Every week at our production facility, we receive calls from procurement managers asking the same question payload capacity tests 1. They worry about buying firefighting drones 2 that cannot handle the added stress of pressurized hoses. This concern is valid. A poorly integrated hose system can turn an expensive drone into a dangerous liability.

To verify supplier fire hose impact on firefighting drone flight stability, request comprehensive flight test data under full water load conditions, examine flight controller specifications for dynamic load compensation, demand CFD modeling results showing reaction force compensation, and verify thrust redundancy through hexacopter or octocopter configurations with at least 1.5 times the required load capacity.

The sections below break down each verification step polymer composites 3. We will cover weight management, material specifications, testing protocols, and custom engineering data. Let us help you make an informed purchasing decision.

How can I verify that the fire hose weight won't compromise my drone's flight stability and endurance?

Our engineering team has spent years solving weight distribution problems for international clients. The challenge is not just lifting weight. It is managing weight that constantly shifts during water discharge. Many buyers underestimate this complexity and face serious operational issues later.

Request documented payload capacity tests showing stable flight at 1.5 times the combined weight of empty hose, full water load, and nozzle assembly. Verify flight endurance data under operational conditions, not ideal laboratory settings. Demand center of gravity shift calculations as water exits the system during active firefighting operations.

Understanding Static vs. Dynamic Weight

The fire hose weight problem has two parts. Static weight is the empty hose hanging from your drone. Dynamic weight is the water-filled hose during operation. Your drone must handle both.

When we calibrate our flight controllers, we account for the dramatic weight change. A 50-meter hose empty might weigh 15kg. Filled with water, it can exceed 80kg. This difference changes everything about flight behavior.

Key Weight Metrics to Request

| Weight Parameter | Why It Matters | Target Specification |

|---|---|---|

| Maximum Takeoff Weight | Sets upper limit for total system | At least 250kg for serious firefighting |

| Payload Capacity | Must exceed hose + water + nozzle | 1.5x combined load weight |

| Empty Hose Weight | Affects base flight characteristics | Under 0.3kg per meter |

| Water-Filled Hose Weight | Primary dynamic load concern | Calculate based on internal diameter |

| Flight Endurance Under Load | Real operational capability | 45+ minutes with full payload |

Center of Gravity Considerations

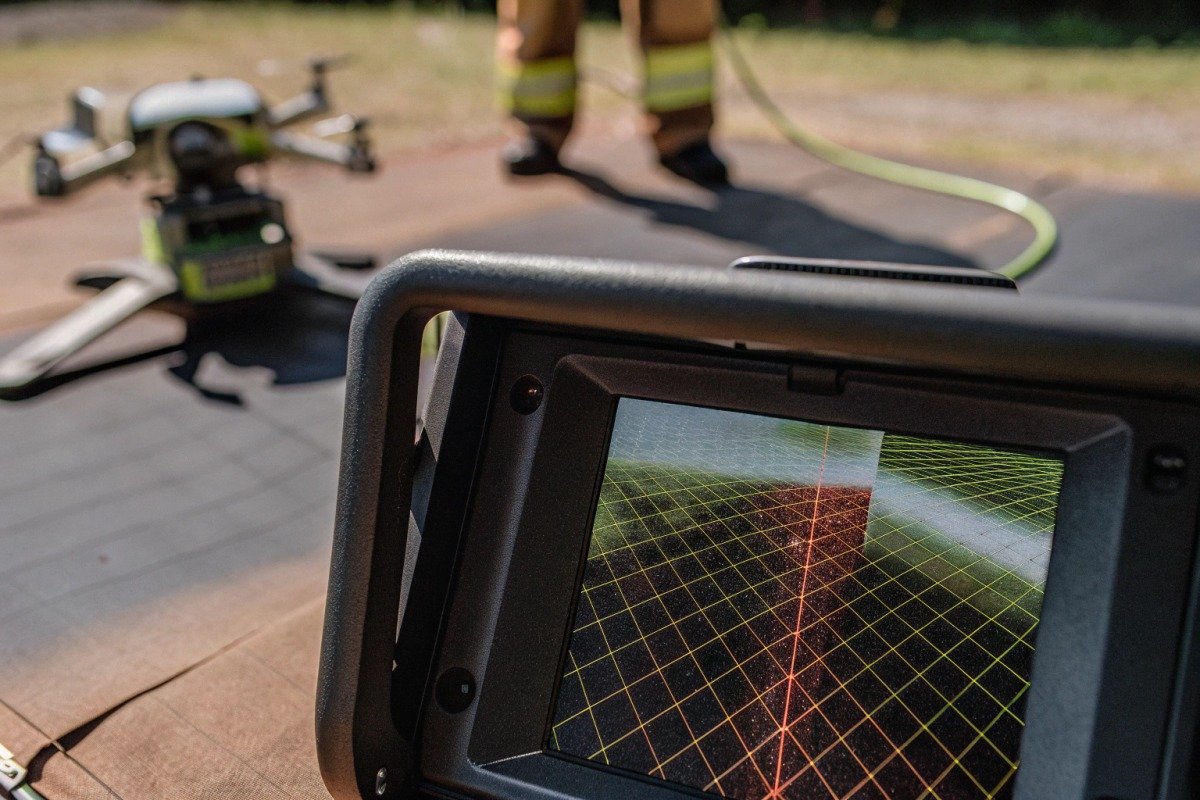

The center of gravity 4 shifts as water flows through the hose. At our factory, we test drones with sensors that track this shift in real-time. Good flight controllers adjust motor speeds hundreds of times per second to compensate. flight controller specifications 5

Ask your supplier for center of gravity documentation. This should include diagrams showing the drone's balance point with various water levels. If they cannot provide this, their engineering team has not done proper analysis.

Thrust-to-Weight Ratio Requirements

A stable firefighting drone needs significant thrust reserves. We recommend a thrust-to-weight ratio of at least 2:1 for firefighting applications. This means if your loaded drone weighs 200kg, your motors should produce 400kg of combined thrust.

This reserve thrust handles unexpected situations. Wind gusts near fires are common. Thermal updrafts can push drones suddenly. Without thrust reserves, the drone cannot recover quickly enough.

What specific hose material specifications should I request to minimize drag on my firefighting drone?

In our experience exporting to the US and Europe, hose material selection causes more stability problems than any other factor. Buyers often focus only on the drone itself. They forget that a heavy, rigid hose creates constant drag and torque during flight.

Request hose materials made from lightweight polymer composites with pressure ratings between 8-12 bar, high-temperature resistance above 200°C, flame retardancy certification, anti-torsion reinforcement, and anti-bending flexibility. The ideal weight is under 0.25kg per meter for drone applications, significantly lighter than standard ground-based firefighting hoses.

Critical Material Properties

Standard firefighting hoses are too heavy for drone use. Ground crews do not care if a hose weighs 1kg per meter. For drones, this weight destroys flight time and stability.

When we help clients select hose suppliers, we focus on aerospace-grade materials. These cost more but provide essential weight savings. A 50% weight reduction in hose material can add 15 minutes of flight time.

Material Specification Comparison Table

| Property | Standard Fire Hose | Drone-Optimized Hose | Why It Matters |

|---|---|---|---|

| Weight per meter | 0.8-1.2 kg | 0.2-0.3 kg | Directly affects payload capacity |

| Pressure rating | 15-20 bar | 8-12 bar | Lower pressure = lighter construction |

| Temperature resistance | 150°C | 200°C+ | Drones operate closer to flames |

| Flexibility radius | 300mm+ | 150mm or less | Tight routing reduces drag |

| Torsion resistance | Low | High | Prevents spin-induced instability |

Drag and Aerodynamic Impact

Hose drag comes from two sources. Air resistance against the hose surface is the obvious one. The second source is flutter and oscillation during flight.

A stiff hose acts like a pendulum below the drone. It swings and creates unpredictable forces. A flexible hose can flutter in the wind like a flag. Both problems destabilize flight.

The best hose materials balance flexibility with damping. They bend easily for routing but do not oscillate excessively. Ask suppliers for vibration test data showing oscillation frequency and amplitude at various wind speeds.

Hose Routing and Attachment Points

How the hose attaches to your drone matters as much as the material itself. Poor attachment creates stress concentration points. These can fail during operation.

Our engineering team designs attachment systems with controlled articulation. The hose can pivot smoothly but has limits to prevent extreme angles. Quick-release mechanisms allow emergency jettisoning if the hose snags.

| Attachment Feature | Purpose | Verification Method |

|---|---|---|

| Gimbal mount | Allows controlled movement | Request CAD drawings |

| Load-rated swivel | Prevents torsion transfer | Ask for load test results |

| Quick-release mechanism | Emergency separation | Demand demonstration video |

| Strain relief | Protects connection point | Inspect physical samples |

| Vibration damper | Reduces oscillation transfer | Request vibration test data |

How do I evaluate my supplier's testing protocols for drone stability when the fire hose is fully pressurized?

When we deliver drones to fire departments, our clients always ask about testing. They want proof that our claims match reality. Good suppliers welcome this scrutiny. Suppliers who avoid testing questions are hiding something.

Evaluate supplier testing protocols by requesting video documentation of pressurized flight tests, wind tunnel data with active water flow, independent third-party certification, real-world deployment case studies, and stress testing records showing performance under maximum load conditions for extended durations exceeding one hour.

Essential Testing Categories

Testing firefighting drones requires multiple approaches. Laboratory tests control variables but miss real-world complexity. Field tests capture operational reality but are hard to repeat precisely. Good suppliers use both.

Laboratory Testing Requirements

| Test Type | What It Measures | Acceptable Results |

|---|---|---|

| Wind tunnel testing 6 | Drag and stability in controlled airflow | Stable flight up to 12 m/s wind |

| Vibration analysis | Resonance frequencies and damping | No resonance in operational RPM range |

| Thermal chamber testing | Performance in high temperatures | Full function at 60°C ambient |

| Water flow reaction force | Thrust compensation needs | Documented force vectors and magnitudes |

| Endurance cycling | Long-term reliability | 100+ hours without component failure |

Field Testing Documentation

Request video evidence of field tests. These should show the drone operating in conditions similar to your intended use. Look for tests that include:

- Crosswind hovering with active water discharge

- Rapid altitude changes with full hose load

- Emergency stop and direction reversal maneuvers

- Extended flight duration at maximum payload

- Operation near heat sources simulating fire conditions

Our quality control team records every test flight. We provide clients with timestamped video showing exact test conditions. If a supplier cannot provide similar documentation, their testing program is inadequate.

Third-Party Verification

Independent testing matters. Supplier claims need verification from parties without financial interest in the results. Ask for test reports from recognized aviation testing laboratories or fire safety certification bodies.

In the US, look for involvement from organizations like UL or similar certification bodies. In Europe, CE marking indicates compliance testing. These certifications require documented evidence of performance claims.

Questions to Ask About Testing

- How many flight hours has this specific model accumulated in testing?

- What failure modes have you discovered and addressed?

- Can I visit your testing facility?

- Will you provide raw test data, not just summary reports?

- Have independent fire departments evaluated your system?

Honest suppliers answer these questions directly. Evasive answers indicate problems.

Can my supplier provide custom engineering data to show how the hose affects my drone's flight controller performance?

Our development team works closely with international clients on custom projects. This collaboration reveals detailed engineering data that standard products do not include. If your supplier cannot provide custom analysis, they may lack true engineering capability.

Request computational fluid dynamics modeling showing water jet reaction forces, flight controller parameter documentation explaining compensation algorithms, sensor integration specifications for real-time load monitoring, and thrust distribution diagrams demonstrating how the system counteracts dynamic forces from pressurized water discharge during firefighting operations.

Understanding Flight Controller Compensation

Modern flight controllers adjust motor speeds constantly. They use data from GPS, gyroscopes, magnetometers, barometers, and accelerometers. For firefighting drones, this compensation must handle forces that standard drones never experience.

When water exits the nozzle at high pressure, it creates reaction force. This force pushes the drone in the opposite direction. Without proper compensation, the drone drifts or becomes unstable. Good flight controllers predict and counteract this force.

Key Engineering Data Points

| Data Category | Specific Information Needed | Why You Need It |

|---|---|---|

| CFD Modeling 7 | Water jet force vectors and magnitudes | Validates compensation algorithm design |

| PID Parameters | Proportional, integral, derivative settings | Shows tuning for firefighting loads |

| Sensor Fusion | How multiple sensors combine data | Indicates response speed and accuracy |

| Failsafe Logic | Behavior during sensor or motor failure | Critical for operational safety |

| Update Rate | How often controller adjusts (Hz) | Higher rates = better stability |

Computational Fluid Dynamics Analysis

CFD modeling simulates water flow and resulting forces. Computational Fluid Dynamics Analysis 8 This analysis should show:

- Force magnitude at different water pressures

- Force direction changes during nozzle movement

- Moment arms created by off-center nozzle positions

- Interaction between water jet and prop wash

When we develop new nozzle designs, CFD analysis guides every decision. Suppliers without this capability are guessing about force compensation. Ask for CFD reports with clear diagrams showing force vectors.

Flight Controller Architecture

Professional firefighting drones use advanced control algorithms. Simple PID control works for basic drones. Firefighting requires more sophisticated approaches.

Look for suppliers using fuzzy logic control, adaptive algorithms, or model predictive control. These methods handle the complex, changing forces that firefighting creates. The controller should adjust its behavior based on current payload and water flow rate.

Redundancy and Failsafe Systems

Firefighting drones must continue operating even with component failures. Ask about:

- Motor redundancy (hexacopter or octocopter configurations)

- Sensor redundancy (multiple GPS, IMU units)

- Communication backup systems

- Automatic return-to-home triggers

- Emergency water dump capability

Our octocopter designs can lose two motors and continue safe flight. thrust redundancy 9 This redundancy costs more but provides essential safety margins. Single points of failure are unacceptable in firefighting applications.

Custom Engineering Support

The best suppliers offer ongoing engineering support. This includes:

- Custom flight controller tuning for your specific hose system

- Integration support for your preferred nozzle design

- Software updates as algorithms improve

- Remote diagnostics and troubleshooting

- On-site technical assistance for deployment

When our team ships drones to new clients, we provide remote calibration support. We monitor initial flights and adjust parameters based on actual performance data. This collaboration ensures optimal performance for each unique deployment.

Conclusion

Verifying fire hose impact on drone stability requires systematic evaluation. Request weight data, material specifications, testing documentation, and engineering analysis. Work with suppliers who provide transparent, detailed information. Your operational success depends on thorough verification before purchase.

Footnotes

1. Details steps for testing drone payloads to ensure accurate data and stable flight. ↩︎

2. Explains functions, advantages, and use cases of firefighting drones. ↩︎

3. Provides a general overview of composite materials, including polymers, used in engineering. ↩︎

4. Explains the importance of center of gravity for drone stability and performance. ↩︎

5. Explains how flight controllers maintain drone balance and stability. ↩︎

6. Describes specialized wind tunnels for UAV development, testing, and certification. ↩︎

7. Provides a comprehensive overview of computational fluid dynamics. ↩︎

8. Provides an academic perspective on the state and importance of CFD in the aerospace industry. ↩︎

9. Explains multicopter redundancy for safety and continued flight. ↩︎