When our engineering team first shipped agricultural drone chargers to a German distributor, we faced a frustrating problem European standards 1. The chargers worked perfectly in our Xi’an facility but tripped circuit breakers across European farms. This mismatch between Chinese production standards and EU requirements cost us time and money.

To ensure agricultural drone chargers meet European standards, verify they accept 230V/50Hz input, use Type C or Type F plugs, carry CE certification, and support the high amperage your drone batteries require. Always check charger labels and request compliance documentation from suppliers before shipping.

This guide walks you through every step of matching your drone chargers to EU electrical requirements Low Voltage Directive (LVD) 2014/35/EU 2. We cover voltage verification, essential certifications, customization options, and pre-shipment testing procedures.

How do I confirm that my agricultural drone charger supports the specific voltage and frequency used in Europe?

Our production lines now test every charger unit against European voltage parameters before packaging Electromagnetic Compatibility (EMC) Directive 2014/30/EU 3. We learned this lesson after early shipments caused compatibility headaches for our partners in France and Spain. The difference between a working charger and a fire hazard often comes down to simple voltage verification.

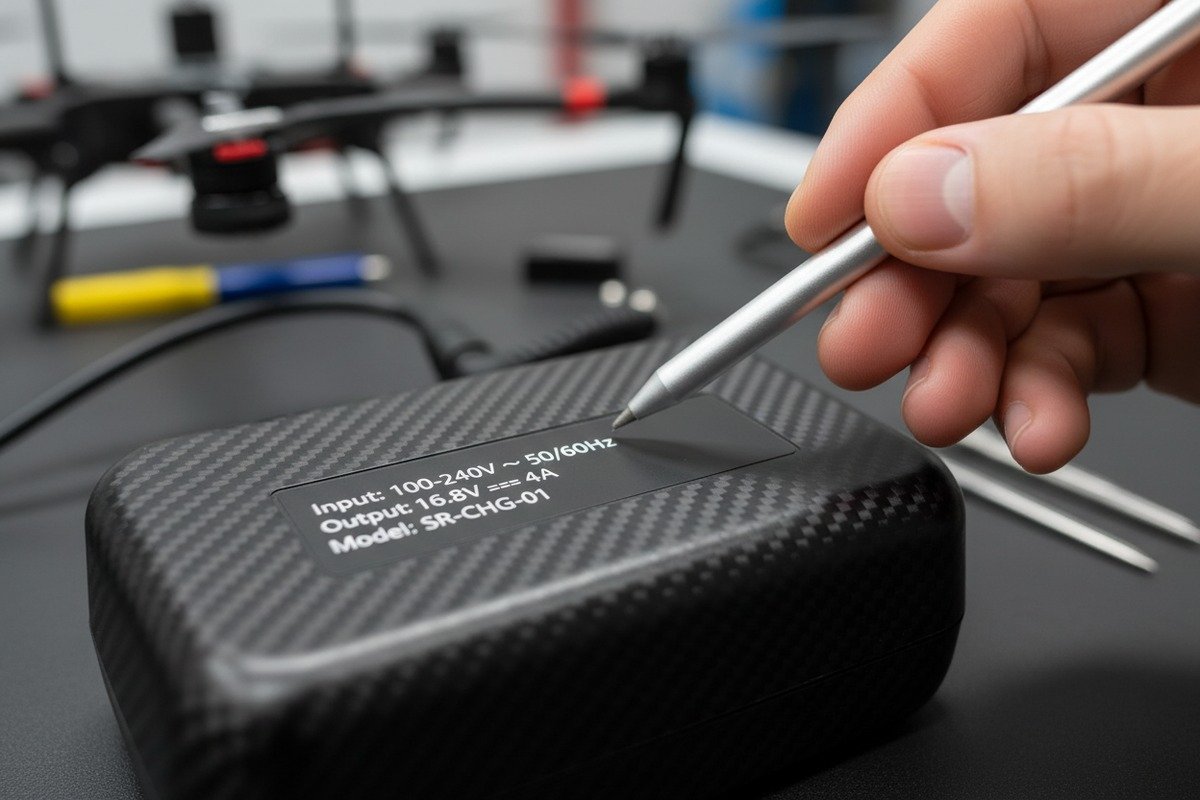

Check the charger's input label for "100-240V" and "50/60Hz" markings. If your charger shows this dual-voltage range, it automatically accepts Europe's 230V/50Hz standard. Single-voltage chargers rated only for 110V require expensive converters and risk damage to your equipment.

Understanding European Electrical Standards

Europe operates on a 230V nominal voltage 4 with a tolerance of ±10%. This means actual voltage ranges from 207V to 253V across different regions and times. The frequency is fixed at 50Hz, unlike North America's 60Hz system.

Most modern agricultural drone chargers from reputable manufacturers include universal input circuits. These accept any voltage between 100V and 240V automatically. However, high-power chargers for large agricultural drones like DJI Agras T30/T40 series draw significant current—up to 16 amperes.

The Amperage Challenge

Here lies a critical issue many importers overlook. European household sockets 5 typically support maximum 16A current. Large agricultural drone chargers operating at full speed can match or exceed this limit.

| Drone Model | Charger Power | Current Draw at 230V | Risk Level |

|---|---|---|---|

| Small Ag Drones (6S) | 400W | 1.7A | Bajo |

| Medium Ag Drones (12S) | 1200W | 5.2A | Medio |

| DJI Agras T30 | 3600W | 15.7A | Alto |

| DJI Agras T40 | 4000W | 17.4A | Critical |

Practical Verification Steps

Before purchasing chargers from any supplier, request clear photos of the input specification label. Look for these key indicators:

- Input voltage range including 230V

- Frequency acceptance including 50Hz

- Maximum input current rating

- Safety certification marks

When our engineers design charger circuits, we build in automatic voltage detection. The charger senses incoming voltage and adjusts internal regulation accordingly. This protects both the charger and connected batteries from damage.

For high-amperage agricultural operations, consider dedicated circuits or generator setups. A 9-12kW portable generator provides clean, stable power for demanding chargers without risking building electrical systems.

What certifications should I require from my Chinese supplier to ensure drone chargers comply with EU safety standards?

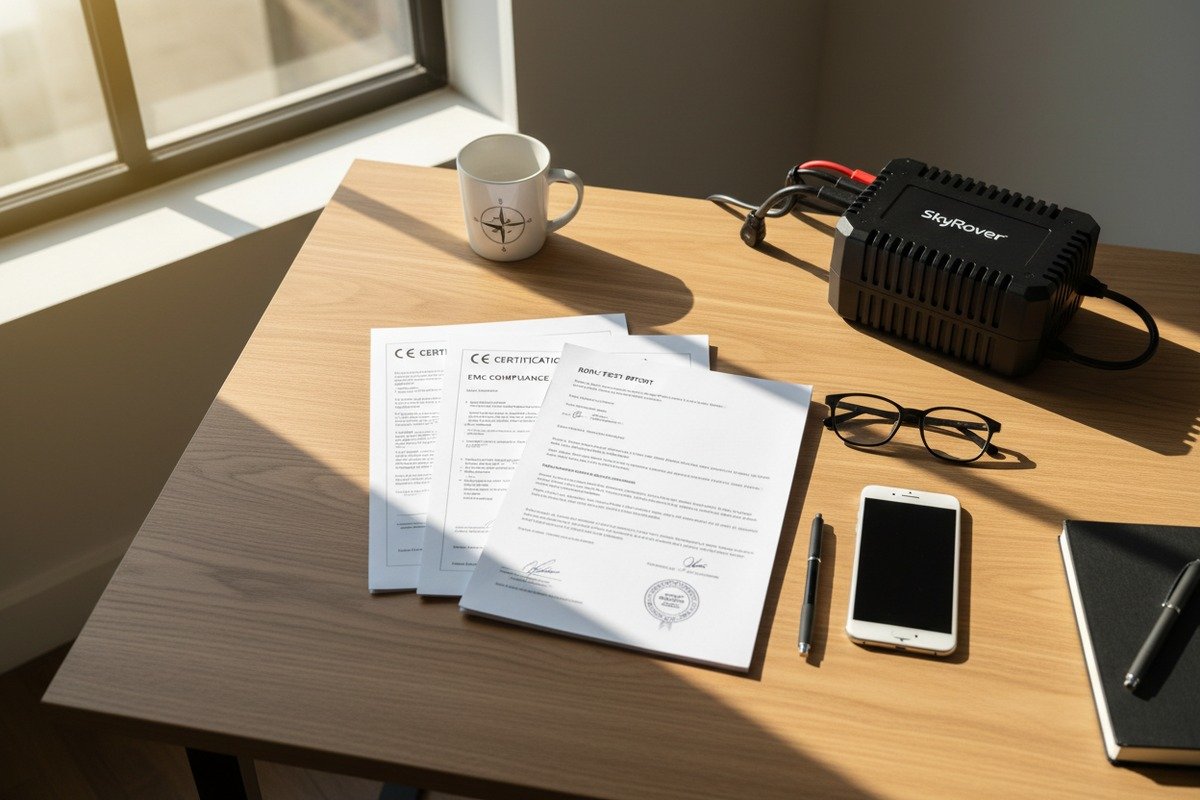

During our early export days, we shipped chargers without proper documentation. Customs held several shipments in Rotterdam for weeks. Now our compliance team prepares certification packages before production even begins. This saves our distributors time and protects their business reputation.

Require CE marking as the minimum standard for EU market entry. Additionally, request RoHS compliance certificates, EMC test reports, and LVD documentation. For battery safety during shipping, UN38.3 certification is essential. These documents protect you legally and demonstrate product quality to your customers.

Essential Certifications Explained

The CE mark is not a single certification but a declaration that products meet multiple EU directives. For drone chargers, two directives matter most:

Low Voltage Directive (LVD) 2014/35/EU covers electrical safety for equipment operating between 50V and 1000V AC. Your charger must not cause electrical shock, fire, or mechanical hazards.

Electromagnetic Compatibility (EMC) Directive 2014/30/EU ensures chargers don't interfere with other electronic equipment and resist interference from external sources.

Certification Requirements Table

| Certificación | Objetivo | Required For | Who Issues It |

|---|---|---|---|

| CE Mark | EU market access declaration | All electrical products sold in EU | Manufacturer self-declaration or Notified Body |

| RoHS | Restriction of hazardous substances | All electrical equipment | Accredited testing lab |

| EMC Test Report | Electromagnetic compatibility proof | CE technical file | Accredited EMC laboratory |

| LVD Test Report | Electrical safety verification | CE technical file | Accredited safety laboratory |

| UN38.3 | Lithium battery transport safety | Air freight shipping | IATA-recognized testing facility |

| UL2271 | Battery system safety | Optional but valuable | UL or equivalent body |

How to Verify Supplier Certifications

Many suppliers claim certifications they don't actually hold. Our recommendation is to verify independently.

Request the full technical file, not just certificates. This file should include test reports from recognized laboratories. Check that the laboratory holds ISO 17025 accreditation 6.

For marcado CE 7, ask for the Declaration of Conformity document. This legally binding statement identifies the responsible party and lists all applicable directives.

Cross-reference certificate numbers with issuing bodies when possible. Some testing laboratories maintain online databases where you can verify report authenticity.

Red Flags to Watch

Be cautious if suppliers:

- Cannot provide test reports, only certificates

- Show certificates with expired dates

- List testing laboratories you cannot verify online

- Refuse to share the Declaration of Conformity

- Claim CE marking for products clearly not meeting standards

Our quality control department maintains relationships with European Notified Bodies. This helps us stay current on changing requirements and ensures our documentation meets the latest standards.

Can I customize the plug type and packaging for my imported drone chargers to match my local market requirements?

Our OEM partners across Europe request different configurations constantly. A Spanish agricultural distributor needs Type F Schuko plugs and Spanish-language manuals. A French partner wants Type E plugs with their logo on the packaging. We handle these variations daily on our production lines.

Yes, reputable manufacturers offer plug type customization and branded packaging for imported drone chargers. You can specify Type C, E, or F plugs, local language documentation, custom box designs, and your company branding. Discuss minimum order quantities and lead times early in negotiations to ensure smooth customization.

European Plug Type Options

Europe uses several plug types depending on the country. Understanding these differences helps you order correctly for your target markets.

| Plug Type | Countries | Key Features | Ideal para |

|---|---|---|---|

| Type C (Europlug) | All EU countries | Two round pins, ungrounded, 2.5A max | Low-power accessories |

| Type E | France, Belgium, Poland | Two round pins + female ground hole | French market chargers |

| Type F (Schuko) | Germany, Austria, Netherlands | Two round pins + grounding clips | High-power chargers |

| Type G | UK, Ireland | Three rectangular pins, fused | British market |

Customization Process at Our Facility

When you place a customization order, our engineering team reviews your specifications. We modify the AC input cable assembly to include your requested plug type. This happens during production, not as an afterthought.

For packaging customization, our design department works from your brand guidelines. We can produce:

- Custom printed boxes with your logo and colors

- Instruction manuals in any European language

- Warranty cards with your contact information

- QR codes linking to your support resources

Minimum Orders and Lead Times

Customization requires setup changes on our production lines. This makes minimum order quantities necessary for cost-effective manufacturing.

| Customization Level | Typical MOQ | Additional Lead Time |

|---|---|---|

| Plug type change only | 50 units | 3-5 days |

| Plug + basic logo on box | 100 units | 7-10 days |

| Full custom packaging design | 200 units | 14-21 days |

| Custom manual translation | 100 units | 10-14 days |

Quality Control for Custom Orders

Custom orders receive the same rigorous testing as standard products. Each charger undergoes:

- Electrical safety testing at operating voltage

- Plug fitment verification with EU-standard sockets

- Visual inspection of branding accuracy

- Functional testing with target battery types

We photograph sample units and send approval images before bulk production. This prevents costly errors and ensures the final product matches your expectations exactly.

Communication is critical during customization. Our project managers provide weekly updates and flag any issues immediately. We use shared documents so you can track production progress in real time.

How can I verify the durability and performance of my drone chargers before they are shipped to my European warehouse?

Three years ago, a distributor returned an entire shipment because chargers failed after two months of field use. The warranty claims cost us significantly. Since then, we implemented comprehensive pre-shipment testing protocols. Now our failure rate sits below 0.5% across all European markets.

Request factory inspection, burn-in testing, and third-party verification before shipment. Effective pre-shipment verification includes 24-48 hour continuous operation tests, temperature cycling, charge cycle counting, and inspection by independent quality agencies. These steps identify weak units before they reach your customers.

Our Standard Testing Protocol

Every charger leaving our facility passes through multiple testing stages. This systematic approach catches defects at different points in the quality spectrum.

Incoming Component Inspection: We test critical components like capacitors, transformers, and control ICs before assembly. This catches supplier quality issues early.

Assembly Line Testing: Each unit receives basic functional verification immediately after assembly. We check output voltage, current regulation, and safety circuit response.

Burn-In Testing: Completed units operate continuously for 24-48 hours under load. This stress test reveals weak solder joints, marginal components, and thermal management problems.

Testing Parameters and Acceptance Criteria

| Test Type | Duración | Parameters Checked | Pass Criteria |

|---|---|---|---|

| Output Voltage Accuracy | 5 minutes | Voltage at various load levels | Within ±1% of rated voltage |

| Current Regulation | 10 minutes | Current stability under load | Within ±2% of rated current |

| Thermal Performance | 2 hours | Surface and internal temperatures | Below 65°C at full load |

| Burn-In Stress | 24-48 hours | Continuous full-load operation | No shutdown, no abnormal heat |

| Safety Circuit | 15 minutes | Overcharge, short-circuit, over-temp | Correct protective response |

Third-Party Inspection Options

For large orders, we recommend third-party inspection services. Companies like SGS, Bureau Veritas, and TÜV offer pre-shipment inspection programs.

These inspectors visit our facility during production and before shipping. They verify:

- Random sample testing against your specifications

- Packaging condition and accuracy

- Documentation completeness

- Quantity verification

The inspection report provides independent verification you can share with your customers. It demonstrates your commitment to quality and reduces your risk as an importer.

Remote Monitoring During Production

Our factory offers video calls during key production stages. You can watch testing procedures, ask questions, and request additional checks in real time.

We also provide detailed test reports for each production batch. These reports include:

- Individual unit serial numbers

- Test results for each parameter

- Any deviations noted and corrective actions taken

- Final inspection photographs

Field Performance Tracking

Quality verification doesn't end at shipping. We track warranty claims and failure reports from all markets. This data feeds back into our design and production processes.

For our European partners, we maintain spare parts inventory in Rotterdam. When issues arise, we can ship replacement units within days rather than weeks. This after-sales support complements our pre-shipment testing and ensures long-term customer satisfaction.

Conclusión

Meeting European electrical standards for agricultural drone chargers requires attention to voltage compatibility, proper certifications, thoughtful customization, and rigorous pre-shipment testing. Work with experienced manufacturers who understand EU requirements and can document compliance at every step.

Notas al pie

1. Explains the role and implementation of European Standards by official bodies. ↩︎

2. Provides the official scope and purpose of the Low Voltage Directive. ↩︎

3. States the official objective of the Electromagnetic Compatibility Directive. ↩︎

4. Replaced with an authoritative source on ISO/IEC 17025, which is relevant to laboratory competence and standards, including voltage testing. While IEC 60038 is the direct standard for voltages, ANAB provides a good overview of accreditation for testing labs. ↩︎

5. Replaced with a comprehensive Wikipedia article on AC power plugs and sockets, which details European types like C and F. ↩︎

6. Replaced with an authoritative source from ANAB (ANSI National Accreditation Board) explaining ISO/IEC 17025 accreditation. ↩︎

7. Official EU source explaining the purpose and requirements of CE marking. ↩︎

8. Explains the process and purpose of burn-in testing in electronics manufacturing. ↩︎