Last year, one of our export partners lost $45,000 when a fuse blowout caused their spraying drone to crash mid-operation IP67 or higher waterproof ratings 1. The humidity in the rice field overwhelmed basic circuit protection.

To evaluate supplier fuse and circuit protection, verify voltage and current ratings match your drone’s power system, confirm environmental certifications like IP67, request test documentation, assess redundancy features in ESCs, and ensure components allow easy field replacement for agricultural maintenance needs.

Circuit protection failures account for a significant portion of agricultural drone crashes 2. Let me walk you through the exact evaluation framework our engineering team uses when designing protection systems.

How do I verify that the drone's circuit protection is durable enough for my clients' agricultural environments?

When we ship agricultural drones to farms in Texas and California, the feedback is consistent UN38.3 battery certification 3. Dust, chemical spray residue 4, and humidity destroy weak circuit protection within months.

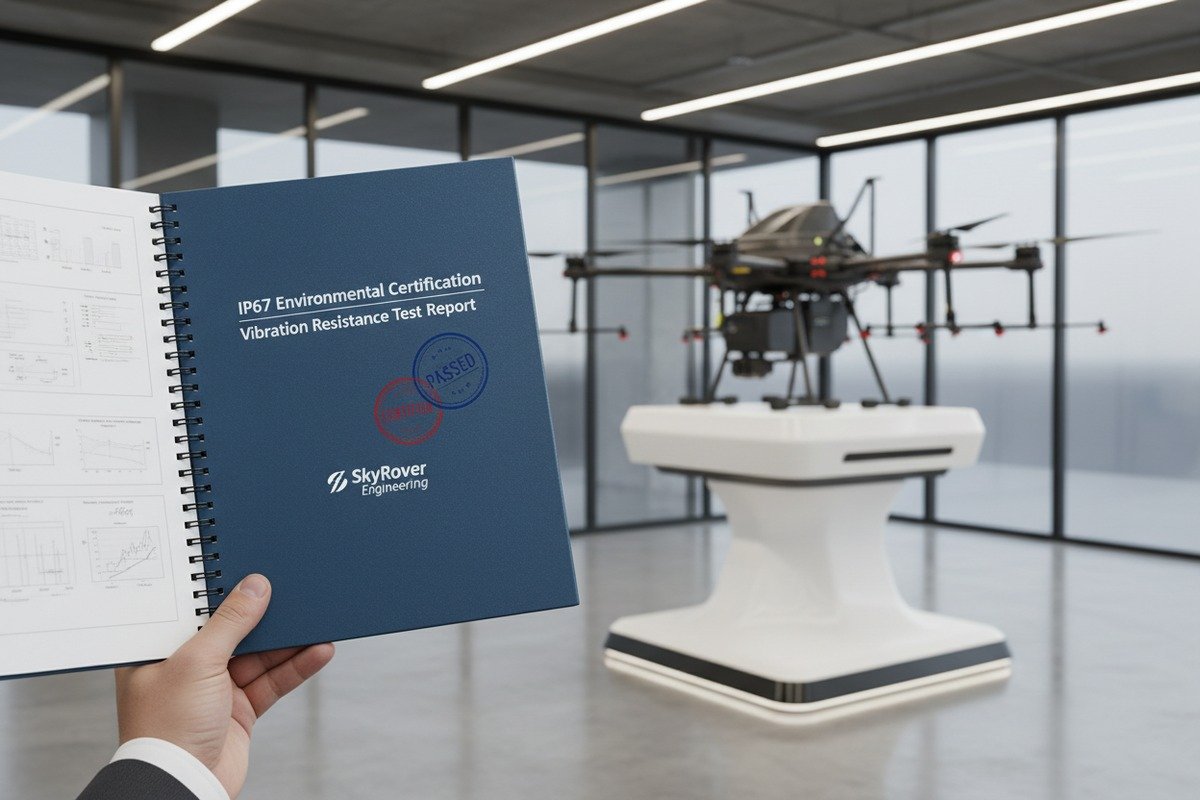

Verify durability by checking IP67 or higher waterproof ratings, confirming temperature tolerance ranges of -20°C to 50°C, requesting vibration resistance test data, and ensuring fuse housings resist corrosion from fertilizers and pesticides commonly used in agricultural spraying operations.

Understanding Environmental Stressors

Agricultural drones face brutal conditions. A single spraying mission exposes circuit components to water droplets, chemical mist, dust particles, and constant vibration RoHS compliance certificates 5. Our production line tests every fuse housing under simulated spray conditions for 200 hours before approval.

The most common failure points are exposed terminals and inadequate sealing around ESC connectors. When moisture enters these areas, corrosion begins within weeks. I have seen drones returned after just 30 flight hours because basic fuses lacked proper coating.

Key Durability Specifications to Request

| Especificaciones | Minimum Standard | Recommended for Agriculture |

|---|---|---|

| Clasificación IP | IP65 | IP67 or IP68 |

| Temperature Range | -10°C to 40°C | -20°C to 50°C |

| Vibration Resistance | 5G | 10G or higher |

| Salt Spray Test | 48 hours | 96 hours |

| Humidity Tolerance | 85% RH | 95% RH |

Your supplier should provide certificates for each specification. Do not accept verbal assurances. Our quality control department rejects components that lack third-party testing verification.

Testing Methods You Can Apply

Before committing to a large order, request sample drones for field testing. Run them in the actual conditions your clients will face. Monitor fuse temperature during peak current draw. Check for corrosion after 50 flight hours. Our engineers recommend thermal imaging during stress tests 6 to identify hot spots in the circuit protection system.

One distributor in Florida tested our drones alongside a competitor's product. After 100 hours in humid citrus groves, our fuses showed zero degradation. The competitor's basic fuses had visible oxidation on terminals.

Can my supplier provide customized fuse configurations and engineering support for my specific drone models?

Our engineering team receives requests every week from distributors who need modified circuit protection for their unique payload configurations. Not every supplier can handle this level of customization.

Capable suppliers offer custom fuse configurations through dedicated engineering teams, provide CAD drawings and circuit schematics, support voltage range adjustments from 22.2V to 51.8V systems, and offer ongoing technical consultation for integration with your existing drone models and battery management systems.

Why Customization Matters

Standard fuse configurations work for standard drones. But agricultural operations vary dramatically. A 10-liter sprayer for vineyard work has different current demands than a 30-liter drone for wheat fields. When we develop custom solutions, we calculate exact peak current requirements based on motor specifications and payload weight.

For example, a client in Spain needed drones for olive grove spraying. The terrain required aggressive maneuvering that spiked motor current beyond standard fuse ratings. Our team redesigned the protection circuit with time-delay fuses that tolerated 150% overcurrent for 3 seconds without tripping.

Preguntas que debe hacerle a su proveedor

Ask these specific questions during supplier evaluation:

- Can you provide engineering drawings of the fuse and ESC layout?

- What is your lead time for custom fuse configuration?

- Do you have electrical engineers available for video consultations?

- Can you modify protection thresholds in the BMS firmware?

- Will you provide test data after customization?

Suppliers who hesitate on these questions likely lack real engineering capability. They may simply resell generic components without understanding the systems.

Configuration Options to Consider

| Drone Size | Battery System | Recommended Fuse Rating | ESC Current Rating |

|---|---|---|---|

| Under 10L | 6S (22.2V) | 80A continuous | 100A minimum |

| 10-20L | 12S (44.4V) | 100A continuous | 120-150A |

| 20-30L | 14S (51.8V) | 120A continuous | 150-180 A |

| Over 30L | 16S (59.2V) | 150A continuous | 200A+ |

Our factory maintains inventory for all these configurations. Custom requests typically add 2-3 weeks to production time. Some suppliers quote 8-12 weeks, which indicates they outsource engineering work.

Engineering Support After Purchase

The relationship should not end at delivery. When your clients encounter field issues, you need a supplier who responds quickly. We provide remote diagnostics through flight log analysis. Our engineers can identify circuit protection failures from telemetry data within 24 hours.

One distributor in Brazil faced repeated ESC failures on a fleet of 20 drones. Our analysis revealed the fuses were rated correctly, but the installation position caused heat accumulation. We provided modified mounting brackets and the problem disappeared.

What documentation should I request from the manufacturer to ensure the circuit safety meets my import standards?

When we prepare export shipments to the United States and Europe, documentation requirements consume significant time. But proper paperwork prevents customs delays and liability issues for our partners.

Request UN38.3 battery certification, CE marking documentation, RoHS compliance certificates, UL or equivalent fuse certifications, IP rating test reports from accredited laboratories, and circuit diagrams with component specifications to satisfy import authorities and ensure regulatory compliance.

Essential Certifications Explained

Each certification serves a specific purpose. UN38.3 proves lithium batteries passed transportation safety tests. CE marking confirms compliance with European safety directives. CE marking documentation 7 RoHS certification verifies the absence of hazardous substances. Without these documents, your shipment may be rejected at the border.

Our documentation package includes 15 separate certificates and test reports. We update these annually or whenever component suppliers change. Outdated documentation creates legal exposure for importers.

Documentation Checklist

| Tipo de documento | Objetivo | Periodo de validez |

|---|---|---|

| UN38.3 Certificate | Seguridad en el transporte de baterías | Until battery design changes |

| CE Declaration | EU market compliance | Continuous with annual review |

| RoHS Certificate | Hazardous substance restriction | Per production batch |

| IP Test Report | Environmental protection rating | Per component design |

| UL/CSA Certification | North American electrical safety | Annual renewal |

| EMC Test Report | Compatibilidad electromagnética | Per design revision |

Verificación de la autenticidad de los documentos

Some suppliers provide fraudulent certificates. I have encountered this problem when auditing potential component suppliers. To verify authenticity, contact the certification body directly. Check certificate numbers against online databases. Request original test reports, not just summary certificates.

Our quality team maintains relationships with testing laboratories. When clients request verification, we can arrange direct communication between the lab and the importer. This transparency builds trust and prevents future disputes.

FAA and Regulatory Compliance

For US imports, circuit protection documentation supports FAA compliance 8. Since Remote ID requirements began in 2023, electrical system reliability directly affects legal operation. Drones that crash due to circuit failures can trigger FAA investigations and fines reaching millions of dollars.

Our drones ship with complete electrical schematics showing fuse placement, current ratings, and failsafe triggers. This documentation helps your clients demonstrate due diligence if accidents occur.

How can I evaluate if the supplier's circuit components are easy for my team to maintain and replace?

Maintenance accessibility determines long-term ownership costs. When our distributors service drones in the field, they need quick access to fuses and protection components without special tools.

Evaluate maintainability by inspecting fuse accessibility without disassembly, confirming standard fuse sizes available from multiple vendors, checking for plug-and-play ESC connections, requesting maintenance manuals with illustrated procedures, and verifying spare part availability with realistic delivery timelines.

Design for Field Service

Our design philosophy prioritizes field serviceability. Every fuse holder is accessible by removing a single panel. ESC connections use industry-standard plugs. No proprietary fasteners or specialized equipment required. This approach reduces service time from hours to minutes.

Some manufacturers seal critical components inside the frame to achieve waterproofing. While this improves protection, it makes field service nearly impossible. Our engineers developed external access panels with IP67 seals that maintain protection while allowing quick component access.

Spare Parts Availability

Before committing to a supplier, verify their spare parts inventory and shipping capabilities. Ask these questions:

- What is the lead time for replacement fuses?

- Do you stock ESCs for immediate shipment?

- Can I purchase protection components separately?

- Do you offer bulk spare parts packages?

We maintain 6-month inventory of all circuit protection components. Standard fuses ship within 48 hours. Complete ESC units ship within one week. This inventory commitment prevents your clients from grounding their fleets waiting for parts.

Maintenance Training and Support

| Tipo de soporte | Proveedor básico | Premium Supplier |

|---|---|---|

| Maintenance Manual | PDF only | PDF + Video tutorials |

| Technical Hotline | Business hours only | 24/7 availability |

| Diagnóstico remoto | No disponible | Through flight logs |

| On-Site Training | Additional cost | Included with large orders |

| Spare Parts Kit | Optional purchase | Included with drone |

Our premium support package includes maintenance training for your technical staff. We conduct video sessions covering fuse replacement, ESC diagnostics, and BMS troubleshooting. Trained technicians can resolve 80% of field issues without shipping drones back to our factory.

Evaluating Component Modularity

Modular design reduces long-term costs. When individual fuses blow, you should replace only the failed component, not entire assemblies. Check whether the supplier uses standard fuse sizes or proprietary components. Standard automotive-style fuses cost under $1 each. Proprietary modules may cost $50 or more.

Our circuit boards use blade-style fuses rated for the appropriate current. Local automotive supply stores stock compatible replacements. This deliberate choice saves our partners significant money over the drone's service life.

Preventing Supplier Lock-In

Some manufacturers, particularly those with integrated systems, restrict component availability. They force customers to purchase replacements exclusively from the original supplier at premium prices. Open-architecture designs allow sourcing from multiple vendors.

We publish complete component specifications so our partners can source alternatives if needed. This transparency may seem counterintuitive for a manufacturer, but it builds long-term relationships based on trust rather than dependency.

Conclusión

Evaluating supplier fuse and circuit protection requires attention to durability specifications, customization capability, documentation completeness, and maintenance accessibility. Partner with manufacturers who provide transparent engineering support and respect your need for long-term serviceability.

Notas al pie

1. Explains the meaning of IP67 rating for protection against dust and water immersion. ↩︎

2. Discusses common mistakes and risks leading to agricultural drone crashes and failures. ↩︎

3. Explains the UN38.3 standard for safe transport of lithium batteries and its global requirements. ↩︎

4. Explains how various chemicals, including those in sprays, can impact electronic components. ↩︎

5. Details the EU directive restricting hazardous substances in electrical and electronic equipment. ↩︎

6. Describes how thermal imaging is used to identify heat issues and improve reliability in electronics. ↩︎

7. This is an official European Union website providing comprehensive and authoritative information on the requirements for technical documentation for CE marking. ↩︎

8. Provides official information on FAA regulations and requirements for drone operation in the US. ↩︎