Every week, our engineering team receives inquiries from US energy procurement managers asking the same question الامتثال لـ NFPA 1. They need طائرات بدون طيار لمكافحة الحرائق 2. They see Chinese manufacturers offering advanced capabilities. But they worry about quality, compliance, and long-term support.

To properly vet Chinese firefighting drone suppliers for US energy applications, you must verify safety certifications like CE and FCC, demand documented case studies from utility deployments, confirm US-based technical support availability, assess cybersecurity protocols, and evaluate OEM customization capabilities through factory audits and pilot programs.

This guide walks you through each critical vetting step. We will cover certifications, track record verification, technical support, and logistics. Let us dive in.

What specific safety certifications should I demand from a Chinese firefighting drone manufacturer to meet US energy industry standards?

When we prepare export documentation for our US energy clients, certification questions always come first. Without proper certifications, your drone cannot legally operate near critical infrastructure. Worse, you risk regulatory penalties and safety incidents.

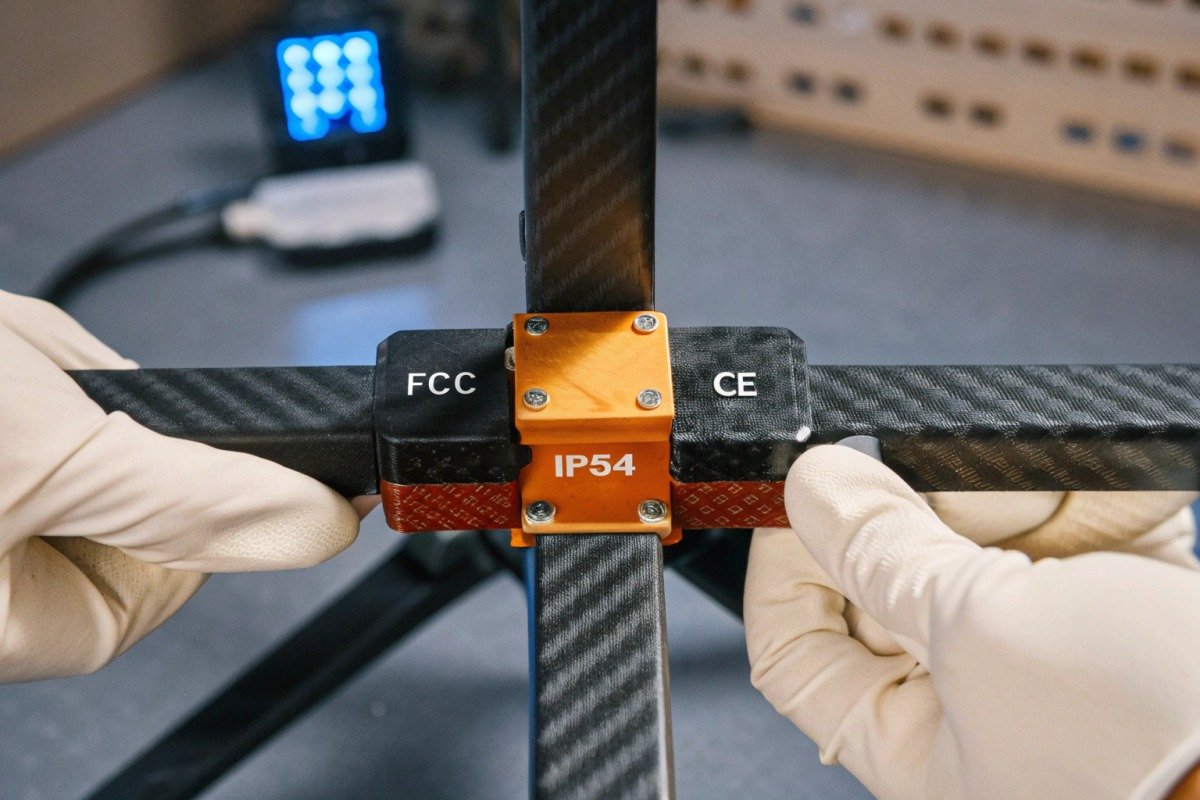

You should demand CE certification, FCC compliance for radio equipment, ISO 9001 quality management, and verify the manufacturer's pathway to FAA Part 107 operational requirements. For energy sector use, also request documentation showing NFPA compliance and any third-party safety testing reports from recognized labs.

Understanding the Certification Landscape

Certifications serve different purposes. CE marking 3 shows compliance with European safety standards. شهادة لجنة الاتصالات الفيدرالية 4 confirms the radio equipment will not interfere with other systems. آيزو 9001 5 proves the manufacturer follows quality management processes.

However, these baseline certifications are not enough for US energy applications. The energy sector has specific requirements. Your drone may fly near high-voltage transmission lines. It may operate during wildfire emergencies. It may carry fire suppression payloads over populated areas.

Key Certifications to Verify

| التصديق | ما الذي يثبته | Why Energy Companies Need It |

|---|---|---|

| علامة CE | European safety compliance | Baseline quality indicator |

| FCC Part 15/Part 107 | Radio frequency compliance | Legal US operation |

| آيزو 9001 | Quality management system | Consistent manufacturing |

| RoHS | Hazardous substance limits | Environmental compliance |

| IP Rating (IP54+) | مقاومة الغبار والماء | Field reliability |

| Third-party fire testing | Payload safety verification | Insurance requirements |

Beyond Basic Certifications

Our experience shows that basic certifications are just the starting point. US energy companies should also ask for:

Third-party testing reports. Independent labs like UL or Intertek can verify manufacturer claims. Do not rely solely on vendor-provided data.

NFPA 1710 alignment. This standard covers fire department response times. Your drone system should integrate with existing emergency protocols.

Cybersecurity documentation. Chinese drones face scrutiny from CISA and DHS. Ask suppliers about data encryption, firmware security, and whether flight data can be stored locally without cloud transmission. Cybersecurity documentation 6

Supply chain transparency. Know where critical components come from. Batteries, flight controllers, and cameras should have documented origins.

Red Flags in Certification Claims

Watch for these warning signs:

- Certificates with expired dates

- Self-declared conformity without testing lab involvement

- Inability to provide original certificate documents

- Vague claims like "meets international standards" without specifics

- Refusal to share test reports or audit results

How can I confirm that a supplier has a proven track record of delivering industrial drones to large-scale utility or energy firms?

During our years of exporting to North American markets, we have learned that track record verification is where many procurement managers struggle most. US Customs data 7 Suppliers make impressive claims. But proving those claims requires systematic investigation.

Confirm supplier track record by requesting verifiable reference contacts from existing US energy clients, reviewing documented case studies with specific deployment details, checking import records through US Customs data, and conducting video calls with reference customers to discuss real-world performance and support quality.

The Challenge of Verification

Chinese manufacturers often serve global markets. They may have excellent experience in Europe, Asia, or the Middle East. But US energy sector experience is different. US regulations are stricter. Insurance requirements are higher. Technical support expectations are more demanding.

When we work with US utility companies, they want to know: Has this exact drone model been deployed in similar conditions? What problems occurred? How were they resolved?

Verification Methods That Work

| طريقة التحقق | What You Learn | Difficulty Level |

|---|---|---|

| Direct reference calls | Real performance feedback | متوسط |

| US Customs import data | Actual export history | منخفضة |

| Site visit to reference customer | Operational reality | عالية |

| Video factory tour | Production capability | متوسط |

| Third-party due diligence report | Comprehensive assessment | عالية |

Questions to Ask Reference Customers

If a supplier provides reference contacts, prepare specific questions:

- How long have you used their drones?

- What problems occurred during the first year?

- How quickly did they respond to support requests?

- Did the actual performance match the specifications?

- Would you purchase from them again?

- How does spare parts availability work?

Industry-Specific Track Record Concerns

Energy sector deployments face unique challenges. Your reference verification should cover:

Wildfire response. Has the supplier's drone operated during active fire conditions? Heat, smoke, and ash create extreme stress on equipment.

Transmission line inspection. Flying near high-voltage lines requires precise control and electromagnetic interference resistance.

Industrial facility protection. Oil refineries and power plants have specific safety zones. The supplier should understand these restrictions.

Regulatory compliance history. Has the supplier's equipment passed FAA inspections? Any incidents or violations?

Building a Verification Checklist

Create a standardized checklist for every potential supplier:

- Minimum 3 verifiable US references

- At least 2 years of documented US market presence

- Specific energy sector deployment examples

- Documented response times for support requests

- Clear warranty claim history and resolution rates

Will my Chinese drone partner offer the long-term technical support and spare parts availability my energy company requires?

When our after-sales team supports US clients, we understand that a drone purchase is just the beginning. Energy companies need reliable support for years, sometimes decades. A supplier that cannot provide long-term support creates operational risk.

Your Chinese drone partner must demonstrate US-based technical support capability, maintain spare parts inventory in North America with documented lead times under 72 hours for critical components, offer comprehensive training programs, and provide clear warranty terms covering at least 2 years with explicit definitions of coverage scope.

Why Long-Term Support Matters More for Energy Companies

Energy infrastructure operates continuously. A firefighting drone that sits grounded for two weeks waiting for parts from China creates unacceptable risk. Your emergency response capability disappears.

Our experience shows that support requirements increase after the first year. Initial deployment goes smoothly. Then wear items need replacement. Software needs updates. Operators encounter edge cases not covered in basic training.

Critical Support Elements to Negotiate

| Support Element | الحد الأدنى من المعايير المقبولة | المعيار المثالي |

|---|---|---|

| Response time | 48 ساعة | 4 ساعات |

| Parts lead time | 2 أسبوعان | 72 hours |

| US-based technicians | Remote support | On-site within 48 hours |

| Warranty period | 1 سنة | 2+ years |

| Software updates | 2 years | Lifetime of product |

| Training availability | Initial only | Annual refresher |

Spare Parts Strategy

Spare parts availability is the most common failure point in Chinese supplier relationships. Ask these specific questions:

Where are spare parts stored? A US warehouse is essential for critical components. Shipping from China takes too long during emergencies.

What is the minimum order quantity? Some suppliers require bulk purchases. This ties up capital and creates storage problems.

How long are parts guaranteed available? Drone models change. Will spare parts be available in 5 years? 10 years?

What are the costs? Get a complete spare parts price list. Watch for unreasonably high markups that indicate the supplier profits primarily from parts, not drone sales.

Technical Support Infrastructure

Strong technical support requires infrastructure investment. Evaluate:

Support team size and location. How many technicians serve the US market? What are their time zones?

Remote diagnostic capability. Can the supplier diagnose problems remotely? This speeds resolution significantly.

Documentation quality. Are maintenance manuals complete and in English? Poor documentation increases support dependency.

Training programs. What training does the supplier offer? On-site training is more valuable than video tutorials.

Contract Terms to Protect Your Interests

Include these provisions in your purchase agreement:

- Guaranteed parts availability for 5+ years

- Maximum response time with penalty clauses

- Defined escalation procedures

- Software update commitments

- Exit provisions if support quality declines

How do I evaluate if a manufacturer can handle the complex OEM customization and secure delivery logistics needed for my US operations?

Our production team regularly works on OEM projects for US distributors. We know that customization and logistics are where many supplier relationships fail. The manufacturer says "yes" to everything during sales. Then problems emerge during execution.

Evaluate OEM customization capability by reviewing past custom projects with similar complexity, conducting factory audits to assess engineering capacity, requesting detailed project timelines with milestones, and verifying secure logistics through documented experience with US Customs clearance, proper export licensing, and established freight forwarding partnerships.

Understanding OEM Customization Complexity

تخصيص المعدات الأصلية 9 ranges from simple branding to complete system redesign. Energy company requirements typically fall in the middle. You may need:

- Custom payload configurations for specific fire suppression systems

- Software integration with existing emergency response platforms

- Modified flight envelopes for specific operational environments

- Specialized sensors for infrastructure inspection

- Custom data handling to meet security requirements

Assessing Engineering Capability

| Capability Area | الأسئلة التي يجب طرحها | الأدلة التي يجب طلبها |

|---|---|---|

| Hardware modification | Can you modify frame design for specific payloads? | Past custom hardware projects |

| Software development | Do you have in-house software engineers? | API documentation, SDK availability |

| Integration testing | How do you validate custom configurations? | Test protocols, quality reports |

| Certification support | Can you help recertify modified systems? | Previous certification submissions |

| Project management | Who will manage my customization project? | Named project manager, timeline |

Factory Audit Essentials

If possible, conduct a factory audit before committing to a major OEM project. Evaluate:

Production capacity. Can they handle your volume without quality degradation? What is their current utilization rate?

Quality control systems. Do they have documented inspection processes? What percentage of units fail QC?

Engineering resources. How many engineers work on custom projects? What are their backgrounds?

Material sourcing. Where do components come from? Can they provide supply chain documentation?

Security protocols. How do they protect your proprietary designs and specifications?

Logistics and Delivery Considerations

Secure delivery logistics involve multiple components:

Export licensing. Drones may require export licenses from China. Verify the manufacturer has experience navigating these requirements.

US import clearance. Your manufacturer should understand US Customs requirements for drones. Incorrect documentation causes delays and penalties.

Shipping method selection. Air freight is faster but more expensive. Sea freight saves money but extends timelines. Your manufacturer should advise based on your priorities.

Insurance coverage. Drones are high-value, fragile items. Verify adequate transit insurance coverage.

Delivery tracking. Modern logistics should include real-time tracking. This is especially important for time-sensitive energy projects.

Cybersecurity in OEM Configurations

US government agencies have warned about cybersecurity risks with Chinese drones. For energy sector applications, this concern is paramount. Address these issues during OEM discussions:

Data storage. Where is flight data stored? Can it be kept entirely on local systems?

Firmware security. Who controls firmware updates? Can updates be reviewed before installation?

Network isolation. Can the drone operate without internet connectivity?

Audit capability. Can you inspect the software for security vulnerabilities?

Managing the OEM Relationship

Successful OEM projects require clear communication and documented agreements:

- Detailed specifications document with acceptance criteria

- Milestone-based payment schedule

- Clear intellectual property ownership terms

- Quality inspection rights at each production stage

- Penalty clauses for delays or specification failures

الخاتمة

Vetting Chinese firefighting drone suppliers for US energy applications requires systematic evaluation across certifications, track record, support infrastructure, and customization capabilities. Take time to verify claims, conduct audits, and build contractual protections before committing to a supplier partnership.

الحواشي

1. Provides information on NFPA standards for small unmanned aircraft systems in public safety. ︎

2. Provides a comprehensive guide to the applications and uses of drones in firefighting. ︎

3. Replaced HTTP 400 PDF with an official EU guide on CE marking. ︎

4. Details the FCC certification process and requirements for radio communication products in the U.S. ︎

5. Explains the ISO 9001 standard for quality management systems and its benefits. ︎

6. Offers best practices and guidance for cybersecurity in commercial drone operations. ︎

7. Explains how to access and use public import and export data from US Customs. ︎

8. Discusses the importance of spare parts inventory management in supply chain efficiency. ︎

9. Defines OEM customization and its role in meeting specific customer needs. ︎