When we design flight systems at our facility in Xi’an, we often see buyers focus solely on today’s specs, ignoring tomorrow’s needs. This short-sightedness leads to fleets becoming obsolete within months, wasting massive amounts of public or private budget. Asking the right roadmap questions now ensures your firefighting equipment remains operational and cutting-edge for years.

Request a detailed 3-to-5-year R&D timeline covering firmware support, hardware modularity, and regulatory compliance. Ask specifically about “end-of-life” policies for current models and guarantee forward compatibility for payloads like cameras or suppression systems to protect your long-term capital investment.

Here is how you can dig deeper into the supplier’s plans to secure a durable and future-proof investment.

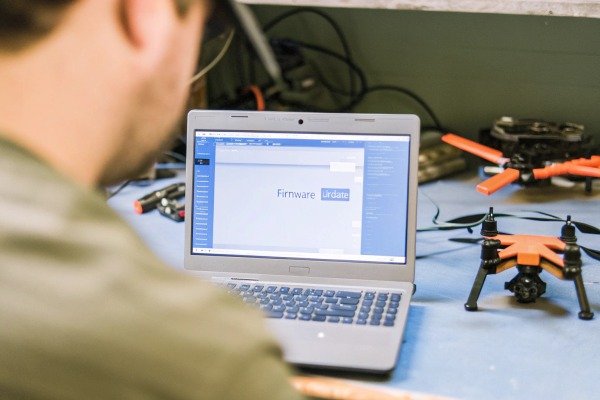

How do I verify the supplier's schedule for future software and firmware updates?

From our experience coding flight controllers in Chengdu, we know that hardware is useless without evolving software. Many buyers face the nightmare of a perfectly good drone being grounded because the software no longer supports new security protocols. security protocols 1 You must verify that the code inside the machine will grow alongside your mission requirements.

Ask for a written software lifecycle commitment specifying the frequency of security patches and feature rollouts. Ensure the roadmap includes updates for autonomous flight modes and compatibility with evolving third-party fleet management platforms to maintain operational efficiency over the drone’s lifespan.

Software in the firefighting drone industry is moving faster than hardware. When we export to the US and Europe, we see a massive shift toward "smart" operations. It is not just about flying anymore; it is about data processing. To understand if a supplier is ready for this, you need to look beyond the current version number.

The Difference Between Maintenance and Innovation

You need to distinguish between "keeping it alive" and "making it better." A roadmap should clearly separate maintenance patches (bug fixes) from feature upgrades.

- Maintenance: How long will they fix critical bugs? If a new GPS spoofing threat emerges, will they patch it next week?

- Innovation: Will your drone get new autonomous features next year? For example, we are currently seeing a trend toward real-time AI fire mapping. If the supplier's roadmap doesn't mention adding AI capabilities to existing flight controllers, you might be buying "dumb" hardware in a "smart" era.

Interoperability and Open Standards

A closed system is a risky system. In our engineering meetings, we emphasize compatibility. You should ask if their software roadmap aligns with open standards like MAVLink. open standards like MAVLink 2 If a supplier insists on a completely closed ecosystem, you are trapped. If they go out of business or stop updating the software, your fleet is dead. Ask if their future updates will support third-party command and control software, which is crucial for large-scale coordination in wildfires.

Frequency of Updates

A vague promise of "continuous updates" is not enough. You need a schedule. Regular updates indicate an active engineering team. Rare updates often mean the product is in "maintenance mode" and might be discontinued soon.

| Update Type | Qué preguntar | Good Response | Respuesta a la bandera roja |

|---|---|---|---|

| Security Patches | "What is your response time for critical security vulnerabilities?" | "We release patches within 72 hours of verification." | "We update the system once a year." |

| Feature Rollouts | "Do you plan to add autonomous swarming capabilities?" | "Yes, swarming is on the roadmap for Q3 2025 via firmware update." | "The current hardware cannot support new features." |

| OS Compatibility | "Will the control software support the next Windows/Android version?" | "We test betas to ensure Day 1 compatibility." | "We recommend keeping an old laptop just for this drone." |

What should I ask to ensure the hardware is compatible with next-generation upgrades?

We build our carbon fiber frames to last for years, but technology shrinks and improves every month. carbon fiber frames 3 A rigid design that we saw five years ago is now a liability for users who want to attach better sensors. If the drone body cannot adapt, you will be forced to buy a whole new aircraft just to get a better camera.

Inquire about the modularity of payload Universal Payload Interface 4 interfaces and battery compartments. Confirm that the airframe utilizes standard mounting points and connectors, allowing for independent upgrades of thermal cameras, sensors, or extinguishing agents without necessitating a complete aircraft replacement.

In the firefighting sector, payloads are king. The drone is just the truck; the payload is the firefighter. The trend is moving toward heavier lifts (>20kg) and smarter sensors. If the roadmap doesn't account for physical modularity, you are making a mistake.

The Payload Interface Roadmap

When we collaborate with clients on design, we often use standard interfaces like HDMI, Ethernet, and GPIO ports. standard interfaces like HDMI 5 However, some suppliers use proprietary connectors. You must ask: "If a better thermal camera comes out in 2026, can I mount it on this 2024 drone?"

If the answer is no, the roadmap is flawed. You should ask about the Universal Payload Interface. Does the supplier plan to support open payload standards? This allows you to buy a camera from a third party and mount it on their drone, giving you freedom and longevity.

Battery Technology and Compartment Size

Battery tech is the biggest bottleneck. We are on the verge of a shift from standard Li-Po to Solid State or Hydrogen fuel cells, which offer much higher energy density. Solid State 6

Here is the critical question: "Is your battery compartment fixed, or is it modular?"

If the battery bay is molded strictly for today's battery size, you cannot use next-gen batteries that might be smaller but more powerful, or slightly larger with double the capacity. A roadmap that includes "adaptable power systems" shows the supplier is thinking ahead.

Motor and ESC Upgrades

Firefighting drones work in harsh environments. Motors wear out. A good hardware roadmap allows for "propulsion system upgrades." Ask if the arms and motor mounts are designed to accept more powerful motors in the future. This is vital for high-altitude operations where you might need more thrust than you currently do.

Hardware Component Lifespan Checklist

Use this table to evaluate if the hardware roadmap matches your depreciation schedule.

| Componente | Esperanza de vida | Roadmap Question |

|---|---|---|

| Estructura del avión | 3-5 Years | "Is the frame designed to accommodate larger props in the future?" |

| Controlador de vuelo | 2-3 Years | "Is the FC processor powerful enough for future AI updates?" |

| Battery System | 1-2 Years (Cycles) | "Will future battery chemistries be compatible with this voltage?" |

| Payload Mount | Variable | "Do you use quick-release standard mounts or proprietary screws?" |

How can I determine if the supplier's R&D capabilities can support my long-term needs?

When potential partners visit our factory, we show them our test labs, not just the assembly line. A supplier who only assembles parts cannot help you when regulations change or when you need a custom feature for a unique fire scenario. You need to verify that their engineering brain is as strong as their manufacturing muscle.

Request evidence of the supplier’s past R&D milestones and their current engineering team structure. Ask specifically about their roadmap for AI integration, edge computing, and regulatory adaptability, ensuring they have the technical resources to evolve with industry standards like Remote ID and BVLOS.

R&D capability is your insurance policy. In the firefighting drone market, regulations like Remote ID and Beyond Visual Line of Sight (BVLOS) are changing the game. Beyond Visual Line of Sight 7 Remote ID 8 If your supplier doesn't have the R&D team to certify their drones for these new rules, your fleet will be grounded legally.

Assessing the Engineering Team

Don't just look at the product; look at the people. Ask the supplier: "What percentage of your staff are engineers versus sales?" At our company, a significant portion of our 70-person team is technical. This matters because when you need a custom feature—like a specific release mechanism for a fire retardant ball—only a supplier with strong R&D can build it for you.

- The Litmus Test: Ask them to explain a recent technical challenge they solved for a client. If they can't give a specific engineering example, they might just be a reseller or a simple assembler.

The AI and Edge Computing Roadmap

The future is Edge Computing—processing data on the drone, not in the cloud. Edge Computing 9 Firefighters need real-time heat maps instantly, without latency.

Ask: "What is your roadmap for on-board computing?"

If they are still relying entirely on ground station processing, they are behind. A strong R&D team will be talking about NPU (Neural Processing Unit) integration and AI-based obstacle avoidance that works through smoke.

Regulatory Adaptability

Regulations are the biggest external risk.

- Remote ID: Is it built-in? Is it upgradable?

- BVLOS: Is the communication link robust enough?

- NDAA Compliance: For US buyers, this is critical. A supplier with strong R&D can redesign circuit boards to swap out banned components. A supplier without R&D will simply lose the market.

Indicators of Strong R&D

| Indicator | Why it Matters | What to look for |

|---|---|---|

| Patents | Shows innovation ownership. | Patents on stability systems or release mechanisms. |

| Customization | Ability to tailor products. | Willingness to modify firmware for specific client needs. |

| Certifications | Proof of compliance. | ISO certifications, local aviation authority approvals. |

What questions reveal the risk of the drone model being discontinued shortly after purchase?

We have seen competitors launch flashy models only to kill the production line six months later, leaving customers with expensive paperweights. This usually happens when a company lacks a clear long-term strategy. You must ask tough questions to ensure you aren’t buying into a dead-end product line.

Directly ask for the projected “End of Life” (EOL) date for the specific airframe and the guaranteed duration of spare parts availability post-discontinuation. Demand a written policy on buy-back programs or trade-in credits to mitigate the financial risk of sudden model obsolescence.

Discontinuation is a major financial risk. Industrial drones are capital assets, not disposable consumer electronics. You need a guarantee that the system you integrate into your workflow today will still be supportable in 2028.

The "End of Life" (EOL) Conversation

Suppliers often hesitate to discuss EOL because they want to make the sale. You must force the issue.

- Question: "When is the scheduled EOL for this airframe?"

- Question: "After EOL, how many years do you guarantee spare parts availability?"

In the industrial sector, the standard should be at least 3-5 years post-production. If they say "we support it as long as we have stock," that is a red flag. It means they have no plan.

Supply Chain Sovereignty and Risk

Global supply chains are fragile. Global supply chains 10 We have learned that controlling the source of components is vital. You should ask about their "Supply Chain Roadmap."

- Are they dependent on a single chip manufacturer?

- If a geopolitical event bans a specific component (like a thermal sensor from a specific country), do they have an alternative design ready?

- The NDAA Factor: For US buyers, if a supplier cannot guarantee that their supply chain will remain compliant with US laws, the risk of discontinuation is high. Ask them about their roadmap for "supply chain diversification."

The "Beta Tester" Trap

Avoid buying the very first batch of a completely new platform unless there is a clear roadmap for revisions. Version 1.0 often has bugs.

Ask: "Is this a Gen 1 product? If so, what is the upgrade path for early adopters?"

Honest suppliers will offer a trade-in program or free upgrades for early versions if major flaws are found. This protects you from being stuck with a prototype that was sold as a finished product.

Legacy Support Roadmap

Finally, ask about backward compatibility.

"If I buy Model X today, and you release Model Y next year, will the batteries and cameras from Model X work on Model Y?"

Cross-generation compatibility is a sign of a mature, customer-focused roadmap. It saves you thousands of dollars in accessories.

Conclusión

Asking these roadmap questions transforms a simple transaction into a strategic partnership. It filters out short-term sellers and highlights manufacturers ready to support your mission for the long haul.

Notas al pie

1. NIST guidelines for implementing robust cybersecurity protocols and frameworks for connected technology systems. ↩︎

2. Official documentation for the MAVLink protocol, an industry-standard communication language for drones. ↩︎

3. Wikipedia entry providing technical details on carbon fiber properties and aerospace applications. ↩︎

4. Technical documentation for DJI’s Payload SDK, which standardizes the integration of third-party drone sensors. ↩︎

5. Official HDMI licensing organization providing technical specifications for high-definition multimedia interfaces. ↩︎

6. MIT research article discussing the development and energy density advantages of solid-state battery technology. ↩︎

7. Official FAA resource explaining the regulatory framework and safety requirements for BVLOS drone operations. ↩︎

8. FAA’s official page detailing Remote ID compliance requirements for unmanned aircraft systems. ↩︎

9. NVIDIA’s technical resources on edge computing platforms for autonomous robotics and AI processing. ↩︎

10. Reuters analysis of current global supply chain risks affecting the technology and electronics sectors. ↩︎