When testing new prototypes at our Chengdu facility, we often see how a single hard landing on uneven soil ruins a perfect mission millimeter-wave radars 1. hard landing 2 Ignoring shock absorption leads to cracked frames, sensor failure, and costly operational downtime.

To evaluate shock absorption, assess the material durability like carbon carbon fiber arms 3 fiber and check for integrated damping components like hydraulic struts. Request drop test data verifying energy absorption metrics and inspect the structural design for stability on uneven terrain to prevent payload sloshing and sensor damage.

Let’s examine the specific factors that define a durable landing system and how they protect your investment.

Why is robust shock absorption essential for protecting my drone's liquid payload and sensors?

We have repaired countless units where excessive vibration destroyed sensitive terrain-following radar. It ruins precision and halts operations.

Robust shock absorption prevents impact energy from transferring to the airframe, protecting delicate IMUs and terrain-following radars from calibration errors. It also mitigates liquid sloshing effects in the tank, ensuring the center of gravity remains stable to prevent tipping during rough landings.

When you purchase an agricultural drone, you are not just buying a flying frame. You are buying a carrier for sensitive electronics and a heavy, shifting liquid payload. Understanding the physics of how landing gear protects these components is critical for making an informed choice.

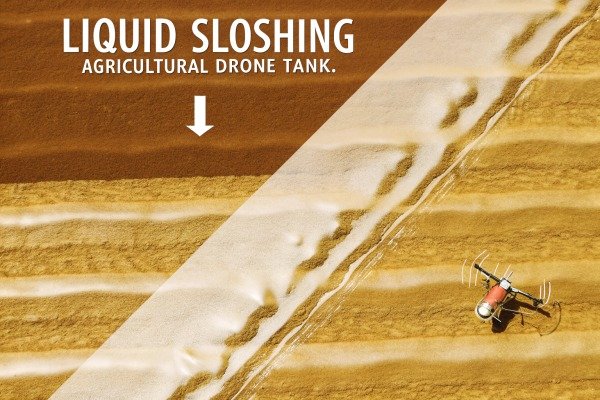

The Physics of Liquid Sloshing

Agricultural drones carry liquid fertilizers or pesticides. Unlike solid cargo, liquid moves. When a drone hits the ground during a landing, the drone stops, but the liquid inside the tank wants to keep moving. This creates a secondary impact force known as "slosh."

If the landing gear is too rigid, this sloshing force transfers directly to the drone's frame. This can cause the drone to tip over sideways, even after it seems to have landed safely. A high-quality shock absorption system dampens this energy. It extends the time of impact, allowing the liquid to settle without flipping the aircraft. In our design labs, we prioritize gear that can handle this shifting center of gravity.

Protecting Sensitive Electronics

Modern agricultural drones rely on Inertial Measurement Units (IMUs) Inertial Measurement Units (IMUs) 4 and millimeter-wave radars Inertial Measurement Units 5 to maintain altitude and avoid obstacles. These sensors are incredibly sensitive to high-frequency high-frequency vibrations 6 vibrations and sudden shocks.

A hard landing without proper damping sends a shockwave through the carbon fiber arms. This shockwave can:

- Dislodge sensor connections: causing intermittent failures.

- Permanently shift calibration: leading to drifting flight paths.

- Crack ceramic components: inside the flight controller.

We often see "flyaways" or stability issues that are eventually traced back to a landing gear that failed to absorb a previous impact.

Structural Stress on the Airframe

The landing gear is the first line of defense for the main fuselage. If the gear does not absorb the energy, the energy must go somewhere. Usually, it goes to the mounting points where the arms meet the body.

Repeated stress at these points leads to microscopic fatigue cracks. Over time, these cracks grow. Eventually, an arm might fail mid-flight, not because of a crash, but because of accumulated stress from hundreds of "normal" landings that were slightly too hard.

Comparison of Impact Effects

The table below illustrates the difference between rigid skids and a proper suspension system regarding component safety.

| Component | Effect with Rigid Gear | Effect with Damped Suspension |

|---|---|---|

| Liquid Tank | High risk of sloshing; potential for tank cracking at mounts. | Sloshing energy dissipated; reduced stress on mounts. |

| IMU Sensors | High vibration transmission; frequent recalibration needed. | Vibration isolated; calibration remains stable longer. |

| Frame Arms | Direct force transfer; high risk of fatigue fractures. | Force absorbed by struts; extends frame fatigue life. |

| Spray Nozzles | Risk of ground impact if gear compresses too much. | Controlled compression keeps nozzles at safe clearance. |

What specific materials and mechanisms should I look for in a high-quality landing gear system?

Sourcing raw materials for our assembly line taught us that cheap alloys snap under pressure. You need materials that flex without breaking.

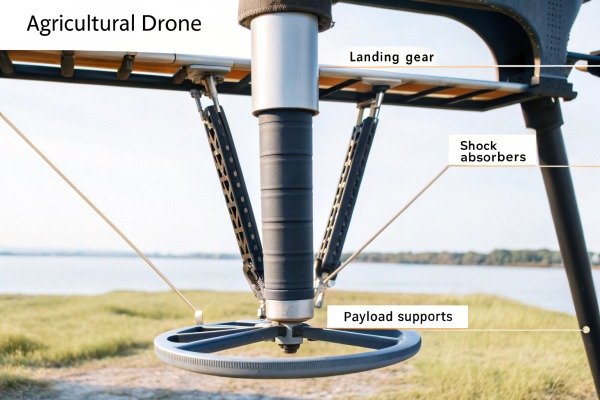

Look for high-strength carbon fiber or titanium alloy tubes that offer high yield strength without adding excessive weight. The best mechanisms combine passive damping elements, such as hydraulic buffers or friction shock absorbers, with wide-stance skid designs to dissipate vertical impact energy effectively.

The material composition and the mechanical design of the landing gear determine its longevity. When evaluating a supplier, you need to look beyond the basic appearance and ask about the specific alloys and composites used.

Material Selection: Strength vs. Weight

In agricultural drones, every gram of weight counts. Heavier gear means less battery life and less liquid payload. However, the gear must be strong enough to support a fully loaded drone falling from a few meters.

- Carbon Fiber: This is the industry standard for high-end drones. However, not all carbon fiber is the same. You should look for "pre-preg" carbon fiber tubes with a woven structure. This offers better resistance to crushing forces than simple pultruded tubes.

- Titanium Alloys: We use titanium in critical joints and hinge points. Titanium has excellent "memory," meaning it can bend significantly and return to its original shape without permanent deformation.

- Aluminum 7075: Avoid standard 6061 aluminum for main load-bearing struts if possible. 7075 acts more like steel but weighs much less. It is brittle, however, so it should be used in thick sections.

Mechanical Damping Systems

Materials alone are not enough. The design must include a mechanism to dissipate energy.

- Hydraulic Dampers: These act like the shock absorbers on a car or motorcycle. They contain oil that is forced through small holes when the gear compresses. This is the most effective method for heavy-lift drones (over 30kg payload). It prevents the "spring back" effect.

- Friction Shock Absorbers (FSA): These use the friction between two sliding surfaces to absorb energy. They are lighter than hydraulic systems and very reliable because they do not leak oil. However, they wear out over time and need maintenance.

- Rubber Grommets and Springs: On cheaper or lighter drones, you might see simple springs inside PVC or metal tubes. While better than nothing, springs store energy rather than dissipating it. This can cause the drone to bounce.

Chemical Resistance is Critical

This is often overlooked. Agricultural drones are constantly covered in pesticides, fungicides, and fertilizers. Many of these chemicals are corrosive or act as solvents.

If the landing gear uses cheap rubber seals or standard plastic bushings, these chemicals will degrade them. The rubber becomes brittle and cracks. The plastic swells and jams the sliding mechanism. You must verify that the manufacturer uses chemical-resistant materials like Viton seals or chemically Viton seals 7 treated metals.

Material and Mechanism Evaluation Matrix

Use this table to assess the quality of the landing gear based on the specifications provided by the seller.

| Feature | Low-End Standard | High-End Standard | Why It Matters |

|---|---|---|---|

| Main Tube Material | Aluminum 6061 or Fiberglass | 3K Woven Carbon Fiber | Weight reduction and crack resistance. |

| Damping Type | Simple Steel Spring | Hydraulic or Friction Damping | Prevents bouncing; protects sensors. |

| Joint Material | Injection Molded Plastic | CNC Machined Aluminum/Titanium | Durability at stress points. |

| Seal Material | Standard Rubber | Viton or NBR (Chemical Resistant) | Prevents corrosion from pesticides. |

How does the landing gear's damping capability affect my drone's stability during takeoff and landing on rough terrain?

Our flight test team often struggles on uneven farm soil. Unstable gear causes immediate tipping and dangerous rotor strikes.

Effective damping absorbs the initial ground impact, preventing the drone from rebounding or bouncing, which causes loss of control. On rough terrain, independent suspension adapts to uneven surfaces, keeping the airframe level and preventing the propeller tips from striking the ground during takeoff or landing.

Stability on the ground is just as important as stability in the air. Agricultural fields are rarely flat runways. They are full of ruts, rocks, mud, and crop debris. The landing gear acts as the interface between the drone and this chaotic environment.

Preventing the "Bounce" Effect

One of the most dangerous moments for a drone is the split second it touches the ground. If the landing gear consists only of springs (elastic deformation) without damping (energy dissipation), the drone will bounce.

When a drone bounces:

- The flight controller detects upward movement.

- It thinks the drone is taking off again uncommanded.

- It may cut motor power or spin motors up aggressively to stabilize.

- This confusion often leads to the drone flipping over.

A proper damping system absorbs the kinetic energy of the vertical speed and turns it into heat. The drone "sticks" to the ground rather than bouncing off it. This is achieved through hydraulic fluid resistance or mechanical friction.

Uneven Terrain Adaptation

In our field tests, we land on slopes and furrows. If the landing gear is a rigid sled, the drone sits at the angle of the ground. If that angle is too steep, the drone tips.

High-quality landing gear often features independent suspension for each leg. When one leg hits a rock or a high spot, it compresses, while the other legs remain extended. This helps keep the main body of the drone more level than the ground beneath it.

This "terrain compliance" is vital for automated landings. The drone does not "see" the rock on the ground. The mechanical system must handle it passively.

Ground Resonance

There is a phenomenon called ground resonance that can ground resonance 8 tear a drone apart. It happens when the vibration of the spinning propellers matches the natural frequency of the landing gear while the drone is lightly touching the ground (during takeoff or landing).

If the landing gear is poorly designed, it can amplify these vibrations. The drone starts to shake violently. Proper shock absorption changes the natural frequency of the structure and dampens these vibrations before they become destructive.

Design Considerations for Stability

- Wide Stance: The wider the landing gear, the harder it is to tip over. However, it must still fit between crop rows if necessary.

- Low Center of Gravity: The gear should position the tank as low as possible without letting the nozzles hit the crops.

- No-Rebound Tech: Look for "dead blow" characteristics where the gear does not snap back immediately after compression.

What tests or certifications should I request from the manufacturer to prove landing gear durability?

Before we ship to US clients, we run rigorous destruction tests. You must demand this data to ensure reliability.

Request drop test reports that simulate maximum takeoff weight impacts from heights of at least 4 meters. Verify fatigue test results showing the gear withstands thousands of cycles without stress fractures, and ask for certifications verifying the Factor of Safety, ideally above 1.5, for structural components.

Marketing brochures often use vague terms like "heavy-duty" or "industrial grade." As a procurement manager, you need hard data to back up these claims. You should treat the landing gear with the same scrutiny as an aircraft part.

The Standard Drop Test

The most fundamental test is the drop test. Manufacturers should have a "drop tower" rig.

- The Setup: The landing gear is loaded with weights equivalent to the drone's Maximum Takeoff Weight (MTOW).

- The Drop: It is dropped from various heights (e.g., 0.5m, 1m, 2m) to simulate hard landings.

- The Measurement: Sensors measure the "G-force" transmitted to the frame.

- What to look for: Ask for the "Limit Landing Load" report. This shows the maximum force the gear can handle before permanent deformation occurs. You want to see that the gear absorbs enough energy so that the G-force on the frame remains within safe limits for the electronics.

Fatigue and Cycle Testing

Agricultural drones fly many missions a day. They might land 20 or 30 times in a single shift. A landing gear that survives one big drop might fail after 1,000 small ones.

Fatigue testing involves a machine that repeatedly compresses and releases the landing gear.

- The Metric: You want to see a "Cycle Life" report. A good benchmark is 5,000 to 10,000 cycles without failure.

- The Failure Mode: The report should note how it eventually failed. Did a seal leak? Did a spring snap? Did the carbon fiber delaminate?

Factor of Safety (FOS)

Engineering designs are built around a "Factor Factor of Safety 9 Factor of Safety 10 of Safety." This is the ratio of the material's strength to the maximum expected load.

- Example: If the maximum load on a strut during a hard landing is 30MPa, and the material yields (bends permanently) at 50MPa, the FOS is 1.67 (50 divided by 30).

- Your Requirement: Demand an FOS of at least 1.5. This means the gear is 50% stronger than the worst-case scenario it is expected to face. If the manufacturer cannot tell you the FOS, they likely have not done the engineering math.

Essential Certification Checklist

When communicating with suppliers, copy and paste this table into your email. It forces them to be transparent.

| Document/Test | What it Proves | Desired Metric |

|---|---|---|

| Drop Test Report | Energy absorption capacity. | Survival at MTOW from >1m height. |

| Fatigue Cycle Report | Long-term durability. | >5,000 cycles with no structural failure. |

| Material Certificate | Quality of raw materials. | Specific alloy grades (e.g., 3K Carbon, 7075 Aluminum). |

| IP Rating Certificate | Dust and water resistance. | IP65 or higher for the damping mechanism. |

Conclusion

Prioritizing shock absorption ensures your agricultural drone survives harsh field conditions. By verifying materials, damping mechanisms, and test data, you secure a reliable asset that minimizes costly downtime.

Footnotes

1. Technical specifications for radar systems used in leading agricultural drones. ↩︎

2. Official safety guidelines regarding drone operations and landing procedures. ↩︎

3. Manufacturer documentation on high-performance carbon fiber materials used in aerospace. ↩︎

4. General background on IMU technology. ↩︎

5. Explains the fundamental sensor technology mentioned in the article. ↩︎

6. MIT research on vibration isolation and mechanical damping systems. ↩︎

7. Official manufacturer information for Viton materials. ↩︎

8. Aviation safety explanation of ground resonance. ↩︎

9. Engineering definition and calculation methods. ↩︎

10. Definition of the engineering concept used to ensure structural integrity. ↩︎