When we test our SkyRover units at our facility in Chengdu, we know that a battery failure during a rescue mission is not just an inconvenience; it is a critical safety risk. critical safety risk 1 Many procurement managers we speak with in the US focus heavily on flight time specs, yet they often overlook the hidden danger of improper battery care until a pack swells or fails mid-operation. To protect your investment and ensure mission readiness, understanding the supplier’s role in battery guidance is essential.

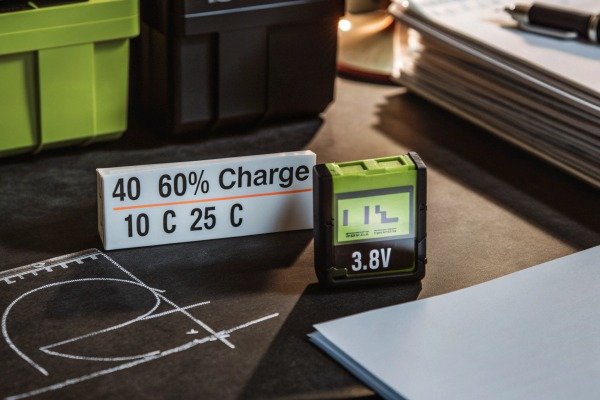

Reputable firefighting drone suppliers invariably provide specific documentation covering lithium battery storage, mandating a 40% to 60% charge level (approximately 3.8V per cell) for long-term idle periods. These guidelines also dictate strict temperature controls between 10°C and 25°C to prevent capacity loss and safety hazards like thermal runaway.

Below, we break down the specific protocols and documentation you should expect from a high-quality industrial partner.

How should I store my firefighting drone batteries when they are not in use?

In our experience exporting to fire departments across Europe and the US, the most common cause of early battery failure is not flight stress, but improper storage in hot vehicles or freezing warehouses. We have seen perfectly good hardware ruined simply because it was left fully charged in a humid locker for weeks.

Store your firefighting drone batteries in a fireproof LiPo safety bag or metal explosion-proof cabinet, kept in a dry, climate-controlled room between 15°C and 25°C (59°F–77°F). Ensure the charge level is maintained at roughly 3.8V per cell (40–60%) to prevent internal chemical decomposition or dangerous swelling.

The Science Behind Storage Voltage

The chemistry of the Lithium Polymer (LiPo) and Lithium-ion batteries we use in industrial drones is volatile. If you store a battery at 100% charge, the high voltage places immense stress on the internal chemistry, leading to electrolyte decomposition and the generation of gas electrolyte decomposition 2—this is what causes the battery to "puff" or swell. Conversely, storing a battery at 0% allows the voltage to drop below the critical threshold due to natural self-discharge, rendering the cell unchargeable and chemically unstable.

We advise our clients to aim for the "storage voltage" sweet spot. For a standard LiPo cell, this is typically 3.80V to 3.85V. This voltage level is chemically stable, minimizing the formation of lithium dendrites that can pierce the separator lithium dendrites 3 and cause internal short circuits.

Environmental Control Requirements

Temperature control is not optional for industrial equipment. While our drones are built to fly in harsh conditions, the batteries are delicate when dormant. Storing batteries in a non-insulated shed during a freezing winter or a hot summer will degrade their internal resistance. internal resistance 4 Higher internal resistance means the battery will sag under load, potentially triggering a low-voltage warning just minutes after takeoff. low-voltage warning 5

Physical Isolation and Safety

Safety infrastructure is a key part of the storage equation. Fire stations should treat these batteries like hazardous materials. Gefahrstoffe 6 We recommend a tiered storage approach: individual batteries go into fire-retardant fiberglass bags, and those bags go into a steel cabinet. This containment strategy ensures that if one defective cell goes into thermal runaway, it does not ignite the entire stockpile thermisches Durchgehen 7 or the building.

Temperature Impact on Battery Health

| Storage Temperature | Self-Discharge Rate (approx.) | Risikostufe |

|---|---|---|

| 10°C – 20°C (50°F – 68°F) | < 2% per month | Low (Ideal) |

| 25°C – 30°C (77°F – 86°F) | 3% – 5% per month | Mäßig |

| > 40°C (> 104°F) | > 10% per month | High (Permanent Damage) |

| < 0°C (< 32°F) | Variabel | High (Plating Risk upon charging) |

What maintenance routine will extend the lifespan of my industrial drone batteries?

Our engineers frequently analyze flight logs from returned units, and we often find that “defective” batteries were actually just victims of neglect. It is frustrating for a procurement manager to approve a budget for replacements only to find out the original set died because the maintenance schedule was ignored.

To extend lifespan, perform a full charge-discharge cycle every three months to recalibrate the Battery Management System (BMS), ensuring accurate percentage readings. Additionally, conduct visual inspections for physical damage, corrosion, or swelling before every flight and avoid “fast charging” unless immediately necessary for an emergency response.

The Readiness Paradox in Firefighting

Fire departments face a unique challenge we call the "Readiness Paradox." Storage guidelines say keep batteries at 50%, but emergency response requires 100% readiness. You cannot tell a fire chief to wait 45 minutes for batteries to charge while a building burns.

To solve this, we recommend a rotation fleet strategy. If you have ten battery sets, keep two sets fully charged for immediate dispatch and the other eight at storage voltage. Rotate them weekly. This ensures that no single battery sits at 100% voltage for months on end, which is the fastest way to kill a LiPo battery.

Recalibrating the BMS

The "Smart Battery" chips inside industrial drones track energy in and energy out to estimate remaining flight time. Over time, small calculation errors accumulate. If you only perform shallow discharges (e.g., landing at 60%), the BMS loses track of the true "zero" point.

Every three months (or every 20 cycles), you must perform a deep cycle. This involves charging to 100% and then discharging the drone (either by hovering or using a specialized discharger) down to roughly 15% or low voltage warning levels. This resets the digital fuel gauge, preventing the terrifying scenario where a pilot sees "30% remaining" on the screen, but the drone suddenly loses power and falls.

Visual and Physical Inspection Protocol

Maintenance is also tactile. We train our technicians to feel the battery surfaces. A healthy battery should be perfectly flat. Any slight curvature or "sponginess" indicates gas buildup. Connectors must be inspected for carbon buildup (black marks), which increases resistance and heat.

Quarterly Maintenance Checklist

| Aktionspunkt | Frequency | Zweck |

|---|---|---|

| Visuelle Kontrolle | Pre/Post-Flight | Identify swelling, cracks, or wire fraying. |

| Connector Cleaning | Monatlich | Remove oxidation to ensure efficient power transfer. |

| Deep Cycle | Every 3 Months | Recalibrate the BMS for accurate percentage display. |

| Firmware-Aktualisierung | As Released | Ensure BMS logic matches the latest safety algorithms. |

Will the manufacturer provide a detailed manual for battery safety and care?

When we prepare documentation for our US clients, we know that a simple “user guide” is insufficient for professional liability standards. We often see competitors provide a single sheet of paper, which leaves procurement managers liable when safety protocols are ambiguous or missing entirely.

Yes, reputable manufacturers provide detailed safety manuals, including Material Safety Data Sheets (MSDS) for transport compliance and specific voltage charts. However, generic suppliers often omit critical context like decontamination procedures after smoke exposure, so you must request these specialized industrial protocols explicitly.

Differentiating Consumer vs. Industrial Documentation

There is a massive gap between the manual for a hobby drone and an industrial firefighting platform. A standard manual might say "Store in a cool place." An industrial manual from a serious manufacturer will specify "Store in a Class D fire-rated environment with active ventilation."

When you purchase from us or similar high-end suppliers, the documentation should include an MSDS (Material Safety Data Sheet). This document is legally required for shipping lithium batteries via air freight and is crucial for your local fire marshal to know what chemical hazards are present in your storage room.

The Missing Link: Post-Mission Decontamination

One area where we see a lack of information in the general market is post-mission care. Firefighting drones fly through smoke, which contains conductive particles and corrosive soot. conductive particles 8 If these particles settle on the battery contacts or enter the BMS housing, they can cause short circuits later during storage.

We advise our clients to look for manuals that include cleaning protocols. This usually involves wiping down the battery casing and contacts with isopropyl alcohol after any flight involving heavy smoke exposure. If your supplier's manual does not cover this, they may just be repackaging a standard camera drone as a "firefighting" unit without understanding the operational environment.

Warranty Implications

The manual is also a legal shield. Most industrial warranties have strict clauses regarding battery care. If a battery fails and the internal logs show it was left at 0% voltage for six months, the warranty is void. The manual provides the "rules of engagement" for keeping that warranty valid. It is vital that your logistics team reads the fine print regarding "deep discharge" and storage temperatures to avoid financial losses on denied claims.

Documentation Checklist for Procurement

| Dokumenttyp | Funktion | Critical For |

|---|---|---|

| Benutzerhandbuch | Basic operation and charging instructions. | Pilots |

| MSDS / SDS | Chemical composition and hazard handling. | Logistics / Safety Officers |

| Warranty Policy | Defines abuse vs. defect criteria. | Procurement Managers |

| Firmware Logs | Explains how data is recorded for claims. | Maintenance Techs |

How do I handle charging cycles for my drone fleet during long-term storage?

We build our charging hubs to be intelligent because we know human memory is fallible. Relying on a warehouse manager to manually discharge batteries every week is a recipe for error, which is why we integrate automation into our ground support equipment.

Utilize “Storage Mode” features on intelligent charging hubs, which automatically discharge batteries to 3.8V if they are left fully charged for more than a few days. For long-term storage, check voltage levels monthly and apply a maintenance charge if any cell drops below 3.7V to prevent irreversible cell collapse.

Leveraging Intelligent Battery Systems

Modern industrial batteries are not just chemical bricks; they are computers. The Battery Management System (BMS) inside our packs is designed to protect the cells. Battery Management System 9 High-quality chargers now feature a dedicated "Storage" button. When pressed, the charger will analyze the battery:

- If the battery is below 50%, it charges it up to 3.8V.

- If the battery is at 100%, it discharges it down to 3.8V.

This automation removes the guesswork. However, you must ensure your team actually uses this mode before putting equipment away. We often see crews land, charge everything to 100% "just in case," and then leave it for a month.

Managing Self-Discharge

Even when disconnected, a battery is chemically active. The BMS itself draws a tiny amount of power to keep its memory alive. This is called parasitic drain. parasitic drain 10 If you store a battery at 50%, it might drop to 45% over a few months. This is fine.

However, if you store it at 10% and ignore it for six months, the parasitic drain will pull the voltage below the absolute minimum (around 3.0V per cell). Once this happens, the chemistry degrades, and safety circuits may permanently lock the battery to prevent a fire hazard upon recharging. We recommend a "touch-point" every 30 days: simply press the power button to check the LED indicators. If it drops to one bar, top it back up to storage level.

Predictive Maintenance via Data

Advanced charging hubs often connect to PC software. This allows you to see the "health" of the battery. We encourage procurement managers to ask for systems that log "cell deviation."

In a healthy pack, all cells discharge at the same rate. If Cell #1 is at 3.8V and Cell #4 is at 3.6V, you have a deviation issue. This imbalance is a leading indicator of failure. By spotting this during a maintenance cycle, you can retire the battery vor it fails in the sky above a fire scene.

Schlussfolgerung

The reliability of your firefighting drone fleet is dictated by the discipline of your battery management. While suppliers like us provide the hardware and the guidelines—ranging from 3.8V storage rules to climate control mandates—the execution relies on your internal protocols. By adhering to strict temperature controls, utilizing smart storage charging modes, and following a rigorous inspection schedule, you protect not only the lifespan of your assets but the safety of the personnel depending on them.

Fußnoten

1. Official safety bulletin regarding the hazards associated with lithium-ion battery use and handling. ︎

2. Scientific resource explaining the chemical degradation processes within lithium-based battery cells. ︎

3. Manufacturer technical overview of lithium-ion technology and internal safety mechanisms. ︎

4. University safety guidelines detailing the environmental factors that impact lithium battery stability. ︎

5. Official manufacturer documentation on battery maintenance and safety protocols for industrial drones. ︎

6. Government regulations and guidance for the safe transportation and handling of lithium batteries. ︎

7. Research and safety standards for energy storage systems from a leading fire protection organization. ︎

8. General background on atmospheric particulates and their physical properties. ︎

9. Technical standards for the safety and reliability of lithium-ion battery management systems. ︎

10. General reference for the concept of parasitic power loss in electrical systems. ︎