We often see farmers frustrated by frames that crack mid-season. When we source materials for our SkyRover series, we know that visual cues alone can be misleading without proper inspection techniques.

To determine carbon fiber quality in agricultural drones, inspect the weave for uniformity without distortions or dry spots. Verify the edge finish is clean with no fraying or fiberglass filler layers. Perform a rigidity test; high-grade carbon fiber shows zero permanent deformation under stress, unlike cheaper composites that flex excessively.

Let’s break down the specific tests and observations you can use to verify quality before buying.

What visual defects should I look for to spot inferior carbon fiber drone frames?

During our quality control checks in Chengdu, we reject frames with even minor surface blemishes because they often signal deeper structural flaws hidden within the composite layers.

Inferior carbon fiber frames often display inconsistent weave patterns, pinholes, or white streaks indicating resin starvation. Look for jagged CNC-cut edges or visible separation between layers, known as delamination. These visual defects suggest poor manufacturing pressure and compromise the structural integrity needed for heavy agricultural payloads.

When evaluating a potential supplier or inspecting a sample unit, your eyes are your first line of defense. High-quality carbon fiber used in heavy-lift agricultural drones serves a functional purpose, not just an aesthetic one. However, the surface finish tells a detailed story about what lies beneath.

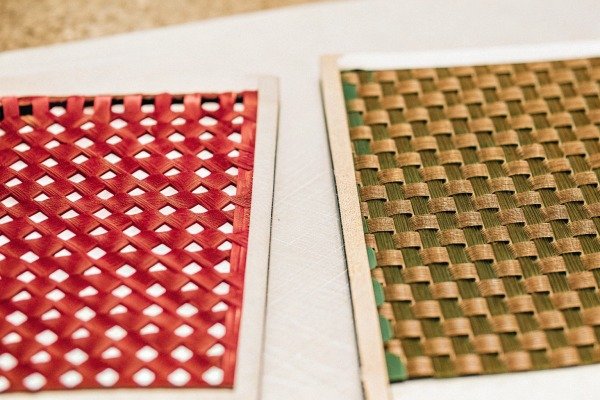

The Significance of Weave Consistency

The most common weave used in our industry is 3K tow, but not all 3K tow 1 3K weaves are created equal. You should look closely at the fiber alignment. In a high-quality arm or landing gear leg fiber alignment 2, the fibers should run perfectly straight. If you see "wavy" fibers or distorted patterns, it indicates that the material shifted during the curing process. This misalignment reduces the load-bearing capacity of that specific section.

Furthermore, watch out for "dry spots." These appear as dull, non-glossy patches where the resin failed to fully saturate the carbon fabric. On the flip side, "resin rich" areas look like pools of plastic with no visible fibers. Both are bad news. Dry spots are brittle and prone to cracking, while resin-rich areas add unnecessary weight without adding strength.

Edge Quality and CNC Precision

The edges of the carbon fiber plates—where the motors mount or where the arms fold—reveal the care taken during post-processing. A premium frame undergoes precise CNC cutting. The edges should be smooth, sealed, and uniform.

If you run your finger along the edge (carefully) and feel roughness, or see loose fibers sticking out, it means the manufacturer used dull tooling or rushed the cutting speed. More dangerously, inspect the cross-section of the cut. Some unethical suppliers use a "sandwich" technique where they hide fiberglass layers between two thin sheets of carbon fiber to cut costs. If the center layers look white or distinctively different from the outer black layers, you are looking at a fiberglass core, which is significantly heavier and weaker than solid carbon.

Table 1: Visual Defect vs. Structural Risk

| Visual Defect | Physical Appearance | Structural Consequence |

|---|---|---|

| Resin Starvation | Dull, dry-looking patches or pinholes | High risk of fracture; moisture can enter the matrix. |

| Fiber Distortion | Wavy or curved weave lines | Reduced tensile strength; unpredictable flex under load. |

| Delamination | Visible gaps or splitting at cut edges | Catastrophic failure during high-vibration flight. |

| Fiberglass Core | White/grey inner layers at cut edge | Increased weight; reduced stiffness; lower payload capacity. |

How does the manufacturing process affect the structural integrity of my agricultural drone?

Our engineering team spent years optimizing autoclave curing cycles because simple wet-layup methods simply cannot survive the intense vibration frequencies generated by heavy-lift 12S motor systems.

The manufacturing process dictates durability; pre-preg carbon fiber cured in an autoclave offers superior strength-to-weight ratios compared to wet-layup methods. Autoclave curing ensures uniform resin distribution and removes air pockets, resulting in a denser, stiffer frame capable of withstanding the intense high-frequency vibrations of agricultural drone motors.

The method used to create the carbon fiber tubes and plates is just as important as the raw material itself. In the drone industry, there is a massive performance gap between "wet-layup" and "pre-preg" manufacturing.

Pre-preg vs. Wet-Layup Techniques

"Wet-layup" is the cheaper, older method. It involves manually brushing resin onto dry carbon fabric. This relies heavily on human skill. Often, this results in uneven thickness and excess resin weight. For a hobby drone, this might be acceptable. For an agricultural drone carrying 20 to 50 liters of liquid, it is a liability.

"Pre-preg" (pre-impregnated) carbon fiber arrives at the factory Kohlefaser 3 with the optimal amount of resin already infused into the fabric by machine. We use this material because it guarantees consistency. Every square inch of the drone arm has the exact same resin-to-fiber ratio. This consistency allows us to predict exactly how much load the arm can take before failing.

The Role of Autoclave Curing

The curing process seals the deal. High-end agricultural drone components are cured in an autoclave—essentially a high-pressure oven. cured in an autoclave 4 The combination of heat and vacuum pressure squeezes the layers of carbon fiber together tightly.

This process eliminates microscopic air bubbles (voids) that get trapped between layers. In a drone frame, these voids are fatal flaws. When a drone vibrates, these air pockets become starting points for cracks. A frame made without high pressure might feel stiff initially, but after 50 hours of flight time, the micro-cracks expand, leading to "soft" arms that twist during flight. This twisting confuses the flight controller, leading to instability or crashes.

Table 2: Manufacturing Method Comparison

| Merkmal | Wet-Layup / Vacuum Bagging | Autoclave Pre-preg (Standard) |

|---|---|---|

| Resin Control | Inconsistent (Manually applied) | Precise (Machine applied) |

| Void Content | High (Air pockets common) | Very Low (<1%) |

| Gewicht | Heavier (Excess resin) | Lighter (Optimized ratio) |

| Vibration Damping | Poor (Resin absorbs less vibration) | Excellent (Solid composite structure) |

| Kosten | Niedrig | Medium to High |

Will the carbon fiber material withstand long-term exposure to pesticides and fertilizers?

We have seen competitor frames delaminate after just one season competitor frames delaminate 5 of spraying because the resin matrix failed to block chemical ingress, causing the arms to swell and weaken.

High-quality carbon fiber resists chemical corrosion effectively, but only if the epoxy resin matrix is specifically formulated for chemical stability. Inferior resins absorb moisture and pesticides, leading to swelling, delamination, and weight gain over time. Always verify that the surface finish includes a UV-resistant, chemically inert clear coat.

Agricultural drones exist in a harsh chemical environment. They are constantly coated in fine mists of fungicides, herbicides, and fertilizers fungicides, herbicides, and fertilizers 6. While carbon fiber itself (the black threads) is chemically inert, the resin holding it together is not.

The Danger of Chemical Ingress

The epoxy resin is the weak link. Cheap generic resins are often porous epoxy resin 7 on a microscopic level. When corrosive agricultural chemicals sit on the frame, they can slowly seep into these pores. Over time, chemicals like sulfur-based fungicides can react with low-grade epoxy, causing it to soften or blister.

Once the resin softens, the structural rigidity is lost. We often see this manifested near the motor mounts, where the heat from the motor accelerates the chemical reaction. A high-quality agricultural drone frame uses resin systems specifically tested for chemical resistance. Additionally, a premium frame will have a high-grade clear coat—usually a polyurethane automotive-grade finish—that acts as a final shield against chemicals.

Moisture Absorption and Weight Gain

There is also the issue of water absorption. Even if you are not spraying chemicals, humidity plays a role. Poorly cured carbon fiber can absorb moisture from the air or during wash-downs.

Water ingress is dangerous for two reasons. First, it adds weight. A frame that absorbs just 2% of its weight in water can reduce flight time by minutes over the course of a day. Second, if the water gets between the layers and then freezes (in colder climates) or expands due to heat, it forces the layers apart. This is why we insist on using materials that meet low water absorption standards. water absorption standards 8

Table 3: Common Agricultural Chemicals vs. Carbon Fiber Resin Types

| Chemical Type | Effect on Standard Epoxy (Budget) | Effect on Chemically Resistant Epoxy (Premium) |

|---|---|---|

| Ammonium Nitrate (Fertilizer) | Can cause surface clouding and micro-cracking over time. | No visible degradation; surface remains glossy. |

| Glyphosate (Herbicide) | Softens topcoat if left unwashed; makes surface sticky. | High resistance; wipes clean without residue. |

| Lime Sulfur (Fungicide) | High corrosion risk; causes yellowing and brittleness. | Resistant; maintains structural modulus. |

| Water/Humidity | Absorption >3%; leads to weight gain and internal expansion. | Absorption <0.5%; structural integrity maintained. |

Which material test reports should I ask the factory to provide before ordering?

Before we ship a container to our US distributors, we ensure every batch has documentation proving it meets aerospace-grade standards, rather than relying on vague marketing claims.

Request independent third-party lab reports covering tensile strength, flexural modulus, and interlayer shear strength. Crucially, ask for fatigue testing data that simulates repetitive load cycles and specific chemical resistance certificates proving the resin system can withstand common agricultural pesticides without degrading the composite matrix.

It is easy for a sales representative to promise "aviation-grade" materials. It is much harder for them to produce the paperwork to prove it. When you are negotiating a purchase, asking for specific data sets separates the serious manufacturers from the assemblers who buy the cheapest parts available.

Tensile Strength and Modulus

The most basic report you need is the Tensile Strength test (often ASTM D3039). This tells you how much pulling force the carbon fiber can take before it snaps. However, for drones, Flexural Modulus (stiffness) is even more critical.

Agricultural drones rely on stiff arms to maintain GPS accuracy. If the arms flex too much during a maneuver, the flight controller thinks the drone Fluglotse 9 is in one position, but the motors are actually pointing in a slightly different direction. This causes oscillation. You want to see a high modulus number, indicating the material is extremely stiff. high modulus 10

Fatigue and Environmental Testing

Real-world durability is measured in cycles, not just max load. Ask if they have Fatigue Testing reports. This involves bending the drone arm thousands of times to simulate years of flight. A high-quality report will show that the material retains 90% or more of its strength after 100,000 cycles.

Furthermore, ask for Environmental Aging tests. This data shows how the material performs after being exposed to UV light and high humidity for hundreds of hours. If a supplier cannot provide this, it usually means they have not tested for it, and you will be the one doing the testing in the field—at your own expense.

Interpreting the Data

Do not just accept a certificate that says "Pass." Look at the numbers.

- Interlayer Shear Strength: This measures how well the layers stick together. A low number here means the drone arms will delaminate (peel apart) easily.

- Glass Transition Temperature (Tg): This is the temperature at which the resin starts to become soft. For agricultural drones operating in hot summers, you want a Tg well above 100°C. If the Tg is low (e.g., 60°C), the frame could warp simply by sitting in a hot truck or operating under direct sunlight.

Schlussfolgerung

Investing in verified carbon fiber quality ensures your fleet remains operational and profitable season after season. By looking beyond the surface and demanding technical proof, you secure the longevity of your agricultural business.

Fußnoten

1. Technical specifications for standard carbon fiber tow sizes from a leading global manufacturer. ︎

2. Explains the importance of fiber orientation in composite strength. ︎

3. Provides general background on the material’s composition and properties. ︎

4. Details the high-pressure manufacturing process essential for aerospace-grade composites. ︎

5. Explains the failure mode where material layers separate, critical for composite structural safety. ︎

6. Official information on agricultural chemicals and their management in farming from the FAO. ︎

7. Defines the polymer matrix used in composites and its properties. ︎

8. Links to the ASTM standard test method for water absorption. ︎

9. Industry standard covering the service protocol and interfaces for unmanned aerial vehicle payloads. ︎

10. Explains the property of stiffness critical for drone frame stability. ︎