We know the deep frustration of seeing a critical production line halted simply because a specific thermal sensor is stuck مستشعر حراري 1 at a port halfway across the world. When we design our heavy-lift units, securing a steady flow of components is just as critical to us as the aerodynamics of the airframe itself.

To assess stability, demand a multi-tier supply supply chain risk 2 chain map identifying the country of origin for critical chips and batteries. Verify the supplier holds at least six months of safety stock for long-lead items and validate their financial liquidity to absorb sudden raw material price spikes without disrupting your delivery schedule.

Let’s look at the specific indicators that separate reliable partners from risky bets.

How can I verify if a drone manufacturer has secured multiple sources for critical components?

Relying on a single vendor for flight controllers keeps our procurement team awake at night وحدات التحكم في الطيران 3, so we actively avoid it to protect our clients. If a supplier cannot show you their backup plan for a sudden motor shortage, your order is already at risk before the contract is even signed.

Request an approved vendor list (AVL) that details primary and secondary sources for key hardware like motors and sensors. A stable manufacturer should demonstrate active contracts with alternative suppliers in different geographic regions to prevent bottlenecks if one location faces geopolitical or logistical disruptions.

To truly verify if a supplier is resilient, you must dig deeper than their marketing brochures. In the industrial drone sector, particularly for specialized equipment like firefighting UAVs, the complexity of the Bill of Materials فاتورة المواد 4 (BOM) is immense. A single drone may contain over 2,000 distinct components, ranging from carbon carbon fiber sheets 5 fiber sheets for the airframe to microscopic semiconductors for the power management unit.

The Approved Vendor List (AVL) Audit

When we negotiate with our own sub-suppliers, we insist on transparency, and you should do the same. Ask to review a sanitized version of their Approved Vendor List (AVL). You are looking for "redundancy." For example, if the manufacturer sources their high-torque brushless motors exclusively from one factory in a region prone to lockdowns or trade tariffs, that is a single point of failure. A robust supply chain will list a "Primary" source and a "qualified Secondary" source for every critical component.

The secondary source must be active, not theoretical. We often see manufacturers list a backup supplier they haven't purchased from in three years. That is not security; that is a wish list. You need to verify that they actively rotate orders between suppliers to keep both channels open and validated.

Geographic Diversification

Geopolitical friction is a reality in the drone industry. drone industry 6 If all the alternative suppliers are located in the same city or the same shipping lane, the risk remains high. We focus on diversifying where our raw materials come from to ensure that a localized event—be it a power outage or a port strike—does not freeze our entire operation.

Component Risk Categories

Not all parts carry the same risk. We categorize parts based on availability and impact. You should ask your supplier to classify their BOM into these categories for you.

| مستوى المخاطرة | Component Type | Supply Chain Strategy to Look For |

|---|---|---|

| High Risk | Thermal Sensors, AI Chips, Specialized Flight Controllers | Strategic Stockpiling: The supplier should hold 6–12 months of inventory. Multi-Sourcing: Alternative chipsets pre-validated by engineering. |

| Medium Risk | Lithium-Ion Cells, Carbon Fiber, Motors | Forward Buying: Contracts locked in for 12 months to guarantee price and volume. Dual Sourcing: At least two active suppliers. |

| Low Risk | Propellers, Landing Gear, Standard Wiring | Regional Sourcing: Ability to source these from multiple local vendors or manufacture in-house (e.g., via 3D printing). |

By scrutinizing their sourcing strategy against this table, you can determine if they are reactive or proactive. A supplier who treats a thermal sensor (high risk) the same way they treat a plastic landing gear foot (low risk) is a supplier who will face delays.

What questions should I ask to ensure the supplier holds enough raw material inventory for my order?

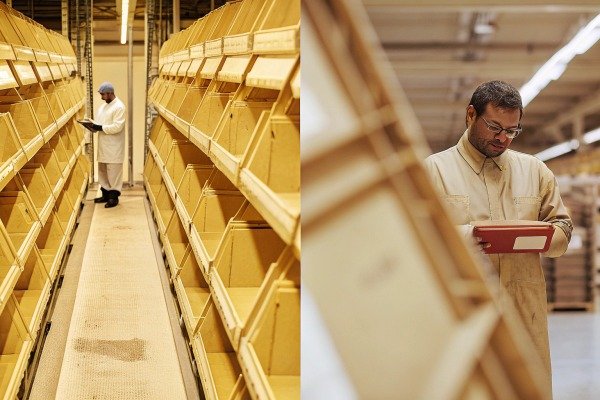

We maintain a warehouse specifically for “safety stock” because we have learned that strict “Just-in-Time” models often fail Just-in-Time models 7 during global crises. A supplier operating with empty shelves cannot guarantee your delivery date when market volatility hits, regardless of their promises.

Ask specifically about their inventory turnover ratio and current stock levels for long-lead items like lithium-ion cells and carbon fiber. Confirm they maintain a buffer stock strategy rather than a Just-in-Time model, ensuring they have materials on hand to complete your order even if global supply lines freeze.

The concept of "Just-in-Time" (JIT) manufacturing is excellent for cost savings in the automotive industry, but it can be disastrous for niche high-tech electronics like firefighting drones. The lead times for specialized aviation-grade components have fluctuated wildly in recent years.

The "Safety Stock" Question

You need to ask your supplier: "What is your safety stock policy for long-lead items?" In our factory, we identify components that take longer than 90 days to arrive and ensure we have a buffer on hand. If a supplier tells you they order parts only بعد you place your deposit, you are financing their supply chain risk.

For a procurement manager, the correct answer you want to hear is that the manufacturer holds "strategic inventory." This means they have already purchased the core components (like the flight control modules and thermal camera cores) before you even sent the Request for Quotation (RFQ).

Financial Liquidity and Inventory

Holding inventory requires cash. A supplier who is cash-poor cannot afford to stockpile expensive lithium batteries or carbon fiber. بطاريات الليثيوم 8 Therefore, asking about inventory is actually asking about their financial health. If they cannot afford to buy raw materials in advance, they are vulnerable to price spikes.

Lead Time Verification

Do not just accept a verbal "4-week delivery" promise. Ask to see the current lead times from their upstream suppliers. If the global lead time for a specific microcontroller is 52 weeks, and your supplier claims they can build your drone in 4 weeks without having the stock on hand, they are likely gambling on the grey market or simply lying.

Critical "Long-Lead" Items

When auditing a supplier, focus your questions on these specific bottlenecks. These are the items that usually cause the "99% complete but cannot ship" syndrome.

| المكوّن | Why it causes delays | Key Question to Ask |

|---|---|---|

| Battery Cells | Volatile lithium prices and hazardous shipping regulations. | "Do you have the cells for my order physically in your warehouse right now?" |

| Thermal Cameras | Export controls and limited global manufacturers (e.g., FLIR sensors). | "Are these sensors allocated to my specific project, or are they shared inventory?" |

| ألياف الكربون | Raw material shortages impact frame production. | "Do you manufacture the frames in-house or rely on a third-party molding factory?" |

If they manufacture the frames in-house—like we do at our facility—they have much more control over the carbon fiber supply chain than if they are waiting for a third-party vendor to mold the parts. This vertical integration is a strong signal of stability.

How do I tell if a factory has a reliable contingency plan for global supply chain disruptions?

When we faced semiconductor delays last year, our engineering team immediately switched to pre-validated alternative chipsets semiconductor delays 9 to keep assembly moving. If your potential partner lacks a documented “Plan B,” a minor shipping delay could become a permanent cancellation of your critical equipment.

Evaluate their component obsolescence management plan to see if they have pre-validated engineering alternatives for rapidly evolving tech. Reliable factories also utilize forward-buying contracts for volatile materials and possess decentralized manufacturing capabilities, such as 3D printing spare parts, to bypass logistics snarls during major global disruptions.

Disruptions are no longer anomalies; they are the new normal. Whether it is a pandemic, a trade war, or a raw material shortage, a firefighting drone supplier must be built to survive turbulence. A "Contingency Plan" is not just a document; it is an engineering philosophy known as Design for Supply Chain (DFSC).

Pre-Validated Alternatives

The strongest indicator of resilience is whether the manufacturer's engineering team has "pre-validated" alternative parts. In our R&D process, we often design circuit boards that can accept footprints from two or three different major chip manufacturers.

If Supplier A stops producing a specific voltage regulator, or if a trade ban impacts a specific sensor, a resilient manufacturer can switch to Supplier B's component immediately because they have already written the software drivers and tested the hardware. If they haven't done this work upfront, a shortage forces them into a 6-month redesign cycle, and your delivery will be delayed by half a year.

The Role of Additive Manufacturing

Look for suppliers who utilize additive manufacturing (3D printing) for non-critical structural parts. additive manufacturing 10 While you cannot 3D print a battery or a motor, you can print brackets, mounts, and casings.

During logistics snarls, being able to print a missing plastic connector in-house rather than waiting for an injection molding shipment from a locked-down region can save the entire shipment. We have found that having industrial-grade 3D printers on-site allows us to bypass minor supply chain hiccups that would otherwise stop the line.

Scenario-Based Assessment

When interviewing a supplier, do not just ask "Do you have a plan?" Test them with scenarios.

- Scenario 1: "If the price of lithium doubles next month, how does that affect my contract price?" (Look for hedging or fixed-price inventory answers).

- Scenario 2: "If the primary port of export closes, do you have alternative logistics partners?" (Look for air freight vs. sea freight options).

Contingency Checklist

Use this checklist to score their preparedness:

| Contingency Factor | ما الذي تبحث عنه | ما أهمية ذلك |

|---|---|---|

| Engineering Agility | Modular design architecture. | Allows swapping out components (e.g., changing a camera payload) without redesigning the whole drone. |

| Logistics Flexibility | Accounts with multiple carriers (DHL, FedEx, Freight Forwarders). | Prevents being stuck if one carrier suspends service to a specific region. |

| Obsolescence Management | A formal plan for End-of-Life (EOL) components. | Ensures they won't sell you a drone that becomes unrepairable in 2 years because the chips are discontinued. |

A supplier who can confidently answer these questions shows they are managing the supply chain, not just reacting to it.

What are the warning signs that a supplier is struggling with raw material shortages before I sign the contract?

We often see competitors quoting impossibly short lead times just to win a bid, only to extend them later once the deposit is paid. Recognizing the subtle red flags in a supplier’s communication style and quote structure can save you from a stalled project and a lost budget.

Be wary of vague delivery dates or refusal to commit to penalty clauses for delays. Frequent price adjustments on valid quotes, an inability to provide recent proof of production, or a lack of transparency regarding sub-tier suppliers often indicate they are already scrambling to secure necessary raw materials.

Before you sign a purchase order, the supplier is on their best behavior. However, there are "tells"—subtle signals that indicate they are under stress regarding raw materials. Identifying these early can prevent you from entering a contract that is destined to fail.

The "Price Validity" Warning

Watch the validity period of their price quotation. In a stable market, a quote might be valid for 30 to 60 days. If a supplier sends you a quote that is valid for only 3 to 7 days, they are signaling that their raw material costs are volatile and they have no inventory buffer. They are buying materials "spot" (at current market price) rather than having long-term contracts. This is a major red flag for stability.

Refusal of Penalty Clauses

We always advise procurement managers to propose a penalty clause for late delivery. If the supplier refuses to accept أي penalty for late shipment (e.g., 0.5% discount per week of delay), they lack confidence in their own supply chain. A manufacturer who knows they have the parts in stock will generally accept reasonable performance clauses. If they flatly refuse, they likely know that shortages are imminent.

Vague Lead Times

"As soon as possible" is not a lead time. "4-6 weeks" is a standard lead time. "Estimated 12-20 weeks depending on parts" is a warning sign. When a supplier cannot give you a tight window, it means they are not in control of their vendors. They are waiting on someone else, who is likely waiting on someone else.

Transparency Deficits

Ask for photos of your specific model currently on the production line. If they send you stock render images or photos from three years ago, be suspicious.

A supplier dealing with shortages often tries to hide it until the last possible moment. Ask for a "Bill of Materials Health Check." If they refuse to share any information about where their motors or batteries come from, citing "confidentiality" too broadly, they may be hiding the fact that they are sourcing from unreliable or sanctioned entities.

Evaluating Communication Patterns

| Healthy Supplier Behavior | Warning Signs of Shortage |

|---|---|

| Clear Timelines: Provides a Gantt chart of production. | Ambiguity: "We will do our best" or "Subject to availability." |

| Proactive Updates: Notifies you of potential risks before you ask. | Silence: Takes days to reply to simple inventory questions. |

| Fixed Pricing: Honors the quote price. | Surcharges: Adds "Emergency Surcharges" or "Material Levies" last minute. |

Trust your instincts. If the sales process feels chaotic, the manufacturing process will be even worse.

الخاتمة

Securing a fleet of firefighting drones is about more than just flight time and payload capacity; it is about ensuring the partner behind the machine can deliver when it matters. By auditing their inventory strategies, demanding transparency on component origins, and testing their contingency plans, you can filter out fragile suppliers. We believe that true reliability comes from preparation, and as a buyer, your due diligence is the first line of defense against global supply chain instability.

الحواشي

1. Technical specifications for micro thermal sensors used in industrial and firefighting drone applications. ︎

2. ISO 28000 provides a framework for managing security and risks within the global supply chain. ︎

3. Academic research regarding the design and reliability of flight control systems for unmanned aerial vehicles. ︎

4. General overview of the structure and purpose of a Bill of Materials in manufacturing processes. ︎

5. Product information for high-performance carbon fiber materials used in aerospace and drone frame construction. ︎

6. Official report on export controls and geopolitical factors affecting the technology and defense industries. ︎

7. Historical and technical analysis of the Just-in-Time manufacturing model and its industrial applications. ︎

8. Official government safety resources and regulations for the transport and handling of lithium batteries. ︎

9. News report on the global semiconductor shortage and its ongoing impact on the technology sector. ︎

10. Background information on 3D printing technologies and their use in industrial manufacturing. ︎