Seeing a client lose their harvest window because their drone fleet arrived two weeks late is painful. At our Xi’an headquarters, we have seen how panic buying without verifying factory throughput destroys ROI during peak planting seasons.

To determine supplier capacity, audit their specific daily output rates for agricultural models and request evidence of scalable assembly lines. Verify inventory levels for long-lead components like flight controllers and demand access to real-time ERP tracking to monitor your batch progress against guaranteed delivery timelines.

Here is exactly how to verify a factory can handle your bulk orders without relying on vague sales promises.

What specific evidence should I request to verify a manufacturer's daily output capabilities?

We often invite clients to video call our floor managers because vague promises about “high capacity” are dangerous. Trusting a brochure instead of raw data risks your entire season’s profitability.

You should request unedited video tours of active assembly lines and daily production logs from previous peak seasons. Ask for the specific number of dedicated workstations for your model and the current cycle time per unit to calculate their true maximum daily output capacity.

The Mathematical Reality of Production

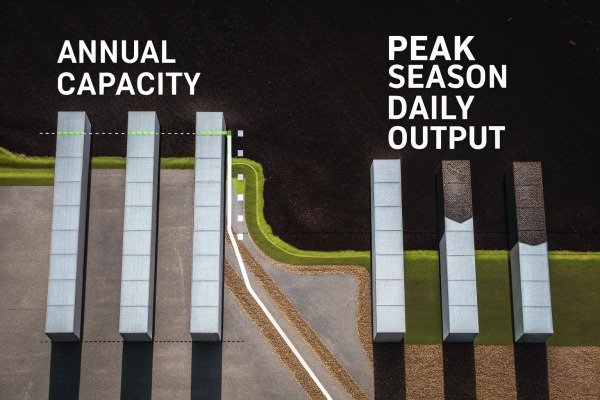

Brochures often list "annual capacity," which is a misleading metric. It does not help you if the factory produces 10,000 units in winter but cannot ramp up during the critical spring rush. When we calibrate our flight controllers, we measure output in minutes, not years. وحدات التحكم في الطيران 1 You need to calculate the Daily Peak Output (DPO).

To verify this, ask the supplier for their Cycle Time. This is the time it takes for one drone to move from the start of the assembly line to the testing phase. If a factory has a cycle time of 30 minutes and operates 10 workstations for agricultural drones, they can theoretically produce 20 units per hour. طائرات زراعية بدون طيار 2 However, real-world friction exists.

Verification Checklist

Do not accept a simple "Yes, we can do it." Demand the following data points:

- Dedicated Lines: How many lines are strictly for agricultural drones? At our Chengdu facility, we separate firefighting and agricultural lines because the testing protocols differ significantly. Shared lines cause bottlenecks.

- Shift Patterns: Can they show payroll records or schedules indicating a second or third shift? A factory running one shift has unused capacity; a factory already running three shifts is capped out.

- Quality Control (QC) Throughput: Production is fast; QC is slow. If they can build 50 drones a day but only have one test cage that handles 10, your shipment will be delayed.

Comparing Claims vs. Reality

Use this table to interpret supplier responses during your audit.

| Supplier Claim | What It Often Means | What You Must Demand |

|---|---|---|

| "We have a large factory." | They have floor space, not necessarily active workers or lines. | A live video walkthrough of the active agricultural line. |

| "We can produce 5,000 units a year." | They average out slow months with busy months. | "What is your maximum output per week in April and May?" |

| "We have stock ready." | They might have 5 demo units, not your 50-unit order. | A photo of the warehouse showing your specific quantity. |

By focusing on these metrics, you strip away the marketing fluff and see the mechanical reality of the factory floor.

How can I ensure my agricultural drone orders won't face delays during the busy farming season?

During the spring rush, our logistics team fights for air freight space, and we know that relying on standard shipping guarantees failure. Without priority contracts, your drones sit in customs while crops grow.

Ensure on-time delivery by requiring a binding contract with penalty clauses for late shipments and verifying the supplier’s pre-booked freight capacity. Demand a production schedule that includes buffer time for customs clearance and confirm they use established logistics partners with priority status.

The Logistics Bottleneck

Manufacturing the drone is only half the battle. In our experience exporting to the US and Europe, the most common reason for missed deadlines is not the assembly line—it is the "Last Mile" of international logistics. Agricultural drones contain high-capacity lithium batteries بطاريات الليثيوم 3, which classifies them as dangerous goods (DG). This significantly reduces the number of available flights and shipping vessels. البضائع الخطرة 4

Contractual Safeguards

You must protect your investment legally. A supplier confident in their supply chain will agree to Lead Time Penalties. For example, for every week the shipment is delayed beyond the agreed date, the supplier grants a discount (e.g., 2-5%). This forces the supplier to prioritize your order over others who did not negotiate these terms.

The Importance of Incoterms

When we discuss terms with clients like procurement procurement managers 5 managers, we emphasize the difference between EXW (أعمال سابقة) و تسليم DDP (تسليم مدفوع الرسوم المدفوعة).

- EXW: The supplier's job ends at their factory door. You deal with Chinese customs, freight forwarders, and US customs. This is risky during peak season.

- DDP: The supplier is responsible until the drones arrive at your warehouse. This shifts the risk of customs delays back to the manufacturer, incentivizing them to get paperwork right the first time.

Assessing Logistics Capability

A capable supplier does not just call FedEx. They have specific freight forwarders who specialize in DG cargo. Ask to see their صحيفة بيانات سلامة المواد (MSDS) و رقم الأمم المتحدة 38.3 battery certifications upfront. If they hesitate to provide these, your shipment will likely be seized or rejected by the carrier, causing weeks of delay.

Timeline Buffer Strategy

Always plan backwards from your "Must-Have" date.

| مرحلة الإنتاج | Standard Time | Peak Season Reality |

|---|---|---|

| Order Confirmation | 1-2 Days | 3-5 أيام |

| توريد المكونات | 3-5 أيام | 10-15 Days (if low stock) |

| Assembly & Testing | 5-7 أيام | 7-10 أيام |

| Export Customs | 2-3 أيام | 5-7 أيام |

| Air Freight (China to US) | 5-7 أيام | 10-14 يوماً |

| إجمالي المهلة الزمنية | ~3 Weeks | ~5-6 Weeks |

Always add a 30% time buffer to whatever the supplier quotes you during the peak season.

Does the supplier have scalable assembly lines to handle sudden increases in my bulk orders?

When a large order hits our Chengdu facility, we immediately activate reserve shifts, but not every factory has trained staff on standby. A rigid production line collapses under pressure, leaving your business stranded.

Verify scalability by checking if the factory utilizes modular assembly stations and maintains a trained pool of seasonal labor. Ask for proof of previous production ramps where they successfully doubled or tripled daily output to accommodate sudden bulk orders without compromising quality control.

Modular Design and Scalability

Scalability is not just about having more people; it is about design. We engineer our SkyRover drones with modularity in mind. This means the arms, tanks, and landing gear are pre-assembled in sub-stations. When a bulk order arrives, the final assembly line only needs to connect these large modules.

If a supplier's drone requires complex, manual soldering for every unit manual soldering 6 on the main line, they cannot scale. Soldering takes skill and time. Connectors take seconds. Ask the supplier: "Are your drones assembled using soldering or modular connectors? modular connectors 7" The latter allows for rapid scaling because new workers can be trained to plug in modules much faster than they can be trained to solder circuit boards.

The Workforce Factor

Machines do not get tired, but they do not assemble drones by themselves. The bottleneck is often skilled labor. A factory that relies solely on a fixed team of 20 people cannot suddenly produce triple the volume.

- Cross-Training: Look for suppliers who cross-train their staff. A worker who builds firefighting drones should be able to switch to agricultural drones when the fire season is low and the planting season is high.

- SOPs (Standard Operating Procedures): Ask to see a page of their assembly manual. If it is just pictures with no text, or if it does not exist, they rely on "tribal knowledge." This is unscalable. Scalable factories have detailed, written steps (ISO 9001 standard) that allow a new hire to become productive in 24 hours. ISO 9001 standard 8

Evidence of "Surge Capacity"

Don't just ask if they can scale; ask if they have scaled. Request a case study or a production log from a previous year showing a sharp increase in output.

- Did they successfully deliver a 500-unit order in 30 days?

- Did their defect rate spike during that time?

A surge in production is useless if the drones arrive with loose screws or uncalibrated IMUs. High-quality scaling requires increased QC staff, not just increased assembly staff.

How do I check if the factory maintains sufficient component inventory to avoid production bottlenecks?

We stock flight controllers months in advance because sourcing chips during a rush is impossible. sourcing chips 9 A supplier without a stocked warehouse is gambling with your delivery date.

Audit the supplier’s inventory of long-lead items like batteries, motors, and chips by requesting current stock reports or visual proof. Confirm they have secondary sourcing agreements for critical parts to prevent production halts if their primary vendor fails during high-demand periods.

The "Golden Screw" Problem

In manufacturing, we call it the "Golden Screw." You can have 99% of the drone parts ready, but if one specific screw or chip is missing, the drone cannot ship. For agricultural drones, the high-risk components are usually:

- Flight Controllers: These often use specialized chips that face global shortages.

- High-Torque Motors: These are not off-the-shelf hobby parts; they are industrial-grade and take weeks to wind and balance.

- Carbon Fiber Frames: Large molds take time to cure.

Financial Stress Testing

Inventory costs money. A factory with a warehouse full of motors has tied up significant cash flow. This is a good sign—it means they are financially stable enough to prepare for your order before you even place it.

- Red Flag: The supplier demands a 70% or 100% deposit before they even order raw materials. This suggests they are "bootstrapping" your order and have no stock.

- Green Flag: The supplier accepts a standard 30% deposit and can show you video proof of motors and batteries already sitting on their shelves.

Supply Chain Redundancy

Single-sourcing is a recipe for disaster. If a supplier buys all their propellers from one factory, and that factory has a power outage, your order stops.

We maintain relationships with multiple vendors multiple vendors 10 for every non-proprietary part. You should ask your potential supplier: "Who is your backup provider for batteries?" If they cannot name one, they are vulnerable.

Critical Component Inventory Checklist

Before placing a peak-season order, ask the supplier to fill out a status report on these specific items.

| المكوّن | مستوى المخاطرة | Required Verification |

|---|---|---|

| وحدة التحكم في الطيران | عالية | Photo of sealed boxes with date codes. |

| بطاريات الليثيوم | عالية | Confirmation of UN38.3 certs and cell availability. |

| فوهات الرش | متوسط | Usually generic, but check quantity. |

| Carbon Fiber Arms | متوسط | Check if they manufacture in-house or outsource. |

| أجهزة التحكم عن بُعد | عالية | often third-party (e.g., Skydroid, SIYI); check stock. |

By auditing these specific inventory levels, you ensure the factory is not just waiting for your money to start shopping for parts.

الخاتمة

Determining production capacity requires looking past the sales pitch and auditing the factory's operational reality. By verifying daily output data, demanding logistics safeguards, checking for scalable labor, and auditing component inventory, you protect your business from costly delays.

الحواشي

1. General background on the technical role of flight controllers in unmanned aerial vehicles. ︎

2. Product documentation from a leading manufacturer of professional agricultural drone systems. ︎

3. Official FAA regulations regarding lithium batteries in air cargo. ︎

4. Official FAA safety regulations for transporting lithium batteries as hazardous materials. ︎

5. US government resource explaining international commercial terms for shipping and procurement. ︎

6. IPC is the global trade association setting standards for electronics soldering. ︎

7. Overview of modular connector designs used to improve assembly efficiency in electronics. ︎

8. Official ISO page explaining the requirements for quality management systems in manufacturing. ︎

9. The Semiconductor Industry Association represents the US chip industry. ︎

10. CIPS is the authoritative body for procurement and supply chain management. ︎