When we field-test our prototypes in Chengdu, we treat every failure as a roadmap for improvement. A failed sample is not a dead end; it is a critical data point that helps us refine stability and performance before mass production. (Max 30 words)

To effectively request improvements, compile a comprehensive technical report linking specific failures to your original RFP requirements. Include visual evidence, raw telemetry logs, and a demand for a formal Root Cause Analysis (RCA). This data-driven approach forces suppliers to provide a documented Corrective Action Plan (CAP) rather than vague promises.

Turning a testing failure into a successful product launch requires clear communication and precise technical demands.

What technical data logs should I send to the engineers to diagnose the failure?

When our engineers analyze returned units, vague descriptions like "it drifted" make diagnosis impossible. We need precise sensor data to distinguish between a hardware defect, magnetic interference, or a software calibration error. (Max 30 words)

You must export and send the flight controller's "black box" logs (usually .BIN or .TLOG files), covering IMU data, GPS signal strength, and motor output levels. Additionally, provide battery voltage curves and thermal sensor readings to help engineers distinguish between software glitches, magnetic interference, or hardware power failures.

To ensure the engineering team can accurately diagnose why the firefighting drone failed—whether it was an issue with vertical climbing, hovering stability, or thermal target identification—you need to provide raw data, not just observations. In our experience collaborating with clients on custom development, the "Black Box" data is the single most important asset for troubleshooting.

The Hierarchy of Log Data

Industrial drones, especially those running on ArduPilot or PX4 firmware which we often utilize, record massive amounts of data. Sending everything can be overwhelming, so you should prioritize the logs that correspond to the specific failure mode. For example, if the drone failed a NIST alignment test due to drifting, the GPS and IMU logs are critical. If the drone initiated an emergency landing prematurely, the battery voltage sag curves are essential.

You should request your flight operators to extract the onboard logs immediately after the failed flight. Do not restart the drone multiple times before extracting data, as this might overwrite the critical log files depending on the storage configuration.

Essential Data Points for Diagnosis

When we receive a complaint about flight instability, we look for specific parameters. Below is a breakdown of the technical logs you must provide to the supplier's engineering team to speed up the resolution process.

| Log Category | Specific Parameter | Diagnosis Utility |

|---|---|---|

| Navigation | GPS.HDop, GPS.NSats |

Determines if the failure was due to poor satellite coverage or hardware GPS module failure. |

| الاستقرار | IMU.AccX/Y/Z, IMU.GyrX/Y/Z |

Reveals excessive vibration (jello effect) or sensor calibration errors causing drift. |

| Power | BAT.Volt, BAT.Curr |

Identifies voltage sag under load, indicating if the battery C-rating is too low for the motors. |

| Control | RCOUT.C1 to C8 |

Shows how hard the motors are working. If one motor is at 100% while others are at 50%, it indicates a physical imbalance or motor failure. |

| Thermal | TEMP.PCB, TEMP.Motor |

Checks if overheating caused the flight controller to throttle performance or shut down. |

Visual Evidence and Environmental Context

Data logs tell us what happened, but video tells us how it happened. Always accompany the logs with high-resolution video of the flight. For firefighting drones, environmental context is vital. Was the drone flying near a heat source? High-velocity thermal updrafts can confuse barometric altimeters. If you were testing in a high-interference environment (like near high-voltage lines or metal structures), mention this explicitly. This context helps the supplier determine if the issue is a product defect or an environmental limitation that requires a different sensor configuration, such as upgrading to an RTK GPS module for better interference resistance.

How do I negotiate the cost of modifying the prototype after a failed test?

We often discuss cost-sharing with clients when design changes exceed the original scope. Clear contract terms regarding "bug fixes" versus "feature upgrades" prevent disputes and ensure the project moves forward without financial friction. (Max 30 words)

Negotiation depends on the root cause: suppliers must cover costs for defects where the product failed to meet agreed specifications. However, if you request new features or higher-grade components post-testing, you should expect to share development costs. Always reference the original technical agreement to define liability clearly.

Negotiating costs after a failed test can be delicate. The key is to objectively categorize the "failure." Was it a failure to meet the promised specifications, or was it a realization that the specifications themselves were insufficient for the real-world application?

Distinguishing Defects from Enhancements

From a manufacturer's perspective, if we agreed that the drone would fly for 30 minutes with a 2kg payload, and the prototype only flies for 20 minutes, that is a defect. The cost to fix this—whether by upgrading the motors or changing the propeller design—should be entirely borne by the supplier. This is a breach of the technical agreement.

However, if the drone meets the 30-minute requirement, but you realize during testing that 30 minutes isn't enough for your specific firefighting mission and you now need 40 minutes, that is a Change Order. In this case, you should expect to pay for the NRE (Non-Recurring Engineering) costs associated with redesigning the battery compartment or upgrading the propulsion system.

The "Grey Area" of Subjective Performance

Failures in "handling characteristics" are often subjective. For instance, if a pilot feels the drone is "too sluggish" in response to stick inputs, but it technically meets the max speed requirements, who pays for the retuning?

- Strategy: Reference industry standards like NIST. If the drone fails a standardized NIST maneuver (like the spiral ascent) that was part of the RFP, it is a performance defect.

- Leverage: Use future order volume as leverage. If you are a distributor planning to buy 50 units, we are often willing to absorb minor modification costs to secure the long-term relationship.

Cost Allocation Matrix

To help you structure your negotiation email, use the following logic to determine who should pay for the modifications.

| Failure Scenario | Root Cause | Financial Responsibility |

|---|---|---|

| Stability Failure | Drone drifts >1m in GPS hold (Spec was <0.5m). | المورد (Product Defect) |

| فشل المكونات | ESC burns out during normal load testing. | المورد (Quality Control Failure) |

| Spec Upgrade | Client requests 4K thermal camera instead of 1080p. | المشتري (Hardware Upgrade) |

| Environmental Fit | Drone melts near fire (Client didn't specify heat tolerance). | المشتري (Scope Change) |

| Software Tuning | Adjusting PID gains for sharper turns. | Negotiable (Often free if simple) |

By clearly categorizing the requested changes using this matrix, you remove the emotion from the negotiation and focus on contractual obligations.

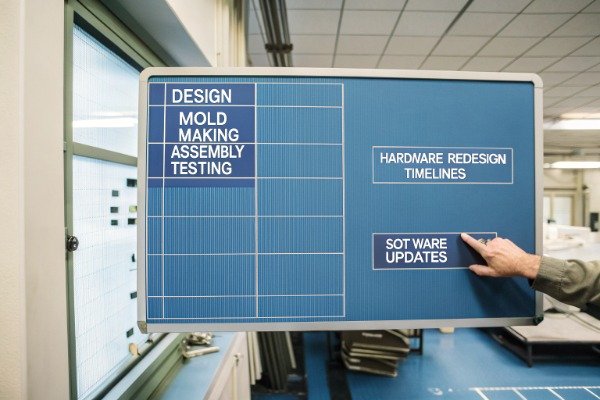

What is a reasonable timeline for the supplier to implement design changes?

In our production planning, re-tooling takes time, but software fixes are faster. Understanding the difference between a firmware patch and a mold change helps you set realistic deadlines and manage your end-customer's expectations. (Max 30 words)

quality assurance process 1

A reasonable timeline ranges from two weeks for software tuning to eight weeks for hardware re-tooling. Simple firmware updates or PID tuning are quick, while structural changes requiring new carbon fiber molds or PCB redesigns demand significantly more time for manufacturing, assembly, and internal quality assurance testing.

Standard Operating Procedure (SOP) 2

When you ask for a "quick fix," it is important to understand the manufacturing reality behind that request. The timeline for implementing changes varies drastically depending on whether the issue is in the code, the electronics, or the physical structure of the drone.

Corrective Action Plan 3

Software and Firmware Adjustments (1–2 Weeks)

If the failure was related to flight stability, GPS lock speed, or fail-safe triggers, these are usually software issues.

- Diagnosis: 1-3 days.

- Coding/Tuning: 3-5 days.

- Internal Testing: 2-3 days.

- Total: ~2 weeks.

Our engineers can often remotely access the flight controller to adjust PID parameters or update firmware. This is the fastest type of modification.

Electronic Component Swaps (3–4 Weeks)

If the failure requires changing a component that fits the existing frame—such as swapping a standard GPS for an RTK module, or upgrading the video transmitter—the timeline extends.

- Sourcing Parts: 1-2 weeks (depending on supply chain).

- Assembly: 2-3 days.

- Integration Testing: 1 week.

- Total: ~3-4 weeks.

Delays here often stem from supply chain availability. For example, high-end thermal cameras often have long lead times.

Structural Redesigns (6–10 Weeks)

This is the most time-consuming category. If the drone arm snapped during a stress test, or if the landing gear obstructed the camera view, we might need to create new molds.

- CAD Design: 1 week.

- Mold Making (Carbon Fiber/Plastic): 3-5 weeks.

- Prototyping & Assembly: 1 week.

- Stress Testing: 1 week.

- Total: 6-10 weeks.

Pushing a supplier to rush this process is dangerous. Rushing mold production can lead to imperfections that compromise structural integrity, leading to another failure in the second round of testing.

Managing Expectations with a Gantt Chart

When a supplier gives you a timeline, ask for a breakdown. A generic "we will fix it in a month" is a red flag. Request a simple schedule that includes:

- Root Cause Identification Date

- Design Completion Date

- Material Procurement Date

- Assembly Completion Date

- Internal QC Test Date

This transparency ensures that the supplier is actively working on your revision and not just prioritizing other orders.

adjust PID parameters 4

How do I ensure the second sample addresses the specific defects I found?

Before we ship a revised unit, we run specific regression tests to verify the fix. You should demand proof that the new unit passed the exact test that failed previously, ensuring accountability. (Max 30 words)

NRE (Non-Recurring Engineering) costs 5

Require a video validation of the specific failure point before shipment and mandate an updated Quality Control (QC) report highlighting the corrective actions. Do not accept a generic "passed" status; insist on seeing the data comparison between the failed unit and the revised sample under identical stress conditions.

Receiving a second sample that fails in the exact same way as the first is a procurement manager's nightmare. It wastes shipping costs, time, and credibility. To prevent this, you must implement a strict "Gatekeeper" process before the second sample leaves the factory in China.

barometric altimeters 7

The Corrective Action Plan (CAP)

Do not authorize the shipment of the second sample until you have reviewed the supplier's Corrective Action Plan. This document should detail:

- The Problem: (e.g., "Drone lost altitude during rapid descent").

- The Root Cause: (e.g., "Barometer was affected by prop wash pressure").

- الإصلاح: (e.g., "Relocated barometer and added foam shielding").

- The Verification: (e.g., "Performed 50 rapid descent tests with no altitude loss").

If the supplier cannot provide this level of detail, they likely haven't fixed the root cause and are hoping the second unit "just works" by chance.

NIST alignment test 8

Remote Validation Protocols

You don't need to wait for the drone to arrive in the US to verify the fix. Use technology to bridge the gap.

- Live Video Demo: Schedule a WeChat or Zoom call with the engineering team. Ask them to perform the specific maneuver that caused the failure live on camera.

- Uncut Video Evidence: If time zones are an issue, request a continuous, uncut video file. For example, if the battery failed at 15 minutes, ask for a continuous 30-minute flight video showing the voltage telemetry on the screen.

Updating the Quality Control Checklist

The failure of the first sample revealed a gap in the supplier's standard QC process. You must ensure this gap is closed for the second sample and all future production units.

- Update the Standard Operating Procedure (SOP): Ask the supplier to add the specific test case that failed to their standard QC checklist.

- Regression Testing: Ensure that the "fix" for one problem didn't create a new one. For example, adding foam shielding to a barometer might cause overheating if not tested properly.

Verification Checklist for Second Sample

Before approving the shipment, tick off these boxes:

| خطوة التحقق | المتطلبات | الغرض |

|---|---|---|

| دليل مرئي | Video of the specific failed maneuver being executed successfully. | Confirms the specific defect is resolved. |

| Data Proof | New telemetry logs showing stable parameters. | Scientific proof beyond visual observation. |

| Physical Inspection | Photos of the internal modification (e.g., new wiring, shielding). | Verifies the hardware change was actually implemented. |

| Regression Check | Confirmation that basic functions (GPS, RTH) still work. | Ensures the fix didn't break existing features. |

By enforcing these strict verification protocols, you transform from a passive buyer into an active partner in the quality assurance process. This not only ensures your second sample works but also trains the supplier to meet your high standards permanently.

IMU logs 9

الخاتمة

Providing structured, data-backed feedback transforms a failed test into a product improvement opportunity. By demanding logs, negotiating fairly, and verifying fixes remotely, you ensure the final drone meets rigorous safety standards. (Max 30 words)

ArduPilot or PX4 firmware 10

الحواشي

1. Industry authority defining quality assurance versus control. ︎

2. Government guidance on creating standard operating procedures. ︎

3. Standard quality management process for resolving systemic issues. ︎

4. Technical explanation of the control loop mechanism. ︎

5. Definition of one-time engineering costs in manufacturing. ︎

6. Explanation of high-precision satellite navigation technology. ︎

7. NASA explanation of how altitude is measured via pressure. ︎

8. Official NIST page detailing aerial robot test methods. ︎

9. Definition of the inertial sensor technology used for stability. ︎

10. Official website for the specific flight controller firmware mentioned. ︎