Every season, our engineering team receives calls from frustrated farm operators. Their drones failed mid-spray during unexpected wind gusts. Crops went untreated. Money was lost. This pain is real and preventable.

To ask suppliers about agricultural drone performance in adverse weather, request specific IP ratings, verified wind resistance test data, operating temperature ranges, and third-party certifications. Demand real-world testing documentation, not just marketing claims. Compare battery performance metrics across temperature extremes and ask for maintenance protocols for weather-exposed components.

The questions you ask your supplier today determine whether your drone survives tomorrow’s storm. Let me walk you through exactly what to ask and why it matters.

How can I verify the maximum wind resistance levels of my agricultural drones during high-stakes spraying?

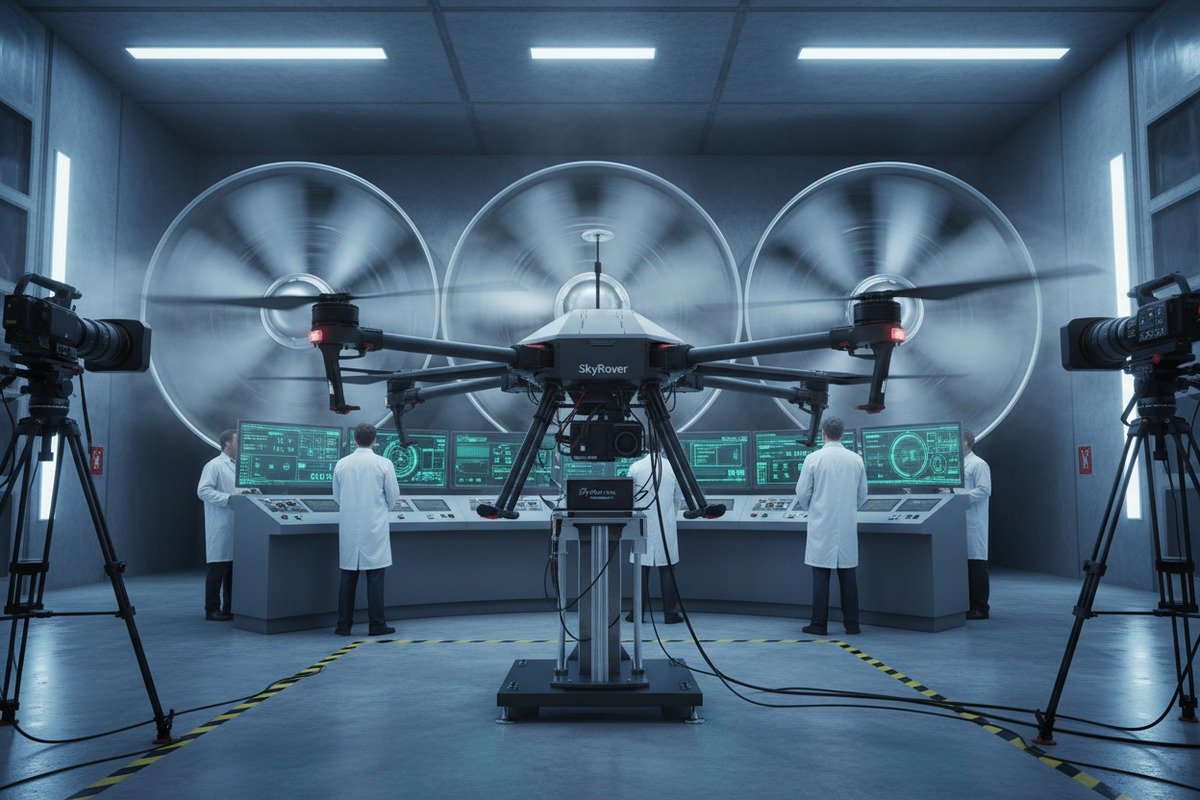

Wind ruins more spray operations than any other weather factor. When we test our hexacopter frames in the نفق الرياح 1, we see exactly how stability breaks down. Most buyers never ask the right questions about wind performance.

Request documented wind tunnel test results showing the maximum operational wind speed in meters per second. Ask for spray drift data at various wind speeds, and verify whether the drone maintains GPS lock and stable hovering at the claimed maximum. Demand video evidence of actual field tests, not just laboratory specifications.

Understanding Wind Speed Thresholds

Wind affects agricultural drones in two critical ways. First, it destabilizes flight. Second, it causes spray drift. Both problems cost you money.

Most professional agricultural drones claim wind resistance between 8-15 m/s. But claims mean nothing without proof. When our quality control team evaluates flight controllers, we test at incremental wind speeds. We record GPS accuracy, altitude hold, and motor compensation at each level.

Here is what you should ask your supplier:

| Question | ما أهمية ذلك | Red Flag Answer |

|---|---|---|

| What is the maximum tested wind speed? | Sets your operational limit | "Up to 15 m/s" with no test data |

| How was wind resistance tested? | Validates the claim | "Based on motor specifications" |

| What happens to spray accuracy at 10 m/s? | Affects crop coverage | No specific data provided |

| Does RTK positioning 2 maintain accuracy in wind? | Critical for precision spraying | Vague or evasive response |

Spray Drift and Wind Interaction

Wind speeds between 3-8 mph are ideal for spraying. Above 10 mph, droplet drift becomes severe. Your supplier should provide specific drift measurements at different wind speeds.

Ask for the following documentation:

- Droplet size distribution data under wind conditions

- Spray pattern width changes at various speeds

- Flight path deviation percentages during gusts

Real-World Testing vs. Lab Claims

Laboratory wind tunnels create steady airflow. Real fields have turbulent gusts. Our production team learned this difference when early prototypes performed perfectly indoors but struggled over uneven terrain.

Request field test videos. Ask where testing occurred. Flat terrain tests do not reflect performance over hilly farms. A trustworthy supplier will share this information openly.

What specific IP waterproof ratings should I demand to protect my investment from sudden rain?

Rain destroys drones. Not gradually, but quickly. When we seal motor housings on our production line, we understand exactly what water does to unprotected electronics. Most buyers underestimate this threat.

Demand IP54 rating as the minimum for agricultural drones operating in variable conditions. For regions with frequent rain, request IP67 or higher. Ask for specific seal testing documentation, including submersion depth and duration. Verify that the rating covers all components, not just the main body.

Decoding IP Rating Numbers

IP ratings 3 have two digits. The first digit indicates dust protection. The second indicates water protection. For agricultural drones, both matter.

| تصنيف IP | Dust Protection | Water Protection | Agricultural Suitability |

|---|---|---|---|

| IP43 | Protected from objects >1mm | Protected from spray | Minimal, dry conditions only |

| IP54 | Protected from limited dust | Protected from splashing | Acceptable for light moisture |

| IP65 | Dust tight | Protected from water jets | Good for most conditions |

| IP67 | Dust tight | Protected from immersion up to 1m | Excellent for rain exposure |

Component-Level Protection Questions

A drone's IP rating often applies only to the main body. Motors, cameras, and sensors may have different protection levels. This gap causes failures.

Ask these specific questions:

- What is the IP rating for each motor?

- Are camera lens seals rated separately?

- How are battery compartment seals tested?

- What is the protection level for spray nozzle connections?

Seal Degradation and Maintenance

Seals degrade over time. UV exposure, chemical contact, and temperature cycling all weaken waterproofing. Our service department sees this pattern repeatedly.

Request information about:

- Expected seal lifespan in hours of operation

- Recommended seal replacement intervals

- Cost and availability of replacement seals

- Visual inspection guidelines for seal condition

Testing Evidence You Should Demand

Marketing materials often overstate protection. Request actual test documentation. A reliable supplier will provide laboratory test certificates showing exactly how the IP rating was verified.

Look for third-party testing from recognized laboratories. In-house testing alone is insufficient. Ask whether testing was performed on production units or special prototypes.

How do I evaluate if the drone's battery and sensors will remain stable in my region's extreme temperatures?

Temperature extremes kill batteries and confuse sensors. When our engineers test lithium cells in climate chambers, the performance drops are dramatic. Your region's weather determines what specifications matter most.

Request battery discharge curves at both temperature extremes relevant to your region. Ask for sensor accuracy data across the full operating temperature range. Verify whether the drone includes active thermal management systems for batteries and electronics. Demand documented flight time reductions at temperature extremes.

Battery Chemistry and Temperature Effects

Lithium-polymer batteries 4 lose capacity in cold conditions. Chemical reactions slow down. Internal resistance increases. Flight times drop significantly.

| نطاق درجة الحرارة | Typical Capacity Retention | Flight Time Impact |

|---|---|---|

| -10°C to 0°C | 60-70% | 30-40% reduction |

| 0°C to 10°C | 80-90% | 10-20% reduction |

| 10°C to 35°C | 95-100% | Optimal performance |

| 35°C to 45°C | 90-95% | Slight reduction, overheating risk |

| Above 45°C | متغير | Significant risk of damage |

Heat causes different problems. Battery cells can swell. Thermal runaway becomes possible. Electronic components may overheat and fail.

Questions About Thermal Management

Modern agricultural drones should include thermal management systems 5. These systems maintain optimal battery and sensor temperatures across conditions.

Ask your supplier:

- Does the drone include battery heating for cold weather?

- What cooling systems protect electronics in heat?

- At what ambient temperature does thermal management activate?

- How much power does thermal management consume?

Sensor Performance Across Temperatures

Cameras, LiDAR, and positioning sensors all respond to temperature changes. Lens fogging, sensor drift, and calibration shifts affect accuracy.

When we calibrate our flight controllers, we perform the process at multiple temperatures. This ensures consistent performance. Ask whether your supplier follows similar protocols.

Request these specific data points:

- Camera focus stability across temperature range

- GPS/RTK accuracy at temperature extremes

- Altimeter and barometer drift compensation methods

- IMU calibration procedures for temperature variation

Regional Adaptation Requirements

Your specific climate determines which specifications matter most. Desert operations require heat management. Northern farms need cold weather capability. Tropical regions face humidity challenges alongside heat.

Provide your supplier with your region's typical operating conditions. Ask how the drone specifically addresses those conditions. Generic specifications are not enough.

What technical documentation should I request to prove the drone's long-term durability in adverse weather conditions?

Documentation separates trustworthy suppliers from unreliable ones. When we prepare export packages for our US and European customers, we include comprehensive test reports. This transparency builds confidence. Demand the same standard.

Request third-party certification reports, accelerated aging test results, and warranty terms specific to weather-related failures. Ask for mean time between failures data for weather-exposed components. Verify that documentation covers real production units, not pre-production prototypes. Demand access to customer case studies from similar climates.

قائمة التحقق من الوثائق الأساسية

Not all documentation holds equal value. Third-party verification carries more weight than internal claims. Production unit testing matters more than prototype results.

| نوع المستند | ما الذي يثبته | Questions to Ask |

|---|---|---|

| IP Test Certificate | Water/dust resistance verified | Which lab? Which production batch? |

| Temperature Cycling Report | Thermal stress endurance | How many cycles? Temperature range? |

| Salt Spray Test Results | Corrosion resistance | Duration? Post-test functionality? |

| Accelerated Aging Data | Long-term durability | Methodology? Equivalent operational hours? |

| Warranty Documentation | Supplier confidence | Weather-related coverage specifics? |

Understanding Accelerated Aging Tests

Accelerated aging tests 6 simulate years of use in compressed timeframes. They expose drones to repeated stress cycles. This reveals weaknesses that would emerge slowly in normal operation.

Our quality assurance team runs humidity cycling, temperature extremes, and vibration tests on every production batch. Ask your supplier about their equivalent processes.

Key questions include:

- How many thermal cycles were performed?

- What humidity levels were tested?

- Were tests performed on production units or prototypes?

- What failures occurred during testing?

Warranty Terms for Weather Exposure

Warranty coverage reveals supplier confidence. Comprehensive weather-related coverage indicates genuine durability. Extensive exclusions suggest known weaknesses.

Examine warranty documents for:

- Specific coverage for rain and moisture damage

- Temperature-related failure coverage

- Seal and gasket replacement terms

- Geographic restrictions based on climate

Customer Reference Verification

Documentation only tells part of the story. Real customer experiences reveal actual field performance. Ask for references from customers operating in similar conditions.

Request permission to contact these references. Ask about:

- Actual uptime percentages during adverse weather seasons

- Repair frequency for weather-related issues

- Supplier responsiveness to weather-related warranty claims

- Long-term performance consistency

Certification Standards to Verify

Industry certifications indicate compliance with established standards. For agricultural drones, relevant certifications include FAA compliance documentation, CE marking 7 for European markets, and agricultural equipment safety standards.

Ask whether certifications were obtained for the specific model you are purchasing. Certifications for related models do not guarantee equivalent compliance.

الخاتمة

Asking the right questions protects your investment and your operations. Demand specific data, verified certifications, and real-world test evidence. Your supplier's answers reveal their reliability as much as their product's capability.

الحواشي

1. Authoritative explanation from NASA on how wind tunnels are used for testing. ︎

2. Explains RTK GPS, its accuracy, and specific relevance to agriculture and drones. ︎

3. Wikipedia offers a comprehensive and authoritative explanation of IP ratings and the IEC 60529 standard. ︎

4. Provides a comprehensive overview of LiPo battery technology and characteristics. ︎

5. Explains the principles and importance of thermal management in electronic devices. ︎

6. Describes the methodology and applications of accelerated aging for product reliability. ︎

7. Official European Union information on CE marking requirements and its significance. ︎