When we assemble flight controllers in our Chengdu facility, we know that a single glitch can jeopardize a critical mission. Yet, many buyers unknowingly purchase drones built with recycled parts to cut costs. This puts your team at risk during high-heat operations.

To determine if a supplier uses refurbished components, inspect physical signs like tool marks on screws, verify component serial numbers with OEMs, and analyze internal internal electronics 1 system logs for previous flight history. Always demand a Certificate of Conformity and original factory test reports linked to your specific unit’s serial number.

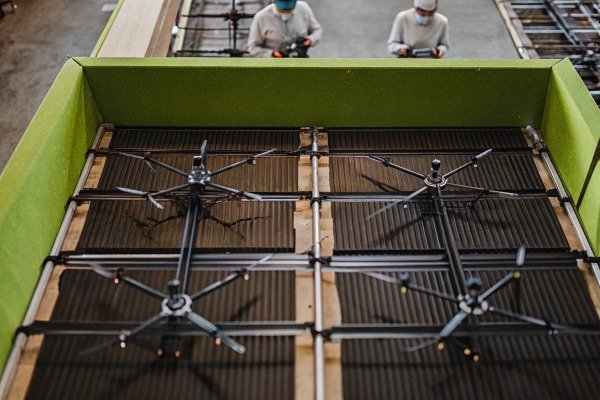

Let’s break down exactly how you can audit your new fleet to ensure every part is factory-fresh.

What physical signs on the motors and sensors suggest they might be refurbished?

During our final quality checks, we look for even the smallest cosmetic flaws before shipping to the US. shipping to the US 2 If you see wear on a "new" drone, it often signals dangerous cost-cutting by the supplier rather than simple shipping damage.

Refurbished motors often display micro-scratches on housing or stripped screw heads from previous disassembly. For sensors, look for dust inside the lens or discoloration on the connectors. These physical markers indicate that the components were salvaged from older units rather than installed fresh from the production line.

When you receive a new industrial drone, the physical condition of the hardware is your first line of defense against fraud. In our factory, we handle components with extreme care, but a supplier using refurbished parts will often leave evidence of previous installation. You must look closely at the high-stress areas of the aircraft.

Inspecting the Motor Housing and Mounts

The motors on a heavy-lift quadcopter endure significant stress. If a supplier has reused motors from a crashed or retired drone, you will often find "tool marks." Look at the screws that hold the motor to the black arm of the drone. If the paint on the screw heads is chipped or if the metal slot is slightly deformed, it means a screwdriver has been used on them more than once. Factory installation is precise and usually done once; reused parts require removal and re-installation, which leaves scars.

Furthermore, inspect the copper windings inside the motor copper windings 3. On a brand-new unit, these should be bright and consistent in color. If the copper looks dark or has a "burnt" smell, the motor has likely been subjected to high heat from previous heavy usage.

Thermal Sensor and Lens Analysis

Firefighting drones rely on thermal cameras. thermal cameras 4 These sensors are expensive, making them prime targets for refurbishment. Perform a visual check of the lens under a strong light. You are looking for micro-dust particles trapped inside the lens glass. In a clean-room factory environment, this does not happen. However, if a sensor was repaired or salvaged in a non-sterile workshop, dust will be trapped inside.

Also, check the connector pins where the gimbal attaches to the main orange body of the drone. Gold-plated pins should be flawless. If you see vertical scratch lines or dullness on the gold plating, the gimbal has been attached and detached many times, suggesting it is not new.

Table: Physical Indicators of Refurbished Parts

| Component | Signs of "Factory New" | Signs of "Refurbished/Used" |

|---|---|---|

| Screw Heads | Pristine paint, sharp edges | Chipped paint, rounded slots (stripping) |

| Motor Windings | Bright copper color | Darkened, dull, or burnt smell |

| Connectors | Smooth gold plating | Vertical scratch marks, dullness |

| Cooling Vents | Clean, dust-free | Fine soot or grey dust in corners |

| Housing | Uniform texture | Polishing swirls (attempts to hide scratches) |

How can I check the internal system logs to detect previous flight history or battery cycles?

We wipe standard test data before shipping, but deep system logs always tell the true story of a drone's life. Hidden data often reveals if a flight controller has seen action in the field before it ever reached your hands.

Access the flight controller’s internal memory to review total flight hours and power-on counts, which should only reflect factory testing. Analyze battery telemetry for high cycle counts or cell voltage imbalances. If the log history exceeds standard calibration times, the internal components have likely been used in previous operations.

Software does not lie, provided you know where to look. While a dishonest supplier might reset the "user-facing" counters, the deep system logs within the flight controller and battery management system (BMS) battery management system (BMS) 5 are much harder to falsify. These logs are critical for verifying the age of the internal electronics.

Analyzing Flight Controller Data

Every industrial drone records its operational history. Connect the drone to its diagnostic software and look for the "Total Flight Time" and "Power-On Count." A truly new drone will have a small amount of flight time recorded, usually less than 2 to 3 hours, which accounts for factory calibration and test flights.

If you see flight records dating back months or totaling dozens of hours, the flight controller is second-hand. Additionally, look at the GPS/RTK logs. If the logs show location data from a region that is neither the factory location nor your current location, the drone has been flown elsewhere. This is a clear "smoking gun" that the core brain of your drone is used.

Battery Telemetry Red Flags

Batteries are consumables, and using old batteries in a firefighting scenario is dangerous. You must check the "Cycle Count" in the battery settings. A new battery should have fewer than 5 cycles (used for initial quality assurance). If you see a count of 50, 100, or more, the battery is used.

Beyond the cycle count, look at the cell voltage deviation. cell voltage deviation 6 In a new battery pack, all cells should show almost identical voltage levels. If cell 1 is at 4.2V and cell 4 is at 3.9V, the battery chemistry is degrading. This level of imbalance typically only occurs after significant usage or poor storage over a long period.

Software Activation Dates

Most enterprise drones require online activation. Check the "Activation Date" in the system settings. If the system says the drone was activated a year ago, but you bought it last week, it is a refurbished unit. The activation date is tied to the serial number on the manufacturer's server and is very difficult for third-party suppliers to alter.

Table: Log Data Benchmarks

| Metric | Acceptable Range (New) | Red Flag Range (Refurbished) |

|---|---|---|

| Flight Time | < 3 Hours (Factory Testing) | > 10 Hours |

| Battery Cycles | 0 – 5 Cycles | > 20 Cycles |

| Power-On Count | < 20 Times | > 100 Times |

| Activation Date | N/A (Should activate upon receipt) | Date is months prior to purchase |

Is it possible to verify component serial numbers directly with the original parts manufacturers?

Our procurement team validates every batch of sensors we import to ensure our supply chain remains pure. supply chain 7 You can do the same verification to ensure your supplier isn't swapping premium parts for salvaged alternatives.

Yes, you can verify serial numbers for critical parts like motors, cameras, and gimbals directly with the original equipment manufacturer (OEM). Cross-referencing these IDs confirms production dates and sales channels. If a number does not exist or is flagged as previously activated, the component is likely second-hand.

Many buyers assume that if the drone body looks new, everything inside is new. This is not always true. Unethical assemblers may take a new frame but fill it with used motors or older camera sensors. The only way to prove the origin of these parts is through Serial Number (SN) verification.

The Serial Number Cross-Check Process

Industrial drones are modular. The camera, the gimbal, the motors, and the remote controller each have their own unique serial numbers. Do not just check the main SN on the drone's chassis.

Take the serial number of the thermal camera thermal camera 8 (often found on a sticker on the gimbal or in the software "About" section) and contact the camera manufacturer directly (e.g., FLIR, DJI, or similar OEM). Ask them two questions:

- "When was this unit manufactured?"

- "Was this unit sold as a standalone component or part of a bundle?"

If the manufacturer tells you the camera was produced three years ago, it is old stock or refurbished, even if your drone was assembled this month.

Identifying Mismatched Hardware Revisions

Hardware evolves. A specific sensor might have a "V1.0" and a "V2.0" version. Suppliers sometimes use the older V1.0 parts because they are cheaper or scavenged from older fleets, selling them as the latest model.

Check the firmware details in your app. It will often list the "Hardware Revision." Compare this against the latest spec sheet from the manufacturer. If you ordered the latest model but the hardware revision indicates an older batch, you have likely received a unit built with leftover or refurbished inventory.

The Risk of "Grey Market" Parts

Sometimes, serial numbers check out as "new" but are flagged for a different region (e.g., a Chinese domestic unit sold in the US). These "grey market" parts are often rejected stock or units intended for different power standards. While not technically "used," they lack the warranty and quality assurance of proper export-grade components. Verifying the SN helps you confirm the intended market for the components.

What specific quality assurance documents should I demand to prove all drone parts are factory new?

We provide extensive paperwork for every export to the US to guarantee traceability for our clients. Without these specific documents, you have no legal proof that your drone was built with new materials or meets safety standards.

Demand a comprehensive Certificate of Conformity (CoC) that traces the chain of custody for all major sub-systems. Additionally, require original factory test reports specific to your drone’s serial number and a bill of materials (BOM) listing the manufacture dates of key components to prove they are not aged stock.

Documentation is the shield that protects your procurement. A verbal guarantee from a salesperson is not enough. You need binding documents that certify the condition of the goods. When you request these documents upfront, it signals to the supplier that you are a professional buyer who cannot be easily fooled.

The Certificate of Conformity (CoC)

The most critical document is the Certificate of Conformity (CoC). Certificate of Conformity (CoC) 9 This document declares that the product meets the required specifications and is factory new. It should be signed by the Quality Control (QC) manager of the manufacturer.

Crucially, the CoC must list the specific serial number of your drone. A generic CoC that applies to "All Drones" is useless. It must explicitly state: "This certifies that unit SN: [Your Number] is new and meets all factory standards." If a supplier hesitates to provide this, it is a major warning sign.

Original Factory Test Reports

Every industrial drone undergoes a flight test before leaving the factory. You should ask for the physical report of this test. This report will show the test date, the technician's name, and the specific parameters tested (hover stability, GPS lock time, gimbal calibration).

If the test report is dated six months ago, but the supplier claims the drone was "just built," there is a discrepancy. The test date should be very close to the shipping date. These reports prove that the drone was functioning correctly as a new unit immediately prior to delivery.

Warranty Discrepancies

Review the warranty terms in writing. New industrial drones typically come with a 12-month standard warranty. Refurbished units often come with a limited 3-month or 6-month warranty.

If a supplier offers a shorter warranty period or excludes specific parts (like the motors or gimbal) from coverage, it is highly likely those parts are refurbished. A manufacturer confident in their new components will always back them with a full warranty.

Table: Essential Documentation for Verification

| Document Name | Purpose | What to Check For |

|---|---|---|

| Certificate of Conformity (CoC) | Legal declaration of quality | Must include specific drone Serial Number. |

| Factory Test Report | Proof of functional testing | Date of test must be recent (near shipping date). |

| Bill of Materials (BOM) | Component listing | Manufacture dates of sub-components. |

| Warranty Certificate | Coverage guarantee | Duration (12 months+) and exclusions. |

Conclusion

Buying a firefighting drone is an investment firefighting drone 10 in safety and efficiency. By rigorously checking system logs, inspecting physical wear signs, and demanding specific traceability documents, you ensure your fleet is reliable, durable, and truly ready for the mission.

Footnotes

1. Global standards body for electronic components and systems used in advanced robotics and aircraft. ↩︎

2. Official FAA regulations for unmanned aircraft systems entering and operating within United States airspace. ↩︎

3. Authoritative industry organization providing technical standards and properties for copper materials in electrical components. ↩︎

4. Technical documentation from a leading manufacturer regarding thermal imaging sensors used in public safety drones. ↩︎

5. Major technology leader providing a clear, authoritative definition of BMS functions in electronics. ↩︎

6. General background on lithium-ion battery chemistry, cell balancing, and voltage characteristics. ↩︎

7. Overview of supply chain management principles and the importance of component traceability. ↩︎

8. Leading global manufacturer of thermal imaging sensors used in firefighting and industrial drones. ↩︎

9. Official US government site explaining conformity assessment standards and certification requirements. ↩︎

10. Department of Homeland Security page detailing drone capabilities and research for first responders. ↩︎