When our production team ships drones contra incendios 1 overseas, we often hear the same concern from procurement managers: “How do I know this drone actually performs as promised?” The frustration is real. You invest thousands of dollars, wait weeks for delivery, and then discover the thermal camera 2 underperforms or the flight time falls short.

To set effective FAT/SAT acceptance criteria for firefighting drones from China, you must define specific performance benchmarks at the factory, verify operational standards upon delivery, validate all custom OEM features before final payment, and establish durability and flight endurance thresholds with measurable test protocols and third-party inspection support.

This guide walks you through each critical step Factory Acceptance Test 3. We will cover exactly what tests to require, what documentation to demand, and how to protect your investment from start to finish.

What specific performance benchmarks should I include in my Factory Acceptance Test (FAT) for firefighting drones?

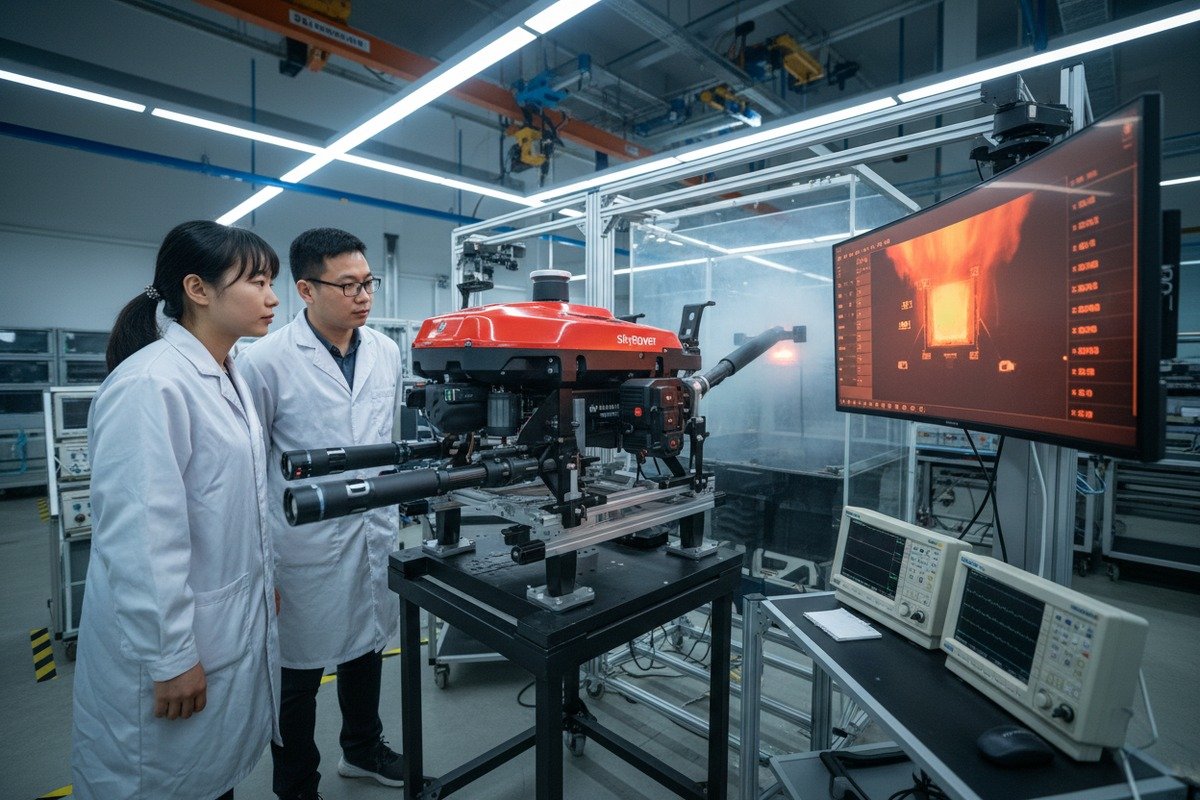

Our engineers have tested hundreds of firefighting drones before they leave our facility Site Acceptance Test 4. We understand what can go wrong—and more importantly, what tests catch problems early. Many buyers skip detailed FAT specifications, only to face expensive surprises later.

Your FAT should include thermal imaging accuracy tests, AI fire detection validation under smoke conditions, payload deployment precision checks, flight controller calibration verification, communication range tests, and full documentation review including calibration records and software version confirmations.

Core Performance Tests to Require

The FAT happens at the manufacturer's site before shipping. This is your best opportunity to catch defects. Here are the essential benchmarks:

Thermal Imaging Accuracy: Request tests that verify temperature measurement accuracy within ±2°C across the operational range. The camera should detect heat signatures through moderate smoke. Ask for recorded test footage with temperature overlays.

AI Fire Detection: If your drone uses AI for fire detection, require validation tests under multiple conditions. AI Fire Detection 5 This includes bright sunlight (glare), smoke interference, and nighttime operation. The detection rate should exceed 95% in controlled scenarios.

Payload Deployment: For drones carrying fire extinguishing agents or rescue equipment, test the release mechanism. Verify accuracy within a 1-meter radius from a 30-meter altitude. Document the release timing and mechanism reliability.

Documentation Requirements

| Tipo de documento | What to Verify | Por qué es importante |

|---|---|---|

| Calibration Records | Sensor calibration dates and values | Ensures accurate readings |

| Software Version Log | Firmware and flight controller versions | Confirms latest stable releases |

| Component Certificates | Battery, motor, ESC certifications | Validates safety compliance |

| Test Flight Data | Telemetry logs from test flights | Proves actual performance |

| Quality Inspection Reports | QC checkpoint records | Shows manufacturing consistency |

Chinese National Standards Compliance

Require adherence to Chinese civil drone standards 6. These cover technical requirements, safety protocols, and operational specifications. Key standards include GB/T 38058-2019 for civilian UAV product general requirements. Compliance documentation should be part of your FAT package.

Third-Party Inspection

We always recommend clients hire independent inspection agencies in China. Companies like SGS, Bureau Veritas, or local specialized drone inspection firms can witness FAT procedures. This adds a layer of verification that protects both parties.

The inspection should cover:

- Visual inspection of all components

- Functional testing of critical systems

- Documentation review and verification

- Packaging quality assessment

How can I verify that my drones meet operational standards during the Site Acceptance Test (SAT) after they arrive from China?

When we ship drones to clients in the US and Europe, we provide detailed SAT checklists because we know the delivery journey is harsh. Vibration, temperature changes, and handling can affect sensitive equipment. The SAT confirms everything still works after transit.

Your SAT should verify physical condition through documented unboxing, confirm all systems function correctly in your operational environment, test integration with your existing command systems, validate communication range and reliability, and compare actual performance against FAT benchmark results.

Unboxing and Physical Inspection

Start with documented evidence. This protects you if you need to file claims for shipping damage or manufacturing defects.

Required Evidence Collection:

- High-resolution photos of packaging condition before opening

- Unboxing video showing all contents and their condition

- Close-up images of any visible damage or concerns

- Photos of serial numbers matching documentation

Functional System Checks

After physical inspection, test each system independently before attempting flight.

| System | Test Procedure | Pass Criteria |

|---|---|---|

| Controlador de vuelo | Power on, check sensor initialization | All sensors report normal |

| Thermal Camera | Display live feed, verify temperature readings | Clear image, accurate temps |

| GPS Module | Acquire satellite lock | Minimum 12 satellites, HDOP < 1.5 |

| Communication | Range test with ground station | Specified range with <1% packet loss |

| Payload System | Cycle release mechanism | Smooth operation, correct timing |

| Battery | Full charge cycle, capacity test | Within 95% of rated capacity |

Integration Testing

Your firefighting drones must work with existing emergency response systems. Test these integrations during SAT:

Command and Control Integration: Connect the drone to your dispatch systems. Verify data flows correctly. Test manual override functions.

Communication Network Compatibility: Confirm the drone communicates reliably on your frequencies. Test through walls, around obstacles, and at maximum planned distances.

Data Sharing: Verify thermal imagery and telemetry data streams to your platforms. Check video latency and quality.

Cybersecurity Validation

This step is often overlooked but critical. Test the drone's resistance to unauthorized access. Verify encryption on data links. Confirm firmware cannot be modified without proper authorization.

Basic cybersecurity tests include:

- Attempting connection with unauthorized controllers

- Testing data link encryption strength

- Verifying GPS spoofing resistance

- Checking for unauthorized network connections

Comparative Performance Analysis

Compare SAT results directly to FAT documentation. Any significant performance degradation indicates potential shipping damage or component failure. Document all variances and address them before final acceptance.

What steps should I take to ensure my custom OEM features are fully validated before final payment?

Our OEM clients often request specialized features—custom payload mounts, proprietary software interfaces, or unique branding elements. We have learned that clear validation protocols prevent misunderstandings and protect both parties. Without proper validation steps, disputes over "custom" versus "standard" features can delay projects for months.

Before final payment, require written feature specifications with measurable acceptance criteria, conduct witnessed testing of each custom element, obtain source code or configuration access for software customizations, verify branding and labeling accuracy, and document everything with signed acceptance certificates for each OEM component.

Define Custom Features Clearly

Ambiguity kills OEM projects. Every custom feature needs precise specifications.

Create a Custom Feature Specification Document that includes:

- Technical parameters with measurable values

- Visual references (drawings, renders, photos)

- Material specifications where applicable

- Performance requirements under defined conditions

- Integration requirements with other systems

Staged Validation Protocol

Do not wait until final delivery to validate custom features. Break validation into stages tied to payment milestones.

| Stage | Validation Focus | Payment Release |

|---|---|---|

| Design Approval | Review drawings and specifications | 10-20% |

| Prototype Validation | Test functional prototype | 20-30% |

| Pilot Batch Test | Validate production samples | 20-30% |

| Final FAT | Complete system validation | Remaining balance |

Software Customization Validation

For custom software features, require specific deliverables:

Source Code Access: If you paid for custom development, you should receive source code or at minimum, configuration files that allow future modifications.

API Documentation: Custom integrations need complete documentation. Verify the documentation matches actual functionality.

Test Cases: Request the test cases used during development. Run these yourself to confirm the software performs as designed.

Hardware Customization Verification

Physical customizations require hands-on validation:

- Dimensional Accuracy: Measure custom components against specifications

- Material Verification: Confirm materials match what was specified

- Fit Testing: Verify custom parts integrate correctly with standard components

- Stress Testing: Apply appropriate loads to custom mounting points

Intellectual Property Protection

When investing in custom development, protect your intellectual property: Intellectual Property Protection 7

- Include IP ownership clauses in your contract

- Require non-disclosure agreements covering your custom specifications

- Obtain certificates confirming your exclusive rights to custom designs

- Verify the manufacturer will not offer your custom features to competitors

Branding and Labeling Accuracy

Check all branding elements carefully:

- Logo placement matches approved artwork

- Colors match specified values (provide Pantone references)

- Text is spelled correctly in all languages

- Regulatory labels include required information

- Serial number formats follow your specifications

How do I define durability and flight endurance criteria to avoid receiving substandard drone equipment?

In our production facility, we test every drone model extensively before releasing it to market. However, we know some buyers have received equipment from other suppliers that failed within weeks. Defining clear durability criteria in your acceptance tests prevents this disappointment.

Define durability criteria by specifying minimum flight cycle counts, environmental operating ranges with tested thresholds, component rated lifespans, warranty coverage terms, IP ratings for weather resistance, and flight endurance tests under realistic payload and environmental conditions—all documented with verifiable test data.

Flight Endurance Testing Standards

Flight time claims are often exaggerated. Require testing under realistic conditions.

Test Conditions to Specify:

- Payload weight during test (full firefighting payload)

- Ambient temperature range

- Wind speed during test

- Flight pattern (hover vs. forward flight)

- Battery state (new vs. after specified cycles)

Environmental Durability Requirements

Firefighting drones face extreme conditions. Define environmental requirements clearly:

| Parameter | Minimum Requirement | Test Method |

|---|---|---|

| Operating Temperature | -10°C to +50°C | Chamber testing |

| Storage Temperature | -20°C to +60°C | Extended exposure |

| Wind Resistance | 12 m/s sustained | Wind tunnel or field |

| Water Resistance | IP54 minimum | Spray testing |

| Dust Resistance | IP54 minimum | Chamber exposure |

| Vibration Tolerance | Per MIL-STD-810 | Shaker table |

Component Lifespan Specifications

Request documented lifespan expectations for critical components:

Motores: Minimum rated hours (typically 200-500 hours for industrial drones)

ESCs: Expected cycle life and MTBF (Mean Time Between Failures)

Baterías: Cycle count rating (typically 300-500 cycles to 80% capacity)

Hélices: Recommended replacement intervals

Bearings: Service intervals and replacement indicators

Long-Term Maintainability Criteria

Durability includes the ability to maintain and repair equipment over time.

Spare Parts Availability: Require guaranteed availability of spare parts for a minimum period (typically 5-7 years). Get this commitment in writing with pricing frameworks.

Field Serviceability: Verify that common maintenance tasks can be performed without specialized equipment. Request maintenance manuals and training materials.

Technical Support Access: Define response time expectations for technical support. Specify whether support includes video calls, on-site visits, or remote diagnostics.

Warranty Terms Validation

Review warranty terms carefully before accepting delivery:

- Coverage period for different components

- What voids the warranty

- Process for warranty claims

- Turnaround time for repairs or replacements

- Who pays shipping for warranty service

Documentation for Long-Term Support

Request comprehensive maintenance documentation including:

- Detailed maintenance schedules

- Troubleshooting guides

- Wiring diagrams and schematics

- Calibration procedures

- Software update procedures

Conclusión

Setting proper FAT/SAT criteria protects your investment when sourcing firefighting drones from China. Define specific benchmarks, require third-party verification, validate custom features before payment, and establish clear durability standards. With proper acceptance criteria, you receive equipment that performs as promised.

Notas al pie

1. Provides an overview of drone applications in firefighting. ↩︎

2. Explains the technology and function of thermal imaging cameras. ↩︎

3. Defines Factory Acceptance Test (FAT) and its purpose. ↩︎

4. Defines Site Acceptance Test (SAT) and its importance. ↩︎

5. Illustrates the application of AI in wildfire detection technology. ↩︎

6. Details mandatory national standards for civil drones in China. ↩︎

7. Provides an authoritative definition and overview of intellectual property and its protection. ↩︎

8. Provides a comprehensive explanation of Ingress Protection (IP) ratings. ↩︎