In our Xi’an facility, we often receive frantic calls from overseas clients during the height of the spraying season. A twenty-dollar seal fails, the machine is grounded, and crops are left vulnerable while the operator waits weeks for international shipping. We hate seeing our partners lose revenue due to simple logistical oversights.

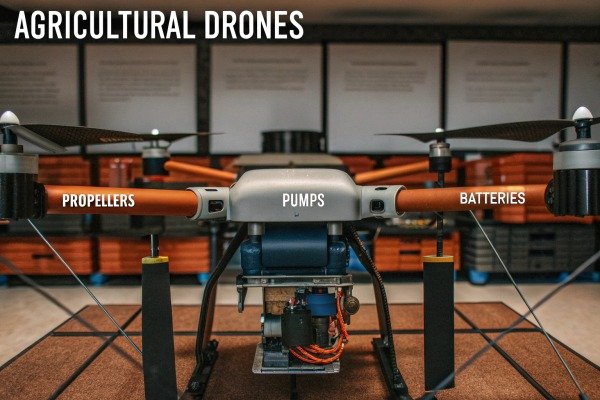

To prepare for future maintenance needs, you should recommend including propellers, spray nozzles, pumps, and landing gear skids in the initial order. Stocking these essential wear parts, along with extra batteries and structural fasteners, prevents costly operational downtime and ensures your agricultural drone fleet remains active during critical farming windows.

Here is a breakdown of the specific components you must secure to keep your operations running smoothly.

What are the most common wear parts I need to stock for agricultural drone maintenance?

We track repair data from thousands of units exported to the United States and Europe, and the pattern is undeniably clear. Operators who ignore the physical stress placed on moving parts often face unexpected failures that turn profitable days into financial losses.

The most common wear parts you need to stock include propellers, which degrade from dust and impact, and spray system components like nozzles and hoses. Additionally, motor bearings and structural fasteners frequently loosen or wear out due to high-frequency vibration, making them essential inventory items for maintaining flight stability and safety.

When we analyze the lifecycle of an agricultural drone, we categorize components based on their exposure to stress. Unlike camera drones that fly in clean air, agricultural drones operate in hostile environments Agrardrohnen 1 filled with dust, moisture, and corrosive chemicals.

The Propeller Hierarchy

Propellers are the first line of defense and the most abused component. In our testing labs, we see that even microscopic chips on a propeller blade can cause catastrophic vibration issues. This vibration travels down the arm and destroys the motor bearings motor bearings 2. If you do not change a chipped propeller immediately, you are not saving money; you are simply waiting for a more expensive motor failure. We recommend stocking at least two full sets of propellers for every drone you purchase.

Fasteners and Anti-Vibration Mounts

It might seem trivial, but screws and rubber dampers are critical. The high-torque motors used in our SkyRover series generate significant vibration. Over time, this loosens the thread-locking compound applied at the factory thread-locking compound 3. We often see structural arms develop "play" or wobble because a few screws were lost in the field. Having a bag of specialized screws, washers, and rubber dampers ensures that a 10-cent part does not ground a heavy-lift platform.

Maintenance Tier List

To help you prioritize your budget, we have compiled a tier list based on our export service records. This table shows what you will likely need within the first 300 hours of operation.

| Prioritätsstufe | Component Name | Typical Replacement Interval | Failure Symptom |

|---|---|---|---|

| Kritisch | Propeller (CW/CCW) | 50-100 Hours (or immediate if damaged) | Excessive vibration, loud noise, reduced flight time |

| Hoch | Spray Nozzles & Tips | 100-150 Hours | Uneven spray pattern, dripping, clogging |

| Mittel | Motor Bearings | 300+ Hours | Grinding sound, heat buildup, motor seizing |

| Preventative | Fastener Kits | Check Monthly | Loose arms, missing screws, structural rattling |

By focusing on these high-wear items, you build a safety net around your operation. It is not about wenn these parts will wear out, but wenn. Being prepared means the difference between a 15-minute field repair and a two-week shipping delay.

Should I include extra spray nozzles and pumps to avoid downtime during the farming season?

Our engineering team spends months testing chemical resistance, yet we know that no seal lasts forever against aggressive herbicides aggressive herbicides 4. When a pump fails in the middle of a job, the panic is real, and the cost of missed application windows far exceeds the price of a spare part.

Yes, you should absolutely include extra spray nozzles and pumps to avoid downtime because agrochemicals are highly abrasive and corrosive to internal seals. Having backup pumps and nozzle tips on hand allows for immediate field replacement, ensuring that your spraying schedules are met regardless of inevitable equipment wear or clogging issues.

The spray system is the business end of the drone. It is also the system most prone to chemical attack. When we design our plumbing, we use high-grade materials, but the reality of field use involves harsh solvents and occasional improper cleaning.

The Vulnerability of Diaphragm Pumps

Most agricultural drones use diaphragm pumps to regulate pressure diaphragm pumps 5. diaphragm pumps 6 These pumps rely on flexible rubber or silicone diaphragms to move liquid. Over time, chemicals stiffen these diaphragms, causing them to crack. Once a crack appears, pressure drops immediately, and the drone cannot spray effectively. We strongly advise our distributors to keep one complete pump assembly in stock for every three drones in their fleet. It is a "plug-and-play" repair that solves 90% of liquid system failures.

Nozzle Erosion and Flow Rates

Many operators underestimate how quickly nozzles wear out. As water and powder-based chemicals are forced through the tiny orifice at high pressure, the plastic or ceramic wears away. This changes the flow rate. flow rate 7 A nozzle that is supposed to spray 1 liter per minute might start spraying 1.2 liters per minute due to erosion. This leads to overdosing the crop, which burns plants and wastes expensive chemicals.

Chemical Compatibility Guide

We have observed that different chemicals accelerate wear on specific parts. Understanding this helps you order the right spares.

| Chemical Type | Primary Wear Component | Effect on Drone | Recommended Spare |

|---|---|---|---|

| Wettable Powders | Pump Diaphragms & Valves | Abrasive friction wears down internal rubber seals quickly. | Replacement Diaphragm Kits |

| Herbicides (Oil-based) | O-Rings & Hoses | Causes rubber hoses to swell and O-rings to degrade/leak. | Complete O-Ring Seal Kit |

| Fertilizers (Salts) | Metal Connectors | high salinity causes rapid corrosion on metal fittings. | Spare Brass/Plastic Fittings |

The "Field-Swap" Strategy

We design our pumps and nozzles to be modular. We encourage you to adopt a "field-swap" strategy. Do not try to repair a pump in a muddy field. Instead, swap the entire pump unit with a spare to finish the day's work. Repair the broken pump back at the workshop when you have clean hands and good lighting. This approach requires inventory, but it guarantees operational continuity.

How many spare batteries and chargers should I purchase to ensure continuous operation?

When we calculate flight efficiency for our clients, we treat batteries as fuel tanks that shrink over time. It is frustrating for pilots to stand idle in a field waiting for a charge, watching the sun go down while work remains unfinished.

You should purchase at least four batteries per drone and one charger for every two batteries to guarantee continuous operation. Since battery capacity degrades with high-cycle use and fast charging, this ratio ensures you always have a fresh pack ready to fly while others are cooling or charging.

Batteries are the single most expensive consumable in your drone program. Unlike the drone frame, which can last for years, lithium polymer batteries have a finite chemical life lithium polymer batteries 8.

The Cycle Life Reality

In agriculture, we push batteries to their limits. High discharge rates during takeoff with a full tank generate immense heat. Then, rapid charging generates more heat. Heat is the enemy of battery longevity. A battery rated for 500 cycles might only last 300 cycles if it is consistently charged while hot. If you only have two batteries, you are forced to charge them immediately after landing, which destroys their internal chemistry internal chemistry 9. Having four batteries allows time for them to cool down naturally before charging, significantly extending their lifespan.

Calculation for Continuous Flight

To fly non-stop, the charging speed must match the consumption speed. Here is the math we use when advising procurement managers:

- Flugzeit: A fully loaded drone flies for about 10-12 minutes.

- Charge Time: A Super Charger takes about 15-20 minutes to fill a battery.

- Abkühlzeit: A battery needs 10-15 minutes to cool before charging.

If you only have two batteries, you have a gap where the drone sits on the ground. With four batteries, you create a perfect loop.

Battery Investment Table

This table illustrates the relationship between fleet size and the necessary power infrastructure to maintain zero downtime.

| Number of Drones | Recommended Batteries | Recommended Chargers | Operational Result |

|---|---|---|---|

| 1 Drone | 2 Batteries | 1 Charger | High Downtime: ~20 mins waiting between flights. |

| 1 Drone | 3 Batteries | 1 Charger | Risk Zone: Continuous flight possible only if temps are cool. |

| 1 Drone | 4 Batteries | 2 Chargers | Continuous: Zero waiting; allows cooling time for safety. |

| 2 Drones | 8 Batteries | 4 Chargers | Continuous: Fully independent operation for both units. |

Connector Wear

Another detail often overlooked is the battery connector. The heavy-duty plugs on the drone and the battery endure thousands of insertions. Over time, the gold plating wears off, and resistance increases. We recommend inspecting these connectors monthly. If you see black marks (arcing), it is time to replace the connector on the drone side. Including a spare "power distribution board" or pigtail connector in your annual order is a wise move for long-term maintenance.

Do I need to order backup propellers and landing gear to prepare for immediate field repairs?

In our experience, gravity is unforgiving, and even the best pilots clip a tree branch or land too hard on uneven terrain. It is devastating to cancel a week's worth of contracts simply because a carbon fiber skid cracked and no replacement was available.

You certainly need to order backup propellers and landing gear because these are the structural components most vulnerable to impact damage and fatigue. Keeping these parts in your inventory allows you to perform immediate field repairs, turning a potential mission-ending crash into a brief 20-minute pause.

Structural repairs sound intimidating, but on modern agricultural drones, they are designed to be simple. We build our SkyRover frames to be modular so that if a part breaks, it protects the expensive electronics inside.

Landing Gear as a Shock Absorber

The landing gear takes a beating. Every time the drone lands with residual liquid in the tank, the gear flexes. Over thousands of landings, carbon fiber tubes can develop stress fractures carbon fiber tubes 10. Furthermore, during transport in pickup trucks, the landing gear often gets banged against the truck bed. If a landing gear leg snaps during touchdown, the drone usually tips over, smashing the propellers and potentially damaging the radar. Replacing a weakened skid vor it snaps is a critical safety protocol.

Propellers as Fuses

Think of propellers as mechanical fuses. We design them to break upon impact to save the motor. If a drone hits a branch, we want the plastic blade to shatter so the energy does not bend the motor shaft. This means you will go through propellers. It is a sign that the safety design is working. However, this only works if you have the spares to replace them. Flying with a taped or glued propeller is dangerous and voids any warranty we offer.

The "Crash Kit" Concept

For our US clients, we suggest building a "Crash Kit" that travels with the drone. This is different from the warehouse inventory. It stays in the truck.

A Standard Field Repair Kit Should Include:

- Propellers: 2 Full Sets (CW and CCW).

- Landing Skids: 1 Left, 1 Right (aluminum or carbon tubes).

- Arm Clamps: Plastic locking mechanisms that hold the arms in place (these often crack in a crash).

- Antennas: RTK or telemetry antennas often snap if the drone flips.

Hidden Wear: The Arm Locking Mechanism

Agricultural drones fold up to fit in vehicles. The folding joint (hinge) is a high-wear area. It relies on a clamping mechanism to stay rigid during flight. Dirt and sand get into these hinges, acting like sandpaper. If the clamp becomes loose, the arm can fold back during flight, causing a crash. We recommend cleaning these joints with compressed air daily and keeping a spare set of "arm clips" or "locking sleeves" in your maintenance order. It is a small plastic part that ensures the structural integrity of the entire machine.

Schlussfolgerung

Purchasing an agricultural drone is not a one-time transaction; it is the start of an operational cycle that requires support. By proactively ordering wear parts like propellers, spray nozzles, pumps, batteries, and landing gear, you insulate your business from the chaos of downtime. We encourage you to view these spare parts not as an extra cost, but as insurance for your productivity. If you are unsure about the specific quantities for your fleet, our team is ready to help you calculate the optimal maintenance package.

Fußnoten

1. Authoritative government resource on the use of drones in precision agriculture. ︎

2. Leading manufacturer providing technical details on bearing types and maintenance. ︎

3. Industry standard manufacturer for thread-locking adhesives used in mechanical assemblies. ︎

4. Official government agency regulating pesticide and herbicide safety and usage. ︎

5. General reference explaining the mechanical operation of diaphragm pumps. ︎

6. General background on the mechanics and applications of diaphragm pumps in fluid transfer. ︎

7. Technical specifications for precision spray nozzles and their corresponding flow rate performance. ︎

8. Academic resource providing technical characteristics of lithium polymer battery technology. ︎

9. Educational resource on maintaining battery health and understanding chemical degradation. ︎

10. Department of Energy page explaining the properties and applications of carbon fiber composites. ︎