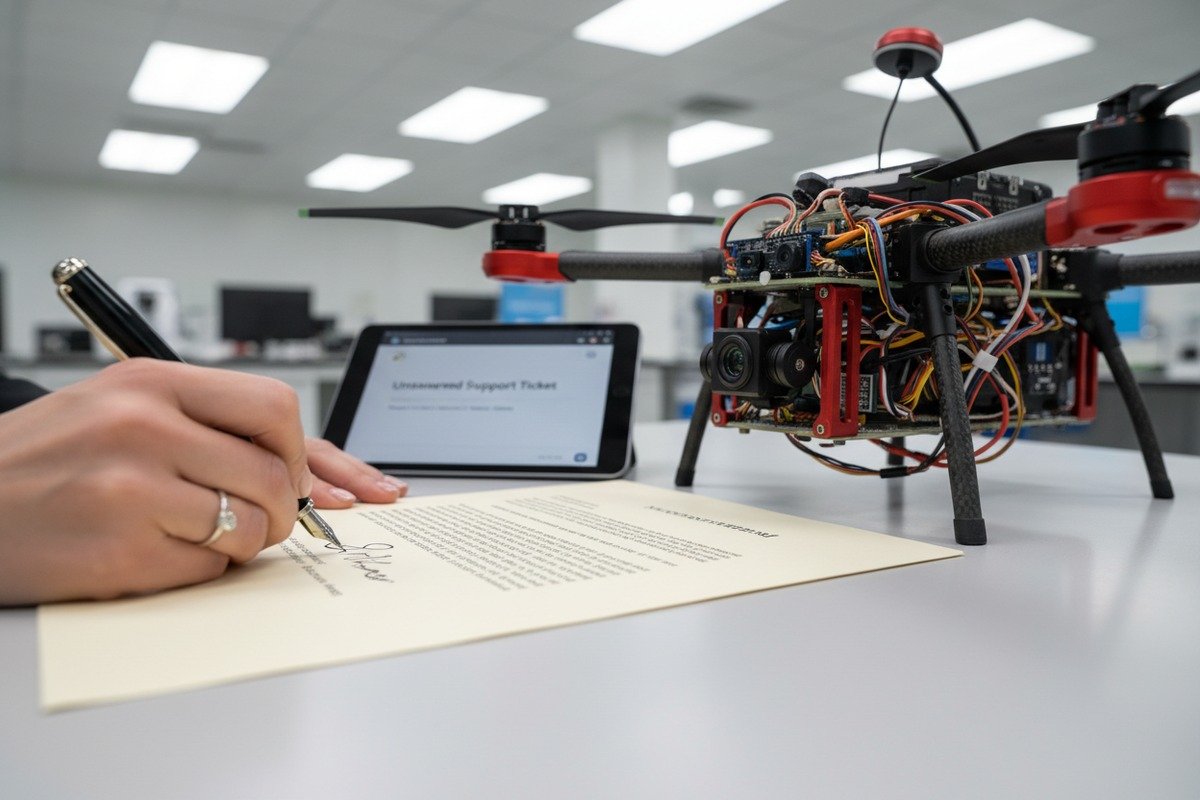

When our engineering team receives a call about a malfunctioning drone mid-wildfire season, we understand the stakes FAA regulatory complaints 1. A single AI hotspot detection error 2 can mean acres lost. Yet many buyers struggle to hold suppliers accountable when quality falls short.

To resolve quality disputes with firefighting drone suppliers, you must document all performance failures with telemetry data and visual evidence, review your contract’s warranty and arbitration clauses, send formal written notices citing specific breaches, and escalate through mediation, arbitration, or FAA regulatory complaints if negotiations fail.

This guide walks you through each step. We will cover evidence gathering, negotiation tactics, replacement logistics, and how to leverage your original specifications third-party inspection reports 3. Let us dive in.

How can I effectively document performance failures to hold my firefighting drone supplier accountable?

We have seen buyers lose valid claims simply because they lacked proper records consignment inventory arrangements 4. When our production line ships a unit, every flight controller log and sensor calibration report goes with it. The question is: are you collecting the same level of detail on your end?

To effectively document performance failures, you must capture timestamped telemetry logs, high-resolution video footage from onboard cameras, third-party inspection reports, and written communication records with the supplier within the contractual inspection window.

Start With Your Contract's Inspection Period

Most supplier contracts include a specific window for reporting defects. This could be 7, 14, or 30 days after delivery. Miss this window, and your claim may be void. Check your purchase agreement immediately.

Gather Technical Evidence From the Drone Itself

Modern firefighting drones generate massive amounts of data. Use it. Here is what to collect:

| نوع الدليل | Source | الغرض |

|---|---|---|

| Flight telemetry logs | Flight controller | Shows altitude, speed, GPS coordinates, motor performance |

| Sensor data | LiDAR, thermal cameras | Proves AI hotspot detection accuracy or failures |

| Battery cycle records | Battery management system | Documents capacity degradation |

| Video footage | Onboard HD camera | Visual proof of malfunctions during operation |

| Communication logs | Remote link system | Shows signal drops or command failures |

Document Environmental Conditions

Suppliers often argue that harsh wildfire conditions caused the failure—not manufacturing defects. Counter this by recording ambient temperature, wind speed, smoke density, and humidity during each flight. This separates operational stress from product flaws.

Use Third-Party Inspections

When our export partners in the US face disputes, we recommend independent testing labs. A neutral report carries more weight in arbitration than internal assessments. Look for FAA-certified inspection services or aerospace engineering firms.

Preserve All Communication

Every email, phone call summary, and support ticket matters. Create a dedicated folder. When you send a notice, use certified mail or tracked email services. This builds a timeline that proves you acted promptly and in good faith.

What should I do if my supplier refuses to provide the technical support needed to fix malfunctioning drones?

In our experience exporting to the US market, we have learned that post-sale support makes or breaks partnerships. But what happens when your supplier goes silent? This is more common than you might think.

If your supplier refuses technical support, escalate through formal written demands citing contract terms, request mediation through industry associations, explore third-party repair services, and file regulatory complaints with the FAA if safety certifications are compromised.

Send a Formal Demand Letter

Do not rely on casual emails. Draft a formal letter that includes:

- Specific contract clauses requiring technical support

- Detailed description of the malfunction

- Timeline of your previous support requests

- Clear deadline for response

- Consequences of non-compliance

Send this via certified mail and email simultaneously. Keep all delivery receipts.

Understand Your Contractual Rights

Review your agreement for these key provisions:

| Contract Clause | ما الذي تبحث عنه | Your Leverage |

|---|---|---|

| Warranty period | Duration and coverage scope | Demand free repairs within period |

| Technical support terms | Response time guarantees | Cite delays as breach |

| Governing law | Jurisdiction for disputes | Know where to file complaints |

| Arbitration clause | Mandatory arbitration requirements | Prepare arbitration demand |

| Remedy provisions | Repair, replace, or refund options | Choose your preferred remedy |

Explore Alternative Repair Options

When our flight controllers need recalibration, our engineers can often guide certified third-party technicians remotely. Ask your supplier if they authorize independent repair centers. If they refuse, document this as failure to mitigate damages.

Some buyers successfully use:

- Drone manufacturer-certified repair shops

- Aerospace electronics specialists

- University engineering departments with UAS programs

File Regulatory Complaints When Appropriate

If your firefighting drone fails to meet FAA Part 107 standards 5 or remote ID requirements, the supplier may face regulatory consequences. The FAA reviews complaints about non-compliant UAS. This creates pressure for suppliers to resolve issues quickly.

Consider Industry Mediation

Trade associations like AUVSI 6 offer dispute resolution resources. Mediation costs less than arbitration and preserves business relationships. Many suppliers prefer mediation to avoid public arbitration records.

How do I manage the logistics of getting replacement parts for my industrial drone fleet without extra costs?

When we ship industrial drones from our Xi'an facility, we include detailed parts catalogs and recommended spare inventories. But supply chain disruptions happen. How do you get parts without absorbing unfair costs?

To manage replacement parts logistics without extra costs, negotiate pre-agreed spare parts pricing in your original contract, establish consignment inventory arrangements, claim shipping costs under warranty terms, and leverage bulk ordering for commonly failing components.

Build Parts Provisions Into Your Original Contract

The best time to solve parts logistics is before you sign. Here is what to negotiate:

| Contract Provision | المزايا | نصيحة تفاوض |

|---|---|---|

| Fixed parts pricing for 3-5 years | Protects against inflation | Tie to raw material indexes |

| Guaranteed availability period | Ensures long-term support | Minimum 7-10 years |

| Consignment inventory | Parts on-site, pay when used | Offer volume commitments |

| Free warranty shipping | Eliminates hidden costs | Specify door-to-door delivery |

| Cross-shipping authorization | Get parts before returning defectives | Reduces downtime |

Claim Warranty Coverage Aggressively

Under most warranty terms, the supplier bears shipping costs for defective parts. Do not assume you must pay. When our US distributors report failures, we cover return logistics through our door-to-door service. Your supplier should do the same.

Document every shipping expense. If the supplier refuses reimbursement, add these costs to your dispute claim.

Establish Regional Parts Depots

For large fleet operators, negotiate regional warehouse arrangements. Having parts in-country cuts delivery time from weeks to days. Some suppliers partner with local logistics companies to maintain buffer stock.

Identify Alternative Parts Sources

Not all components are proprietary. Motors, propellers, and battery cells often have compatible alternatives. When we design our carbon fiber frames, we use industry-standard mounting patterns for this reason.

Work with aerospace parts distributors who stock:

- Brushless motors (common specifications)

- LiPo and Li-ion battery packs

- Carbon fiber propeller sets

- GPS and communication modules

- Camera gimbal components

Track Parts Consumption Patterns

Use your fleet management data to predict which parts fail most often. Order these proactively. Waiting until a drone is grounded costs more in downtime than maintaining reasonable inventory.

Our engineering team recommends keeping these spares on hand:

- Propellers (4 full sets per drone)

- Motors (2 per drone)

- Battery packs (1 extra per drone)

- مكونات معدات الهبوط

- Antenna assemblies

How can I use my initial quality specifications and certifications to resolve disputes over substandard drone components?

Our production line runs strict quality control 7 because we know these specifications become legal documents. When buyers discover substandard components, the original specs and certifications are their strongest weapons.

To resolve disputes using quality specifications, compare delivered products against contracted specs sheets, verify FAA certifications and remote ID compliance, engage independent testing to confirm deviations, and cite specific non-conformances in your formal dispute notice.

Your Specs Sheet Is a Binding Agreement

When you signed the purchase order, the attached specifications became contractual requirements. Common spec elements include:

- AI hotspot detection accuracy percentage

- Battery capacity and cycle life

- Payload capacity for retardant spraying

- Maximum flight endurance at altitude

- Communication link range and reliability

- Operating temperature range

Any deviation from these specifications is a potential breach. Document the gap precisely.

Verify Certification Compliance

FAA regulations require specific certifications for commercial drones. Your supplier must provide:

| التصديق | المتطلبات | طريقة التحقق |

|---|---|---|

| FAA Part 107 compliance | All commercial operations | Check registration database |

| Remote ID capability | Required for UAS >0.55 lbs by 2024-2027 | Test remote ID broadcast |

| Airworthiness standards | Performance-based safety | Review test reports |

| FCC communication approval | Radio frequency compliance | Check FCC ID database |

| Battery safety certification | UN38.3 transport compliance | Request test certificates |

If certifications are missing or fraudulent, your dispute claim strengthens significantly. The FAA takes certification violations seriously.

Conduct Independent Testing

Do not rely solely on supplier-provided test results. Engage a third-party lab to verify:

- Actual battery capacity versus rated capacity

- Real-world flight endurance versus claimed specs

- AI detection accuracy under controlled conditions

- Communication link performance at rated distances

- Payload capacity under various wind conditions

When our engineers calibrate flight controllers, we welcome independent verification. Honest suppliers do the same.

Use Acceptance Quality Limits Strategically

Professional procurement includes AQL standards for defect tolerance. Acceptance Quality Limits 8 If your contract specifies AQL levels, use them:

| Defect Type | Typical AQL | Implication |

|---|---|---|

| Critical defects (safety) | 0% | Any occurrence justifies rejection |

| Major defects (function) | 1.0-2.5% | Exceeding triggers remedies |

| Minor defects (cosmetic) | 4.0% | Higher tolerance, lower priority |

Document every defect found. Calculate your actual defect rate. Compare to AQL thresholds. This quantifies your claim.

Build Your Formal Dispute Notice

Your notice should include:

- Contract reference and purchase order number

- Specific specification requirements

- Documented deviations with evidence

- Certification non-compliance findings

- Requested remedy (repair, replacement, refund)

- Deadline for supplier response

- Statement of intent to escalate

Reference arbitration clauses if your contract requires them. Many multi-state firefighting contracts mandate arbitration over litigation for efficiency.

Prepare for Arbitration

If negotiations fail, arbitration panels review technical evidence carefully. A recent US drone firefighting case saw a panel order recalibration and damages after AI hotspot errors were proven through flight logs. Quantify your efficiency losses using contract metrics.

Gather:

- All technical documentation

- Independent test results

- Communication records

- Expert witness statements

- Financial impact calculations

الخاتمة

Quality disputes with firefighting drone suppliers require systematic documentation, contract knowledge, and strategic escalation. By gathering telemetry evidence, asserting warranty rights, managing parts logistics proactively, and leveraging your original specifications, you protect your investment and maintain operational readiness.

الحواشي

1. Provides official FAA guidance on reporting unsafe drone operations and enforcement. ︎

2. Explains how AI and drones improve wildfire hotspot detection accuracy. ︎

3. Highlights the benefits of independent drone inspection services for defect documentation. ︎

4. Replacement URL from Wikipedia provides a clear and authoritative definition of a consignment agreement, which encompasses consignment inventory arrangements. ︎

5. Replacement URL is the official Code of Federal Regulations (eCFR) for 14 CFR Part 107, providing the most authoritative and comprehensive details on FAA Part 107 standards. ︎

6. Introduces the leading non-profit organization for unmanned systems and robotics. ︎

7. Defines the process of reviewing production factors to meet quality requirements. ︎

8. Explains a statistical method for determining acceptable defect levels in product batches. ︎