Seeing a drone fail mid-spray due to a mystery component defect is a nightmare we work hard to prevent on our assembly lines in Xi’an. It costs time, money, and trust. As we develop our flight platforms, we understand that for a procurement manager, the inability to track a failure back to its source is a major financial risk.

To determine if a supplier has a comprehensive quality traceability system, verify they hold ISO 9001 certification and utilize unique serial numbers for component-level tracking. Request a demonstration of their digital التوأم الرقمي 1 management platform to ensure it links specific batch data, manufacturing logs, and quality control reports to each drone’s unique ID.

Let’s dive into the specific evidence and documentation you need to demand before signing that purchase order to ensure long-term reliability.

What specific documents should I request to verify the manufacturing history of each agricultural drone?

When we prepare export documentation for our US clients, we know that a simple commercial invoice is never enough to prove the quality of the machinery inside the box. We believe transparency starts with the paper trail generated before the drone even leaves the factory.

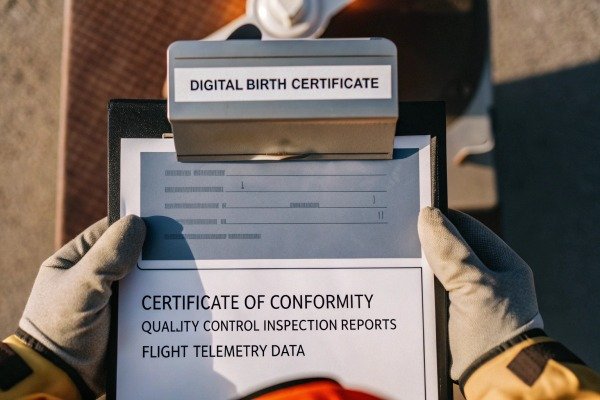

You should request a “Digital Birth Certificate” for every unit, which aggregates the Certificate of Conformity, detailed Quality Control (QC) inspection reports, and firmware version logs. Additionally, ask for the specific test flight telemetry data that validates the drone’s performance before it left the factory floor.

The Importance of the "Digital Birth Certificate"

In the world of industrial machinery, a drone is not just a toy; it is an asset. When evaluating a supplier, you must look beyond the general product manual. A comprehensive traceability system generates what we often call a "Digital Birth Certificate" for each specific serial number. This is not a generic template used for thousands of units; it is a unique dossier for that specific machine.

If a supplier hands you a generic "Quality Passed" sticker and nothing else, that is a red flag. Real traceability means they can provide a document that lists the exact date of assembly, the ID of the technician responsible for the final check, and the specific calibration values for the IMU (Inertial Measurement Unit) and compass IMU (Inertial Measurement Unit) 2. وحدة القياس بالقصور الذاتي 3

Specific Reports to Demand

To ensure you are getting a machine that has been rigorously tested, you need to ask for three specific categories of documents. These documents prove that the supplier isn't just assembling parts but is verifying the integrity of the system as a whole.

- The Assembly QC Checklist: This should show that every screw torque was verified, and every solder joint was inspected. It transforms "quality" from a buzzword into a measurable metric.

- Test Flight Telemetry Logs: Every agricultural drone should fly before it ships. You should ask for the log file (often verifiable in software like Mission Planner or proprietary apps Mission Planner 4 Mission Planner 5) that shows the drone held a steady hover, the GPS locked onto sufficient satellites, and the pump system responded to commands.

- Firmware Consistency Report: Agricultural drones rely on complex software. You need a document stating exactly which version of the flight controller firmware, ESC (Electronic Speed Controller) firmware Electronic Speed Controller 6, and RTK module firmware was installed at the factory.

Differentiating Between Standards

It is common for buyers to confuse general company certifications with product-specific traceability. Here is a breakdown of what different documents actually tell you about the supplier's ability to track quality.

Comparison of Quality Documentation

| نوع المستند | ما الذي يثبته | Traceability Value |

|---|---|---|

| ISO 9001 Certificate | The company has a management system in place. | متوسط – It shows they have a process, but doesn't prove your specific unit was checked. |

| CE / FCC Certificate | The design meets regulatory safety standards. | منخفضة – This applies to the model type, not the individual manufacturing history. |

| Unit-Specific QC Report | This specific drone passed inspection. | عالية – This links the physical asset to a specific quality event and time. |

| Flight Log Data | The drone actually flew and functioned. | عالية جداً – This is undeniable proof of functional status at the point of origin. |

By insisting on unit-specific QC reports and flight logs, you force the supplier to demonstrate their internal tracking capabilities. If they cannot produce these records for a specific Serial Number (SN) upon request, they likely do not have a robust traceability system.

How can I confirm that the supplier tracks the origin of key components like motors and batteries?

We often tell our procurement partners that a drone is only as reliable as its weakest sub-component, which is why we monitor our supply chain so strictly. A battery failure in the field is rarely just bad luck; it is usually a traceability gap in the cell manufacturing process.

Confirm component tracking by auditing the supplier’s use of unique serial numbers (SN) and batch codes for motors, batteries, and flight controllers. Verify they use an ERP system that links these sub-tier component IDs directly to the finished drone’s main serial number for full supply chain visibility.

The Critical Role of Sub-Tier Traceability

An agricultural drone is a system of systems. The manufacturer you buy from is often an integrator of high-tech parts. However, if they do not track where those parts came from, they cannot protect you from defects. When we source components, we don't just buy a box of motors; we buy motors with a known lineage.

If a supplier cannot tell you which batch of battery cells is inside your drone, they are exposing you to immense risk. Batteries are the most volatile component. If one battery catches fire due to a manufacturing defect, a traceable supplier can instantly identify every other battery from that same production batch and issue a recall. A supplier without traceability will have to recall everything or, worse, ignore the problem and hope for the best.

Verifying the Bill of Materials (BOM) Management

To confirm a supplier tracks these components, you need to ask about their MES (Manufacturing Execution System) or ERP (Enterprise Resource Planning) workflow ERP (Enterprise Resource Planning) 7. Enterprise Resource Planning 8 When you are in negotiation, ask this simple question: "If I give you a drone's serial number, can you tell me the serial numbers of the six motors installed on it?"

If the answer is "No" or "Let me check the paper files," their system is outdated. In a modern factory, scanning the drone's chassis SN should instantly pull up a "family tree" of that unit, listing the specific IDs of the flight controller, the pump, the radar module, and the batteries.

Key Components Requiring Individual Tracking

Not every screw needs a serial number, but critical flight safety components must be traceable. You should focus your verification on these high-risk areas:

- Propulsion System (Motors & ESCs): These wear out. Knowing the batch helps predict lifespan.

- Power System (Batteries & Chargers): Critical for fire safety and chemical consistency.

- Guidance (RTK & GPS): Essential for precision spraying; bad batches cause flyaways.

Risk Assessment of Non-Traceable Components

The table below outlines the operational risks you face if your supplier fails to track these specific critical components.

Component Traceability Risk Table

| المكوّن | Risk of No Traceability | Why It Matters for Ag Operations |

|---|---|---|

| LiPo Batteries | Fire hazards, inconsistent voltage drops. | If one pack fails, you need to know which other packs are from the same bad batch to prevent fires. |

| محركات بدون فرش | Bearing seizures, coil overheating. | A motor failure mid-flight means a crash. Batch tracking identifies weak production runs. |

| وحدة التحكم في الطيران | Software bugs, sensor drift. | Traceability ensures you know exactly which hardware version you have for firmware compatibility. |

| Spraying Nozzles | Inconsistent flow rates. | If a nozzle batch is defective, your chemical application will be wrong, potentially damaging crops. |

By confirming that the supplier tracks these elements, you are not just buying a product; you are buying data integrity that protects your investment.

Will a comprehensive traceability system help me secure faster maintenance and spare parts support?

Our service team relies heavily on historical data when a client contacts us about a repair, because guessing causes delays. We know that when a customer’s crop is waiting to be sprayed, every hour of downtime translates to lost revenue.

Yes, a comprehensive system significantly accelerates support by allowing the supplier to instantly identify the exact specifications and batch dates of installed parts. This precision eliminates compatibility errors, speeds up root cause analysis for defects, and ensures the correct replacement components are shipped immediately without manual verification.

The Connection Between Data and Speed

Many buyers view traceability as a "quality control" feature, but it is actually a "customer support" feature. When you are 5,000 miles away from the factory, the speed of support depends entirely on information. If you report a broken arm on a drone, a supplier with poor traceability has to ask you for photos, measurements, and version numbers. They might send you a part that fits the 2024 model but not your specific early-2024 batch.

With a comprehensive system, you simply provide the drone's ID. The supplier's system tells them: "This unit was built in March using the V2.1 motor mounts and the 30mm carbon tubes." They can ship the exact replacement part immediately. This eliminates the back-and-forth emails that usually consume days of precious time.

Root Cause Analysis and Predictive Maintenance

A robust traceability system allows for "Closed-Loop Feedback." If a supplier notices that a high percentage of drones built in Week 42 are reporting pump failures, they can proactively warn you. This is impossible without data.

For example, if you encounter a GPS error, a traceable supplier can look up your GPS module's batch. If they see that five other clients with that same batch had similar issues, they know immediately it is a hardware defect, not user error. They won't waste your time asking you to recalibrate the compass ten times; they will just ship a replacement.

Compatibility Management

Industrial drones evolve rapidly. Manufacturers often change suppliers for small internal cables or sensors without changing the model name of the drone.

- Scenario A (No Traceability): You order a replacement ESC. It arrives, but the connector is different because the manufacturer changed the design last month. You are grounded for another week.

- Scenario B (With Traceability): The supplier sees your drone uses the "Type-A" connector based on its serial number and ensures the spare part matches your specific configuration.

Impact on Maintenance Timelines

The following table illustrates the time difference in support scenarios between a traceable and non-traceable supplier.

Support Timeline Comparison

| Support Stage | Supplier WITH Traceability | Supplier WITHOUT Traceability |

|---|---|---|

| Issue Reporting | You send the Serial Number. | You send photos, videos, and descriptions. |

| Problem Diagnosis | Supplier checks production logs for known batch issues. | Supplier guesses based on visual evidence. |

| Part Identification | System auto-selects the compatible part ID. | Manual verification; risk of sending wrong version. |

| Resolution Time | 24-48 ساعة to ship parts. | 5-7 أيام of communication before shipping. |

A comprehensive system essentially acts as an insurance policy against downtime. It transforms a chaotic troubleshooting process into a data-driven solution.

What signs should I look for during a factory audit to validate their quality tracking capabilities?

Walking through our Chengdu facility, visitors often notice the scanners at every station, which are there to prevent human error during assembly. We encourage our partners to look beyond the cleanliness of the floor and examine how data flows through the production line.

During an audit, look for physical evidence like barcode or QR code scanners at every assembly station and real-time digital dashboards displaying quality metrics. Check if workers scan components before installation and verify that the “Traveler” document accompanying the drone on the line matches the digital system records.

Visualizing the "Digital Twin"

When you visit a factory (or hire a third-party auditor), you want to see the creation of a "Digital Twin." This means that for every physical action taken on the assembly line, there is a corresponding digital record.

The most obvious sign of this is hardware. Do the workstations have barcode scanners or RFID readers? RFID readers 9 If workers are manually writing down serial numbers on a piece of paper, that is a failure of traceability. Handwriting is prone to error, and paper records are difficult to index and search later. You want to see a worker pick up a motor, scan it, scan the drone chassis, and wait for a green light on their screen before proceeding.

The "Traveler" Sheet Test

Every drone on a production line usually travels with a document called a "Traveler" or "Router." This sheet lists the steps the drone has gone through.

To test the system, pick a random drone on the line:

- Look at the traveler sheet.

- Ask the production manager to pull up that specific unit in their computer system.

- Compare them. If the computer says the unit is at "Station 4" but it is physically at "Station 6," their tracking is lagging or broken. If the computer says the GPS is installed but the physical unit doesn't have it yet, their process control is flawed.

Real-Time Quality Gates

A sophisticated traceability system acts as a gatekeeper. Look for "Go/No-Go" systems.

- Example: If a torque wrench is Bluetooth-connected to the system, the assembly line should not allow the drone to move to the next station until the wrench records the correct torque value.

- Observation: Watch a station. Does the computer screen block the worker if they miss a step? Or can they just push the drone down the line regardless of what the screen says?

Audit Checklist for Traceability

Use this checklist during your factory tour or video audit to score the supplier.

Factory Traceability Audit Checklist

| Audit Point | ما الذي تبحث عنه | Good Sign | Bad Sign |

|---|---|---|---|

| Incoming Material | How are raw parts labeled? | Each box has an internal barcode label upon arrival. | Original supplier labels only; no internal tracking. |

| Assembly Line | Data input methods. | Handheld scanners, RFID mats, connected tools. | Pen and paper logs; typing numbers manually. |

| Testing Station | Flight simulation/Testing. | Automated data upload to server after test. | Pass/Fail sticker only; no data saved. |

| Final Packing | Box pairing. | Scanning the box and drone to link them. | Random boxing; box label doesn't match drone SN. |

If a supplier can demonstrate these "Digital Twin" capabilities, it shows they have invested heavily in process control, which directly correlates to the reliability of the agricultural drones you receive.

الخاتمة

Determining if a supplier has a comprehensive quality traceability system requires looking beneath the surface quality traceability system 10 of shiny marketing brochures. By verifying the existence of "Digital Birth Certificates," ensuring critical components like batteries are tracked by batch, and validating the use of digital scanning in the factory, you protect your business from costly failures. A supplier who invests in traceability is a supplier who invests in accountability. In the agricultural sector, where timing is everything, this data transparency is the difference between a quick repair and a ruined season.

الحواشي

1. Authoritative definition of the manufacturing concept by a tech leader. ︎

2. General background definition of the technical component. ︎

3. General background on the IMU sensor used in drones. ︎

4. Official documentation for the specific flight control software mentioned. ︎

5. Official documentation for the open-source flight telemetry software mentioned. ︎

6. Technical background on ESC components in drone propulsion. ︎

7. Definition of the system by a major industry leader. ︎

8. Major company documentation explaining ERP systems for supply chain tracking. ︎

9. Official government page explaining the technology standards. ︎

10. Official ISO page explaining the standard for quality management systems. ︎