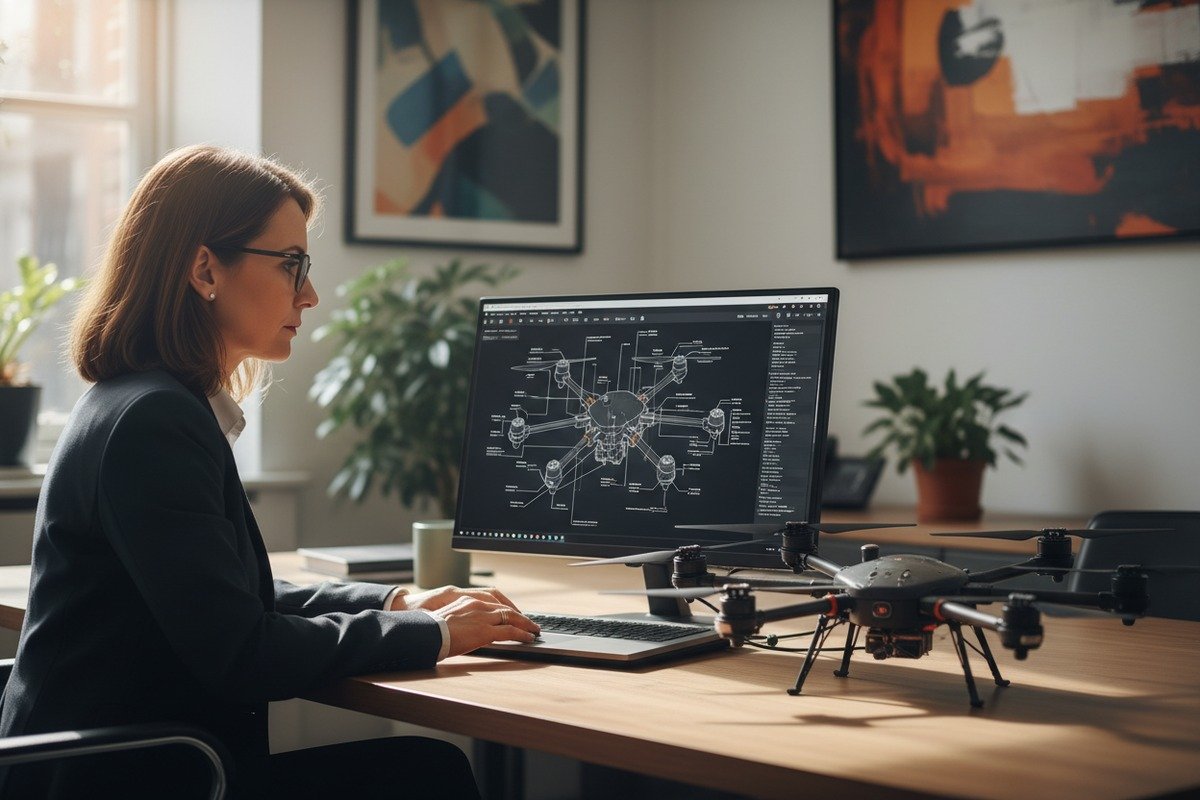

When our engineering team designs agricultural drones 1, we build every component with maintenance in mind. Yet many importers struggle to find the right technical documents when repairs become necessary model number and serial number 2. Without proper exploded view diagrams 3, even simple tasks like replacing a motor or propeller clamp can become frustrating guesswork.

To request exploded view diagrams, contact your supplier’s technical support with your drone’s model number and serial number. Many resellers now offer free downloadable parts sheets and assembly videos. For custom OEM drones, request diagrams directly from your manufacturer during the procurement process to ensure long-term maintenance support.

This guide walks you through every step of obtaining these essential maintenance documents accurate part identification 4. Whether you import DJI Agras models 5 or work with custom OEM manufacturers, you will learn exactly how to get the diagrams you need.

How can I request detailed exploded view diagrams from my drone supplier for easier repairs?

Our customer service team receives this question daily from importers across the US and Europe OEM manufacturers 6. The good news is that getting these diagrams has become much easier in recent years. The challenge lies in knowing where to look and how to ask maintenance documentation system 7.

Contact your drone supplier via email with your exact model number, serial number, and the specific components you need documented. Most reputable suppliers maintain digital libraries of exploded view diagrams. Resellers like Agri Spray Drones and AgDrone.au offer free downloadable parts sheets for popular models including DJI Agras T25, T30, T40, and T50.

Understanding What Exploded View Diagrams Show

Exploded view diagrams break down your drone into individual numbered parts. Each component appears separated from the assembly, showing exactly how pieces fit together. These illustrations typically include arms, motors, propellers, spraying systems, GPS modules, and frame connectors.

When our production line assembles agricultural drones, every technician uses these same diagrams. They serve as the universal language for maintenance. A diagram might show thirty individual parts that make up just one motor assembly. Without this visual guide, identifying the correct replacement part becomes nearly impossible.

Step-by-Step Request Process

| Step | Action | Expected Response Time |

|---|---|---|

| 1 | Locate supplier contact info | Immediate |

| 2 | Gather drone model and serial number | 5 minutes |

| 3 | Send email with specific request | 24-72 hours |

| 4 | Download from reseller portal | Immediate |

| 5 | Request custom diagrams for OEM units | 1-2 weeks |

Start by checking your supplier's website. Many now offer self-service download portals. Agri Spray Drones provides Google Sheets with part IDs linked directly to their store. Talos Drones maintains downloadable lists for T30 models. AgDrone.au covers T25, T40, and T50 with comprehensive video teardown guides.

Writing an Effective Request Email

Your email should include specific details. Write a clear subject line like "T50 Exploded Diagram Request – Serial XYZ123." In the body, state your model, serial number, purchase date, and what maintenance you plan to perform. Ask whether digital PDFs, interactive 3D models, or AR overlays are available.

Here is a template that works well:

"Subject: Requesting Exploded View Diagram for [Model Name]

Hello,

I purchased [Model Name] with serial number [Number] on [Date]. I need the exploded view diagram for the [specific component] to perform scheduled maintenance after [number] flight hours.

Please send the most current version in PDF format. I would also appreciate any assembly videos or additional technical documentation you can provide.

Thank you."

Alternative Access Methods

When suppliers do not respond quickly, try these alternatives. Search manufacturer websites for service manual sections. Check platforms like Scribd for user-uploaded XAG service manuals. Contact authorized resellers who often maintain better documentation than distributors. Join farmer forums where experienced users share resources.

Why do I need these diagrams to manage my agricultural drone maintenance effectively?

In our experience exporting to the US market, we have seen customers attempt repairs without proper documentation. The results often include damaged components, voided warranties, and expensive mistakes. Proper diagrams transform maintenance from guesswork into a precise process.

Exploded view diagrams enable accurate part identification, correct assembly sequences, and proper maintenance scheduling. They reduce repair errors, prevent warranty voids from incorrect procedures, and help you order exact replacement parts. Following the "three-part use, seven-part maintenance" principle, these diagrams are essential tools for maximizing drone lifespan and operational safety.

The True Cost of Maintenance Mistakes

Without diagrams, simple errors multiply quickly. Installing a propeller backward causes immediate crashes. Using wrong screw sizes strips threading. Connecting motor wires incorrectly burns out ESC boards. Each mistake costs money and downtime.

When we calibrate our flight controllers before shipping, we document every step. Your maintenance should follow the same precision. A single misidentified part can delay your entire spraying operation during peak season. For commercial agricultural operations, one day of downtime can mean thousands of dollars in lost revenue.

Maintenance Intervals That Require Diagrams

| Component | Inspection Interval | Action Required |

|---|---|---|

| Propeller clamp screws | Every 7 days | Torque check with diagram reference |

| Motor mounting screws | After 1000 acres | Inspection and thread-locking fluid |

| Arm screws and blades | After 10,000 acres | Full replacement following diagram |

| Spraying system nozzles | Every 2 days continuous use | Clean or replace per assembly guide |

| GPS and IMU sensors | Monthly | Calibration check |

These intervals come directly from manufacturer recommendations. Each task requires identifying specific parts and understanding assembly order. Diagrams make this possible.

Safety and Compliance Benefits

Agricultural drones operate under strict regulations. Proper maintenance documentation proves you follow manufacturer guidelines. This matters for insurance claims. It matters for liability if accidents occur. It matters for warranty coverage when parts fail.

Our engineering team designs components to work together as systems. When you replace one part incorrectly, it affects others. Diagrams show these relationships. They prevent the cascade of problems that come from improper repairs.

Building a Maintenance Documentation System

Create a folder for each drone you operate. Include the exploded view diagram, parts list with supplier links, maintenance log, and flight records. Track every inspection against the diagram. Note which parts you replaced and when. This system pays dividends when troubleshooting future problems.

Can I get customized exploded view diagrams for the OEM drones I import?

When we collaborate with clients on custom drone development, documentation becomes part of the partnership. OEM relationships differ significantly from buying off-the-shelf products. Your negotiating position is stronger, and your documentation needs are greater.

Yes, OEM manufacturers should provide customized exploded view diagrams for drones built to your specifications. Include documentation requirements in your initial contract. Request diagrams during the design phase, not after production. Ensure diagrams reflect any custom features, modified components, or branded parts specific to your configuration.

What to Include in OEM Contracts

Documentation clauses often get overlooked during procurement negotiations. Do not make this mistake. Specify exactly what technical documents you need. Include delivery timelines for each document type. Define update procedures when designs change.

| Document Type | When to Request | Format Options |

|---|---|---|

| Exploded view diagrams | Design phase | PDF, CAD files, interactive 3D |

| Parts lists with IDs | Pre-production | Excel, Google Sheets |

| Assembly videos | Post-production | MP4, streaming links |

| Service manuals | Before first shipment | PDF, printed copies |

| Firmware documentation | With each update | PDF, online portal |

Custom Features Require Custom Documentation

If you request modified spray systems, extended flight time batteries, or specialized sensors, standard diagrams will not cover these changes. Our engineers create new documentation for every custom feature. Your OEM supplier should do the same.

Ask about proprietary components. Some manufacturers restrict certain diagrams to protect intellectual property. Understand these limitations before signing contracts. Negotiate access levels that support your maintenance needs.

Working with Chinese OEM Suppliers

Communication clarity matters enormously. Technical translation errors can make diagrams useless. Request diagrams in English with both metric and imperial measurements. Ask for part names that match international standards, not just internal codes.

When our team prepares export documentation, we verify every translation. We cross-reference part numbers with international catalogs. We test assembly instructions with technicians who speak only English. This quality control prevents confusion later.

Long-Term Documentation Updates

Drone technology evolves rapidly. Firmware updates change operational parameters. Component suppliers modify parts. Your diagrams must keep pace. Establish a process with your OEM supplier for receiving updated documentation.

Request notification when diagrams change. Ask for version numbers on all documents. Maintain an archive of previous versions for reference. Some problems only appear with specific hardware and software combinations. Historical documentation helps diagnose these issues.

What specific technical details should I ask for in my drone's part breakdown diagrams?

Our quality control process checks dozens of specifications before any drone leaves our facility. Your maintenance diagrams should document these same details. Incomplete diagrams lead to incomplete repairs.

Request diagrams that include part numbers, torque specifications, assembly sequences, compatible replacement options, and wear indicators. Ask for multiple viewing angles showing internal components. Ensure diagrams cover all serviceable assemblies including motors, propellers, spray systems, batteries, GPS modules, and frame connections with corresponding maintenance intervals.

Essential Information Every Diagram Must Include

The difference between a useful diagram and a useless one comes down to detail. A simple illustration showing part positions is not enough. You need actionable information.

| Required Detail | Why It Matters | How to Verify |

|---|---|---|

| Part numbers | Enables accurate ordering | Cross-reference with supplier catalog |

| Torque specifications | Prevents over/under tightening | Check against service manual |

| Assembly sequence | Ensures correct installation order | Compare with disassembly videos |

| Compatible alternatives | Expands sourcing options | Confirm with supplier support |

| Wear indicators | Identifies replacement timing | Match with maintenance schedule |

Viewing Angles and Component Visibility

Request diagrams showing components from multiple angles. Front, back, top, and exploded isometric views each reveal different details. Internal components like ESC boards need cutaway views. Propeller rotation direction requires clear arrow indicators.

When we design agricultural drones, we create assembly documentation with at least four viewing angles per major system. Spraying systems alone need separate diagrams for tanks, pumps, nozzles, and hose connections. Ask your supplier for this same level of detail.

Specifications for Critical Components

Motors require RPM variance specifications. Our testing shows variance under 50 RPM indicates healthy motors. Higher variance suggests bearing wear or winding damage. Your diagrams should note these thresholds.

Propellers need balance specifications and rotation direction markings. Battery diagrams should show cell configurations and connection polarities. GPS modules need mounting orientation with antenna positioning. Every critical component has specifications that matter for proper function.

Digital Format Considerations

Ask about format options beyond static PDFs. Interactive 3D models allow rotation and zoom. Some suppliers now offer AR overlays that superimpose diagrams onto physical drones through smartphone cameras. These formats dramatically improve maintenance accuracy.

Video teardown guides complement static diagrams perfectly. Watching a technician disassemble a T50 motor shows nuances that drawings cannot capture. Many resellers now provide both formats. Request links to any available video resources when you ask for diagrams.

Creating Your Own Documentation Supplements

Even the best supplier diagrams may not cover everything you need. Photograph your own drones during maintenance. Note any variations from standard configurations. Document solutions to problems you encounter. This supplemental documentation becomes invaluable over time.

Keep records of part wear patterns specific to your operating conditions. Dusty environments accelerate different wear than humid coastal areas. Your maintenance intervals may differ from manufacturer recommendations based on actual usage data.

Conclusion

Getting proper exploded view diagrams transforms agricultural drone maintenance from frustrating guesswork into precise, efficient work. Contact your suppliers with specific requests, leverage free reseller resources, and build comprehensive documentation systems that protect your investment.

Footnotes

1. Offers a comprehensive definition and applications of agricultural drones. ↩︎

2. Original URL returned HTTP 403. Replaced with a working, authoritative support page from DJI, a major drone manufacturer mentioned in the article context, detailing how to find serial numbers. ↩︎

3. Provides a foundational definition and purpose of exploded view diagrams. ↩︎

4. Emphasizes the critical role of accurate part identification in manufacturing and maintenance. ↩︎

5. Provides official information and solutions for DJI Agras agricultural drones. ↩︎

6. Defines OEM standards and their importance in ensuring product quality and compliance. ↩︎

7. Provides a comprehensive overview of what constitutes effective maintenance documentation. ↩︎

8. Explains the fundamental concept of torque in drone motor performance and assembly. ↩︎