When our production team assembles each agricultural hexacopter 1, we see firsthand how one mismatched component can ground an entire fleet. Farmers lose money. Crops miss treatment windows. Frustration builds quickly.

To ask suppliers about parts compatibility, specify your exact drone model and serial number, request detailed technical specifications including voltage ratings and connector types, verify firmware compatibility, and demand written confirmation of OEM versus aftermarket part sources. Always ask for thrust curves and installation documentation before purchasing.

The questions you ask before buying determine your operational success for years detailed technical specifications 2. Let me walk you through exactly what to say and what documents to request from any supplier.

How do I verify if the drone's core components are compatible with universal or third-party replacement parts?

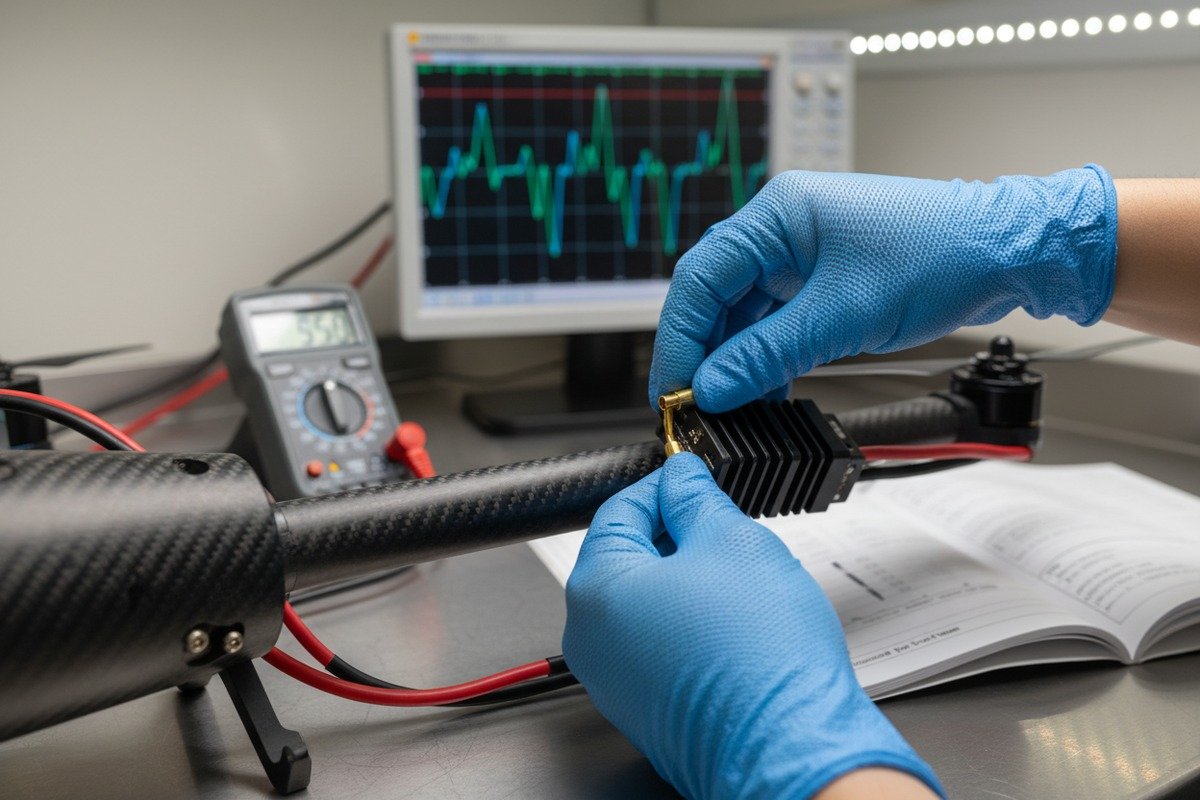

Our engineers spend countless hours testing component combinations in our Xi'an facility thrust-to-weight ratios 3. We have seen motors fail, ESCs burn out, and flight controllers crash—all from compatibility mismatches that seemed minor on paper.

Verify compatibility by requesting the supplier's technical specification sheets, cross-referencing connector types and voltage requirements, checking firmware version support, and testing thrust-to-weight ratios. Ask for documented test results showing the third-party part performing with your specific drone model under load conditions.

Start With Exact Model Identification

Never assume two drones with similar names share parts. A DJI Agras T30 uses different connectors than an XAG Y100. A JIYI K++ V2 flight controller may not sync with older motor firmware. firmware compatibility 4

When contacting any supplier, provide:

- Full model name and version number

- Serial number from your drone

- Current firmware version installed

- Date of manufacture if known

This information prevents 80% of compatibility errors that we see in returned parts.

Critical Parts Categories to Verify

Not all parts carry equal compatibility risk. Here is how we categorize them:

| Part Category | Compatibility Risk | Verification Priority |

|---|---|---|

| Controladores de vuelo | Very High | Always verify firmware sync |

| Motors & ESCs | Alto | Match KV ratings and current |

| Hélices | Medio | Check diameter and pitch |

| Baterías | Alto | Verify voltage and connector |

| Spraying Nozzles | Bajo | Usually universal fit |

| GPS/RTK Modules | Very High | Protocol must match |

| Marcos | Medio | Weight affects balance |

The Connector and Voltage Question

Ask your supplier directly: "What connector type does this part use, and what voltage range does it accept?"

A motor rated for 48V will damage systems designed for 24V. An ESC with XT90 connectors will not plug into an AS150 socket without adapters—and adapters introduce failure points.

We recommend requesting a physical connector photo before ordering. Many suppliers list "compatible" parts that require modification.

Firmware Synchronization Matters

Modern agricultural drones run sophisticated software. When we update flight controller firmware on our production line, older ESCs sometimes lose communication.

Haga estas preguntas específicas:

- "Does this part support firmware version [your version]?"

- "Will installing this part require a firmware update?"

- "If updates are needed, do you provide them?"

Some aftermarket parts work perfectly with current firmware but fail after manufacturer updates. Get written confirmation of ongoing software support.

OEM Versus Aftermarket Decision Framework

| Factor | OEM Parts 5 | Aftermarket Parts |

|---|---|---|

| Cost | Higher (baseline) | 20-50% lower |

| Warranty Impact | Preserved | May void warranty |

| Reliability | Guaranteed match | Variable quality |

| Disponibilidad | Limited suppliers | Wider sources |

| Mejor caso de uso | Critical systems | Consumable items |

For flight controllers and motors, we strongly suggest OEM parts. For propellers and nozzles, vetted aftermarket options save money without significant risk.

What specific questions should I ask to ensure the supplier maintains a steady stock of repair parts for my fleet?

In our experience exporting to US and European markets, fleet operators face their biggest losses not from part failures but from waiting for replacements. One grounded drone during peak spraying season costs thousands in lost revenue.

Ask suppliers about their current inventory levels for your specific model, average restock times, minimum order quantities for bulk purchasing, warehouse locations relative to your operation, and whether they offer priority fulfillment agreements. Request their historical fill rate data and backup sourcing arrangements.

Inventory Depth Questions

Do not accept vague answers like "we keep plenty in stock." Push for specifics:

- "How many units of [specific part] do you currently have?"

- "What is your average monthly sales volume for this part?"

- "At current sales rates, how many months of inventory do you hold?"

A supplier selling 50 motors monthly but holding only 30 in stock will backorder your urgent request.

Lead Time and Restock Transparency

When we run low on components at our factory, we communicate immediately with customers. Expect the same transparency from your suppliers.

Ask:

- "What is your typical lead time if this part is out of stock?"

- "Do you have manufacturer-direct relationships or buy through distributors?"

- "Can you notify me when inventory drops below a certain level?"

Direct manufacturer relationships mean faster restocking. Third-party sourcing adds weeks.

Geographic Considerations

| Supplier Location | Typical Shipping Time to US | Emergency Premium Available |

|---|---|---|

| US Domestic | 2-5 days | Yes, 1-2 day options |

| European Warehouse | 5-10 days | Sometimes |

| China Direct | 15-30 days | Expensive air freight |

| Regional Distributor | 3-7 days | Usually available |

For critical parts, establish relationships with at least one domestic supplier even if costs are higher. The speed advantage during emergencies pays for itself.

Bulk Purchasing Agreements

Fleet operators should negotiate inventory reservation. Here is a sample conversation framework:

"We operate 15 drones and expect to need approximately [X] motors, [Y] propeller sets, and [Z] nozzles annually. Can we establish a quarterly order schedule with guaranteed allocation?"

Many suppliers offer 5-15% discounts for committed volume with predictable ordering patterns.

Backup Sourcing Verification

Smart fleet managers never rely on single suppliers. Ask each potential vendor:

- "If you cannot fulfill an order, do you have partner suppliers?"

- "Can you provide contacts for alternative sources you trust?"

- "What happens to my order if you experience supply chain disruption 6?"

Honest suppliers acknowledge their limitations and help you build redundancy.

Can I customize the drone's hardware or software to work with my existing agricultural spraying systems?

When we calibrate our flight controllers for different spraying configurations, we see how small software changes create big field performance differences. Your existing equipment represents significant investment—integration matters.

Yes, customization is possible through API integration for software, physical adapter fabrication for hardware connections, and firmware parameter adjustments. Ask suppliers about their engineering support capabilities, available SDKs, connector adaptation services, and whether they offer custom development partnerships for unique integration requirements.

Hardware Integration Pathways

Your existing spraying system likely uses specific pump controllers, tank sensors, and nozzle arrays. Connecting these to a new drone platform requires careful planning.

Key questions for suppliers:

- "What communication protocols does the flight controller support?"

- "Are there available mounting points for third-party equipment?"

- "Can you provide wiring diagrams for custom sensor integration?"

- "What is the maximum payload capacity including my existing equipment?"

Software and Data System Compatibility

Modern precision agriculture 7 relies on data flow between drones, farm management software, and analysis platforms. When our development team creates integration features, we prioritize open standards.

| Integration Type | Common Protocols | Preguntas que hay que hacer |

|---|---|---|

| Flight Data Export | MAVLink, DJI SDK | "Can I export flight logs in [format]?" |

| Spray Mapping | Shapefiles, KML | "Does your system generate prescription maps?" |

| Farm Software Sync | API, Direct Import | "Do you have [software name] integration?" |

| Sensor Data | CAN bus, Serial | "What data outputs are available?" |

Custom Development Partnerships

Some integration needs exceed standard options. Ask suppliers:

- "Do you offer custom firmware development?"

- "What is your engineering team's capacity for special projects?"

- "Can you modify hardware configurations for our specific needs?"

- "What are typical timelines and costs for custom development?"

At our facility, we regularly collaborate with clients on specialized features. Suppliers willing to invest engineering resources demonstrate long-term partnership commitment.

Physical Mounting and Balance

Adding your existing equipment changes drone weight distribution. Every gram affects flight stability and battery consumption.

Request from suppliers:

- Detailed center-of-gravity specifications

- Maximum offset tolerance for mounted equipment

- Recommended mounting locations and methods

- Impact calculations for your specific equipment weight

A 500-gram sensor mounted 10cm off-center creates very different flight characteristics than one mounted at the drone's center.

Regulatory Compliance After Modification

Modified drones may require re-certification depending on your jurisdiction. Ask:

- "Will this modification affect FAA type certification 8?"

- "Do you provide documentation supporting modified configurations?"

- "Have other customers successfully certified similar modifications?"

Suppliers with export experience understand these requirements and can provide necessary paperwork.

How do I confirm that the supplier provides a long-term availability guarantee for critical maintenance components?

Our production planning team thinks in five-year cycles. We know agricultural drones represent major capital investments that must deliver returns over many seasons. Customers rightfully worry about parts disappearing.

Confirm long-term availability by requesting written End-of-Life policies, asking about minimum production run commitments, verifying whether the supplier manufactures or merely distributes parts, negotiating contractual availability guarantees, and establishing escrow arrangements for critical components if necessary.

End-of-Life Policy Documentation

Every product eventually becomes obsolete. Professional suppliers plan for this transition.

Ask directly:

- "What is your stated End-of-Life support period for this model?"

- "How much advance notice do you provide before discontinuing parts?"

- "Do you offer last-time-buy opportunities before discontinuation?"

- "Will you share your EOL policy in writing?"

Reputable manufacturers commit to 5-7 years of parts support minimum. Anything less should raise concerns for fleet investments.

Manufacturer Versus Distributor Distinction

This matters enormously for long-term supply security.

| Supplier Type | Availability Control | Long-Term Risk |

|---|---|---|

| Original Manufacturer | High – they make it | Lowest |

| Authorized Distributor | Medium – contracted supply | Moderate |

| Independent Reseller | Low – market dependent | Higher |

| Broker/Trader | Very Low – spot market | Highest |

When speaking with suppliers, ask: "Do you manufacture these parts, or do you source them from another company?" Follow up with: "What is your contractual relationship with the manufacturer?"

Contractual Protection Strategies

For fleet purchases, negotiate specific provisions:

- Minimum stocking requirements: Supplier agrees to maintain X units of critical parts

- Advance discontinuation notice: 12-24 months warning before parts unavailability

- Price protection: Rates locked for specified periods

- Alternative sourcing rights: Permission to seek other suppliers if primary fails

- Technical documentation escrow: Access to specifications if supplier exits market

These provisions cost nothing to request and provide significant protection.

Critical Parts Inventory Strategy

Build your own buffer stock for parts that would ground your fleet. Calculate based on:

| Part Type | Recommended Stock Level | Reasoning |

|---|---|---|

| Hélices | 2 sets per drone | High wear, easy storage |

| Motores | 1 per 3 drones | Medium failure rate, expensive |

| ESCs | 1 per 4 drones | Lower failure rate |

| Nozzles | 4 sets per drone | Very high wear, cheap |

| Controlador de vuelo | 1 per 10 drones | Rare failure, critical function |

Supplier Financial Stability Assessment

A supplier's business health affects their ability to honor long-term commitments.

Research questions:

- "How long has your company been in business?"

- "Are you profitable and self-sustaining?"

- "What is your annual revenue trend?"

- "Do you have backing from stable investors?"

You can also check business registration databases, request trade references, and review their facility capabilities. When we host customer visits at our Xi'an headquarters, we demonstrate our manufacturing capacity directly—genuine suppliers welcome this scrutiny.

Documentation and Technical Transfer

Even with supplier commitments, protect yourself with documentation:

- Obtain complete technical specifications for all critical parts

- Request CAD files or dimensional drawings where available

- Keep copies of all calibration procedures and software settings

- Document any custom configurations in detail

If your primary supplier fails, this information helps alternative sources produce compatible replacements.

Conclusión

Parts compatibility questions protect your agricultural drone investment for years. Ask about exact model specifications, verify supplier inventory depth, explore customization options, and demand long-term availability commitments in writing. Your fleet's uptime depends on these conversations.

Notas al pie

1. Defines this specific type of drone used in agriculture. ↩︎

2. Explains why comprehensive technical specifications are crucial for project success. ↩︎

3. Explains the definition and importance of thrust-to-weight ratio for drone performance. ↩︎

4. Addresses common issues arising from firmware mismatches and their solutions. ↩︎

5. Authoritative source providing a clear definition of OEM parts and their comparison to aftermarket parts. ↩︎

6. Explains unexpected events that interrupt the flow of goods and services. ↩︎

7. Defines the data-driven farming approach that optimizes resource use. ↩︎

8. Explains the regulatory process for type certification of Unmanned Aircraft Systems. ↩︎

9. Defines product End-of-Life policies and their importance in product management. ↩︎