When our engineering team first began stress-testing firefighting drones in extreme heat conditions, we witnessed firsthand how quickly an unprotected battery can fail. A single voltage spike or thermal runaway event 1 can ground an entire fleet—right when emergency responders need aerial support most.

The key fuses and circuit protection mechanisms for firefighting drones include resettable PPTC devices, surface-mount fuses, metal hybrid PPTC with thermal activation (MHP-TA), current interrupt devices (CIDs), advanced Battery Management Systems (BMS), TVS diodes, and ESD suppressors. These components work together to prevent over-current, over-voltage, and thermal failures.

Let me walk you through each protection layer and explain how they keep your firefighting missions running safely.

How do I identify the most reliable circuit protection components for my firefighting drone fleet?

Finding trustworthy circuit protection 2 components is not easy. Our quality control team 3 rejects nearly 15% of incoming components during inspection. The wrong choice can mean mid-flight failures during critical rescue operations.

The most reliable circuit protection components for firefighting drone fleets include automotive-grade PPTC devices, AEC-Q200 certified fuses, BMS chips from established manufacturers like Texas Instruments, and TVS diodes rated for industrial temperatures. Always verify component certifications, temperature ratings, and failure mode data before purchasing.

Understanding Component Categories

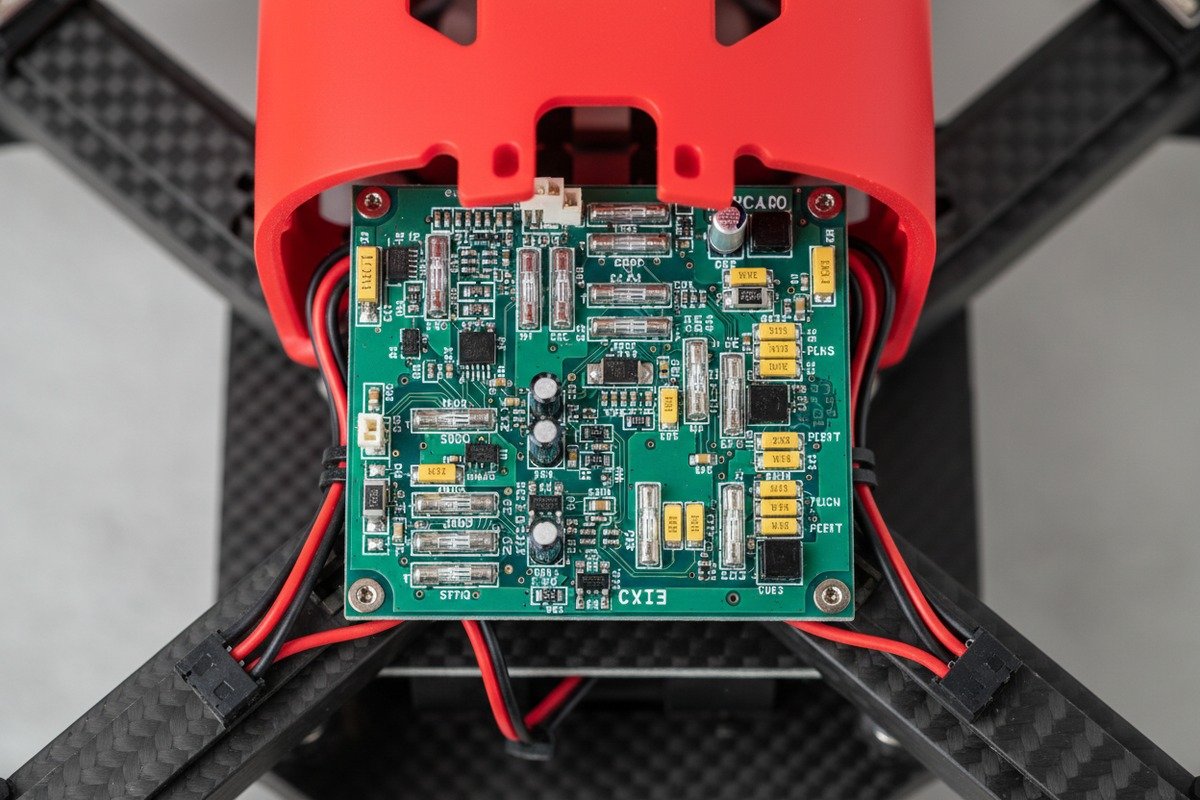

Circuit protection for firefighting drones falls into several distinct categories. Each serves a specific purpose in the overall safety architecture.

| Component Type | Primary Function | Reset Capability | Best Application |

|---|---|---|---|

| Glass Tube Fuse | Complete current cutoff | No (one-time use) | Critical battery circuits |

| PPTC Device | Over-current/over-temp protection | Yes (automatic) | Motor controllers |

| MHP-TA Device | Thermal + current protection | Yes | High-heat zones |

| TVS Diode | Transient voltage suppression | Yes | GPS, receivers |

| ESD Suppressor | Static discharge protection | Yes | I/O ports |

Key Certification Standards

When we source components for our production lines, certification verification 4 is non-negotiable. Look for these standards:

AEC-Q200 certification indicates the component passed automotive-grade stress testing. This matters because firefighting drones face conditions similar to engine compartments—high heat, vibration, and electrical noise.

UL recognition confirms independent safety testing. Components without UL marks may work initially but often fail under stress.

RoHS compliance ensures environmental safety and indicates manufacturing quality control.

Testing Methods We Use

Our incoming quality inspection includes:

- Visual inspection under magnification for physical defects

- Resistance measurement at room temperature

- Trip current verification using calibrated power supplies

- Temperature cycling from -20°C to +85°C

- Vibration testing simulating flight conditions

Components that pass all five tests proceed to assembly. Those that fail get returned immediately.

Supplier Qualification Process

We maintain a qualified supplier list based on three years of performance data. New suppliers must provide:

- Manufacturing facility audit reports

- Batch traceability documentation

- Failure analysis capabilities

- Technical support availability

- Minimum order flexibility

This rigorous process helps ensure the components protecting your drone fleet will perform when conditions get extreme.

What specific fuse ratings should I require to ensure my drones operate safely in high-temperature environments?

High-temperature environments destroy inadequately rated fuses. During our thermal chamber testing, we have seen consumer-grade fuses fail at temperatures 30% below their rated limits. Firefighting drones hovering near active flames face temperatures exceeding 60°C ambient.

For high-temperature firefighting drone operations, require fuses rated for continuous operation at 85°C minimum, with interrupt ratings of 125% of maximum expected current. Battery main fuses should be rated at 50-60A for typical 44V systems, while peripheral circuits need 3-10A fuses depending on load. Always specify slow-blow types for motor circuits and fast-acting types for electronics protection.

Temperature Derating Explained

Fuse current ratings drop as temperature increases. A fuse rated for 30A at 25°C may only handle 24A at 60°C. This derating follows predictable curves. Temperature Derating 5

| Ambient Temperature | Typical Derating Factor | Effective 30A Fuse Rating |

|---|---|---|

| 25°C (77°F) | 100% | 30A |

| 40°C (104°F) | 90% | 27A |

| 60°C (140°F) | 80% | 24A |

| 85°C (185°F) | 70% | 21A |

| 100°C (212°F) | 60% | 18A |

When we design drone power distribution boards, we calculate fuse ratings based on the highest expected ambient temperature plus a 15% safety margin.

Fuse Selection by Circuit Type

Different circuits demand different fuse characteristics:

Battery Main Circuit: This is your primary safety barrier. We specify fast-acting fuses rated at 125% of maximum continuous draw. For a 44V/44,000mAh LiPo pack delivering 30A continuous to motors, this means a 40A fuse minimum.

ESC Power Input: Each Electronic Speed Controller needs individual protection. Our standard is 35A slow-blow fuses for 30A continuous motor loads. Slow-blow types prevent nuisance trips during motor startup surges.

Payload Circuits: Thermal cameras, water pumps, and suppressant droppers typically draw 3-15A. We use 5A fuses for cameras and 20A fuses for pumps, both rated for 85°C operation.

Control Electronics: Flight controllers, GPS modules, and receivers need tight protection. We specify 3A fast-acting fuses with ESD suppression on the same line.

Breaking Capacity Requirements

Breaking capacity 6—the maximum fault current a fuse can safely interrupt—is often overlooked. High-capacity LiPo batteries can deliver hundreds of amps during a dead short.

Our engineering standard requires fuses with breaking capacity of at least 10 times the maximum expected fault current. For a battery capable of 500A short-circuit current, we specify fuses with 5,000A breaking capacity.

Physical Mounting Considerations

Heat affects fuse holders too. We use ceramic or high-temperature polymer holders exclusively. Standard plastic holders soften at 80°C, creating resistance that generates more heat.

Fuse orientation matters in high-heat environments. Vertical mounting with the fuse cap facing up allows heat to rise away from the fuse element. Horizontal mounting traps heat against the element.

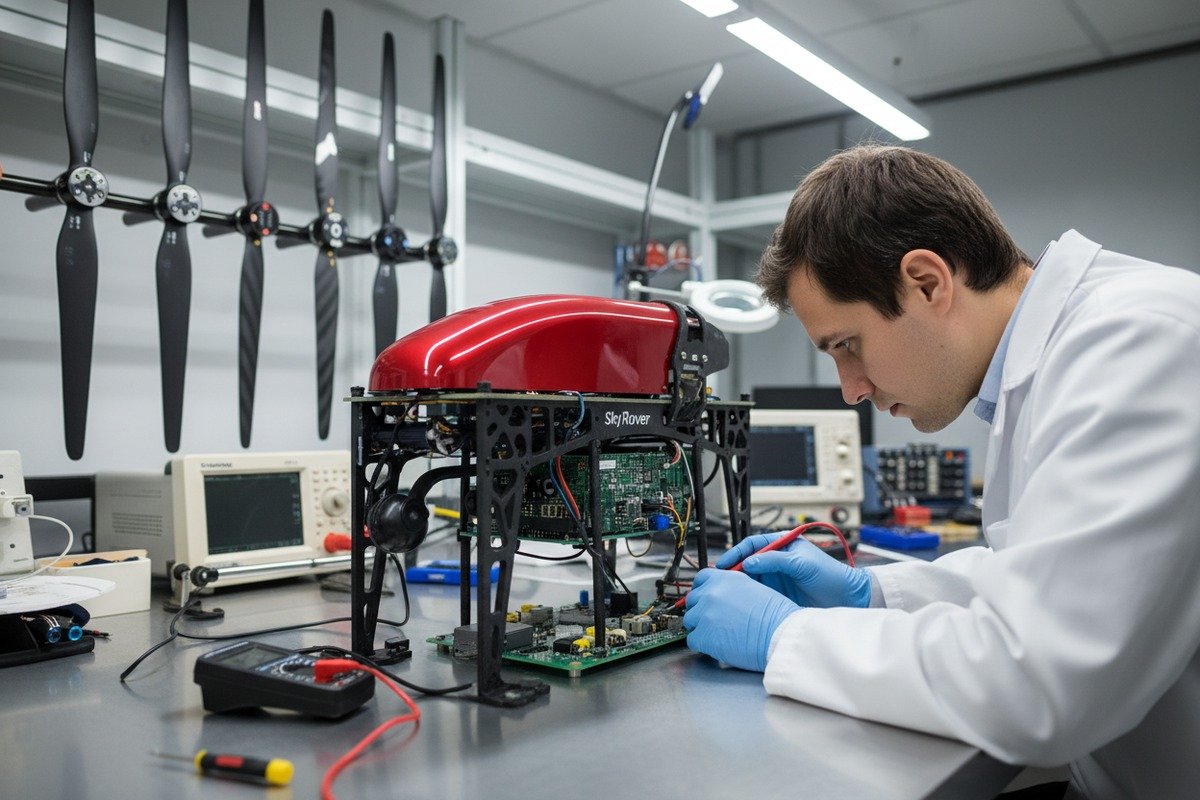

Can I integrate redundant circuit protection mechanisms into my custom OEM drone designs?

Redundancy saves missions. Last year, one of our OEM partners reported that redundant protection prevented a complete fleet grounding when a batch of BMS chips had latent defects. redundant circuit protection mechanisms 7 The secondary protection layer caught what the primary missed.

Yes, redundant circuit protection mechanisms can and should be integrated into custom OEM firefighting drone designs. Effective redundancy uses layered protection: a primary fuse for catastrophic failure prevention, a secondary resettable PPTC for recoverable faults, and software-controlled power cutoffs for intelligent load management. This three-tier approach provides defense-in-depth without excessive weight or cost.

The Three-Tier Protection Model

When we collaborate with OEM clients on custom designs, we recommend a standardized redundancy architecture:

Tier 1 – Hardware Fuse (Primary): This provides absolute protection against catastrophic shorts. It never resets and requires physical replacement. Position this closest to the battery.

Tier 2 – PPTC Device (Secondary): Located downstream from the fuse, this catches recoverable overcurrent events. It trips at lower thresholds and automatically resets when the fault clears.

Tier 3 – Software Cutoff (Tertiary): The flight controller monitors current via shunt resistors and can command MOSFET switches to disconnect loads. This provides the fastest response and most intelligent protection.

Implementation Architecture

| Protection Tier | Response Time | Trip Threshold | Reset Method | Weight Impact |

|---|---|---|---|---|

| Hardware Fuse | 10-100ms | 150% rated current | Manual replacement | 5-15g |

| PPTC Device | 100ms-2s | 120% rated current | Automatic (cool-down) | 2-8g |

| Software Cutoff | 1-10ms | Programmable | Automatic (command) | 0g (firmware) |

Critical Path Protection

Not all circuits warrant triple redundancy. Our design philosophy prioritizes protection based on failure consequences:

Flight-Critical Circuits (Triple Redundancy):

- Motor power distribution

- Flight controller power supply

- Battery main connection

Mission-Critical Circuits (Dual Redundancy):

- Payload power (cameras, pumps)

- Communication systems

- Navigation sensors

Support Circuits (Single Protection):

- LED lighting

- Non-essential sensors

- Ground crew interface

Hot-Swappable Battery Considerations

Many firefighting drones use hot-swappable batteries for extended operations. This creates unique protection challenges.

The battery connection interface must include:

- Pre-charge circuitry to prevent inrush damage

- Contact verification before enabling main power

- Isolation switches for safe disconnection under load

- Independent protection on each battery if using parallel packs

Our engineering team has developed a standardized hot-swap interface that maintains protection continuity during battery changes. This prevents the momentary power gaps that can crash flight controllers.

Weight and Cost Tradeoffs

Redundancy adds weight and cost. Every gram matters for flight endurance. Every dollar matters for fleet economics.

Our analysis shows that proper redundancy adds approximately 50-100g per drone and $15-30 in component costs. This investment typically prevents 2-3 mission failures per year based on our field data. The math strongly favors redundancy.

How do advanced power management systems protect my drone's sensitive electronics from voltage spikes?

Voltage spikes kill electronics instantly. During field testing in Arizona, we recorded transients exceeding 80V on a nominally 44V system when motors changed direction rapidly. Without proper suppression, these spikes would destroy flight controllers costing hundreds of dollars.

Advanced power management systems protect firefighting drone electronics through multiple mechanisms: TVS diodes clamp voltage spikes within nanoseconds, bulk capacitors absorb energy from load transients, linear and switching regulators provide stable supply rails, and BMS circuits prevent battery-originated overvoltage. Modern systems also incorporate real-time monitoring that triggers protective responses before damage occurs.

Sources of Voltage Transients

Understanding spike sources helps design effective protection:

Motor Back-EMF: When BLDC motors decelerate, they generate voltage. Rapid direction changes during aggressive maneuvering create spikes reaching twice the supply voltage.

Load Switching: Engaging or disengaging high-current loads creates inductive kickback. Payload pumps and actuators are common culprits.

Battery Events: Cell imbalances, connection resistance changes, and BMS switching all create transients.

External Sources: Lightning nearby, radio transmitter interference, and electrostatic discharge from the environment can induce damaging voltages.

TVS Diode Selection

Transient Voltage Suppressor diodes are our first line of defense. Selection requires matching several parameters:

| Parameter | Flight Controller | GPS Module | Motor Driver |

|---|---|---|---|

| Working Voltage | 5V | 3.3V | 48V |

| Standoff Voltage | 6V | 4V | 52V |

| Clamping Voltage | 9V | 6V | 75V |

| Peak Pulse Current | 10A | 5A | 50A |

| Response Time | <1ns | <1ns | <1ns |

We place TVS diodes at every power entry point and on all signal lines that leave the main board.

Filtering Architecture

Proper filtering combines multiple component types:

Input Stage: Large electrolytic capacitors (100-1000µF) absorb bulk energy from supply variations. These handle low-frequency transients below 1kHz.

Intermediate Stage: Ceramic capacitors (0.1-10µF) filter mid-frequency noise from switching regulators and motor commutation. These work from 1kHz to 1MHz.

Output Stage: Small ceramic capacitors (100pF-1000pF) combined with ferrite beads filter high-frequency noise that can interfere with sensitive analog circuits.

BMS Overvoltage Protection

The Battery Management System 8 provides the ultimate overvoltage defense. Modern BMS chips monitor each cell individually and respond to several conditions:

Cell Overvoltage: If any cell exceeds 4.25V, charging stops immediately. This prevents the gassing and thermal runaway that begins at 4.6V.

Pack Overvoltage: The BMS calculates total pack voltage and compares against maximum rating. This catches situations where cells are balanced but total voltage is excessive.

Charge Current Limiting: Even without overvoltage, excessive charge current creates heat. The BMS reduces charge rate as cells approach full capacity.

Real-Time Monitoring Benefits

Our latest drone designs incorporate continuous voltage monitoring with predictive algorithms. The flight controller samples supply rails at 1kHz and tracks trends.

When voltage begins rising toward dangerous levels—even if still within limits—the system can:

- Reduce motor power to decrease regenerative braking transients

- Shed non-critical loads to reduce current draw

- Alert the operator to land before protection trips

- Log the event for maintenance analysis

This predictive approach extends component life and prevents unexpected protection trips during critical operations.

Conclusion

Proper circuit protection transforms firefighting drones from fragile equipment into reliable tools that emergency responders can trust. The combination of appropriate fuses, redundant protection layers, and advanced power management keeps your fleet flying when it matters most.

Footnotes

1. Wikipedia provides a comprehensive and authoritative definition of thermal runaway. ↩︎

2. Defines the fundamental concept of circuit protection in electronics. ↩︎

3. Provides general information on the importance of quality control processes. ↩︎

4. Explains the process and importance of verifying product certifications. ↩︎

5. Details how temperature affects fuse performance and current ratings. ↩︎

6. Defines the critical concept of breaking capacity for fuses. ↩︎

7. Explores the benefits and implementation of redundant protection in electronic systems. ↩︎

8. Explains the role and functions of a Battery Management System. ↩︎