During our years of exporting firefighting drones to fire departments across the US and Europe, one question keeps coming up from procurement teams: what happens when a bird hits my drone mid-mission Octocopter designs 1? This is a real concern. Wildfires attract massive bird populations seeking insects and food sources near smoke plumes. A single collision at the wrong moment can ground your expensive equipment—or worse, cause mission failure during a critical rescue operation.

To evaluate bird strike damage resistance, request manufacturer impact test data following aviation standards like ASTM F330, examine frame materials such as carbon fiber or reinforced polycarbonate, verify propulsion redundancy systems, and confirm post-strike parts availability. These four factors determine whether your drone survives a collision and continues flying safely.

Let me walk you through each evaluation criterion. Our engineering team has spent considerable time adapting aircraft bird-strike principles to drone design. Below, I will share what we have learned and what you should ask before signing any purchase order.

How can I assess if the drone's frame materials are durable enough to withstand a high-speed bird collision?

When we source materials for our production lines, durability against sudden impacts ranks among our top priorities. Many buyers assume that any drone labeled "industrial" will handle bird strikes. That assumption can cost you thousands in repairs. The truth is that frame material choice varies dramatically between manufacturers, and not all materials perform equally under high-velocity impacts.

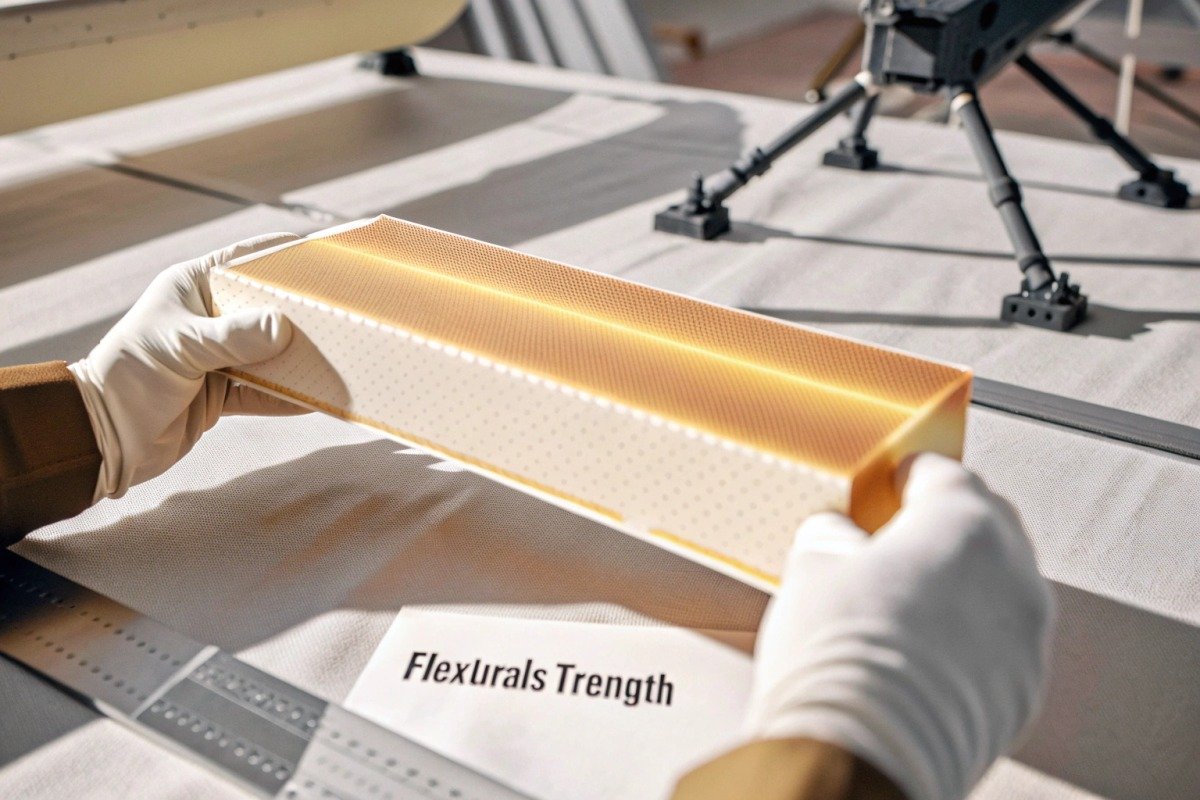

Assess frame durability by examining material specifications—carbon fiber composites offer rigidity but may crack internally, while laminated polycarbonate (16mm thick) has proven resistance to 1.81kg bird impacts without failure. Request material certifications, inspect layup construction methods, and compare flexural strength ratings across models.

Understanding Material Behavior Under Impact

Frame materials respond to bird strikes in different ways. Metals deform plastically—they bend but often maintain structural integrity. Composite materials like carbon fiber behave differently. Kohlefaserverbundwerkstoffe 2 They are stiff and lightweight, perfect for flight efficiency. However, composites can experience hidden internal damage from low-speed impacts. High-speed collisions cause significant strength loss that may not be visible externally.

Our engineers have found that a frame looking undamaged after a bird strike might actually have micro-fractures inside. These fractures weaken the structure over time. On subsequent flights, the frame could fail unexpectedly.

Key Material Properties to Compare

| Material Type | Gewicht | Impact Resistance | Hidden Damage Risk | Kosten |

|---|---|---|---|---|

| Carbon Fiber Composite | Sehr niedrig | High rigidity, brittle failure | Hoch | Hoch |

| Laminated Polycarbonate 3 | Mittel | Excellent energy absorption | Niedrig | Mittel |

| Aluminum Alloy | Hoch | Good plastic deformation | Niedrig | Mittel |

| Reinforced Nylon | Niedrig | Moderate flexibility | Mittel | Niedrig |

When evaluating drones, ask the manufacturer which specific composites they use. Request data sheets showing flexural strength and impact absorption ratings. At our facility, we test sample frames using drop towers and quasi-static pressure machines to verify real-world performance matches specifications.

What Questions to Ask Manufacturers

First, ask about layup construction. How many layers? What fiber orientation? Random fiber orientation weakens impact resistance compared to woven patterns.

Second, request information about resin systems. Some resins absorb energy better than others. Epoxy-based systems tend to be more brittle than toughened thermoplastic resins.

Third, inquire about joining methods. Bonded joints may separate under impact stress. Bolted or riveted joints might handle collisions better but add weight.

A reputable manufacturer will provide detailed material specifications without hesitation. If they cannot answer these questions, consider that a red flag.

What kind of impact test data should I ask for to prove the drone can survive a bird strike?

Our quality control team frequently receives requests from US distributors asking for test certificates. The problem is that no drone-specific bird strike regulations exist yet. This creates confusion. Some manufacturers claim "impact tested" without standardized methods. Others provide aviation-grade documentation that actually proves capability. Knowing what to request separates informed buyers from those who get surprised later.

Request impact test data following ASTM F330 standards or equivalent aviation protocols, including air cannon tests with bird masses between 0.9kg and 1.81kg at velocities up to 150 meters per second. Also accept validated finite element analysis simulations showing component behavior under strike conditions. Documentation should specify no penetration and maintained functionality post-impact.

Aviation Testing Standards Applied to Drones

The aviation industry has decades of bird strike testing experience. ASTM F330 4 and FAA regulations require components like radomes, propellers, and windshields to withstand bird impacts. Tests use air cannons to propel bird carcasses or certified substitutes at target components.

Key requirements include:

- No penetration of critical surfaces

- Maintained functionality of essential systems

- Safe landing capability after impact

While drones are not aircraft, these principles apply directly. At our testing facility, we adapt these protocols for drone components. We test propeller guards, frame sections, and sensor housings using similar methodologies.

Physical Tests vs. Simulation Methods

| Prüfverfahren | Advantages | Disadvantages | Reliability |

|---|---|---|---|

| Air Cannon with Real Birds | Most accurate real-world data | Expensive, ethical concerns | Sehr hoch |

| Air Cannon with Gel Substitutes | Repeatable, no ethical issues | May not perfectly match bird behavior | Hoch |

| Finite Element Analysis (FEA) | Low cost, rapid iteration | Requires validation against physical tests | Mittel-Hoch |

| Drop Tower Testing | Simple setup, good for screening | Limited velocity range | Mittel |

Finite element analysis using software like ABAQUS 5 or CATIA models bird impacts digitally. These simulations show good correlation with physical tests when properly calibrated. Research from institutions like Fraunhofer EMI demonstrates that FEA can predict damage patterns accurately. However, simulations require validation. Ask if the manufacturer has correlated their FEA models with actual physical tests.

Specific Data Points to Request

When reviewing test documentation, look for these specific details:

Bird mass used in testing should range from 0.9kg to 1.81kg. This covers most common bird species encountered during wildfire operations.

Impact velocity matters. Birds and drones can close at combined speeds up to 150 meters per second. Tests at lower velocities may not represent realistic worst-case scenarios.

Strike location data shows which components were tested. Propellers, frame joints, camera gimbals, and battery compartments each require separate evaluation.

Post-impact functionality reports confirm whether the drone maintained flight control, sensor operation, and communication links after the test impact.

If a manufacturer only provides vague claims like "impact resistant" without numerical data, request specifics or move to another supplier.

Does the drone have enough propulsion redundancy to stay airborne if a bird damages one of my propellers?

In our experience exporting octocopter configurations to emergency response teams, propulsion redundancy becomes the deciding factor between a controlled return and a crash landing. Quadcopters lose approximately 25% thrust capacity if one motor fails. Octocopters can sustain one or even two motor failures while maintaining controlled flight. This difference matters enormously when your drone carries expensive thermal cameras and water payload over active wildfires.

Verify propulsion redundancy by confirming motor count, thrust-to-weight ratio with payload, and flight controller failsafe programming. Octocopter designs with 8 motors can sustain single motor failure while maintaining controlled flight. Ensure the flight controller automatically compensates for damaged propellers and can execute autonomous return-to-home sequences.

Motor Configuration and Failure Tolerance

Different drone configurations offer varying levels of redundancy. The table below compares common setups:

| Konfiguration | Motoren | Single Motor Failure | Double Motor Failure | Nutzlast Auswirkungen |

|---|---|---|---|---|

| Quadcopter | 4 | Loss of control likely | Crash | Minimal weight penalty |

| Hexacopter | 6 | Controlled flight possible | Limited control | Moderate weight penalty |

| Octocopter | 8 | Full controlled flight | Controlled flight possible | Higher weight penalty |

| Coaxial Octocopter | 8 (stacked) | Full controlled flight | Limited control | Moderate weight penalty |

When we design firefighting drones for harsh environments, we recommend octocopter configurations. The additional motors add weight but provide essential safety margins. A bird striking one propeller should not end your mission or destroy your investment.

Thrust-to-Weight Considerations

Redundancy only works if remaining motors have enough power to compensate. Calculate the thrust-to-weight ratio 7 with full payload. A healthy ratio for redundant operation is at least 2:1 under normal conditions. This means your drone produces twice the thrust needed to hover.

With one motor down on an octocopter, remaining motors must work harder. If your original ratio was marginal, the drone may not maintain altitude. Ask manufacturers for thrust curves showing performance under degraded motor conditions.

Flight Controller Failsafe Programming

Hardware redundancy means nothing without smart software. Modern flight controllers detect motor failures through current monitoring and RPM feedback. flight controller failsafe programming 8 When failure occurs, the controller should:

- Immediately redistribute power to remaining motors

- Alert the operator through telemetry

- Automatically initiate return-to-home if signal is lost

- Maintain stable hover for operator decision-making

During our flight controller calibration process, we program multiple failsafe layers. Some competing products only offer basic failsafes that trigger emergency landing regardless of remaining capability. Better systems assess actual flight envelope and maintain maximum safe operation.

Request a demonstration or video showing the drone maintaining controlled flight after simulated motor failure. Any manufacturer confident in their redundancy design will provide this evidence.

How will the manufacturer support my team with replacement parts if a bird strike occurs during a mission?

When we ship drones to fire departments through our US distribution partners, the conversation always turns to after-sales support. Your drone surviving a bird strike means nothing if replacement parts take six weeks to arrive. Mission-critical equipment requires rapid restoration. The best frame materials and redundancy systems become worthless if you cannot get your drone operational quickly after an incident.

Evaluate manufacturer support by confirming parts inventory availability, shipping timeframes to your location, technical support accessibility, and modular design enabling field repairs. Request documentation of spare parts pricing, typical delivery windows, and whether the manufacturer stocks common wear components like propellers, motor assemblies, and camera gimbals.

Parts Availability and Delivery Windows

Not all manufacturers maintain adequate spare parts inventory. Some produce components only on demand, creating weeks of delay. Others stock common replacement items for immediate shipment.

Stellen Sie diese spezifischen Fragen:

Where are spare parts warehoused? Parts stored in your country or region arrive faster than international shipments requiring customs clearance.

What is the typical delivery window for propellers, motors, and frame sections? Acceptable answers range from same-day to one-week delivery for critical components.

Does the manufacturer offer expedited shipping options for emergency situations? Fire season does not wait for standard ground shipping.

At our company, we maintain parts inventory in regional distribution centers. Our US partners can typically deliver common replacement components within 48-72 hours to most locations. This capability developed from customer feedback about frustrating delays from other suppliers.

Modular Design Benefits

Drones designed with modularity in mind simplify field repairs. modular design 9 Instead of returning the entire aircraft for service, operators can swap damaged modules on-site.

Key modular features include:

- Quick-release propeller systems

- Plug-and-play motor assemblies

- Removable arm sections

- Interchangeable sensor mounts

When evaluating drones, examine how components attach. If replacing a damaged motor arm requires complete disassembly and specialized tools, field repair becomes impractical. Better designs allow trained technicians to swap components in under 30 minutes using standard tools.

Technical Support Accessibility

Parts alone do not solve every problem. Bird strike damage may affect flight controller calibration, sensor alignment, or wiring harnesses. You need technical guidance.

Evaluate manufacturer support channels:

| Art der Unterstützung | Verfügbarkeit | Reaktionszeit | Am besten für |

|---|---|---|---|

| E-Mail-Unterstützung | Geschäftszeiten | 24-48 Stunden | Non-urgent questions |

| Phone Hotline | Geschäftszeiten | Unmittelbar | Troubleshooting guidance |

| Video Consultation | Geplant | Same day possible | Complex repairs |

| On-Site Service | By arrangement | 1-2 Wochen | Major overhauls |

Remote diagnostics through flight logs and telemetry data help our technical team identify damage extent without physical inspection. We can often guide customers through repairs using video calls and shared documentation.

Before purchasing, ask for references from existing customers. Contact them about their actual support experiences. Marketing promises differ from real-world delivery.

Schlussfolgerung

Evaluating bird strike damage resistance requires examining frame materials, requesting validated impact test data, verifying propulsion redundancy, and confirming manufacturer support infrastructure. These four criteria protect your investment and ensure mission continuity when collisions inevitably occur during wildfire operations.

Fußnoten

1. Replaced 405 link with a comprehensive guide detailing various drone frame types, including octocopter designs. ︎

2. Replaced 404 link with an authoritative source on carbon fiber reinforced plastics (CFRP) in aviation. ︎

3. Details the development and use of laminated polycarbonate for bird impact resistance in aircraft. ︎

4. Describes the standard test method for bird impact testing of aerospace transparent enclosures. ︎

5. Provides a technical strategy for performing bird strike simulations using Abaqus/Explicit software. ︎

6. Reviews numerical methods for simulating bird strikes, including finite element analysis. ︎

7. Explains how to calculate and the importance of thrust-to-weight ratio for drone performance and payload. ︎

8. Describes the Betaflight failsafe system to safely manage potential hazards from radio link loss. ︎

9. Explains how modular drone design allows for interchangeable payloads and battery configurations. ︎