Sourcing high-value firefighting drones without visiting the factory feels very risky. We understand the anxiety of trusting a supplier thousands of miles away with mission-critical equipment.

Conducting a remote audit involves hiring a third-party inspection agency as your local proxy and utilizing live-streaming tools for real-time assembly line verification. You must rigorously review digital quality management records, validate ISO certifications online, and demand unscripted stress tests of the drone's flight stability and thermal sensors via video.

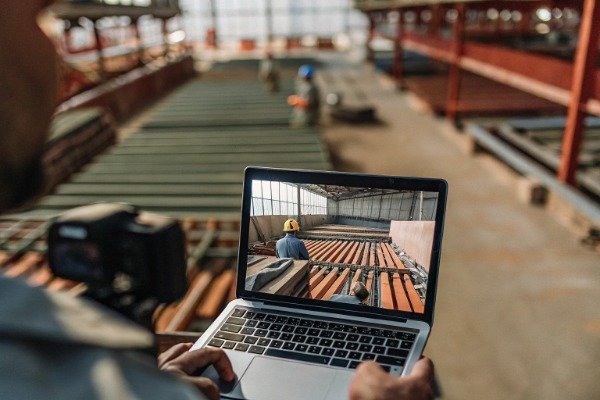

To ensure your investment is secure, we have outlined the specific tools and verification strategies that allow you to inspect our facilities as effectively as if you were standing on the production floor.

What video conferencing tools are best for a live virtual factory tour?

When we host international clients virtually, lagging video kills confidence. You need tools that capture the minute details of our soldering and assembly processes clearly without interruption.

The best tools combine stability with high resolution, such as Zoom or Microsoft Teams for general walkthroughs, paired with specialized hardware like Insta360 cameras. These platforms allow for screen sharing of schematics while simultaneously streaming wide-angle views of the production floor and close-ups of intricate drone components.

Selecting the Right Technology Stack

In our experience facilitating remote inspections for European and American clients, the success of the audit depends entirely on the technology stack used. A standard smartphone camera is often insufficient for inspecting the complex wiring of a firefighting drone or the precision of a gimbal mechanism. We recommend a multi-camera setup. The primary feed should come from a stabilized gimbal camera or a 360-degree camera (like the Insta360 RACK system), which allows you to look around the room independently, rather than just seeing what the cameraman wants you to see.

For the detailed inspection of printed circuit boards (PCBs) and soldering joints, we utilize high-definition macro cameras that can stream directly to the conference platform. This allows you to verify that our electrostatic discharge (ESD) protocols are being followed in real-time.

electrostatic discharge (ESD) 1

Overcoming Connectivity Barriers

One specific challenge we face when connecting with clients in the US is the "Great Firewall" of China, which can cause latency or connection drops on certain platforms. While we use VPNs to access global tools, choosing the right software is critical for stability.

Comparison of Remote Audit Tools

To help you prepare, here is a breakdown of the tools we use and their specific applications during a drone factory audit:

| Tool Category | Recommended Software/Hardware | Best Use Case for Drone Audits | Pros & Cons |

|---|---|---|---|

| General Conferencing | Zoom, Microsoft Teams | Opening meetings, document review, general floor walkthroughs. | Pros: Familiar UI, screen sharing. Cons: Video compression can hide defects. |

| 360° Streaming | Insta360, Avatour | Immersive tours of the assembly line and warehouse scale. | Pros: Auditor controls the view, difficult to "stage." Cons: Requires high bandwidth upload. |

| Smart Glasses | Google Glass, RealWear | "See what I see" perspective for hands-free inspection of manual assembly. | Pros: First-person view of technician skills. Cons: Can be shaky if the operator moves fast. |

| Instant Messaging | WeChat, WhatsApp | Quick photo exchange and backup communication if video fails. | Pros: Immediate transfer of high-res photos. Cons: Not suitable for formal audit trails. |

By stipulating these tools in your audit request, you ensure that the visual data you receive is granular enough to make an informed decision about our manufacturing capabilities.

Which documents should I request to verify their ISO quality certifications?

In our export department, we often see buyers accept PDFs at face value. However, verifying the legitimacy of these critical safety certifications requires a deeper digital investigation.

You should request the complete Quality Management System (QMS) manual, recent internal audit reports, and the specific ISO 9001 certificate number for online verification. Additionally, ask for equipment calibration logs and raw material inspection records to ensure the manufacturer's documentation matches their actual production standards.

Digging Deeper Than the Certificate

Simply having a PDF of an ISO 9001 certificate is not proof of quality. When we prepare for a client audit, we expect to show the "living" documents that prove the system is active. For firefighting drones, which must perform in hazardous environments, the paper trail is your safety net. You need to verify that the Quality Management System (QMS) is not just a plaque on the wall but a daily practice.

Essential Documentation for Drone Safety

We recommend requesting a "Traceability Audit" for a specific component. For example, ask us to trace the batch number of a lithium polymer battery pack installed in a finished drone back to the incoming raw material inspection report. This tests our internal record-keeping rigor. If a supplier cannot produce these records within a few minutes during a live call, it is a red flag.

Critical Documents Checklist

Below is a table of specific documents you must request to validate the quality and safety of industrial drones:

| Document Type | Purpose in Drone Sourcing | Verification Method |

|---|---|---|

| ISO 9001:2015 Certificate | Proves a standardized Quality Management System (QMS). | Verify the certificate number on the accreditation body's website (e.g., CNAS, UKAS). |

| UN38.3 Test Report | Mandatory for the safe transport of lithium batteries. | Check that the battery model number matches the drone specs exactly. |

| Calibration Logs | Ensures testing equipment (e.g., thermal chambers) is accurate. | Look for recent dates and stamps from third-party calibration labs. |

| Incoming Quality Control (IQC) | Verifies raw materials meet specs before assembly. | Request IQC reports for critical parts like motors and carbon fiber frames. |

| Corrective Action Reports (CAR) | Shows how the factory handles defects. | Ask to see a recent CAR to evaluate their problem-solving process. |

Validating Third-Party Lab Reports

For our firefighting drones, we also maintain test reports from accredited third-party labs regarding water resistance (IP rating) and electromagnetic interference (EMI). Do not just look at the summary page; ask to scroll through the detailed test data during the screen-sharing session. This ensures the test conditions match the real-world scenarios your procurement team anticipates.

How can I check the authenticity of their manufacturing facility remotely?

We have heard horror stories of "factories" that are actually just empty offices. Validating that we possess the machinery and workforce we claim is absolutely essential.

Google Earth 3

Verify authenticity by requesting a real-time, unscripted video walkthrough where you direct the camera operator to specific, random areas of the factory. Cross-reference the facility's location using satellite imagery, check electricity usage records if possible, and demand to see the specialized testing equipment in operation.

electromagnetic interference (EMI) 4

The "Unscripted" Walkthrough Strategy

The biggest risk in a remote audit is a "staged" tour. Some trading companies may rent a factory floor for a day or guide you along a pre-planned route that hides idle machinery. To counter this, we encourage our clients to take control of the tour. Do not let the host lead you linearly. Instead, ask to see the "quarantine area" for defective parts or the employee cafeteria. These areas are rarely staged.

If we say we have 70 employees, ask to see the attendance logs or the shift schedule posted on the wall. If we claim to manufacture the carbon fiber bodies in-house, ask us to walk over to the autoclave machine and open it. If the host hesitates or claims "bad Wi-Fi" prevents them from entering certain areas, be skeptical.

IP rating 5

Utilizing External Data Points

Before the call, use Google Earth or Baidu Maps to view the satellite imagery of the address provided. Does the building size match the production capacity claimed? We also recommend checking the background noise during the call. A real drone factory is noisy—CNC machines whirring, propellers being tested, and pneumatic screwdrivers operating. A silent factory floor during working hours is suspicious.

Red Flags vs. Green Lights

Here is how to distinguish a genuine manufacturer from a middleman during a remote inspection:

| Feature | Green Light (Genuine Manufacturer) | Red Flag (Potential Middleman/Scam) |

|---|---|---|

| Branding | Workers wear uniforms with the company logo; posters on walls match the brand. | Workers wear plain clothes; logos are printed on paper and taped over other signs. |

| Inventory | Visible raw materials (motors, frames) and semi-finished goods (WIP). | Only finished, boxed products are visible; no raw material stock. |

| Equipment | Heavy machinery (CNC, SMT lines) is bolted down and running. | Machinery looks brand new, unplugged, or is covered in dust. |

| Knowledge | The host can explain the function of specific machines immediately. | The host needs to translate questions to a "technician" constantly or cannot explain the process. |

The "Kidnap the Cameraman" Technique

A highly effective tactic is to ask the camera operator to zoom in on a shipping label of a box sitting in the loading bay. This confirms that they are shipping products to other customers and verifies the sender's address matches the factory location. We are always happy to show these details because they prove our legitimacy.

Should I interview the production manager during the virtual audit?

Our production managers know the floor better than any sales rep. Speaking directly with the people building your drones reveals the true culture of quality control.

lithium polymer battery 6

Yes, interviewing the production manager is crucial for assessing technical competence and problem-solving capabilities. Their answers regarding handling production bottlenecks, quality deviations, and supply chain disruptions often reveal the factory's true operational maturity better than rehearsed sales presentations or static documentation.

Assessing Technical Competence

Salespeople are trained to say "yes." Production managers are trained to identify problems. When we facilitate audits, we often bring our Production Manager or Quality Director into the conference room. You should ask them open-ended, technical questions. For example, ask: "What was the last major quality issue you faced with the flight controller calibration, and how did you fix it?"

A genuine manufacturer will have a specific, technical answer involving root cause analysis. A middleman or an inexperienced factory will likely give a vague answer like, "We have very high quality, no issues."

Great Firewall 8

Evaluating the Quality Culture

The attitude of the production leadership determines the quality of your firefighting drones. During the interview, observe their engagement. Are they relying on the sales team to translate simple concepts, or do they understand the technical requirements of your order?

Key Questions to Ask the Production Team

To get the most out of this interview, move beyond generalities. Here are specific questions that dig into the operational reality:

- Capacity Planning: "If we increase our order by 20% next month, how will you adjust the production schedule without compromising the testing phase?"

- Supply Chain Management: "How do you handle shortages of critical components like thermal sensors? do you have alternative validated suppliers?"

- Staff Training: "How do you train new operators on the assembly line? Can I see the training matrix?"

Language and Cultural Barriers

We recognize that language can be a barrier. Our production staff may not speak fluent English. However, this should not stop the interview. A professional supplier will provide a translator who translates your questions accurately, rather than answering for the manager. Watch the body language of the manager—if they look confused or disengaged, it may indicate a disconnect between the sales promises and production reality.

By engaging directly with the people who build the product, you gain insights that no brochure can provide. It validates that we have the in-house expertise to support your custom requirements and technical development needs.

Insta360 cameras 9

Conclusion

Remote audits, when executed with the right tools and skepticism, can be just as rigorous as on-site visits. We welcome these deep-dive inspections because they allow us to demonstrate our commitment to quality and transparency.

Microsoft Teams 10

Footnotes

1. Definition of the safety protocol for handling electronic components. ↩︎

2. Authoritative definition of this quality control methodology by ASQ. ↩︎

3. Official tool mentioned for verifying factory locations via satellite. ↩︎

4. Definition of the technical interference concept mentioned in testing. ↩︎

5. Explanation of the Ingress Protection standard for water resistance. ↩︎

6. Technical definition of the specific drone power source mentioned. ↩︎

7. Official standard page for the quality management certification discussed. ↩︎

8. Contextual information about the internet censorship system mentioned. ↩︎

9. Official website for the specific 360-degree camera hardware recommended. ↩︎

10. Official product page for the recommended video conferencing software. ↩︎