When our engineering team first designed folding arms for agricultural hexacopters, we underestimated the stress from thousands of field cycles ASTM protocols 1. Many buyers face the same hidden problem—folding mechanisms fail unexpectedly, grounding entire fleets during critical spraying seasons.

To request folding mechanism fatigue test data, ask suppliers for complete documentation including cycle-to-failure counts, FEA simulation results, Von Mises stress analysis, environmental testing conditions, and material degradation reports. Verify that testing follows recognized standards like ASTM or ISO protocols and covers agricultural stressors like humidity and chemical exposure.

This guide walks you through exactly what to request, how to verify supplier claims, and when to push for custom testing on your OEM orders Finite element analysis 2. Let’s break it down step by step.

Why should I prioritize folding mechanism fatigue data when evaluating my drone supplier?

Every week, our customer service team hears from buyers who chose the cheapest quote—only to face cracked hinges and bent arms after a few hundred cycles. The folding mechanism seems like a simple feature, but it's actually the most vulnerable point on any portable agricultural drone.

Folding mechanism fatigue data reveals how long your drone arms will survive repeated folding, field vibrations, and environmental stress. Without this data, you risk buying drones that fail mid-season, causing costly downtime, lost revenue, and potential crop damage from interrupted spraying operations.

The Hidden Costs of Ignoring Fatigue Data

Most agricultural drones fold their arms to reduce transport size by up to 50%. This sounds great for logistics. But each fold-unfold cycle creates stress at hinge points. Our internal tests show that poorly designed mechanisms can develop micro-cracks after just 500 cycles.

Consider what happens during a typical season. A commercial operator might fold and unfold their drone 10-15 times per day. Over a 100-day spraying season, that's 1,000-1,500 cycles. Add rotor vibrations during flight—which create additional cyclic stress—and the total effective stress cycles multiply dramatically.

What Fatigue Testing Actually Measures

Fatigue tests 3 simulate real-world conditions. They apply repeated loads to the folding mechanism until failure occurs. Good suppliers track several key metrics:

| Metric | What It Tells You | Why It Matters |

|---|---|---|

| Cycle count to failure | How many fold/unfold operations before breaking | Predicts service life |

| Von Mises stress 4 | Maximum stress concentration points | Identifies weak spots |

| Deformation rate | How much the arm bends under load | Shows structural integrity |

| Crack initiation point | Where micro-cracks first appear | Reveals design flaws |

Real-World Failure Examples

One of our distribution partners shared a case where untested drones from another supplier failed after just three months. The folding arms had passed basic functionality tests but nobody had run fatigue simulations. The hinge pins wore down, creating dangerous wobble during flight.

Compare this to drones with proper fatigue testing. Redesigned mechanisms based on test data have shown 300% lifespan improvements. Maintenance costs dropped by 60%. This isn't just about avoiding breakdowns—it's about total cost of ownership.

What specific technical documentation should I ask for to prove folding arm durability?

When our export team prepares documentation for US and European buyers, we often receive vague requests like "send us your quality reports." This doesn't help anyone. You need to know exactly which documents prove durability—and which ones suppliers sometimes skip.

Request these specific documents: finite element analysis (FEA) reports showing stress distribution, cyclic load test results with cycle counts, material certification with fatigue properties, environmental test data covering humidity and temperature extremes, and locking mechanism wear analysis. Each document should include test methodology, equipment used, and clear pass/fail criteria.

Essential Documentation Checklist

Not all test reports carry equal weight. Here's what separates useful documentation from marketing fluff:

| Document Type | Key Information to Check | Red Flags |

|---|---|---|

| FEA Simulation Report | Mesh density, boundary conditions, material properties | Missing input parameters, unrealistic assumptions |

| Physical Test Report | Sample size, test duration, failure photos | Single sample tested, no failure analysis |

| Material Certificate | Alloy grade, heat treatment, fatigue limit | Generic specifications, no batch traceability |

| Environmental Test | Temperature range, humidity levels, exposure time | Room temperature only, no chemical exposure |

| Locking Mechanism Report | Wear measurements, cycle count, torque values | No measurements after extended cycling |

Understanding FEA Reports

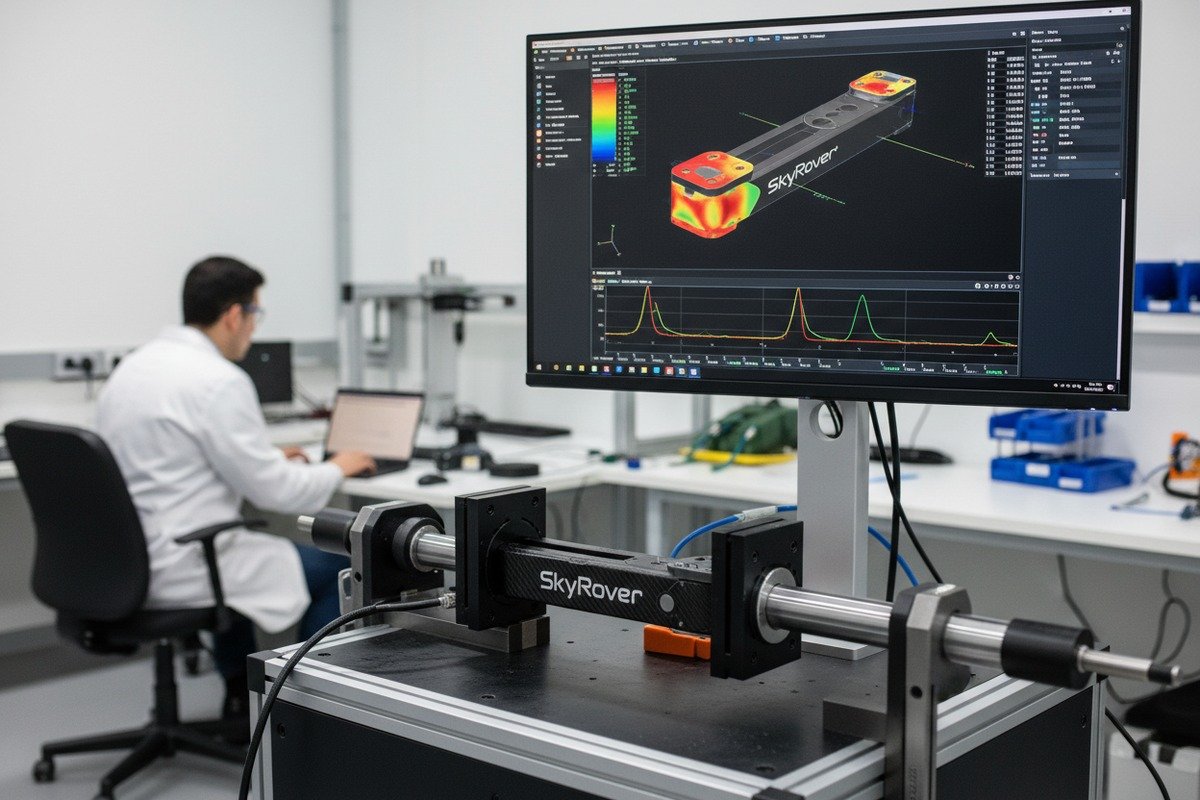

Finite element analysis 5 is computer simulation of stress under load. Good FEA reports show colorful stress maps where red indicates high stress and blue indicates low stress. But don't just look at the pretty pictures.

Check that the simulation used realistic boundary conditions. Did they model the actual folding motion? Did they include vibration loads from the motors? Our engineering team has found that simulations without vibration data underestimate real stress by 40% or more.

Verifying Physical Test Results

Simulations are useful but they're not enough. Physical testing catches problems that computers miss. Ask for reports that include:

- Number of samples tested (minimum 3-5 units)

- Test equipment calibration certificates

- Photos of failures showing crack locations

- Comparison between predicted and actual failure points

Non-Destructive Testing Records

Smart suppliers use NDT methods during fatigue testing. Non-Destructive Testing 6 These techniques detect internal damage before visible failure. Common methods include:

- Ultrasonic inspection 7 for internal cracks

- Dye penetrant testing for surface cracks

- X-ray imaging for hidden defects

Request NDT records at intervals during testing—not just at the end. This shows how damage progresses over time.

Material Traceability

Every folding mechanism in your shipment should trace back to a specific material batch. Ask for batch numbers that link to:

- Raw material certificates

- Heat treatment records

- Fatigue test data for that specific alloy lot

This traceability becomes critical if problems appear later. You can identify whether the issue affects your entire order or just specific units.

How can I ensure the fatigue test results from my Chinese manufacturer are accurate?

Our US buyers often ask this question directly. They want to trust us, but they've heard stories about falsified reports. Honestly, this skepticism is healthy. The verification steps below protect both buyer and seller by establishing clear expectations.

Verify accuracy through multiple methods: request third-party testing from accredited labs, compare reported data against industry benchmarks, ask for video documentation of actual tests, demand traceability between test samples and production batches, and conduct spot-check audits either remotely or on-site. Cross-reference results with similar products from independent sources.

Third-Party Testing Options

Independent labs provide unbiased verification. Several options exist:

| Testing Approach | Cost Level | Reliability | Turnaround |

|---|---|---|---|

| Chinese accredited lab (CNAS) | Low | Medium | 2-3 weeks |

| International lab in China (SGS, TÜV) | Medium | High | 3-4 weeks |

| Lab in destination country | High | Very High | 4-6 weeks |

| Witnessed testing at supplier | Medium | High | Varies |

For high-value orders, witnessed testing offers a good balance. You or your representative watches the actual tests. This eliminates questions about sample switching or data manipulation.

Benchmark Comparison

Good test results should align with industry benchmarks. If a supplier claims their aluminum alloy hinge survives 50,000 cycles while industry averages show 20,000-30,000 for similar designs, ask questions. Either they've made a genuine breakthrough (request the design innovation details) or the testing methodology differs from standards.

Our team maintains internal benchmarks from years of testing. When customer questions arise, we can show how our results compare to established ranges.

Video Documentation

Request video of the actual fatigue tests. Modern testing equipment can record throughout the process. Videos should show:

- Test setup and sample identification

- Running test with cycle counter visible

- Failure moment and post-failure inspection

- Date/time stamps throughout

This documentation costs the supplier almost nothing if they're already running the tests. Reluctance to provide videos raises legitimate concerns.

Sample-to-Production Traceability

The samples tested must represent what you'll actually receive. Suppliers sometimes test specially prepared samples while shipping lower-quality production units. Protect yourself by:

- Requesting blind samples pulled from production lines

- Comparing material certificates between test and production batches

- Requiring the same quality control for all units

Remote Audit Options

Travel to China isn't always practical. Virtual audits have become accepted practice. Use video calls to:

- Tour the testing facilities

- Review equipment calibration records

- Interview quality engineers

- Inspect sample storage and identification systems

Reputable suppliers welcome these audits. They're an opportunity to demonstrate capability and build trust.

Can I request additional stress testing for my custom OEM agricultural drone order?

When customers approach our OEM team with specific requirements, they sometimes hesitate to ask for custom testing. They assume it's too expensive or that we'll refuse. Actually, custom stress testing benefits everyone. It catches problems before mass production and builds confidence in the final product.

Yes, you can and should request additional stress testing for custom OEM orders. Specify agricultural conditions including pesticide exposure, humidity cycling, temperature extremes, and rough landing impacts. Negotiate testing scope, sample quantities, and cost-sharing during contract discussions. Include clear pass/fail criteria and remediation procedures in your agreement.

Defining Agricultural-Specific Test Requirements

Standard fatigue tests may not cover agricultural stressors. Work with your supplier to define tests that match your operating environment:

| Agricultural Stressor | Suggested Test | Acceptance Criteria |

|---|---|---|

| Pesticide exposure | Chemical immersion + fatigue cycling | No degradation after 100 hours exposure |

| High humidity | 95% RH cycling + fold tests | No corrosion, normal operation |

| Dust/debris | Particulate injection during operation | Locking mechanism functions normally |

| Rough landings | Drop tests from operating height | No structural damage, alignment maintained |

| Temperature cycling | -10°C to +50°C thermal fatigue | No binding, no excess wear |

Negotiating Test Scope and Costs

Custom testing adds project costs. Discuss these factors upfront:

Sample quantity: More samples provide better statistical confidence. Minimum three units for meaningful data; five or more for reliable predictions.

Test duration: Accelerated tests save time but may miss some failure modes. Real-time tests take longer but better simulate actual use.

Cost sharing: Many suppliers will share custom testing costs, especially for larger orders or long-term partnerships. We've structured deals where testing costs apply to the first order but are waived for repeat purchases.

Building Test Requirements Into Contracts

Don't leave testing as a verbal agreement. Your purchase contract should specify:

- Exact tests to be performed

- Standards or methods to be followed

- Number of samples and how they're selected

- Pass/fail criteria with specific numbers

- What happens if tests fail (redesign, cost allocation, order cancellation rights)

- Documentation to be delivered and retention period

Prototype Validation Before Production

For truly custom designs, insist on prototype testing before approving mass production. Our development process includes:

- Design review and FEA simulation

- Prototype fabrication (3-5 units)

- Full fatigue and environmental testing

- Design revision if needed

- Validation testing of revised design

- Production approval only after test passage

This process adds 4-8 weeks but prevents expensive problems later. One customer saved over $50,000 by catching a hinge design flaw during prototype testing rather than after receiving 200 units.

Ongoing Quality Monitoring

Testing shouldn't stop after initial approval. Establish ongoing monitoring:

- Periodic batch testing during production runs

- Field failure analysis with root cause investigation

- Annual revalidation if designs or materials change

Good suppliers view this as partnership, not burden. It protects their reputation as much as your investment.

Conclusion

Requesting folding mechanism fatigue data protects your investment and your reputation with end customers. Ask for specific documentation, verify accuracy through third parties, and don't hesitate to request custom agricultural testing. Your supplier should welcome these conversations—they demonstrate you're a serious, long-term partner.

Footnotes

1. Official site for ASTM International, a global standards organization. ↩︎

2. NAFEMS is a global association for engineering analysis. ↩︎

3. Explains material fatigue and testing principles. ↩︎

4. Explains the Von Mises yield criterion used in stress analysis. ↩︎

5. Provides a comprehensive overview of FEA. ↩︎

6. Official site for the American Society for Nondestructive Testing. ↩︎

7. Explains the principles and applications of ultrasonic testing. ↩︎

8. ILAC is the international cooperation for laboratory accreditation. ↩︎