Crashing a high-value asset into a utility pole is the fastest way to lose a client’s trust and destroy profit margins. At our Xi’an manufacturing facility, we spend thousands of hours refining radar algorithms because we know radar algorithms 1 that specifications on paper do not always translate to safety in the field.

To evaluate obstacle avoidance radar performance, prioritize millimeter-wave technology for its ability to penetrate dust and fog. Verify detection ranges exceed braking distances at top speeds, check for omnidirectional 360-degree coverage, and conduct field tests to measure false-positive rates caused by spray drift or dense crop canopies.

Here is a detailed breakdown of the technical criteria and testing protocols you need to verify before finalizing your procurement.

Which radar specifications matter most for ensuring the safety of my drone fleet?

We often see customers get confused by the overwhelming data listed on component sheets from various suppliers. When we design our flight control systems, we filter flight control systems 2 out the marketing noise and focus strictly on the metrics that prevent mid-air collisions.

The most critical specifications are detection range, field of view (FOV), and update frequency. A range of at least 40 meters ensures safe braking at 10m/s, while a 360-degree horizontal FOV prevents blind spots. High update rates above 20Hz are essential for reacting to thin obstacles like wires.

To truly understand if a drone is safe for your customers, you must look beyond the basic "obstacle avoidance" label. The agricultural environment is hostile, and consumer-grade sensors simply cannot survive or perform adequately. Here is what we look for when engineering our systems.

detection Range vs. Braking Distance

The most common failure point we see in inferior drones is a mismatch between flight speed and radar range. If a drone sprays at 7 meters per second, it needs a significant distance to come to a complete halt without the payload sloshing and destabilizing the aircraft.

- Reaction Time: The system needs time to process the signal.

- Braking Physics: A heavy drone (30kg+) has high inertia.

If the radar only detects objects at 10 meters, but the drone needs 15 meters to stop, a crash is inevitable. We recommend a minimum detection range of 40 to 50 meters for effective operation.

Field of View (FOV)

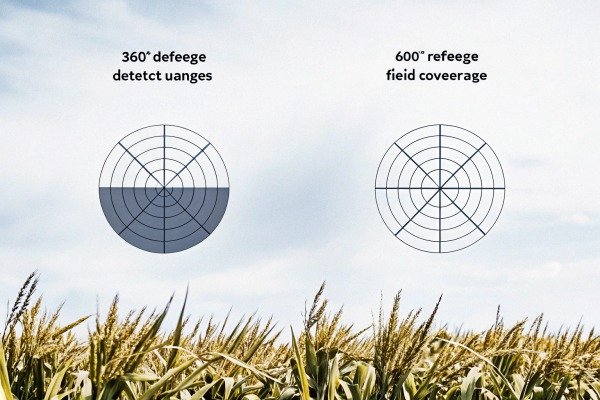

Early generations of agricultural drones only had forward-facing radar. This proved disastrous when the drone reached the end of a crop row and performed a "return-to-line" maneuver, often flying sideways or backward into trees.

You must demand Omnidirectional Sensing. This is usually achieved using 4D millimeter-wave radar or a rotating array. 4D millimeter-wave radar 3

- Horizontal FOV: Should be 360 degrees.

- Vertical FOV: Should be at least ±45 degrees to detect hanging branches above and terrain changes below.

Resolution and Frequency

The frequency of the radar determines its resolution. Older 24GHz radars are cheaper but struggle to distinguish between two close objects (like a gap between trees). We are shifting our production lines toward 77GHz millimeter-wave radar. This higher frequency provides better resolution, allowing the drone to detect thin obstacles like power lines or guy wires, which are the silent killers of agricultural UAVs.

Table 1: Critical Radar Specifications for Agriculture

| Spezifikation | Mindestanforderung | Recommended Standard | Warum es wichtig ist |

|---|---|---|---|

| Operating Frequency | 24 GHz | 77 GHz | Higher frequency detects thinner wires and separates close objects. |

| Detection Range | 20 Meters | 50+ Meters | Allows the drone to stop safely when flying at full speed. |

| Horizontal FOV | 120° (Front only) | 360° (Omnidirectional) | Protects the drone during turns, lateral movements, and return flights. |

| Update Rate | 10 Hz | >20 Hz | Faster updates mean faster reaction times to sudden obstacles. |

How well does the system handle obstacle avoidance in dusty or low-light environments?

Our engineers have analyzed crash data from regions with high humidity and heavy dust, finding that visual sensors are the first to fail. We specifically choose radar components that can “see” through the particulate matter that blinds standard cameras.

Millimeter-wave radar systems excel in low-light and dusty conditions where optical cameras fail. Unlike vision sensors, radar radio waves penetrate fog, pesticide spray, and darkness without signal degradation. Evaluate performance by testing the drone in heavy mist to ensure it detects poles without false alarms triggered by particles.

Agriculture is a dirty business. Drones operate in clouds of pesticide, kicked-up dust during harvest clouds of pesticide 4, and often in the low light of early morning or late evening. If you rely on a system that depends primarily on visual cameras (binocular vision), your fleet will be grounded half the time. binocular vision 5

The Limitation of Visual Sensors

Visual cameras function like human eyes—they need light and clear air.

- Direct Sunlight: Glare can blind cameras, causing the drone to stop unexpectedly.

- Low Light: At dusk, cameras lose depth perception.

- Obscuration: Dust on the lens or heavy fog renders them useless.

The Radar Advantage

Radio waves used in millimeter-wave radar have millimeter-wave radar 6 wavelengths that physically bypass small particles like water droplets (fog) or dust. This is why we integrate these sensors. They provide a reliable "structure" of the world regardless of visibility. When we test our drones, we subject them to artificial smoke and water spray to ensure the radar ignores the "cloud" but detects the wall behind it.

Dealing with "Ghost" Obstacles

A major challenge in this environment is sensitivity tuning. If the radar is too sensitive, it might interpret a dense cloud of spray drift as a solid object. This causes the drone to brake violently in the middle of a field, wasting battery and potentially causing a crash due to fluid instability.

- Algorithm Filtering: High-quality systems use algorithms to filter out "soft" returns (like spray) and focus on "hard" returns (like poles).

- Self-Cleaning: While radar signals penetrate dust, a thick layer of wet mud on the sensor face can still block signals. Check if the radar housing is made of hydrophobic material or is easily wipeable.

Table 2: Sensor Performance Comparison in Adverse Conditions

| Environment | Visual Camera (Stereo Vision) | LiDAR | mmWave Radar |

|---|---|---|---|

| Bright Sunlight | Poor (Glare issues) | Gut | Ausgezeichnet |

| Pitch Darkness | Fails completely | Ausgezeichnet | Ausgezeichnet |

| Heavy Dust/Fog | Fails completely | Moderate (Scattering) | Excellent (Penetrates) |

| Rain/Spray | Poor | Mäßig | Gut |

| Kosten | Niedrig | Hoch | Mittel |

Is millimeter-wave radar the right technology for my complex agricultural terrains?

When we export to regions with terraced fields or orchards, we advise clients against relying on basic ultrasonic sensors. Our testing shows that simple distance sensors cannot handle the complex geometry of uneven ground or scattered tree canopies.

Millimeter-wave radar is currently the superior choice for complex agricultural terrain. It offers better range and resolution than ultrasonic sensors and is more durable than fragile LiDAR systems. It effectively maps uneven ground for terrain following and detects thin obstacles like branches in orchards, making it ideal for variable landscapes.

Complex terrain presents two distinct problems: avoiding obstacles in front of the drone and maintaining the correct height above the ground (terrain following). ground (terrain following) 7 Millimeter-wave radar is the industry standard for solving both, but you need to understand why it beats the alternatives.

Why Ultrasonic Sensors Fail

Many entry-level agricultural drones use ultrasonic sensors for altitude hold because they are cheap. use ultrasonic sensors for altitude 8 However, they have severe limitations:

- Sound Absorption: Crops like corn or wheat can absorb sound waves, resulting in no return signal. The drone thinks it is flying high and may descend into the crop.

- Range: They typically work well only up to 5-8 meters.

- Speed: The speed of sound is slow compared to light/radio waves, causing latency at high flight speeds.

The Role of 4D Imaging Radar

For orchards and terraced fields, we utilize what is often called "4D Imaging Radar." This technology creates a point cloud similar to LiDAR but is much more robust against the elements.

- Terrain Following: The radar directs beams downward and forward. It can predict the slope of a hill before the drone reaches it, allowing the flight controller to adjust the throttle smoothly. This keeps the spray height consistent, which is crucial for chemical application.

- Canopy Penetration: In orchards, the drone must fly between trees. Radar can detect the trunk and heavy branches while ignoring small leaves, allowing for tighter operation in confined spaces without constant false alarms.

Durability Concerns

We also prefer radar over LiDAR because of durability. LiDAR sensors often contain spinning mirrors or precise lasers that are sensitive to vibration and shock. Agricultural drones undergo immense vibration and rough landings. Radar is solid-state electronics—no moving parts—making it far more durable for the rough life of farm machinery.

Application in Hillside Operations

If your customers operate on hills, verify that the radar has a "Ground Slope Adaptive" feature. Standard radar might look straight down (90 degrees). If the drone approaches a steep slope, looking down isn't enough; it needs to look forward-down (e.g., 45 degrees) to anticipate the rising ground.

What on-site tests should I perform to confirm the radar's sensitivity and reaction time?

We invite our distributors to our test fields in Chengdu to witness “stress tests” personally, rather than just reading a manual. We strongly suggest you replicate these specific scenarios to verify that the manufacturer’s claims hold up in the real world.

Conduct on-site tests by flying the drone towards standard obstacles like trees and thin hazards like power lines at varying speeds. Measure the actual braking distance and verify the “stop-and-hover” action. Additionally, test for false positives by flying through spray drift to ensure the radar does not trigger unnecessary stops.

Do not finalize a bulk order until you have performed these three specific tests. These protocols will reveal the true quality of the radar integration and the flight controller logic.

Test 1: The Incremental Braking Test

Do not start at full speed.

- Set up a soft target (like a cardboard box tower or a foam wall) to avoid damaging the drone if it fails.

- Fly the drone toward the object at 2 m/s. Measure the distance where it detects the object and where it stops.

- Increase speed to 5 m/s, then 8 m/s, and finally top speed (usually 10-12 m/s).

- Success Metric: The drone must stop vor the object every time. If it hits the object at high speed, the radar range is insufficient for the drone's inertia.

Test 2: The "Thin Wire" Challenge

This is the hardest test.

- Suspend a standard electrical wire or a thin PVC pipe between two poles.

- Fly the drone perpendicular to the wire.

- Success Metric: Does the radar detect it? Many lower-end radars filter out thin objects as "noise." If the drone flies right through, it is a major safety risk for farm operations involving power lines power lines 9.

Test 3: The Drift/Interference Test

This tests for "False Positives."

- Load the drone with water (to simulate payload).

- Fly the drone while spraying.

- Ideally, fly it near another drone or in a dusty area.

- Success Metric: The drone should strictly follow its path. If it jerks, brakes randomly, or climbs unexpectedly, the radar is interpreting the liquid spray or dust as a wall. This makes the drone unusable for real work.

Table 3: Field Testing Checklist for Obstacle Avoidance

| Test Name | Zielsetzung | Kriterien für das Bestehen | Warnschilder |

|---|---|---|---|

| High-Speed Brake | Verify stopping distance matches speed. | Drone hovers >2m from obstacle. | Drone drifts past the safety margin or brakes too abruptly (tilting). |

| Corner Trap | Test 360° protection. | Drone stops when backing into a wall. | Drone hits obstacle when flying backward or sideways. |

| Wire Detection | Test resolution sensitivity. | Detects cable >1cm thick. | Drone fails to slow down or visual camera takes over (check logs). |

| Spray Loop | Test noise filtering. | Smooth flight while spraying. | Random braking ("Phantom Obstacles") during spray operation. |

Schlussfolgerung

Evaluating agricultural drone radar is not landwirtschaftliche Drohne 10 just about checking a box for "obstacle avoidance." It requires ensuring the system uses millimeter-wave technology for environmental robustness, possesses sufficient range for the drone's weight and speed, and passes rigorous field tests against wires and dust. By prioritizing these technical standards, you protect your investment and ensure your customers can operate safely in the challenging environments of modern farming.

Fußnoten

1. Defines the technical processing method mentioned. ︎

2. Explains the system architecture managing the drone. ︎

3. Technical whitepaper explaining the high-resolution capabilities of 4D imaging radar sensors. ︎

4. Official EPA resource regarding pesticide safety and environmental regulations for application. ︎

5. Explains the concept of binocular vision and its role in depth perception for optical sensors. ︎

6. Authoritative technical definition from a major manufacturer. ︎

7. Peer-reviewed research on radar-based terrain following algorithms for unmanned aerial vehicles. ︎

8. Manufacturer documentation explaining the operational principles and limitations of ultrasonic sensors. ︎

9. Official safety guidelines for the cited hazard. ︎

10. Regulatory context for agricultural unmanned aircraft. ︎