue the core hardware) while reducing your operational costs (batteries and warranty).

radiometric thermal cameras 5

What Specific Performance Metrics Justify a Higher Upfront Investment?

Our engineers prioritize specs that survive real fires, knowing that on paper specs don’t always translate to the field. Ignoring metrics like thermal sensitivity or wind resistance renders a drone useless when smoke thickens and conditions worsen.

OEM (Original Equipment Manufacturer) 6

Investments in high-resolution thermal imaging (640×512 or higher), IP55+ weather resistance, and extended flight endurance of over 45 minutes are justified performance metrics. These specifications directly correlate with mission success rates in adverse conditions, ensuring the drone delivers actionable data when cheaper models would be grounded.

Not all specifications are created equal. In firefighting, "good enough" is often a recipe for failure. There are three specific areas where spending more money upfront provides an exponential return on investment (ROI) in terms of capability.

IMU (Inertial Measurement Unit) 8

1. Thermal Sensor Resolution (Radiometric)

The difference between a 320×256 resolution camera and a 640×512 resolution camera is massive.

- Low Res (320px): You can see there is heat, but you might not distinguish a person from a heated vent at 50 meters.

- High Res (640px): You can identify specific hotspots, read temperature gradients on chemical tanks, and locate victims through thick smoke.

- Justification: If the drone cannot clearly identify the target, the flight is wasted. High-resolution radiometric thermal cameras are expensive, but they are the primary tool for the job.

2. Ingress Protection (IP) Rating

Firefighting involves water, foam, and often rain. A consumer drone usually has no IP rating. An industrial drone should be at least IP45, preferably IP55.

- Scenario: A fire breaks out during a storm. A non-rated drone stays grounded. An IP55 drone launches.

- Justification: The ability to fly in rain or heavy dust ensures 24/7 readiness. A cheaper drone that is grounded 30% of the time due to weather has a very low value.

3. Data Link Transmission Stability

In urban fires, buildings block signals. In forest fires, terrain blocks signals. Cheap drones use standard Wi-Fi based transmission which fails beyond 1-2km in noisy environments. High-end systems use encrypted, frequency-hopping transmission systems (like our proprietary links or similar tech) that can penetrate obstacles.

Performance vs. Cost Matrix

Use this table to evaluate if a spec is worth the extra cost:

| Característica | Entry-Level Spec | Professional Spec | Verdict |

|---|---|---|---|

| Thermal Resolution | 320 x 256 | 640 x 512 | Worth it. Essential for SAR and hotspot analysis. |

| Flight Time | 25-30 mins | 45-55 mins | Worth it. Allows for persistent observation without constant swapping. |

| Obstacle Avoidance | Front/Down | Omnidirectional (360°) | Worth it. Critical for flying near structures/trees. |

| Video Resolution | 4K | 8K | Skip. 4K is sufficient for situational awareness; 8K adds data bloat. |

| Speed | 15 m/s | 23 m/s | Skip. Stability is more important than top speed for firefighting. |

By focusing your budget on the "Worth it" categories, you ensure that every dollar spent directly contributes to saving lives and property, rather than paying for marketing gimmicks.

situational awareness 9

Conclusión

Balancing specs and cost requires looking beyond the sticker price to the Total Cost of Ownership. Prioritize reliability, thermal capability, and safety features to ensure your fleet performs when it matters most.

lithium cells 10

Notas al pie

- Authoritative definition of the environmental hazard affecting drone electronics. ↩︎

- Professional definition of the procurement strategy advocated in the conclusion. ↩︎

- Technical overview of the secure communication method used in high-end drones. ↩︎

- Links to the official international standard for ingress protection. ↩︎

- Educational resource from an industry leader explaining the sensor technology. ↩︎

- Defines the manufacturing business model suggested for bulk buyers. ↩︎

- Explains the maintenance strategy enabled by advanced telemetry. ↩︎

- Provides a technical definition for the specific sensor component. ↩︎

- Defines the critical operational concept for first responders. ↩︎

- Explains the underlying technology and limitations of battery cells mentioned. ↩︎