At SkyRover, we see how battery failures destroy missions. Unstable power risks lives and equipment. You need reliable energy systems to fly safely in extreme heat.

To determine BMS safety, verify the supplier uses internationally renowned battery brands or provides third-party certifications like UN38.3. A safe system must feature real-time cell monitoring, automatic protection against overcharging and short circuits, and auto-discharge functions for storage, ensuring stability during high-intensity firefighting operations.

Let's explore the critical checkpoints for evaluating a supplier's battery technology to ensure your fleet remains operational.

Does the BMS Include Automatic Protection Against Overcharging and Short Circuits?

We test our drones rigorously because electrical faults cause crashes. Without protection, a voltage spike ruins your investment. You must ensure the system defends itself automatically.

A robust BMS must include integrated hardware protections that instantly cut power during overcharging, over-discharging, or short circuits. This prevents thermal runaway, a critical safety feature that stops the battery from catching fire or exploding when electrical limits are exceeded during flight.

The First Line of Defense: Hardware Protections

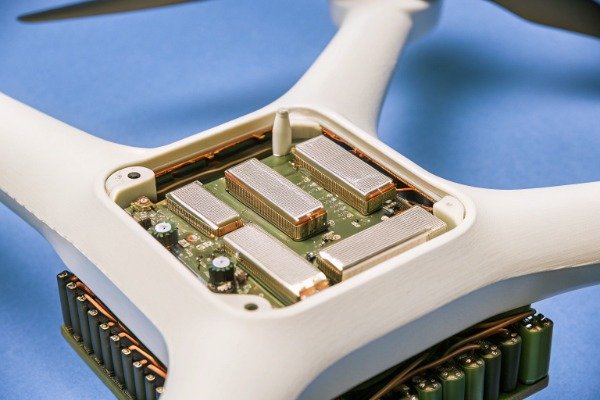

When we design power systems for heavy-lift drones, we treat the Battery Management System (BMS) as the brain of the power unit. In firefighting scenarios, drones operate in high-stress environments. The motors draw massive currents to maintain stability against updrafts from fires. If the BMS is weak, these current spikes can cause catastrophic failure.

نظام إدارة البطارية (BMS) 1

You need to ask your supplier specifically about the hardware architecture. A safe BMS uses high-quality MOSFETs (Metal-Oxide-Semiconductor Field-Effect Transistors) to act as digital switches. If the current exceeds a safe limit—for example, during a short circuit caused by damaged wiring—the BMS must physically disconnect the circuit within milliseconds. This is not just software; it is a hard-wired safety net.

Metal-Oxide-Semiconductor Field-Effect Transistors 2

Understanding Thermal Runaway

The biggest risk in lithium batteries is thermal runaway. This happens when a cell gets too hot, causing a chemical reaction that creates more heat, leading to a fire. In our engineering lab, we simulate these failures to ensure our systems stop them before they start.

بطاريات الليثيوم 3

Protection against overcharging is equally vital. If a charger fails and keeps pumping energy into a full battery, the voltage rises to dangerous levels. A quality BMS detects this voltage rise (usually above 4.2V or 4.35V per cell) and severs the connection. Without this, a battery charging overnight in a fire station could ignite.

Comparing Protection Levels

We have compiled a comparison to help you distinguish between a basic hobbyist BMS and an industrial-grade system suitable for firefighting.

| الميزة | Basic BMS (Avoid) | Industrial BMS (Required) |

|---|---|---|

| Short Circuit Protection | Often relies on a simple fuse that blows permanently. | Uses electronic switching (MOSFETs) that can reset after the fault clears. |

| Overcharge Response | May only monitor the total pack voltage. | Monitors every single cell individually to prevent one cell from spiking. |

| وقت الاستجابة | Slow (>1 second), which may be too late for sensitive electronics. | Instant (<10 milliseconds), protecting the flight controller and ESCs. |

| Temperature Cutoff | Often missing or measures only one spot. | Multiple sensors across the pack to detect hotspots immediately. |

The Importance of Redundancy

In our experience with export orders, we find that clients often overlook redundancy. A truly safe system has backup circuits. If the primary logic chip fails, a secondary "watchdog" circuit should still be able to shut down the battery if it detects a short circuit. When you speak to suppliers, ask them: "What happens if the main BMS processor freezes?" The answer should be that the hardware protection remains active.

What International Safety Certifications Should the Batteries Hold?

Shipping our units globally taught us that uncertified batteries get stuck at customs. Worse, they endanger crews. You cannot afford compliance risks or safety hazards.

Essential certifications include UN38.3 for safe transport and UL 1642 or IEC 62133 for cell safety. These standards verify that the battery withstands vibration, shock, and altitude changes without leaking or igniting, providing a baseline guarantee of quality and reliability for industrial use.

Why "Generic" Isn't Good Enough

We often see cheaper drones entering the market with "white label" batteries that have no markings. This is a major red flag. In the industrial sector, a battery is a hazardous material. If a supplier cannot provide a test report, it usually means the battery has not been tested against extreme conditions.

hazardous material 4

When we source components, we look for cells from Tier 1 manufacturers like Samsung, Sony (Murata), or top-tier Chinese brands like Grepow or Tattu. If your supplier manufactures their own packs, they must provide the certification documents for the cells inside.

The UN38.3 Standard Explained

The most common document you will need is UN38.3. This is not just a piece of paper; it is a rigorous test suite. It ensures the battery is safe for air transport. Since firefighting drones are often transported by air or driven over rough terrain to wildfire sites, this standard is relevant to your daily operations.

The tests include:

- Altitude Simulation: Does the battery leak at low pressure?

- Thermal Cycling: Can it handle rapid changes from freezing to hot?

- Vibration and Shock: Will it explode if the truck hits a pothole?

- External Short Circuit: What happens if the terminals touch metal?

Critical Certifications Checklist

Use this table to audit the documentation provided by your potential supplier.

| التصديق | What It Tests | Why You Need It |

|---|---|---|

| رقم الأمم المتحدة 38.3 | Transport safety (shock, vibration, altitude). | Required for legal shipping and ensures ruggedness. |

| UL 1642 / UL 2054 | Cell and pack safety (fire, explosion). | The gold standard for safety in the US market. |

| IEC 62133 | Safety requirements for portable sealed secondary cells. | Common requirement for European compliance. |

| CE / FCC | Electromagnetic compatibility. | Ensures the battery electronics don't jam your radio signals. |

Verifying the Documents

Do not just accept a PDF file at face value. We have seen forged certificates in the industry. You should check the certificate number on the issuing laboratory's website. If the supplier is hesitant to share the full report or if the brand name on the certificate does not match the battery label, proceed with extreme caution. A legitimate manufacturer will be proud to show you their compliance proofs because it justifies their price point.

Can the System Monitor Individual Cell Temperatures During Flight?

Our engineers analyze flight logs and often see heat spikes ruin missions. Blind flying leads to failure. You need real-time data to prevent mid-air disasters.

Yes, a high-quality BMS monitors individual cell temperatures and voltages in real-time. It communicates directly with the flight controller, triggering automated warnings or landings if a cell overheats. This prevents imbalance and ensures the drone operates safely even in high-temperature fire environments.

The Danger of Cell Imbalance

A drone battery is a pack of many smaller cells wired together. In a 12S battery (common for heavy drones), there are 12 cells in a series. If just one cell is weaker than the others, it will drain faster and get hotter.

Without individual monitoring, the drone only sees the total voltage. The total might look fine, but that one weak cell could be on the verge of failure. When that cell dies, the voltage drops instantly, and the drone falls out of the sky. We integrate smart BMS protocols to prevent this exact scenario.

Communication Protocols: CAN Bus and SMBus

You should ask the supplier: "How does the battery talk to the drone?" A simple "dumb" battery just provides power. A "smart" battery uses data protocols like CAN Bus or SMBus.

ناقل CAN 5

These protocols allow the BMS to send a stream of data to your remote controller. You should be able to see:

- Voltage of every single cell.

- Temperature of the battery core.

- Number of charge cycles (history).

- Current draw in real-time.

Automated Safety Triggers

The real value of monitoring is automation. In the heat of a fire mission, your pilot is focused on the flames, not the battery voltage. A smart system takes over safety duties.

- Thermal Throttling: If the BMS detects the temperature rising above 60°C, it can tell the flight controller to limit the maximum speed. This reduces the current draw and lets the battery cool down while allowing the drone to return home.

- Low Voltage Landing: Instead of falling, the drone detects the weakest cell hitting a critical level (e.g., 3.5V) and initiates an auto-landing sequence.

Telemetry Data Analysis

Here is what your maintenance team should look for in the flight logs provided by the BMS.

| Data Point | Healthy Reading | علامة تحذير | الإجراء المطلوب |

|---|---|---|---|

| Cell Voltage Deviation | < 0.05V difference between cells. | > 0.1V difference. | Balance charge immediately; replace if persistent. |

| درجة الحرارة | 30°C – 50°C during flight. | > 60°C. | Land immediately; check for motor issues or overload. |

| Internal Resistance (IR) | Low and consistent across cells. | High or uneven IR. | The battery is aging; mark for training use only. |

Does the Battery Have an Auto-Discharge Feature for Safe Long-Term Storage?

We advise clients that fully charged batteries swell when left sitting. This destroys expensive equipment silently. You need smart batteries that manage their own health during downtime.

The battery must feature an auto-discharge function that lowers the charge level to a storage-safe voltage (usually around 3.8V per cell) after a set period of inactivity. This prevents gas buildup, swelling, and capacity loss, significantly extending the lifespan of your firefighting equipment.

The Chemistry of "Puffing"

Lithium batteries hate being full. When a battery sits at 100% charge (4.2V or 4.35V per cell) for days, the electrolyte inside begins to decompose. This process generates gas. Since the battery is sealed, the gas causes the pack to swell up—we call this "puffing."

Once a battery puffs, it is dangerous. The internal layers are compressed, increasing the risk of a short circuit. Furthermore, the capacity is permanently reduced. We have seen fire departments ruin entire fleets of batteries simply because they charged them on Friday and didn't fly until the next Wednesday.

How Auto-Discharge Works

A smart BMS solves this human error. It contains a small discharge circuit. If the onboard computer detects that the battery has not been used for, say, 48 hours, it begins to slowly burn off the excess energy as heat.

Electromagnetic compatibility 6

It will drain the battery down to a storage voltage (typically 3.80V – 3.85V). This is the chemical "sweet spot" where the battery is most stable. It can sit at this level for months without degrading.

IEC 62133 7

User-Configurable Settings

The best systems allow you to configure this. Through the drone's software, you should be able to set the "Time to Discharge."

- Aggressive (2 Days): Good if you fly frequently but want maximum protection.

- Standard (5-10 Days): Useful if you are on standby for a fire season and need to be ready to fly, but want protection if the standby lasts too long.

Economic Impact of Storage Maintenance

Replacing industrial drone batteries is expensive. A set of batteries for a heavy firefighting drone can cost thousands of dollars.

UL 1642 8

- Without Auto-Discharge: Batteries may last 50-100 cycles before swelling makes them unusable.

- With Auto-Discharge: Batteries can last 300-500 cycles or more.

By insisting on this feature, you are effectively tripling the return on your investment. It also reduces the workload on your logistics team, as they don't have to manually discharge batteries after every cancelled mission.

UN38.3 for safe transport 9

الخاتمة

Your drone is only as safe as its power source. By demanding a BMS with hardware protections, valid UN38.3 certifications, real-time cell monitoring, and auto-discharge features, you ensure mission success and crew safety.

الهروب الحراري 10

الحواشي

1. Defines the core technology and system architecture discussed in the article. ︎

2. Explains the specific electronic components used for hardware protection. ︎

3. Provides background on the battery chemistry used in these drones. ︎

4. Official government source regarding hazardous materials classification. ︎

5. Explains the communication protocol used for smart battery data. ︎

6. Official FCC page explaining EMC standards and regulations. ︎

7. Direct link to the international safety standard for secondary cells. ︎

8. Direct link to the official UL standard for lithium battery safety. ︎

9. Links to the IATA regulations requiring this specific test standard. ︎

10. Authoritative definition of the critical failure mode mentioned. ︎